Hastings Piston Ring Gap Chart

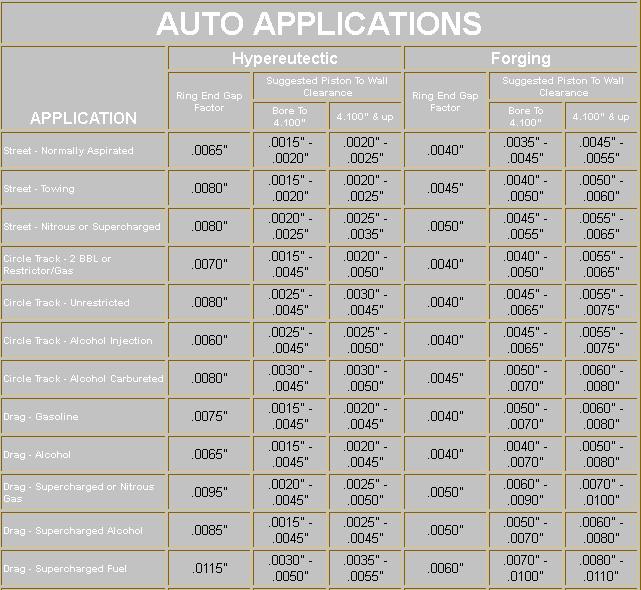

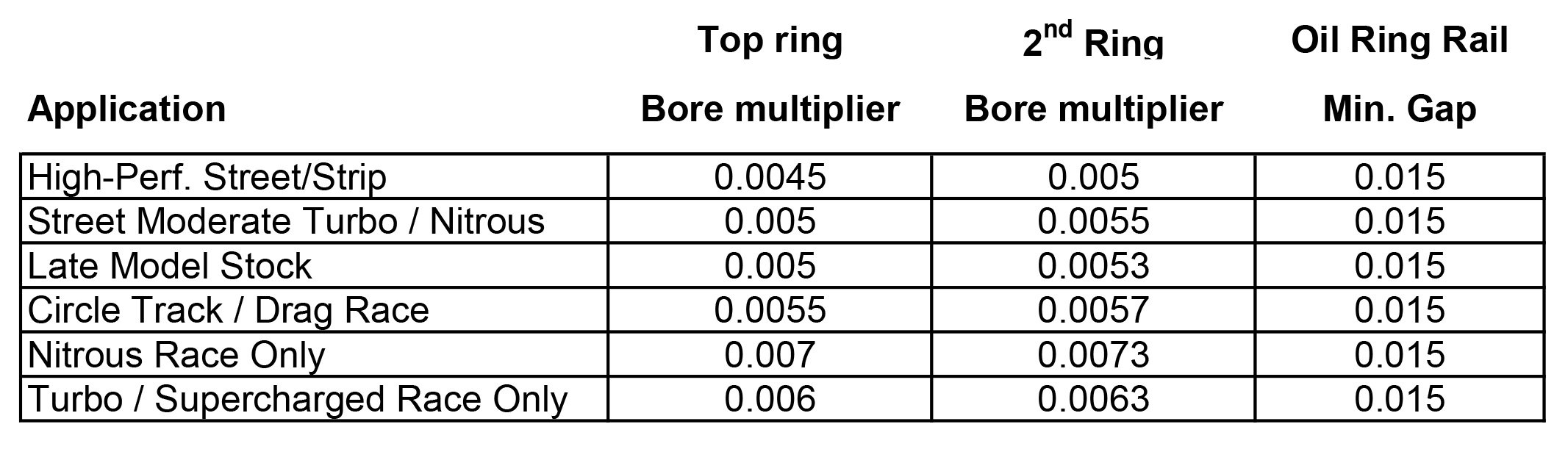

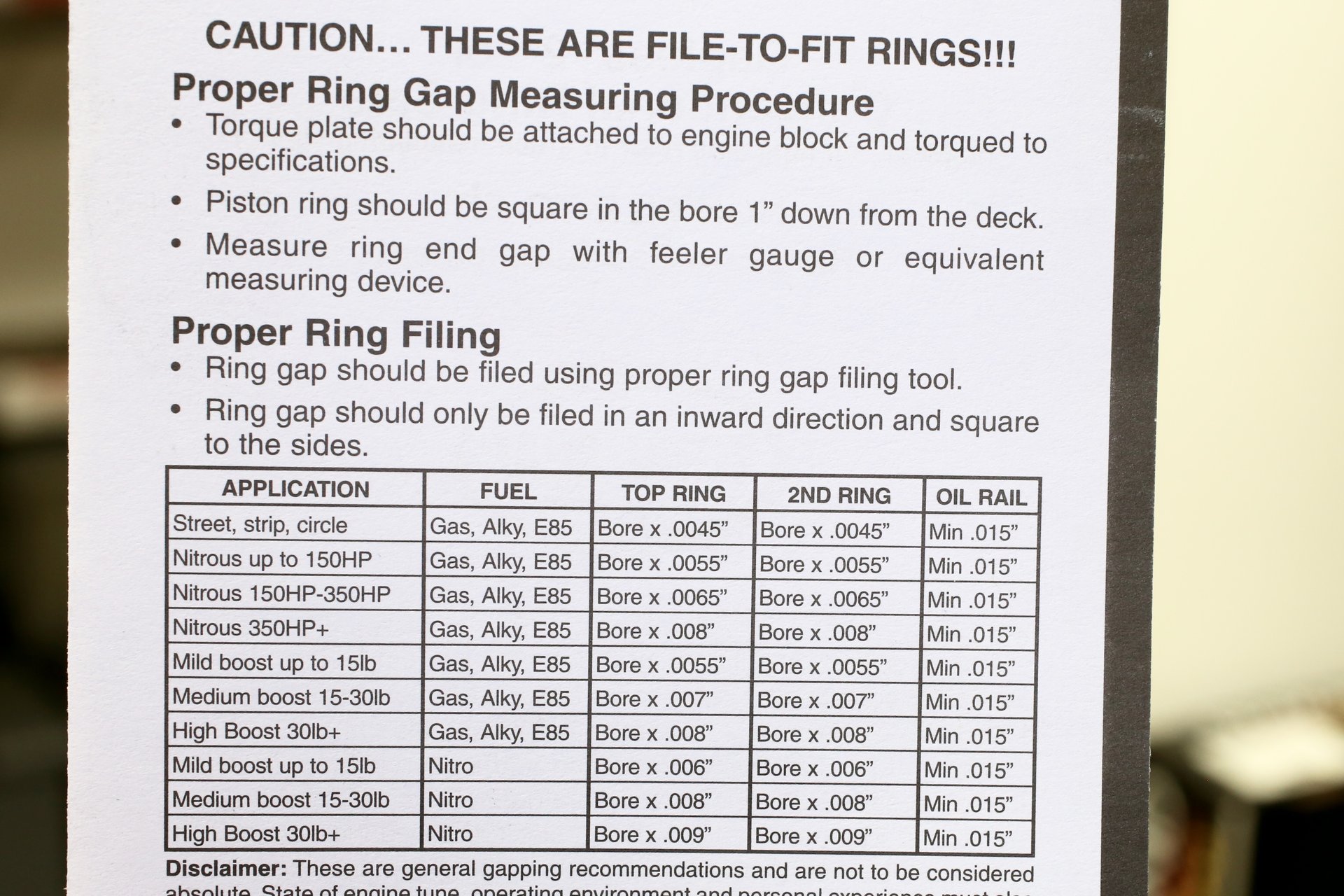

Hastings Piston Ring Gap Chart - A common practice in racing applications is file fitting piston ring end gaps. 442k views 3 years ago #d4a #boostschool. Web as you can see, for a high performance street/strip application, a minimum end gap of 4.5 thou per inch of bore is recommended, so that means if we have a 3.386 inch bore, we multiply that by 0.0045 to arrive at our recommended end gap of 15.2 thou. Web position the expander ends in the desired orientation on the piston, an image of the recommended installation location is provided in the proper ring alignment section. Web hastings manufacturing designs and manufactures piston rings for the world’s most recognizable and trusted brands. Web for over 100 years, we’ve never wavered from our first and only mission—to make the best piston ring possible. It is important that the ring end gaps are not lined up. Most hastings performance rings are available in file fit (+.005”) oversizes. This prevents oil flow past the rings. Cylinder should be free of any taper. Check the ring end gap by placing the ring into the cylinder. See table 1 for proper end. 442k views 3 years ago #d4a #boostschool. Web hastings manufacturing designs and manufactures piston rings for the world’s most recognizable and trusted brands. Install the lower steel ring, the ring end gap must be approximately 90° to 120° left from the. It is important that the ring end gaps are not lined up. See table 1 for proper end. Measure the ring end gap with a feeler gauge. Cylinder should be free of any taper. Web we discussed how piston rings work, demonstrated the correct way to do a piston ring orientation, and identified the ring gap position on a piston. End gaps for performance application. A common practice in racing applications is file fitting piston ring end gaps. Most hastings performance rings are available in file fit (+.005”) oversizes. Not only is piston rings what we do—it’s all we do. Web once the piston rings are on the piston, “stagger” the end gaps. It is important that the ring end gaps are not lined up. View tech tip » ring groove depths of piston. Web it is this advanced ring technology that gives us both performance and efficiency. Ring end gap should be measured with the ring square in the bore on a fresh hone. Use a piston or caliper to ensure that. Web for over 100 years, we’ve never wavered from our first and only mission—to make the best piston ring possible. Most hastings performance rings are available in file fit (+.005”) oversizes. See table 1 for proper end. Find out the minimum ring end gap for different bore sizes and piston designs. For over 100 years, we’ve never wavered from our. Web it is this advanced ring technology that gives us both performance and efficiency. Measure the ring end gap with a feeler gauge. Web once the piston rings are on the piston, “stagger” the end gaps. End gaps for performance application. Web we discussed how piston rings work, demonstrated the correct way to do a piston ring orientation, and identified. Most hastings performance rings are available in file fit (+.005”) oversizes. Install the lower steel ring, the ring end gap must be approximately 90° to 120° left from the. Ring end gap should be measured with the ring square in the bore on a fresh hone. Is there a measurable power difference between these two gaps? This prevents oil flow. End gaps for performance application. Web once the piston rings are on the piston, “stagger” the end gaps. Web hastings manufacturing designs and manufactures piston rings for the world’s most recognizable and trusted brands. Ring end gap should be measured with the ring square in the bore on a fresh hone. Not only is piston rings what we do—it’s all. That is a huge difference in the gap as compared to the production ring package. Not only is piston rings what we do—it’s all we do. Ring end gap should be measured with the ring square in the bore on a fresh hone. Find out the minimum ring end gap for different bore sizes and piston designs. Web as you. Find out the minimum ring end gap for different bore sizes and piston designs. Check the ring end gap by placing the ring into the cylinder. Most hastings performance rings are available in file fit (+.005”) oversizes. Web position the expander ends in the desired orientation on the piston, an image of the recommended installation location is provided in the. Use this chart to determine the proper end gap for your engine. Most hastings performance rings are available in file fit (+.005”) oversizes. That is a huge difference in the gap as compared to the production ring package. Web learn how to file fit piston ring end gaps for racing applications with a chart and examples. A common practice in racing applications is file fitting piston ring end gaps. Web position the expander ends in the desired orientation on the piston, an image of the recommended installation location is provided in the proper ring alignment section. View tech tip » ring groove depths of piston. Web as you can see, for a high performance street/strip application, a minimum end gap of 4.5 thou per inch of bore is recommended, so that means if we have a 3.386 inch bore, we multiply that by 0.0045 to arrive at our recommended end gap of 15.2 thou. Cylinder should be free of any taper. We don’t manufacture other engine parts. 442k views 3 years ago #d4a #boostschool. Measure the ring end gap with a feeler gauge. Use a piston or caliper to ensure that the ring is placed squarely in the bore. It is important that the ring end gaps are not lined up. Check the ring end gap by placing the ring into the cylinder. Web we discussed how piston rings work, demonstrated the correct way to do a piston ring orientation, and identified the ring gap position on a piston and piston ring gap.

Piston Ring Gap How Important Is It And How To Get Them Correct

ring gapping and basic piston ring info YOULL NEED Grumpys

Piston Ring Gap How Important Is It And How To Get Them Correct

Piston ring gap chart. Greg Clark Flickr

Hastings Ring Gap? For A Bodies Only Mopar Forum

How to Clock Piston Rings Gap Orientation and Install Tips YouTube

Hastings Ring Gap? For A Bodies Only Mopar Forum

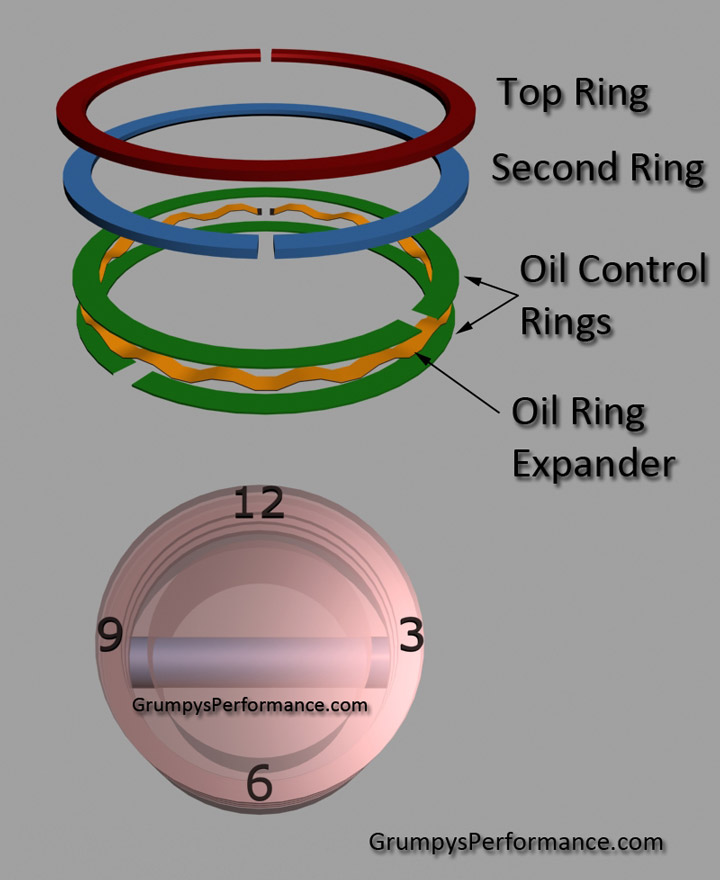

installing rings in piston grooves Grumpys Performance Garage

Blueprint Series The How And Why Of Setting Piston Ring End Gap

How to FileFit and Install Piston Rings

End Gaps For Performance Application.

Install The Lower Steel Ring, The Ring End Gap Must Be Approximately 90° To 120° Left From The.

Ring End Gap Should Be Measured With The Ring Square In The Bore On A Fresh Hone.

For Over 100 Years, We’ve Never Wavered From Our First And Only Mission—To Make The Best Piston Ring Possible.

Related Post: