Anodizing Voltage Chart

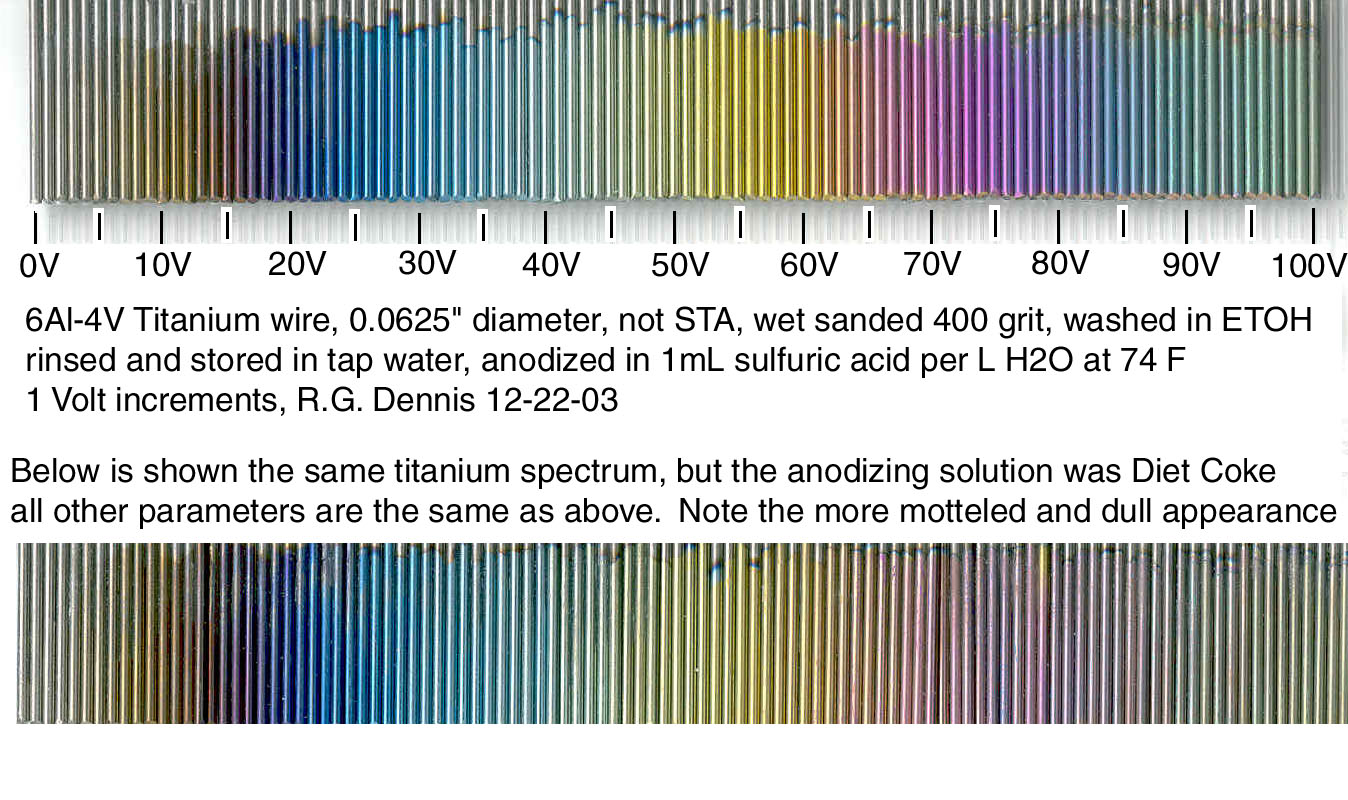

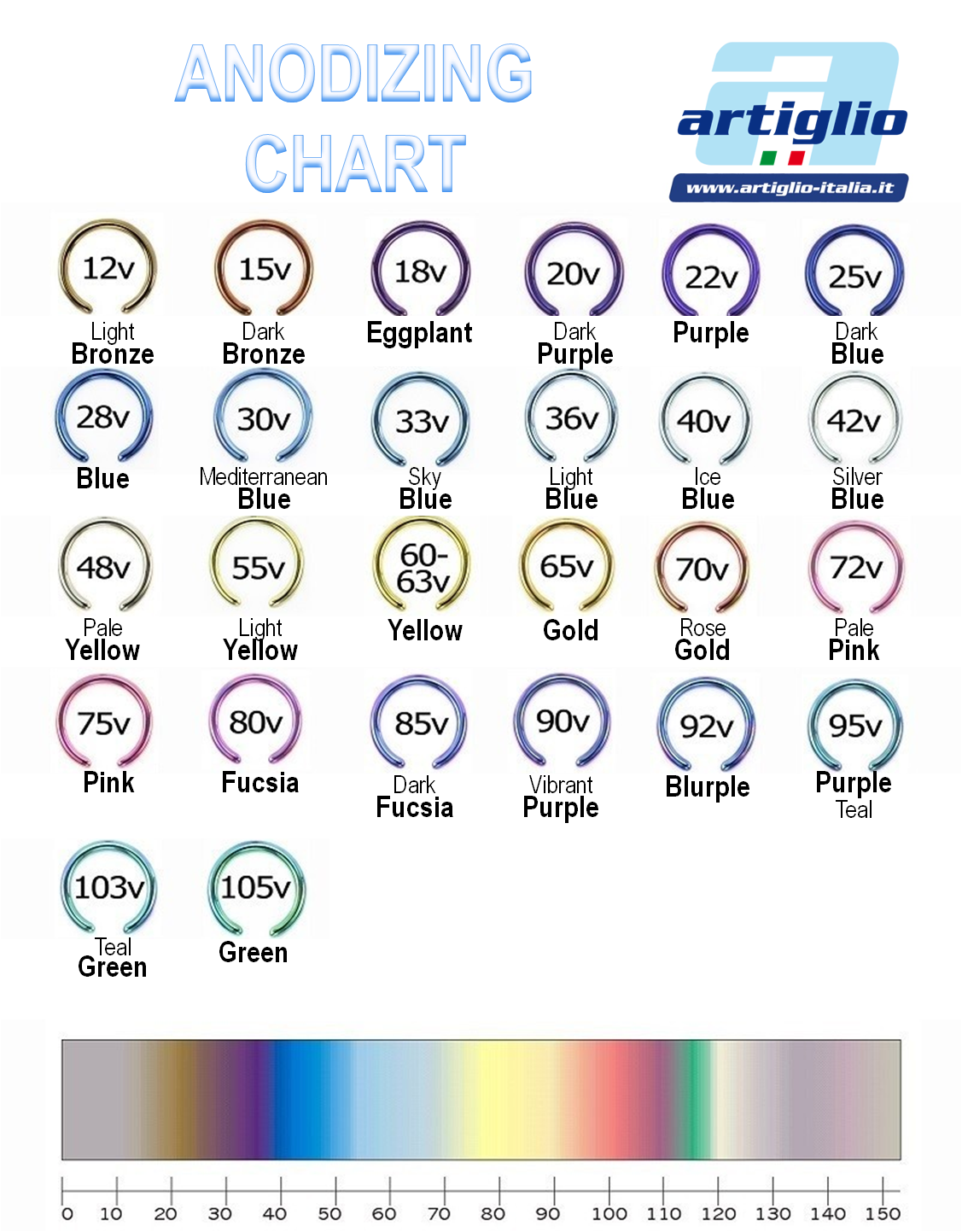

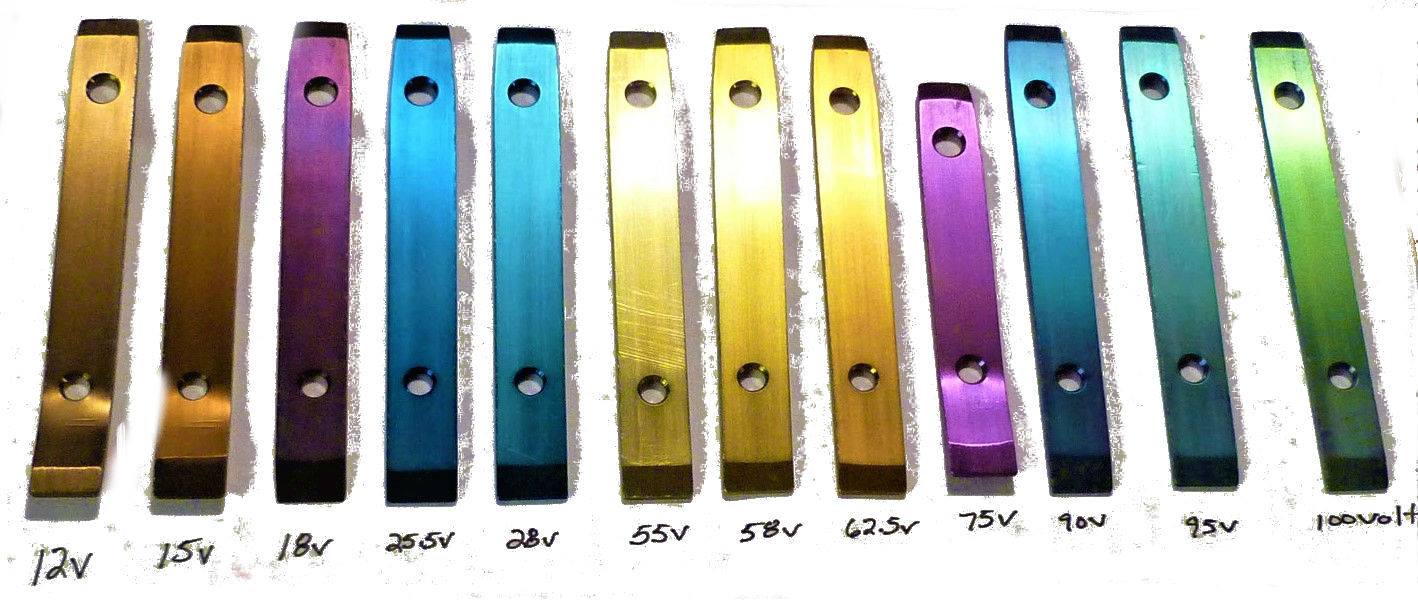

Anodizing Voltage Chart - Any titanium fasteners we sell can be custom anodized for our customers. Take the sq ft and multiply by 24 for 2000/7000 alloy and 30 for the rest. A green color, with the thickest oxide layer, can be achieved with 106 volts. Titanium anodizing is an electrochemical surface treatment that alters the metal's oxide layer to alter its properties. The higher the voltage, the thicker the oxide layer. Because the anodization process is slightly different depending on the metal being anodized, we will keep to the theme of this article and talk specifically about. Fades from one voltage to another are acceptable. To run asf anodizing you will need to accurately calculate the sq ft of the part tricky but not impossible. Web aluminum can accept a wide spectrum of anodized colors, including: Making a quality anodized part requires knowledge of the three types of anodization, which are highlighted below: A major part of the paper will center around the complete spectrum of control factors at the anodize tank. Most alloys cap out somewhere in the 60s for voltages. Take the sq ft and multiply by 24 for 2000/7000 alloy and 30 for the rest. This paper will present and review the important factors with which the anodizer should really. Web some of you know i've been anodizing. Type i (chromic acid anodizing) A green color, with the thickest oxide layer, can be achieved with 106 volts. This causes an oxide layer to build up on the surface of the titanium. Coating weights must be greater than 200 mg/ft2. Type i (chromic acid anodizing) Any titanium fasteners we sell can be custom anodized for our customers. Web low voltage (22)2v) chromic acid anodized coating. Anodizing titanium is done by applying a specific voltage while in an electrolyte. It’s a chemical conversion process that penetrates into the aluminum component and changes its stability. Titanium anodizing is an electrochemical surface treatment that alters the metal's oxide layer to alter its properties. Web low voltage (22)2v) chromic acid anodized coating. This article will discuss titanium anodizing colors, their importance, the types of anodization processes and components, as well as provide tips to get the best results. What do i need in order to anodize titanium?. After doing this, i now understand why. A green color, with the thickest oxide layer, can be achieved with 106 volts. Web anodizing is usually done in sulfuric or phosphoric acid electrolytes, and it creates a protective layer of various colors that can be used for decorative purposes, protective coating that enhances the metal’s properties. Anodization improves the durability, stability,. This causes an oxide layer to build up on the surface of the titanium. A major part of the paper will center around the complete spectrum of control factors at the anodize tank. The range here is from 0 volts to 100 volts. Web use the voltage chart (pictured) to specify the voltage for your preferred color choice (s). Web. Anodizing titanium is done by applying a specific voltage while in an electrolyte. Typically associated with higher temperature, more concentrated chromic acid electrolytes. A major part of the paper will center around the complete spectrum of control factors at the anodize tank. Take the sq ft and multiply by 24 for 2000/7000 alloy and 30 for the rest. The science. Because the anodization process is slightly different depending on the metal being anodized, we will keep to the theme of this article and talk specifically about. The difference is due to the electrodes, electrolytes, and energy used in each. High optical qualities can only be obtained with special rolled products, so called anodizing qualities [eq]. Web whereas anodizing is typically. Type i (chromic acid anodizing) After doing this, i now understand why. There are a few different types of anodizing methods you can use for titanium. Web in titanium anodizing, the voltage dictates the color. This paper will present and review the important factors with which the anodizer should really be concerned in order to improve quality to a high. What do i need in order to anodize titanium? Web anodizing, which means the roughness of the gained surface mainly depends on the roughness of the basic material. Web anodized titanium is widely used in commercial and military jet engine applications, rocket engines, airframe components, and to a limited degree in aircraft skin parts—in particular around jet engine inlets and. Choose two colors from the voltage chart, one higher than the other. A major part of the paper will center around the complete spectrum of control factors at the anodize tank. Most alloys cap out somewhere in the 60s for voltages. The science behind titanium anodizing is not only fascinating but also pivotal to many industries that require both robust and visually appealing components. Web low voltage (22)2v) chromic acid anodized coating. This causes an oxide layer to build up on the surface of the titanium. Web anodizing, a term derived from “anode”, is an electrochemical process that thickens and toughens the naturally occurring protective oxide on titanium’s surface. Web to effectively run constant current/asf anodizing you will need at least 60 volts to cover most alloys. If you want to increase your load size, you'll also want to make sure your cooling system can handle your needs, as well. Web some of you know i've been anodizing. Web anodizing is usually done in sulfuric or phosphoric acid electrolytes, and it creates a protective layer of various colors that can be used for decorative purposes, protective coating that enhances the metal’s properties. Web whereas anodizing is typically associated with aluminum, similar processes are used for other base metals, including magnesium, titanium, and zinc; Web anodizing, which means the roughness of the gained surface mainly depends on the roughness of the basic material. Pink, blue, black, silver, gold, green, orange, red, and purple. Web use the voltage chart (pictured) to specify the voltage for your preferred color choice (s). High optical qualities can only be obtained with special rolled products, so called anodizing qualities [eq].Anodized titanium color chart 9 thru 90 volts Oakley Forum

Anodized titanium color chart 9 thru 90 volts Oakley Forum

Titanium Anodizing Chart — 11 X 17 Poster ubicaciondepersonas.cdmx.gob.mx

Titanium Anodizing Voltage Color Chart

Titanium Anodizing Voltage Color Chart A Visual Reference of Charts

Anodized titanium color chart 9 thru 90 volts Oakley Forum

Titanium anodizer Milling machines/Parallelometers/Dental attachments

Titanium Anodization (See Color Chart) EDC Specialties Every Day

Aluminum Anodizing Voltage Chart

Toronto Cycles Titanium Anodizing at set Voltages

Web We Can Define Anodizing As A Process Of Increasing The Film Thickness Of The Natural Oxide Layer On The Anodized Surface Of Metal Parts.

Titanium Anodizing Is An Electrochemical Surface Treatment That Alters The Metal's Oxide Layer To Alter Its Properties.

Coating Weights Must Be Greater Than 200 Mg/Ft2.

The Higher The Voltage, The Thicker The Oxide Layer.

Related Post: