Aluminium Alloy Chart

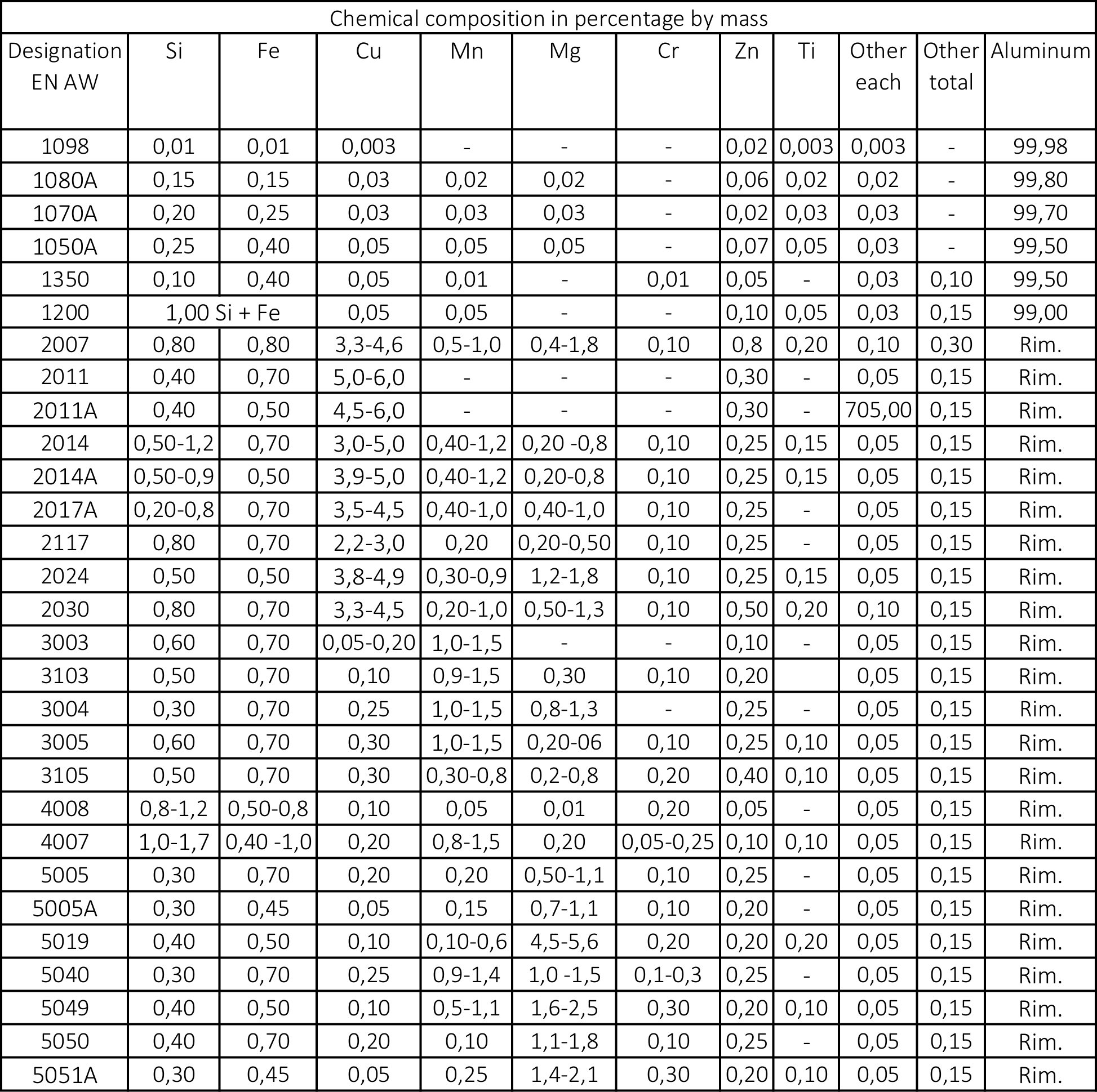

Aluminium Alloy Chart - There are over 300 wrought alloys with 50 in common use. Mechanical properties of copper grades and alloys. Therefore people often use it for applications that require these unique properties, such as reflectors, heat exchangers, and electrical components. Web the chart below shows different alloy series and what makes them unique. The typical alloying elements are copper, magnesium, manganese, silicon, tin, nickel and zinc. 1 ω·mm²/m = 1 μω·m. Mechanical properties of aluminum grades and alloys. Web aluminum is typically alloyed with different elements to change and improve its chemical or mechanical properties. Mechanical properties of stainless steel grades and alloys. A further differentiation for each category is based on the primary mechanism of property development. Web 6063 aluminum alloy physical properties. − to provide a survey of the aluminium alloys available to the user − to describe their various properties − to give an insight into the choice of aluminium for a proposed application. These are all categorized into a designation system to help welders make sense of them and choose the appropriate combination. Mechanical. Web an aluminium alloy ( uk / iupac) or aluminum alloy ( na; Wrought compositions and cast compositions. The following tables and lists summarize 6061 aluminum properties, datasheet and specs including chemical composition, physical properties and mechanical properties, welding, hardness, machinability, heat treating, etc. Web aluminum is typically alloyed with different elements to change and improve its chemical or mechanical. 1 ω·mm²/m = 1 μω·m. − to provide a survey of the aluminium alloys available to the user − to describe their various properties − to give an insight into the choice of aluminium for a proposed application. Wrought aluminum alloy lookup table. These are all categorized into a designation system to help welders make sense of them and choose. Web the chart below shows different alloy series and what makes them unique. Wrought compositions and cast compositions. Web access our comprehensive global aluminium alloy conversion chart for easy reference and comparison of casting and alloy specifications. Web aluminium alloy 7075 physical properties are given in the following lists, including aluminum density, melting point, coefficient of thermal expansion, elastic modulus,. Web classifications of aluminum alloys may be in several ways: See spelling differences) is an alloy in which aluminium (al) is the predominant metal. Wrought aluminum alloy lookup table. One of the most popular metals in the manufacturing sector is aluminum. The typical alloying elements are copper, magnesium, manganese, silicon, tin, nickel and zinc. Mechanical properties of titanium grades and alloys. Web aluminium alloy 7075 physical properties are given in the following lists, including aluminum density, melting point, coefficient of thermal expansion, elastic modulus, thermal conductivity, specific heat capacity electrical conductivity, and electrical resistance. Web aluminum alloy can be divided into two types based on processing method: The typical alloying elements are copper, magnesium,. Web classifications of aluminum alloys may be in several ways: Physical properties, characteristics and alloys 60 pages, 44 figures basic level prepared by ron cobden, alcan, banbury objectives: Please be aware that much of the data is adequate for industrial, however academic requirements are more stringent. This table is convenient for you to understand and compare aluminum alloy grades from. Aluminum futures rose to over $2,770 per tonne in may, the highest in two years, and tracking the strong momentum for base metals amid ongoing setbacks to supply. These are all categorized into a designation system to help welders make sense of them and choose the appropriate combination. Wrought compositions and cast compositions. Please be aware that much of the. Wrought aluminum alloy lookup table. As a result, there is a wide range of combinations of alloying elements available. These are all categorized into a designation system to help welders make sense of them and choose the appropriate combination. The wrought category includes rolling, extruding, drawing, forging, and a number of other more specialized processes. The following tables and lists. Mechanical properties of copper grades and alloys. Web 11 min read. Deformed aluminum alloy and cast aluminum alloy. Additionally, the series of aluminum and aluminum alloys are mainly divided into eight series. The typical alloying elements are copper, magnesium, manganese, silicon, tin, nickel and zinc. Additionally, the series of aluminum and aluminum alloys are mainly divided into eight series. Wrought aluminum alloy lookup table. Web aluminum is typically alloyed with different elements to change and improve its chemical or mechanical properties. Web the chart below shows different alloy series and what makes them unique. Web aluminum alloys are divided into the wrought and cast categories according to how they are produced. Deformed aluminum alloy and cast aluminum alloy. Web an aluminium alloy ( uk / iupac) or aluminum alloy ( na; 1 ω·mm²/m = 1 μω·m. These are all categorized into a designation system to help welders make sense of them and choose the appropriate combination. As a result, there is a wide range of combinations of alloying elements available. Web aluminum alloy 6061 properties, data sheet & specs. Numerical designations are assigned in accordance with the recommendation—international designation system for wrought aluminum and wrought aluminum alloys, which is printed on pages 28 through 30. Web aluminum alloy can be divided into two types based on processing method: Aluminum futures rose to over $2,770 per tonne in may, the highest in two years, and tracking the strong momentum for base metals amid ongoing setbacks to supply. Wrought compositions and cast compositions. Mechanical properties of aluminum grades and alloys.

Master Alloys for Aluminum Alloys Part Two Total Materia Article

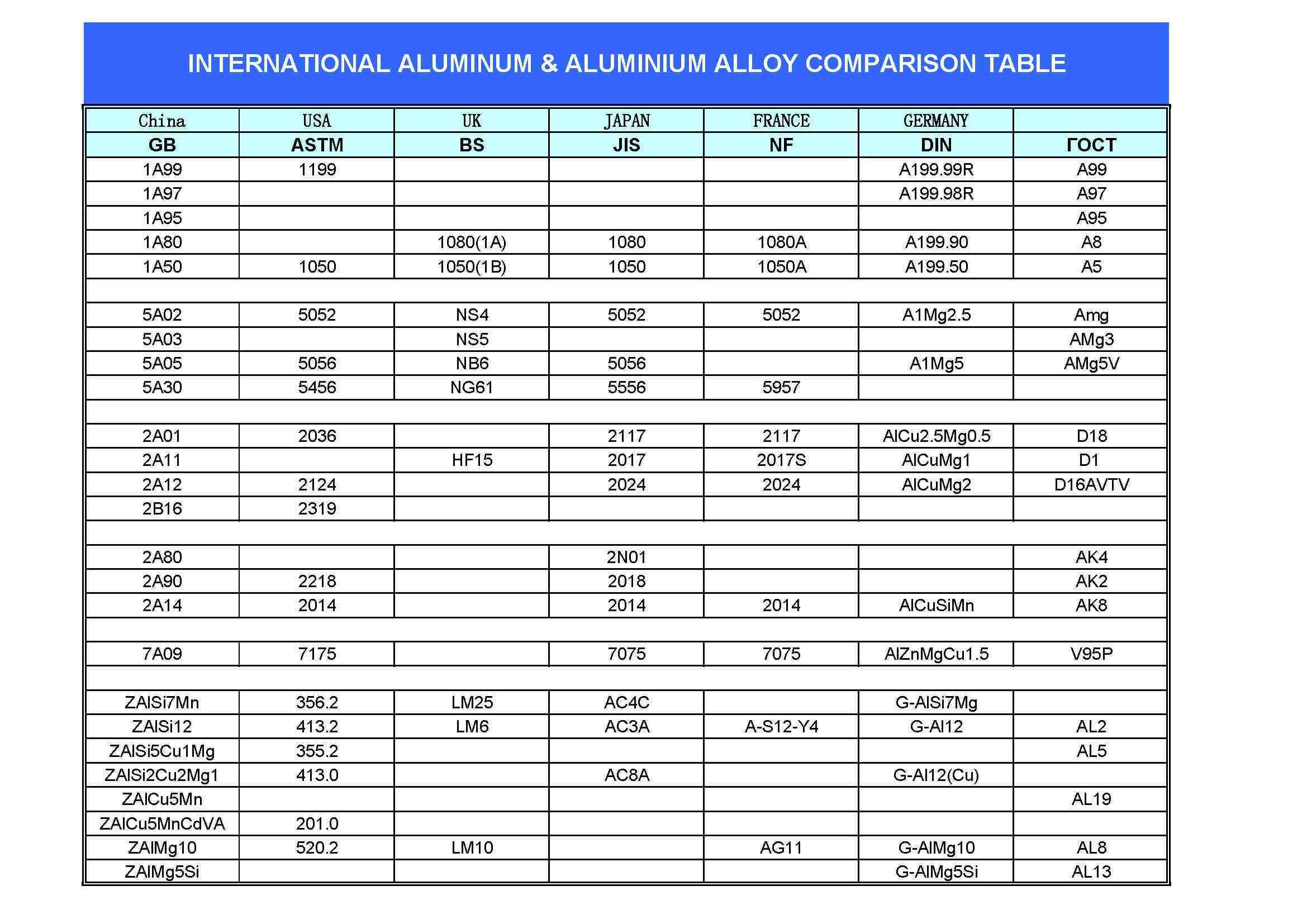

INTERNATIONAL ALUMINUM & ALUMINIUM ALLOY COMPARISON TABLE Technology

Aluminum Filler Alloy Selection Chart PDF Welding Construction

AlAlloysTable I Alloy Elements Light Metal Age Magazine

Alloys Superior Extrusion

Properties of AA8014 aluminium alloy Download Table

Aluminum and his alloys Custom Online Laser Cutting

Aluminum Yield Strength Of Aluminum

3003 or 5052 aluminium All MetalShaping

Aluminum Alloys Chart Properties

Web Wrought Aluminum Alloys Registered With The Aluminum Association.

Various Combinations Of The Main Alloying Elements With Other Alloying Elements.

Web 6063 Aluminum Alloy Physical Properties.

Many Alloys Respond To Thermal Treatment Based On Phase Solubilities.

Related Post: