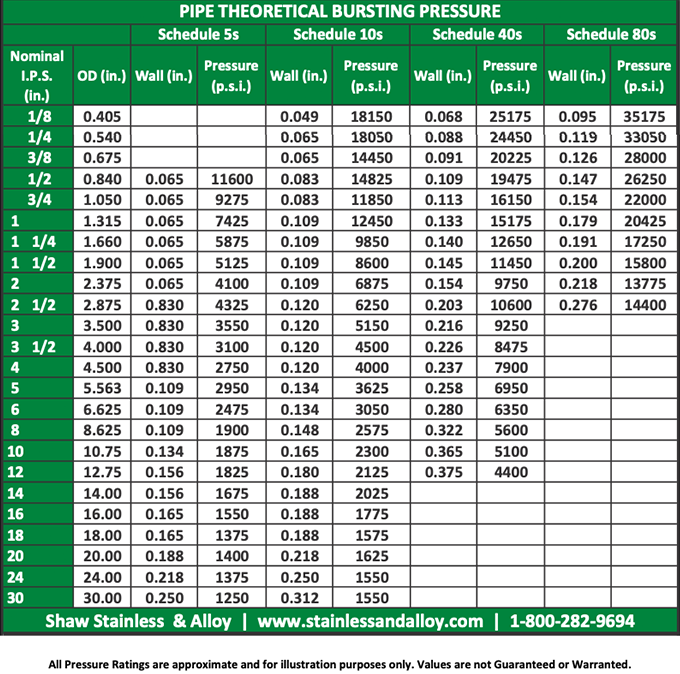

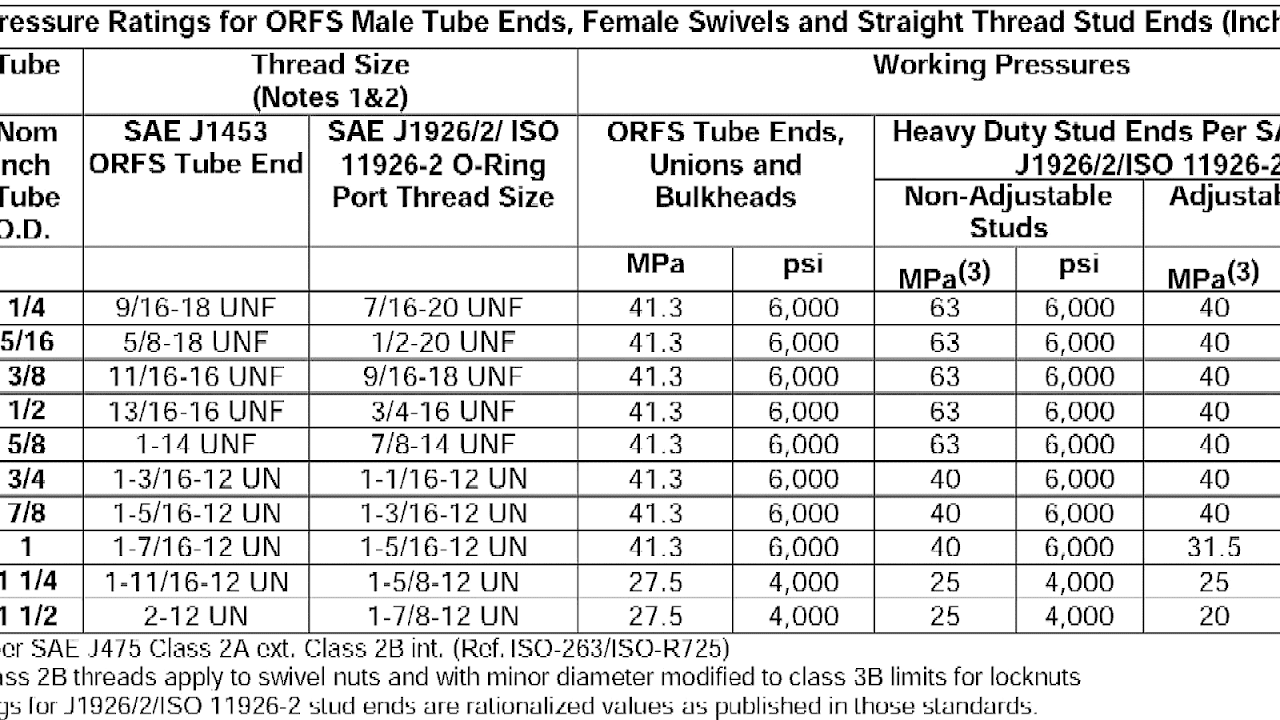

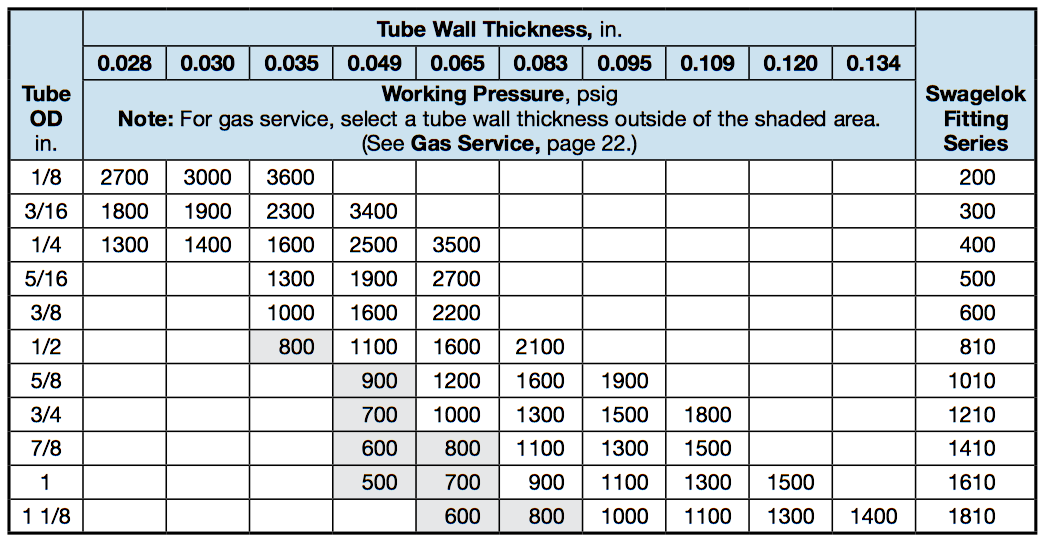

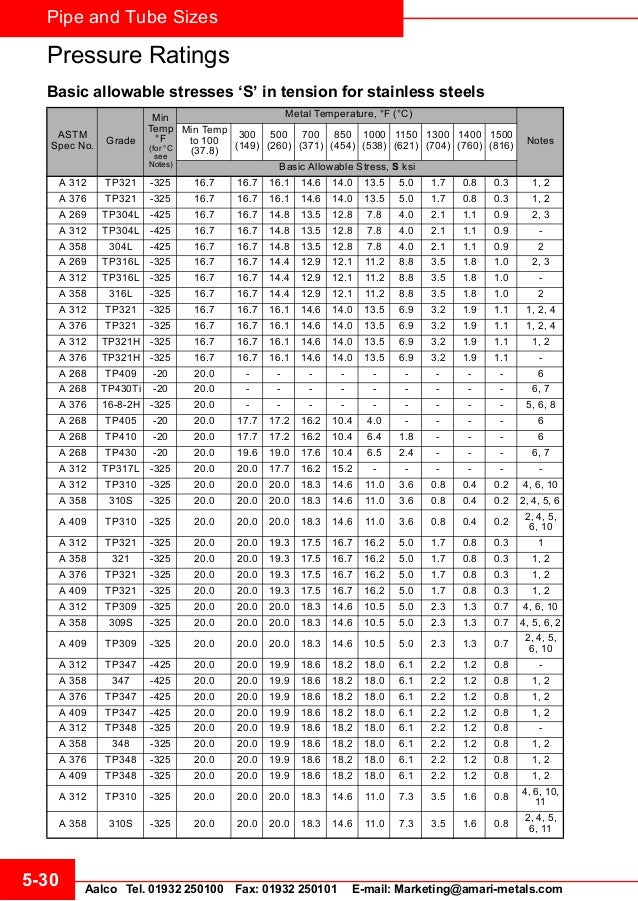

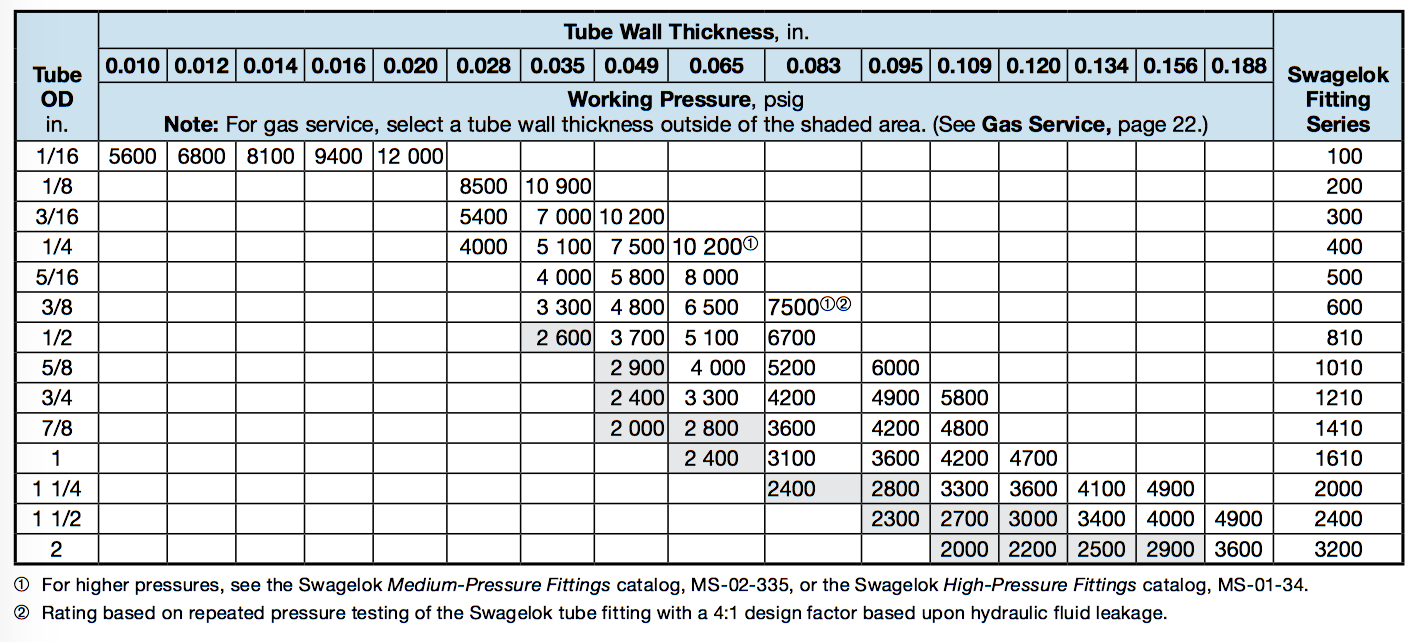

Stainless Steel Tubing Pressure Rating Chart

Stainless Steel Tubing Pressure Rating Chart - Web the accompanying tables show working pressure ratings of tubing in a wide range of wall thicknesses. The asme 0.049 0.066 0.080 0.105 0.128 0.148 0.157. Web the allowable working pressures for 304 stainless steel and 316 stainless steel welded tubing to astm a269, astm/asme a249 or equivalent based on the following data: D4, t3 tolerance 14 to 50 mm), using a stress value of 137.8 mpa (20 000 psi) and tensile strength of 516.4 mpa (74 900 psi). An additional weld joint efficiency factor (typically 85%) must be allowed for standard welded pipe, and allowance made for corrosion or wear loss if appropriate. Allowable pressure is calculated with the asme 31.3 allowable pressure equation with quality factor e = 0.6 and wall thickness coefficient y = 0.4. Specific design factors may be determined by using the burst pressures shown in the above table. Web as 4041 design pressures at ambient temperature. C = the sum of the mechanical allowances (thread or groove depth) plus corrosion and erosion allowances. Upper figures — max psi rating. Every part you'll need for your fluid system is here at ryan herco. Part numbers shown are standard from stock. All ratings in psig based on ansi/asme b 31.1. This data is indicative only and as such is not to be relied upon in place of the full specification. Web calculations are for seamless pipe to specification astm a312/a312m (austenitic. Web the accompanying tables show working pressure ratings of tubing in a wide range of wall thicknesses. Part numbers shown are standard from stock. Web our imperial and metric stainless steel tubing theoretical burst charts, including bp for pipe, have been provided for your convenience. Lower figures — weight in pounds per foot. Dynamic pressure ratings are calculated in accordance. Welded tube certified to astm a249m (weld joint factor must be applied). Tm = minimum required thickness, including mechanical, corrosion and erosion allowances. Web the allowable working pressures for 304 stainless steel and 316 stainless steel welded tubing to astm a269, astm/asme a249 or equivalent based on the following data: The asme 0.049 0.066 0.080 0.105 0.128 0.148 0.157. Web. Specific design factors may be determined by using the burst pressures shown in the above table. Values are not guaranteed or warranted. An additional weld joint efficiency factor (typically 85%) must be allowed for standard welded pipe, and allowance made for corrosion or wear loss if appropriate. Other sizes are available upon request. Web the following chart lists the nominal. All pressure ratings are approximate and for illustration purposes only. D4, t3 tolerance 14 to 50 mm), using a stress value of 137.8 mpa (20 000 psi) and tensile strength of 516.4 mpa (74 900 psi). Pressure ratings & weight per foot data. An additional weld joint efficiency factor (typically 85%) must be allowed for standard welded pipe, and allowance. Web 1.4571 stainless steel static pressures are calculated in accordance with din 2413 part 1. This data is indicative only and as such is not to be relied upon in place of the full specification. Web calculations here are seamless tube to specifications such as astm a213. For threaded components, the nominal thread depth (dimension h of asme b1.20.1, or. Web stainless steel fittings should be used only with stainless steel tubing, aluminum fittings with aluminum tubing, etc. These pressure ratings are derived from the lame formula with 12,500 psi (86 mpa) allowable. Web calculations are for seamless pipe to specification astm a312/a312m (austenitic grades) or astm a790/a790m (grade 2205). Web stainless steel tube pressure rating charts | titan fittings.. Every part you'll need for your fluid system is here at ryan herco. Part numbers shown are standard from stock. This data is indicative only and as such is not to be relied upon in place of the full specification. Web 1.4571 stainless steel static pressures are calculated in accordance with din 2413 part 1. Web stainless steel fittings should. This data is indicative only and as such is not to be relied upon in place of the full specification. Web this chart details the theoretical bursting pressures and weights of stainless steel tubing. For threaded components, the nominal thread depth (dimension h of asme b1.20.1, or equivalent) shall apply. Tm = minimum required thickness, including mechanical, corrosion and erosion. Web stainless steel fittings should be used only with stainless steel tubing, aluminum fittings with aluminum tubing, etc. The asme 0.049 0.066 0.080 0.105 0.128 0.148 0.157. Specific design factors may be determined by using the burst pressures shown in the above table. Part numbers shown are standard from stock. Web the following chart lists the nominal pressure ratings for. Web this chart details the theoretical bursting pressures and weights of stainless steel tubing. Web calculations are for seamless pipe to specification astm a312/a312m (austenitic grades) or astm a790/a790m (grade 2205). Specific design factors may be determined by using the burst pressures shown in the above table. D4, t3 tolerance 14 to 50 mm), using a stress value of 137.8 mpa (20 000 psi) and tensile strength of 516.4 mpa (74 900 psi). Dynamic pressure ratings are calculated in accordance with din 2413 part 3. For threaded components, the nominal thread depth (dimension h of asme b1.20.1, or equivalent) shall apply. Tm = minimum required thickness, including mechanical, corrosion and erosion allowances. All ratings in psig based on ansi/asme b 31.1. Web tm = t + c. Web the following chart lists the nominal pressure ratings of tubing products which conform to sae j524, sae j525, sae j526 and sae j365. Web stainless steel fittings should be used only with stainless steel tubing, aluminum fittings with aluminum tubing, etc. The asme 0.049 0.066 0.080 0.105 0.128 0.148 0.157. Web our imperial and metric stainless steel tubing theoretical burst charts, including bp for pipe, have been provided for your convenience. Web ratings for standard seamless stainless steel pipes, temperatures ranging 100 o f to 750 o f. In particular, mechanical property requirements vary widely with temper, product and product dimensions. Welded tube certified to astm a249m (weld joint factor must be applied).

Sch 40 Stainless Steel Pipe Pressure Rating

316 Stainless Steel Tube ASTM A312 TP316 Seamless and ERW Pipe

Stainless Steel Tube Pressure Rating Steel Choices

Steel Tubing Strength Chart

Stainless Steel Tube Pressure Rating Charts Titan Fittings

Stainless steel pressureratings

Pressure Ratings Stainless Steel Pipe Pipe (Fluid Conveyance

ASTM A312 Stainless Steel Pipe, SA312 Material

Stainless Steel Tube Pressure Rating Charts Titan Fittings

Stainless Steel Pipe Pressure Rating

A Weld Joint Efficiency Factor Of 85% Is Usually Allowed For Standard Welded Pipe And Tube, And Allowance Made For Corrosion Or Wear Loss If Appropriate.

C = The Sum Of The Mechanical Allowances (Thread Or Groove Depth) Plus Corrosion And Erosion Allowances.

All Information Is Based On Our Present Knowledge And Is Given In Good Faith.

Web As 4041 Design Pressures At Ambient Temperature.

Related Post: