17 4 Hardness Chart

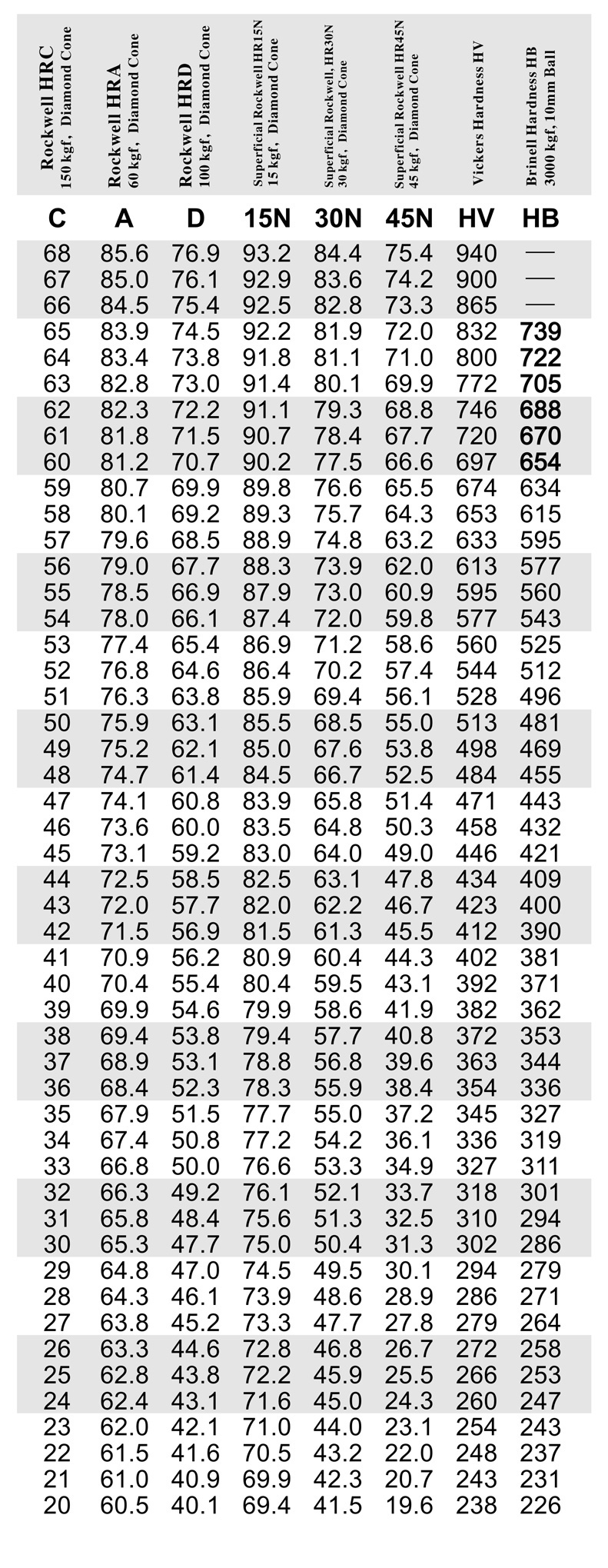

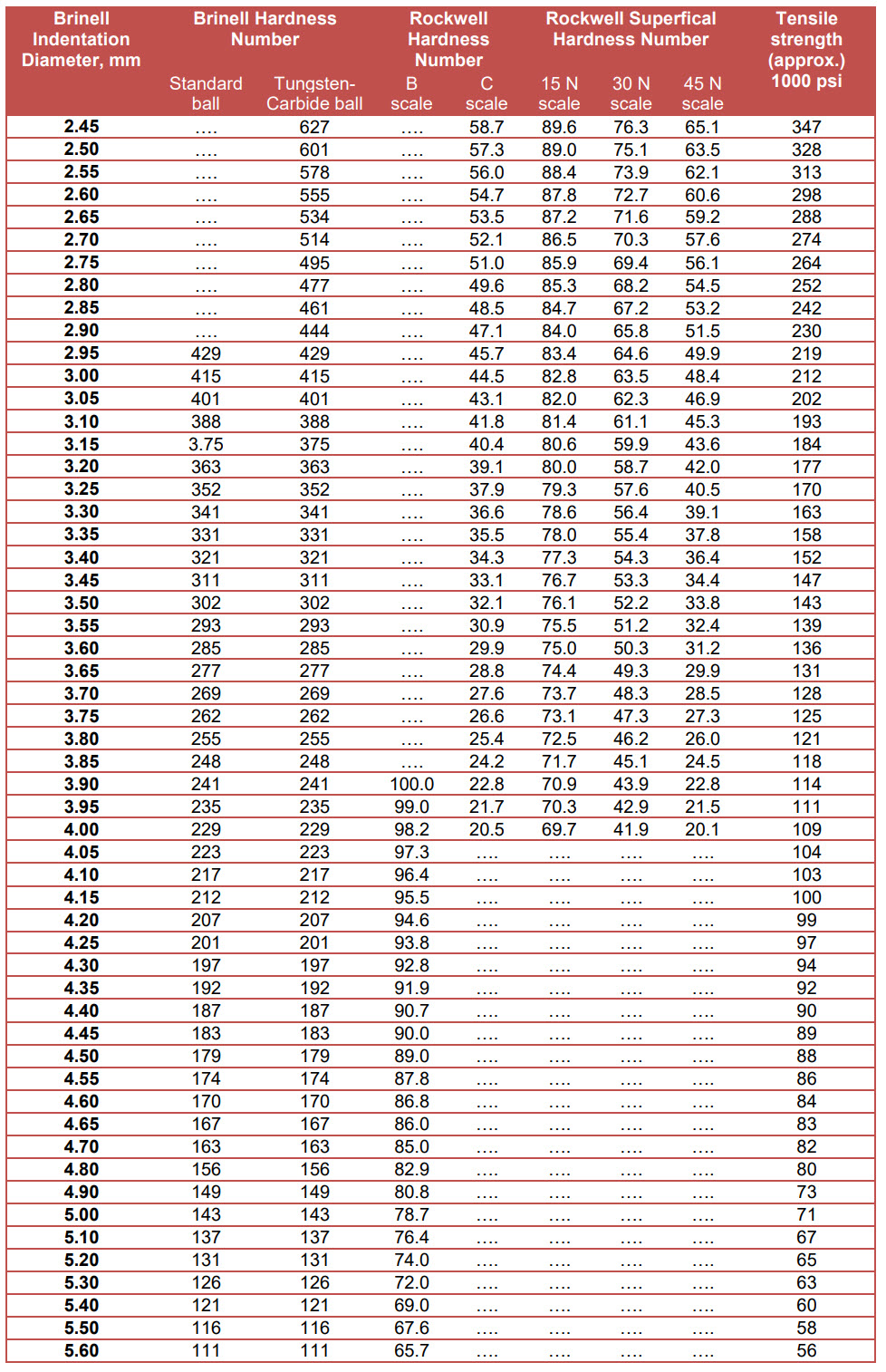

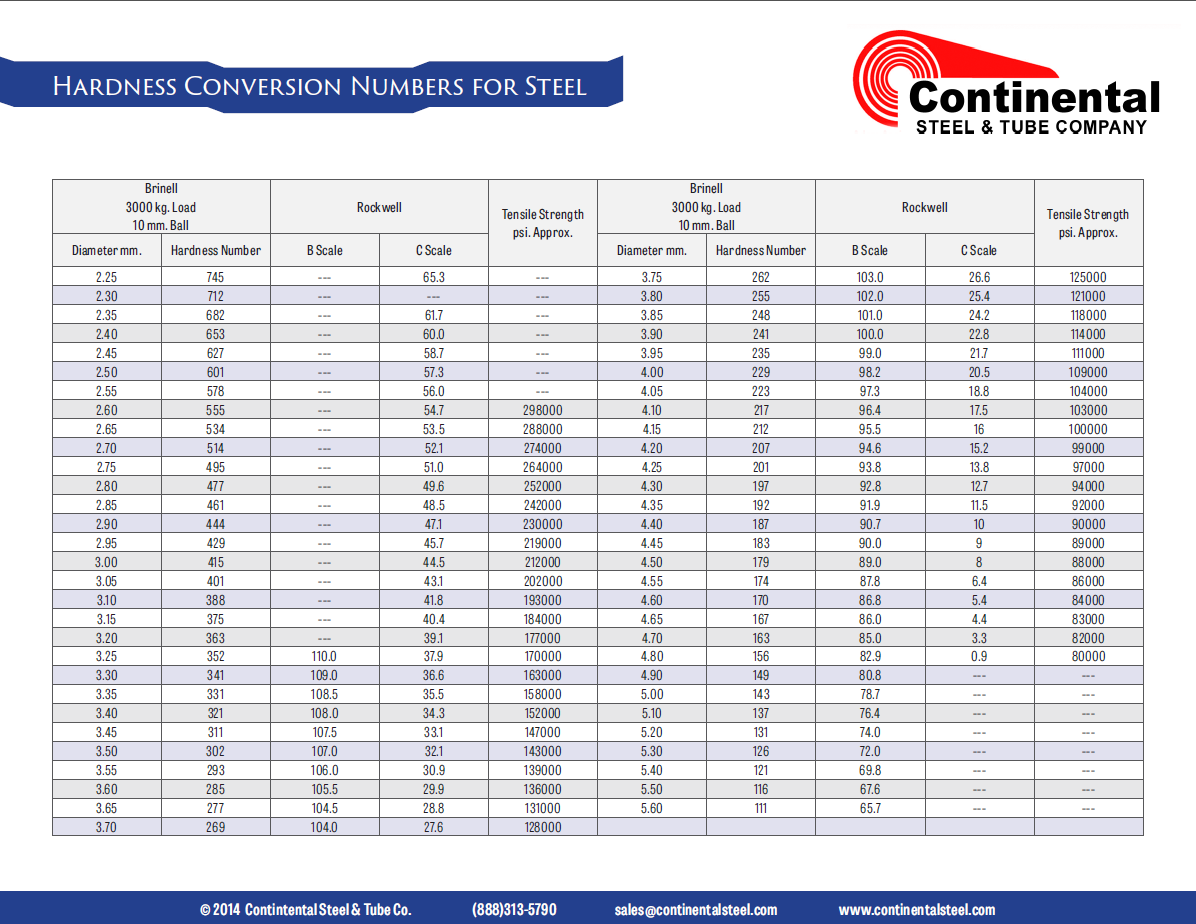

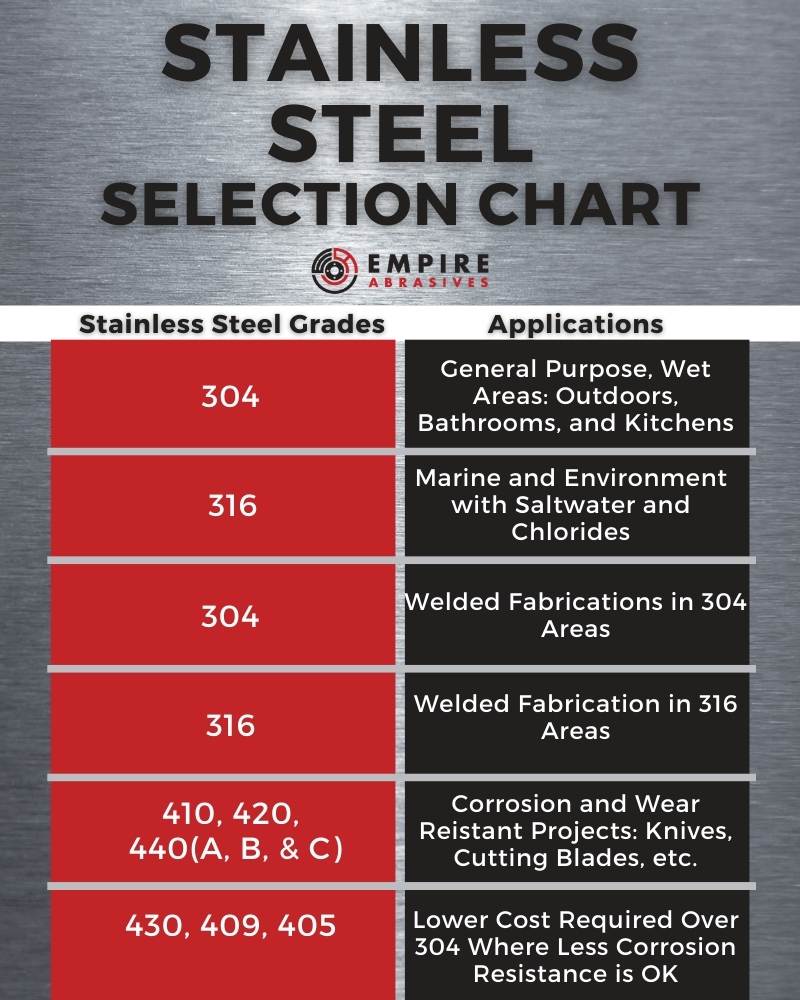

17 4 Hardness Chart - It also has similar corrosion and heat resistance to grade 304. It can be further hardened to various strength levels by a single precipitation hardening heat treatment that minimizes scaling and distortion. Superior to all 400 class stainless steels. * listed designations are for reference purposes only. And it’s not official material grade name too. It is easily heat treated from the annealed temper. Ability to be edm machined easily. Values listed below compare markforged samples processed in three diferent ways: Web ss 17/4 ph® is a precipitation hardenable martensitic stainless steel with high strength, and good corrosion resistance. Web uns s17400 is a grade of martensitic precipitation hardened stainless steel. Markforged represent typical tested values, while mim h900 and wrought h900 represent typical reference values from mpif standard 35. The name comes from the additions 17% chromium and 4% nickel. The alloy is furnished in the solution annealed condition (condition a). * listed designations are for reference purposes only. The material should not be used in the annealed condition. Composition and mechanical properties may vary. A very useful combination of high strength and hardness, excellent corrosion resistance, and easy heat treatment makes this an important alloy to designers and engineers. It is easily heat treated from the annealed temper. It also has similar corrosion and heat resistance to grade 304. The material should not be used in the annealed. The name comes from the chemical makeup which is approximately 17% chromium and 4% nickel. It can be further hardened to various strength levels by a single precipitation hardening heat treatment that minimizes scaling and distortion. Superior to all 400 class stainless steels. And it’s not official material grade name too. It also contains 4% copper and 0.3% niobium. It also contains 4% copper and 0.3% niobium. Values listed below compare markforged samples processed in three diferent ways: Superior dimensional stability in heat treatment. Ability to be edm machined easily. High strength is maintained to approximately 600°f (316°c). High strength is maintained to approximately 600°f (316°c). Composition and mechanical properties may vary. Also known as uns s17400) is a grade of martensitic precipitation hardened stainless steel. This alloy is typically furnished in condition a (annealed) but can be cold rolled to various temper ranges. Web uns s17400 is a grade of martensitic precipitation hardened stainless steel. High strength is maintained to approximately 600°f (316°c). Values listed below compare markforged samples processed in three diferent ways: And it’s not official material grade name too. It can be further hardened to various strength levels by a single precipitation hardening heat treatment that minimizes scaling and distortion. Composition and mechanical properties may vary. High strength is maintained to approximately 600°f (316°c). Composition and mechanical properties may vary. Markforged represent typical tested values, while mim h900 and wrought h900 represent typical reference values from mpif standard 35. A very useful combination of high strength and hardness, excellent corrosion resistance, and easy heat treatment makes this an important alloy to designers and engineers. The alloy. High resistance to corrosive environments. Web ss 17/4 ph® is a precipitation hardenable martensitic stainless steel with high strength, and good corrosion resistance. High strength is maintained to approximately 600°f (316°c). This alloy is typically furnished in condition a (annealed) but can be cold rolled to various temper ranges. High strength is maintained to approximately 600°f (316°c). It can be further hardened to various strength levels by a single precipitation hardening heat treatment that minimizes scaling and distortion. It also contains 4% copper and 0.3% niobium. Superior to all 400 class stainless steels. The name comes from the additions 17% chromium and 4% nickel. Ability to be edm machined easily. And it’s not official material grade name too. Composition and mechanical properties may vary. High strength is maintained to approximately 600°f (316°c). Superior dimensional stability in heat treatment. The alloy is furnished in the solution annealed condition (condition a). High strength is maintained to approximately 600°f (316°c). The alloy is furnished in the solution annealed condition (condition a). It is easily heat treated from the annealed temper. High resistance to corrosive environments. A very useful combination of high strength and hardness, excellent corrosion resistance, and easy heat treatment makes this an important alloy to designers and engineers. High strength is maintained to approximately 600°f (316°c). The name comes from the chemical makeup which is approximately 17% chromium and 4% nickel. Markforged represent typical tested values, while mim h900 and wrought h900 represent typical reference values from mpif standard 35. It can be further hardened to various strength levels by a single precipitation hardening heat treatment that minimizes scaling and distortion. Superior dimensional stability in heat treatment. Values listed below compare markforged samples processed in three diferent ways: Composition and mechanical properties may vary. It has high toughness, strength, and corrosion resistance. The name comes from the additions 17% chromium and 4% nickel. This alloy is typically furnished in condition a (annealed) but can be cold rolled to various temper ranges. It also has similar corrosion and heat resistance to grade 304.Stainless Steel Hardness Chart

17 4 Hardness Chart

Hardness comparison table WS STAHL

Hardness Conversion Chart For Aluminium Alloys Hardness Conversion

Stainless Steel Hardness Scale Steel Choices

17 4 Hardness Chart

Stainless Stress Values Pressure Vessel Engineering

chart library

What is the Rockwell Scale? Hardness Tester

Stainless Steel Finish Chart

It Also Contains 4% Copper And 0.3% Niobium.

* Listed Designations Are For Reference Purposes Only.

Superior To All 400 Class Stainless Steels.

It Is Typically Used In Gate Valves, Chemical Processing Equipment, Pump Shafts, Gears, Ball Bearings, Bushings, And Fasteners.

Related Post: