Standard Keensert Drill Chart

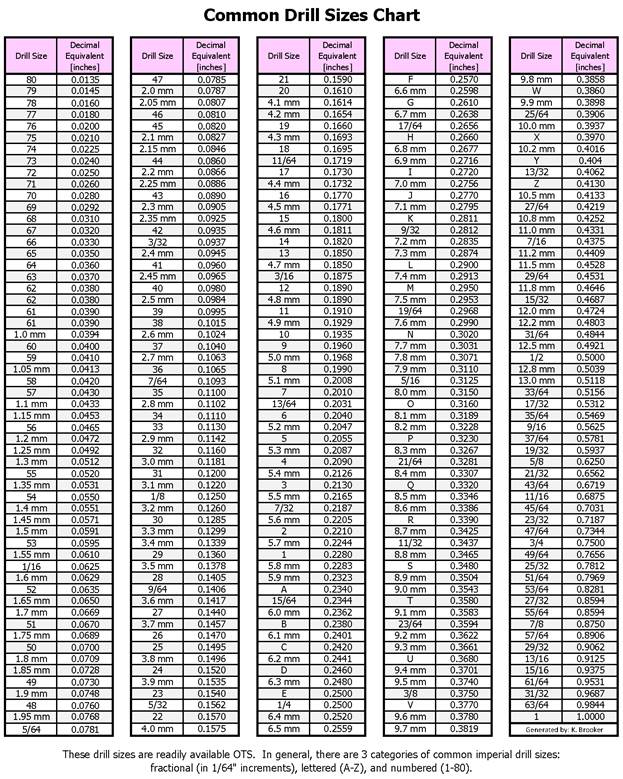

Standard Keensert Drill Chart - Number of locking kees in the stud. Thread b ø b class 2a mod. Hole prepared with standard drill and tap. Camloc® keenserts® provide high strength joints in low strength materials. Web drill out old threads with a standard drill. Drill is oversize — see charts for proper dimensions. Deflect kees inward and break off. Drill is oversized see charts for proper dimensions. Countersink with a standard countersink (82° to 100°). Drill out old threads with a standard drill. Deflect kees inward and break off. Because of our years of application experience, we are geared to provide solutions to all types of special fastener problems. Hole prepared with standard drill and tap. Thread b ø b class 2a mod. Drill with a standard drill. Tap new threads with a standard tap. Tridair pioneered the design of this type. Web browse floating keenserts® in the howmet aerospace catalog including item #,material,finish description,internal thread lock,internal thread size,external thread. Number of locking kees in the stud. An identical insert drill to remwe insert inward and break off. Can be removed very simply when necessary. Camloc® keenserts® provide high strength joints in low strength materials. Thread a ø a class 3b. Drill is oversize — see charts for proper dimensions. Web the drill size chart provides a list of standard size drill bits in several measurement systems, including fractional, metric, wire gauge number, and letter. The smallest tap drill diameter for which broaching tools can be made is.213. Chamfer the hole with a standard. Use standard drill, as listed for each part number to remove insert material between kees. Web installation using slotted tool. Drill is oversize — see charts for proper dimensions. Camloc® keenserts® provide high strength joints in low strength materials. Drill is oversize — see charts for proper dimensions. Drill is oversized see charts for proper dimensions. Countersink with a standard countersink (82° to 100°). Web drill out old threads with a standard drill. Web standard version (fourteen steps) 1. Web drill out old threads with a standard drill. Camloc® keenserts® provide high strength joints in low strength materials. Drill with a standard drill. Can be removed very simply when necessary. Deflect kees inward and break off. Camloc® keenserts® provide high strength joints in low strength materials. Web drill out old threads with a standard drill. Thread a ø a class 3b. Web no special skill required to use keenserts® inserts and studs. Thread a ø a class 3b. Web drill out old threads with a standard drill. Tap with a standard unified thread series tap. Use standard drill, as listed for each part number to remove insert material between kees. An identical insert drill to remwe insert inward and break off. Thread b ø b class 2a mod. Web browse floating keenserts® in the howmet aerospace catalog including item #,material,finish description,internal thread lock,internal thread size,external thread. Web choice of standard sizes, lengths, materials and types. Plus formulas and charts for tap drill size. Can now be installed in material. Tridair pioneered the design of this type. Drill is oversize — see charts for proper dimensions. Tap new threads with a standard tap. Typical applications are transmission housings, electronic equipment and. Number of locking kees in the stud. Can now be installed in material. Camloc® keenserts® provide high strength joints in low strength materials. Drill is oversize — see charts for proper dimensions. An identical insert drill to remwe insert inward and break off. Drill is oversized see charts for proper dimensions. Number of locking kees in the stud. Locking keys are driven down into the parent material during installation, providing a positive. Deflect kees inward and break off. Tap new threads with a standard tap. Tridair pioneered the design of this type. Hole prepared with standard drill and tap. Web choice of standard sizes, lengths, materials and types. Drill out old threads with a standard drill. Web installation using slotted tool. Chamfer the hole with a standard. The smallest tap drill diameter for which broaching tools can be made is.213.

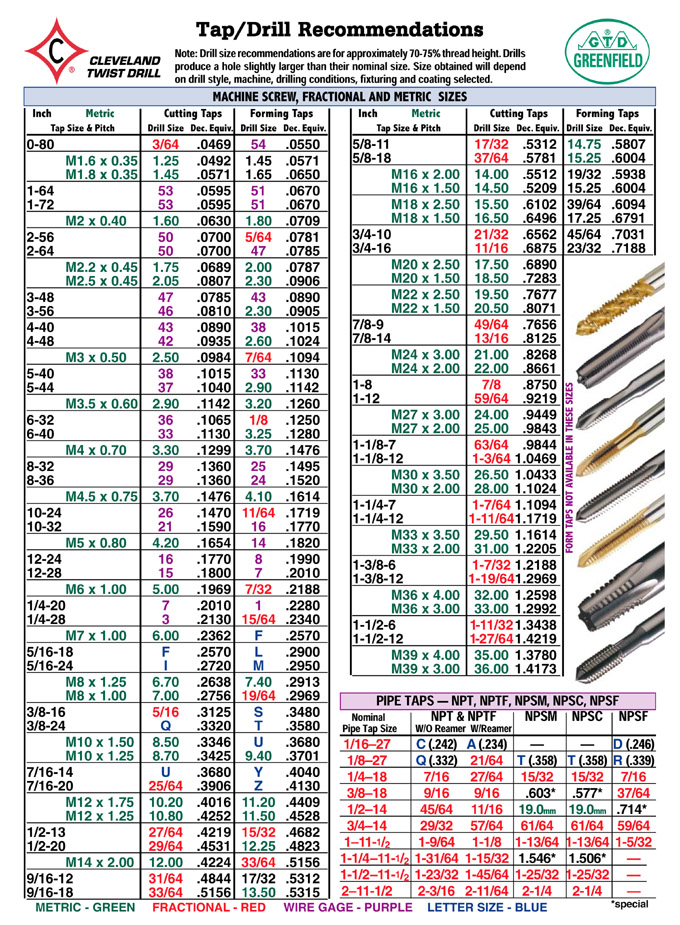

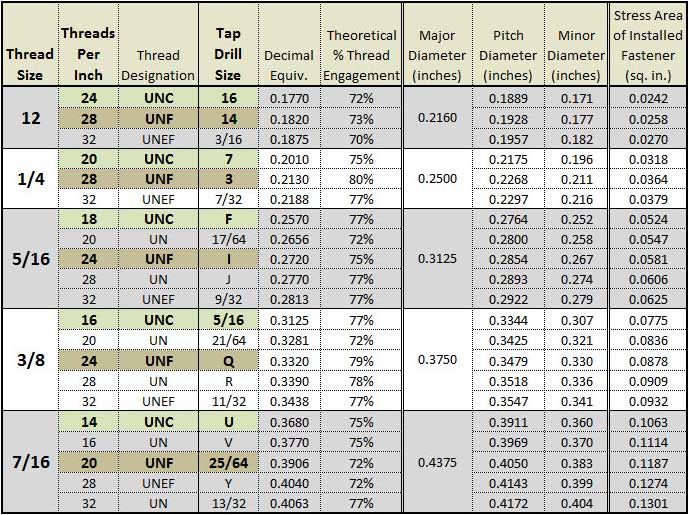

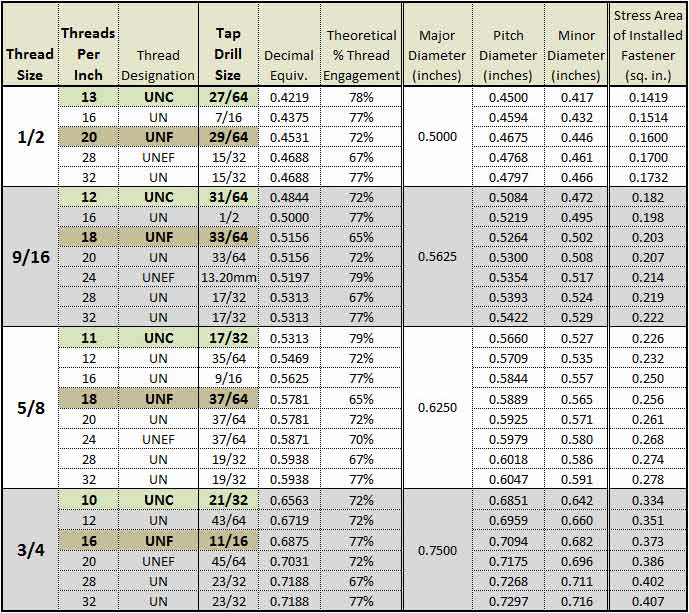

Tap Drill Chart Business Mentor

Stabil drill z bit windows, used tools for sale victoria bc, keensert

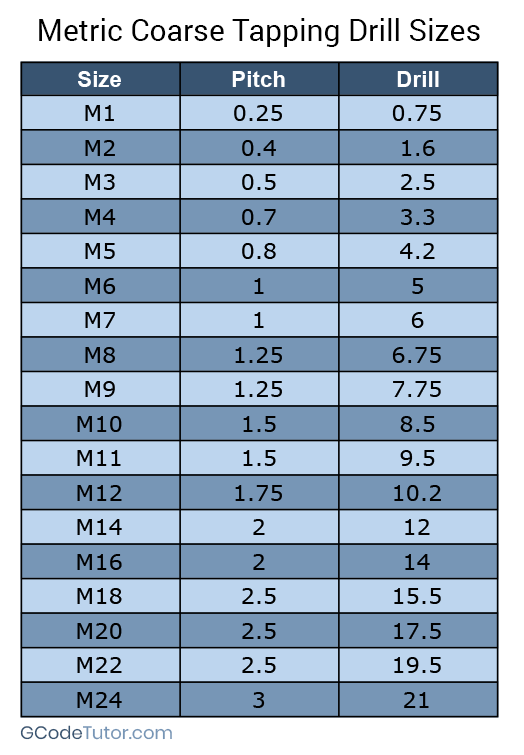

Tap Drill Chart

Tap Drill Chart Business Mentor

Tap And Drill Size Chart

keensert drill and tap chart Laman

Laboratory Resources

Drill Core Size Chart

Keensert tap drill chart formsrilo

Tap Drill Size Chart For Standard Threads My XXX Hot Girl

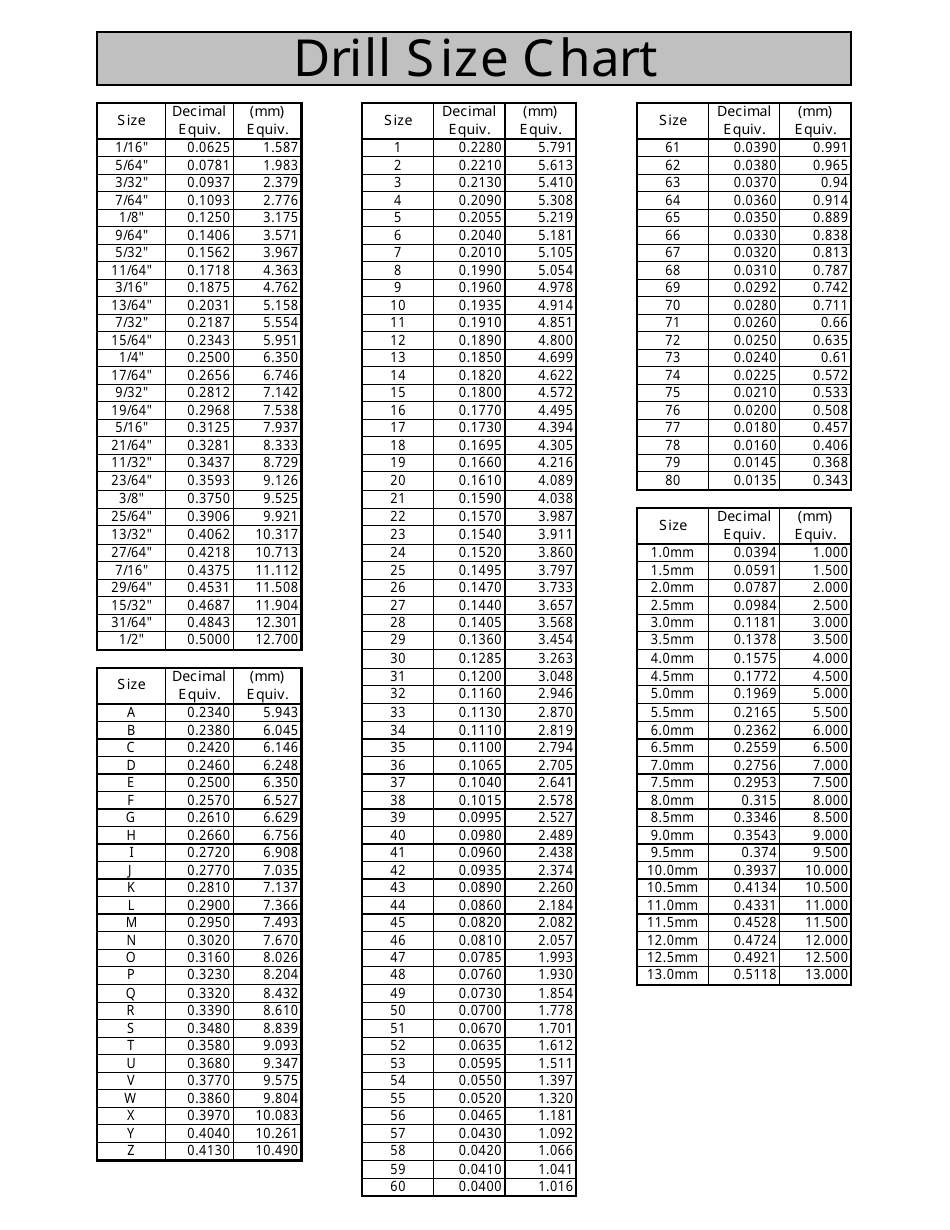

Web The Drill Size Chart Provides A List Of Standard Size Drill Bits In Several Measurement Systems, Including Fractional, Metric, Wire Gauge Number, And Letter.

Drill With A Standard Drill.

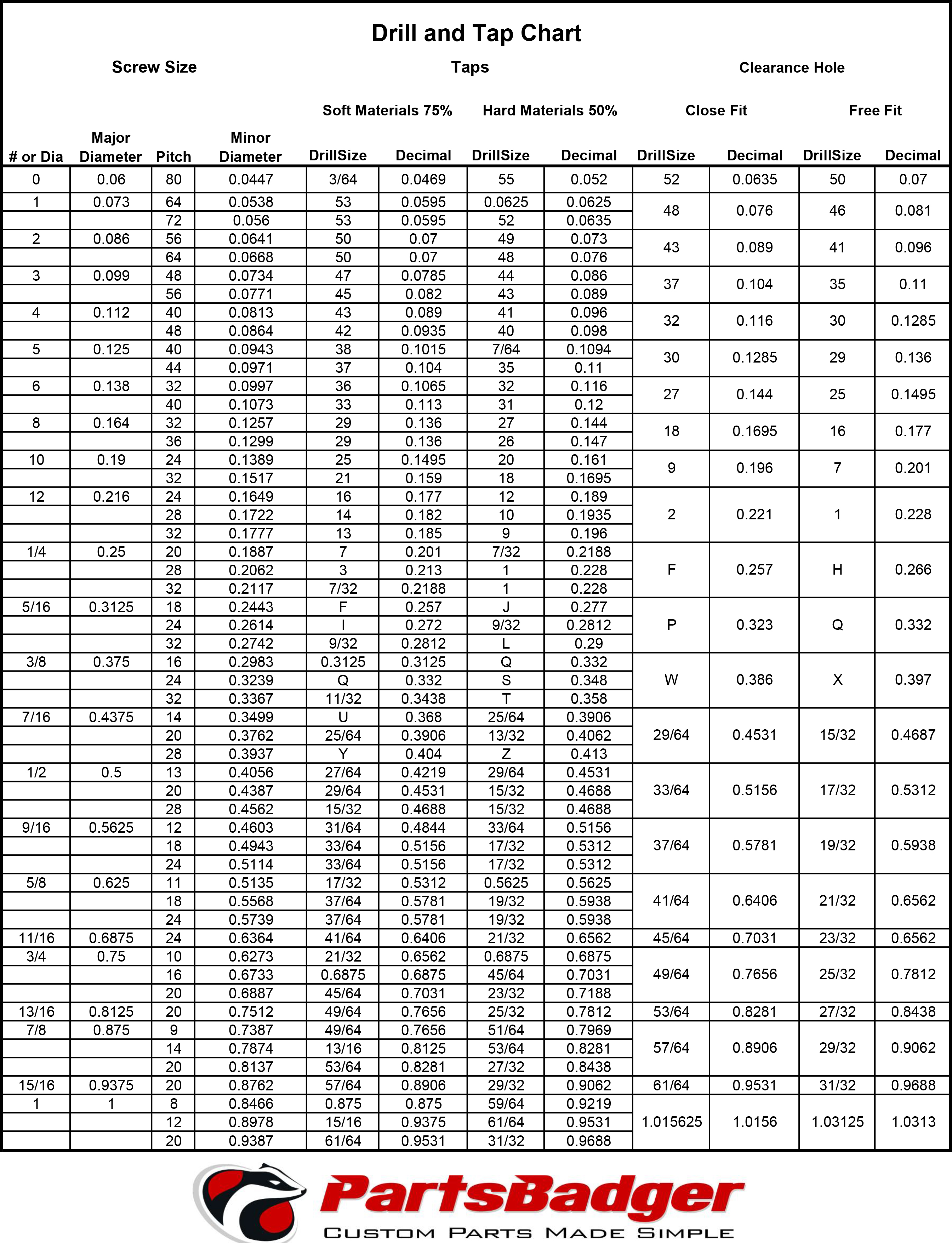

Tap With A Standard Unified Thread Series Tap.

Typical Applications Are Transmission Housings, Electronic Equipment And.

Related Post: