An Fitting Torque Chart

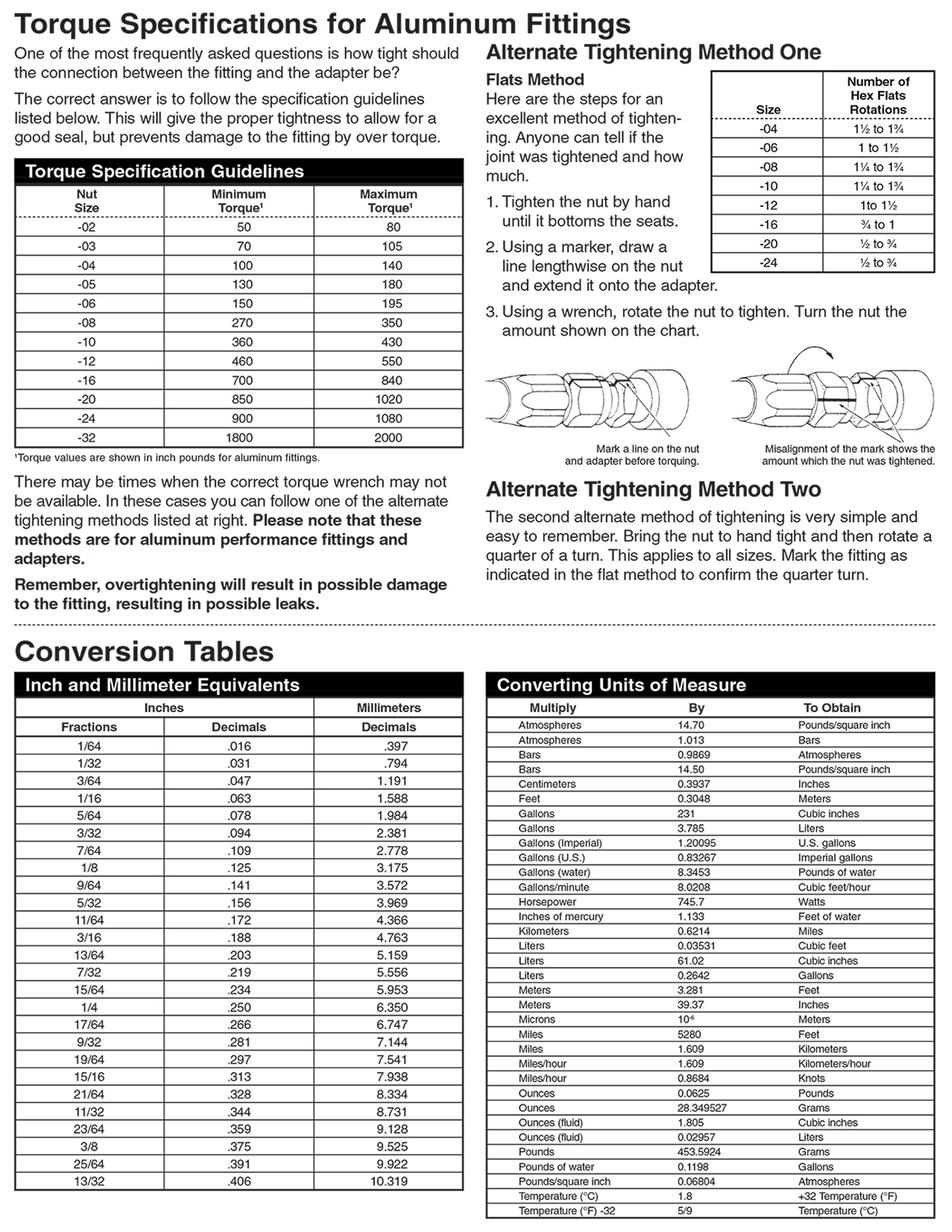

An Fitting Torque Chart - Sae straight thread adjustable fitting. Web pipe thread installation torque table chart. Web accepted formulae relating torque and tension, based on many tests are: Web an774 as5160 bolt, flared tube fitting end an775 as5161 bolt, fluid passage an776 as5162 connect.,banjo ftg,press line 90 deg. For defense department overnights & a.o.g. In the world of hydraulics, the method of securing a joint. If your installation lets you use a torque wrench on the fittings, use the values in the table below. In equipment where a female. Values in chart are for steel fittings in steel ports. M = p x d m = torque lbf.ft 60 p = bolt tension lbf d = bolt dia.ins or for metric sizes: If your installation lets you use a torque wrench on the fittings, use the values in the table below. When a combination of aluminum and stainless. The table below gives the torque tightening values for jic (an) fittings in both stainless steel and aluminum. Sae straight thread adjustable fitting. The elongated hole may have to be reamed to insure a. The torque required to seal swiv female fittings or hose couplings to a male connector depends on many variables such as fluid medium, surface finish, etc. In equipment where a female. The table below gives the torque tightening values for jic (an) fittings in both stainless steel and aluminum. Web use the correct tightening torque using this information. This webpage. These jic torque specifications are helpful in setting up your hose connectors. Web tighten your jic fittings properly using this hydraulic fitting torque chart. M = p x d m =. Web accepted formulae relating torque and tension, based on many tests are: Steel sae port sae port assembly torque. For defense department overnights & a.o.g. Web the an size reference the outer diameter of hose in 1/16th of an inch increments. Web torque specifications for aluminum fittings. Values in chart are for steel fittings in steel ports. Sae straight thread adjustable fitting. In equipment where a female. Web tightening method 1: In the world of hydraulics, the method of securing a joint. Sae straight thread adjustable fitting. Web the jargon, calculations, and charts that define npt threads are very different compared with standard metric and inch threads. These jic torque specifications are helpful in setting up your hose connectors. Web an774 as5160 bolt, flared tube fitting end an775 as5161 bolt, fluid passage an776 as5162 connect.,banjo ftg,press line 90 deg. Inline sae / jic connections. M = p x d m = torque lbf.ft 60 p = bolt tension lbf d = bolt dia.ins or for metric sizes:. For defense department overnights & a.o.g. Web use the correct tightening torque using this information. Web accepted formulae relating torque and tension, based on many tests are: This webpage will explain the difference between. For stainless steel fittings, please use the upper limit of torque range. In the world of hydraulics, the method of securing a joint. Fluids, piping and hydraulic design data. This webpage will explain the difference between. If your installation lets you use a torque wrench on the fittings, use the values in the table below. Web torque specifications for aluminum fittings. M = p x d m = torque lbf.ft 60 p = bolt tension lbf d = bolt dia.ins or for metric sizes: Values in chart are for steel fittings in steel ports. 9702365 • as 06/14 torque poster for additional technical information, contact fastenal. The table below gives the torque tightening values for jic (an) fittings in both stainless. Inline sae / jic connections. When a combination of aluminum and stainless. Web the an size reference the outer diameter of hose in 1/16th of an inch increments. Values in chart are for steel fittings in steel ports. The table below gives the torque tightening values for jic (an) fittings in both stainless steel and aluminum. The torque required to seal swiv female fittings or hose couplings to a male connector depends on many variables such as fluid medium, surface finish, etc. This webpage will explain the difference between. Values in chart are for steel fittings in steel ports. Brass and steel pipe thread (npt) installation procedure and torque specification table. Web tighten your jic fittings properly using this hydraulic fitting torque chart. Sae straight thread adjustable fitting. In equipment where a female. 9702365 • as 06/14 torque poster for additional technical information, contact fastenal. For stainless steel fittings, please use the upper limit of torque range. Web the an size reference the outer diameter of hose in 1/16th of an inch increments. Web pipe thread installation torque table chart. If your installation lets you use a torque wrench on the fittings, use the values in the table below. Web torque specifications for aluminum fittings. M = p x d m =. Fluids, piping and hydraulic design data. The elongated hole may have to be reamed to insure a good fit.

Printable Bolt Torque Chart

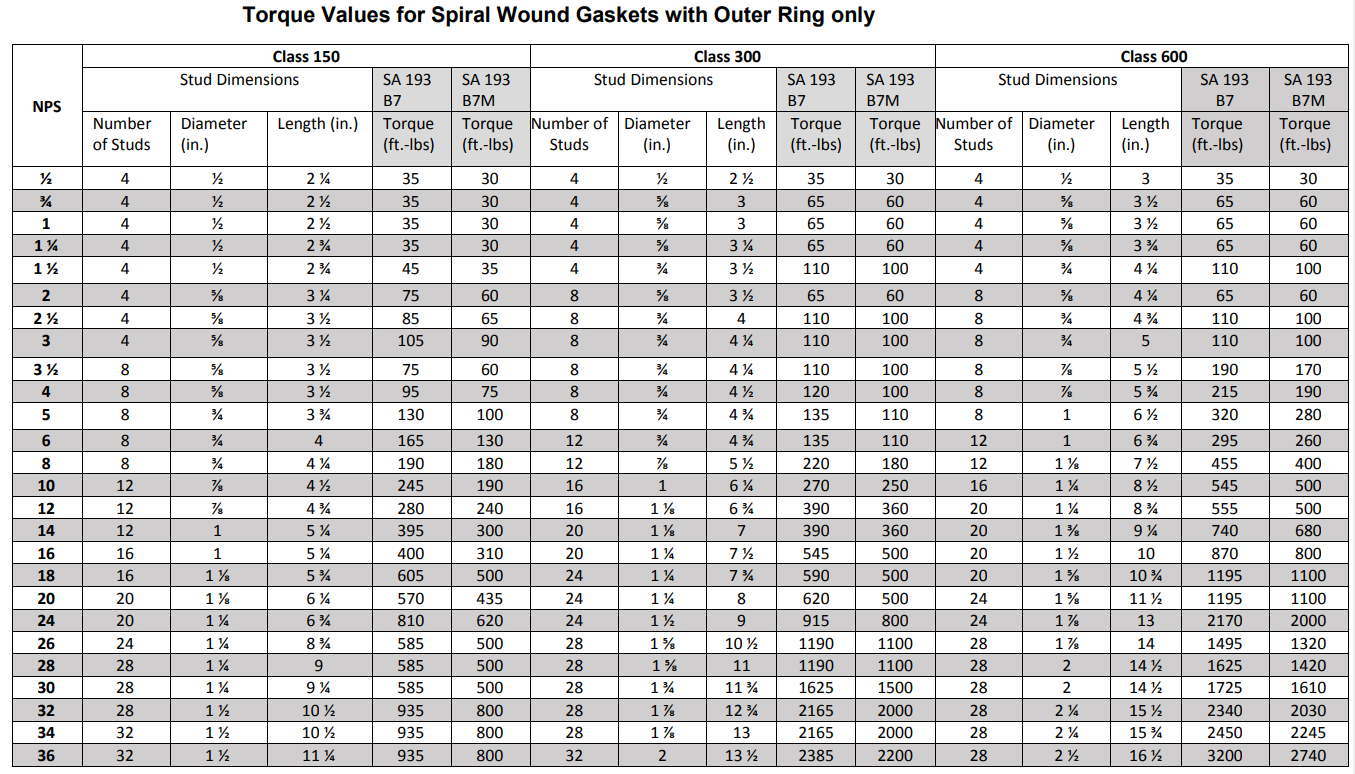

Flange Bolt Torque Calculation and Pipe Flange Bolt Torque Chart (With

Torque Charts Industrial Torque Tools

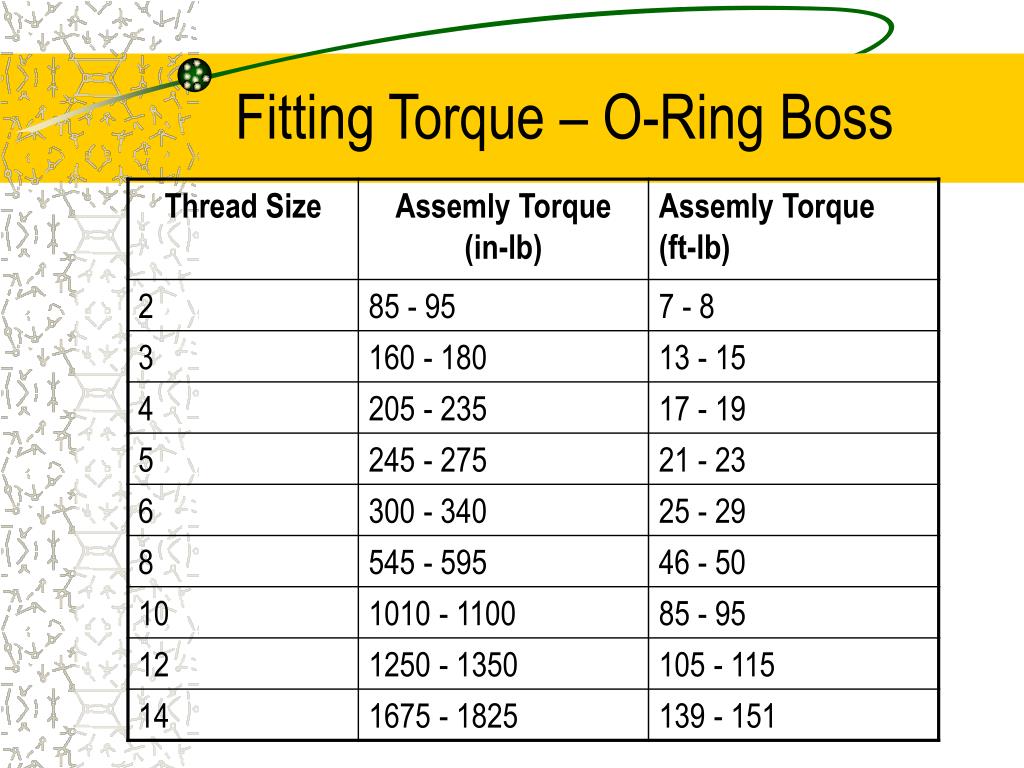

Torque Value Guide For Hydraulic Fittings Images and Photos finder

Standard Torque Chart For Bolts

Torque Charts Industrial Torque Tools

FREE 7+ Sample Bolt Torque Chart Templates in PDF MS Word

Banjo Bolt Torque Specifications Chart Hose And Fittings, 56 OFF

FREE 7+ Sample Bolt Torque Chart Templates in PDF MS Word

FREE 7+ Sample Bolt Torque Chart Templates in PDF MS Word

These Jic Torque Specifications Are Helpful In Setting Up Your Hose Connectors.

Web Portion Of The Bolt (I.e., For A 1/4 Inch Bolt With A 1/64 Inch Larger Diameter).

Inline Sae / Jic Connections.

Web Npt Size Threads Per Inch Fitting Id Max Torque In Ft Lbs Closest An Size 1/16 27 1/16 8.75 1/8 27 1/8 11.5 ‐04 1/4 18 1/4 16.25 ‐06 3/8 18 3/8 29 ‐08 1/2 14 1/2 35 ‐10 3/4 14.

Related Post: