West System Cure Time Chart

West System Cure Time Chart - 206 slow hardener is used when extended working and cure time is needed, or to provide adequate working time at higher temperatures. Web post cure post cures at elevated temperatures will be effective in achieving a fast cure, but longer cure times at a gradually increasing temperature are recommended for achieving. Web check for correct pump (5:1 or 3:1 ratio) and pump group size (group b epoxy resin and group b epoxy hardener). Web west system user manual open time and cure time determine the build and repair operations. Cure to working strength.1 to 4 days Web readily available near you at local marine & hardware stores. Web learn how to choose the right hardener and control the cure time of west system epoxy depending on temperature and conditions. Web select your hardener to give you the pot life you want at the temperature and conditions in which you will work. Find out how pot life, exothermic heat and. All times given are based on working at 25°c. Web working time, thin film*. Select your hardener by cure speed or select 207 if you need a clear epoxy. Web readily available near you at local marine & hardware stores. Find out how pot life, exothermic heat and. Web post cure post cures at elevated temperatures will be effective in achieving a fast cure, but longer cure times at. Web west system user manual open time and cure time determine the build and repair operations. All times given are based on working at 25°c. Cure to a solid, thin film*.10 to 15 hours. Sizes 1.15 l (group size a) 4.55 l (group size b) 20 l (group size c) sold since: Get started with the west system selection guides,. Pot life (100 grams cupful): Web open time and cure time govern much of the activity of building and repairing with epoxy. Web west system user manual open time and cure time determine the build and repair operations. Find out how pot life, exothermic heat and. 5 to 7 hours *epoxy cures faster at. Web working time, thin film*. Local marine & hardware stores. Web readily available near you at local marine & hardware stores. Open time dictates the time available for mixing, application, smoothing, shaping,. Cured resin and hardener yields. Open time dictates the time available for mixing, application, smoothing,. Web readily available near you at local marine & hardware stores. Web west system user manual open time and cure time determine the build and repair operations. Web select your hardener to give you the pot life you want at the temperature and conditions in which you will work. Web. Open time dictates the time available for mixing, application, smoothing, shaping,. Web learn how to choose the right hardener and control the cure time of west system epoxy depending on temperature and conditions. Pot life (100 grams cupful): Web select your hardener to give you the pot life you want at the temperature and conditions in which you will work.. 5 to 7 hours *epoxy cures faster at. Cured resin and hardener yields. Web mix with one of four west system hardeners. Check epoxy pump ratio (see 300 mini pump instructions ). Web west system user manual open time and cure time determine the build and repair operations. Check epoxy pump ratio (see 300 mini pump instructions ). Local marine & hardware stores. 206 slow hardener is used when extended working and cure time is needed, or to provide adequate working time at higher temperatures. Web west system user manual open time and cure time determine the build and repair operations. Web working time, thin film*. Web readily available near you at local marine & hardware stores. Web open time and cure time govern much of the activity of building and repairing with epoxy. Web the focus of the user manual & product guide is using west system epoxy safely and effectively. Web post cure post cures at elevated temperatures will be effective in achieving a. 9 to 12 minutes ; 206 slow hardener is used when extended working and cure time is needed, or to provide adequate working time at higher temperatures. Get started with the west system selection guides, learn how the epoxy 105. Web mix with one of four west system hardeners. Web the focus of the user manual & product guide is. Web check for correct pump (5:1 or 3:1 ratio) and pump group size (group b epoxy resin and group b epoxy hardener). Select your hardener by cure speed or select 207 if you need a clear epoxy. Pot life (100 grams cupful): Web mix with one of four west system hardeners. Web learn how to choose the right hardener and control the cure time of west system epoxy depending on temperature and conditions. Open time dictates the time available for mixing, application, smoothing, shaping,. 5 to 7 hours *epoxy cures faster at. Cured resin and hardener yields. #205 fast hardener, mixed at a 5:1 ratio with #105 resin, results in. Web south africa follows a proportional voting system where parties and candidates compete for 400 seats in the parliament known as the national assembly. Pot life (100 grams cupful): Select your filler (if needed) for. 9 to 12 minutes ; Find out how pot life, exothermic heat and. Web the focus of the user manual & product guide is using west system epoxy safely and effectively. Web select your hardener to give you the pot life you want at the temperature and conditions in which you will work.

5 Tips for Applying an Epoxy Floor Coating System in Cold Weather or

West System Cure Time Chart

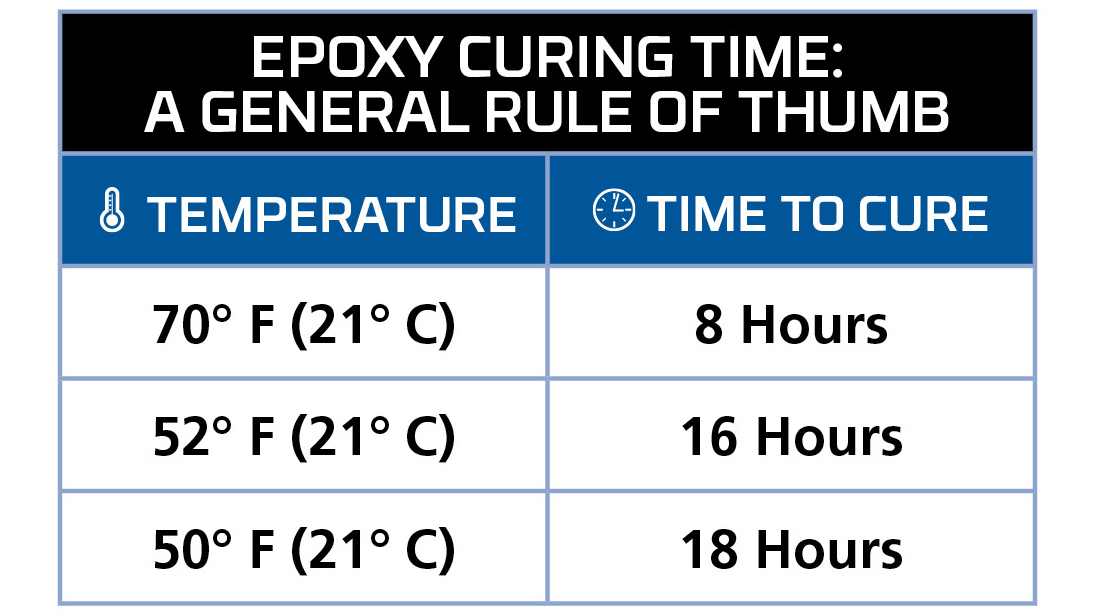

Epoxy Cure Time Chart

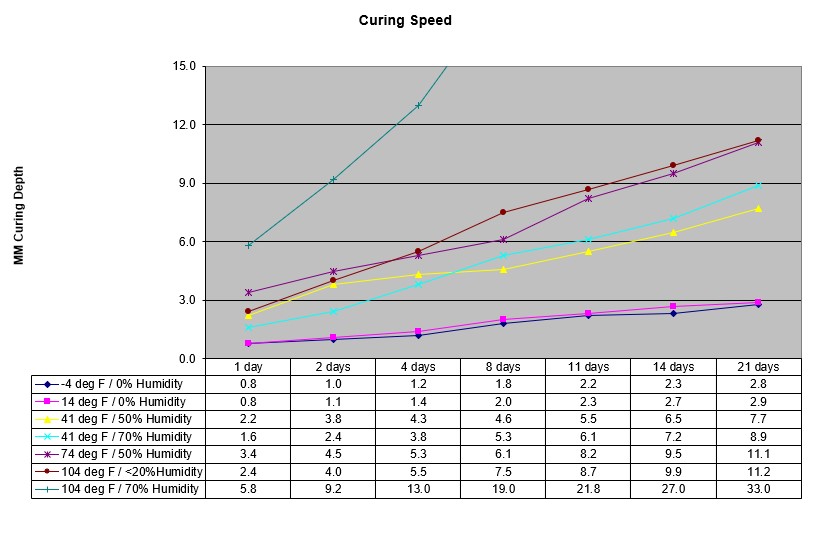

Concrete Curing Chart

Concrete Floor Cure Time Flooring Site

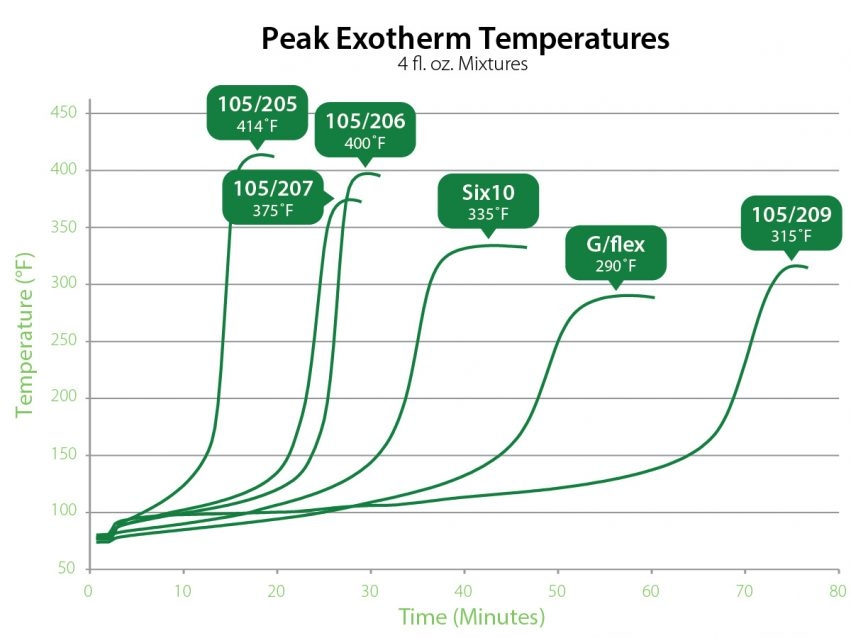

Uncontrolled Cure WEST SYSTEM Epoxy

Epoxy Cure Time Chart

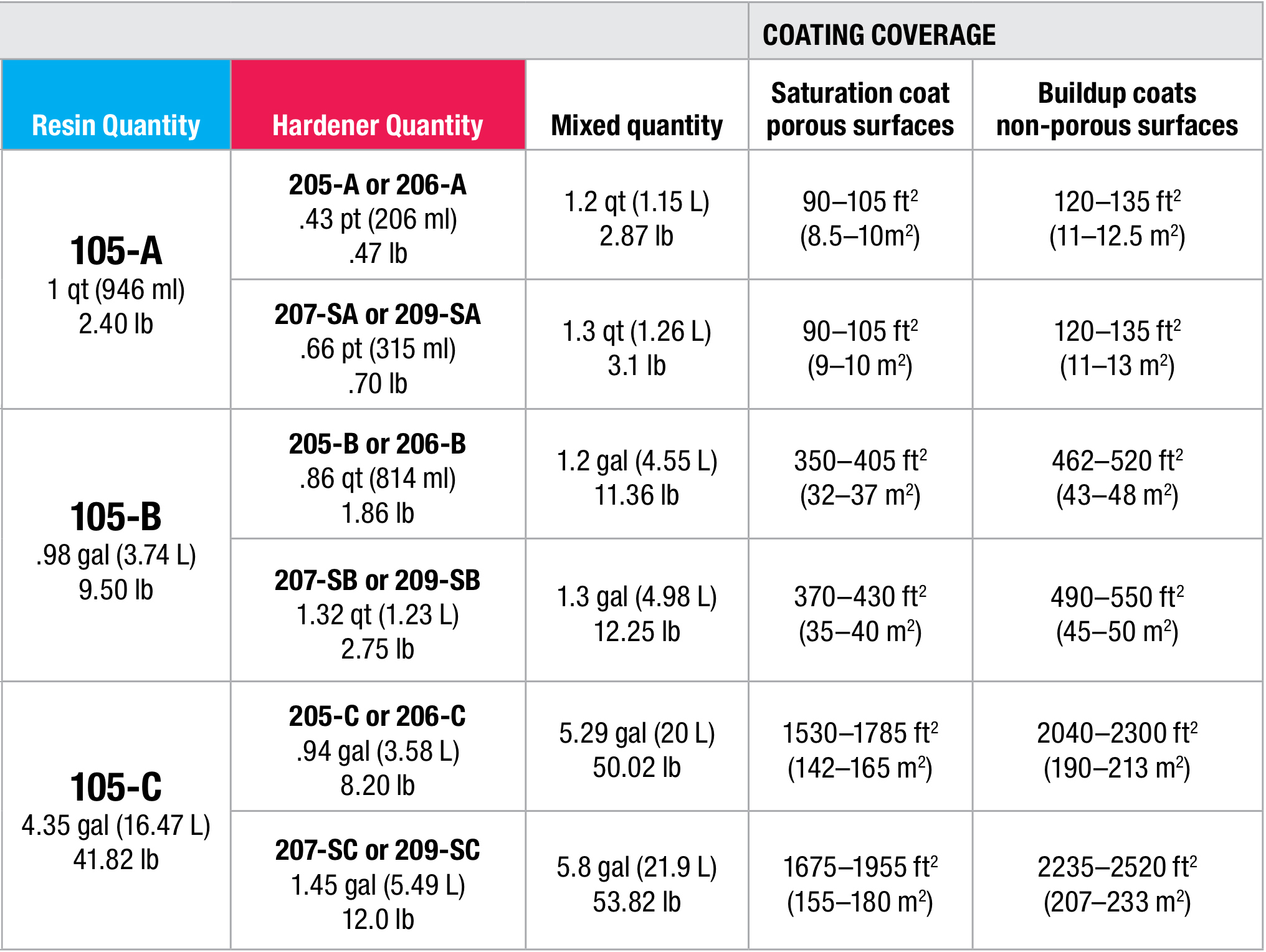

Epoxy Resin Coverage Chart

West System Cure Time Chart

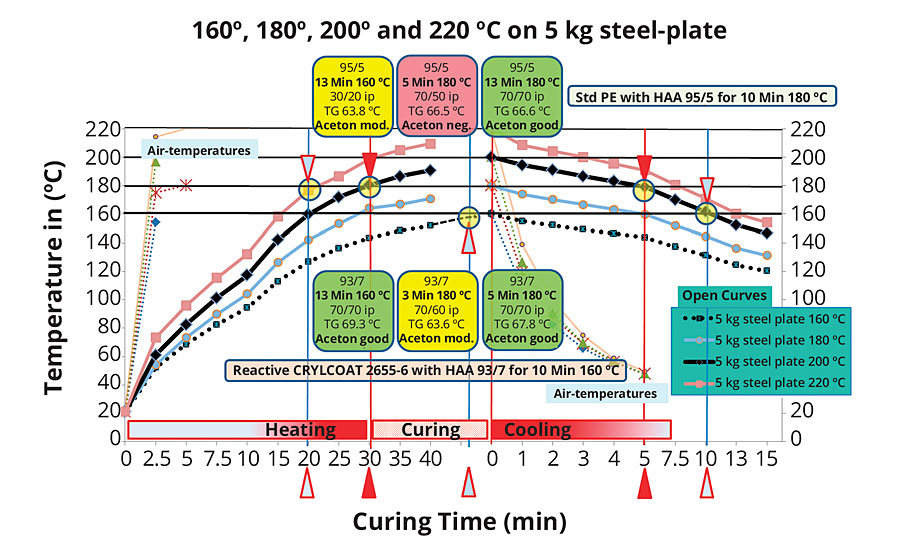

LowTemperatureCuring Powder Coatings System 20181009 PCI Magazine

Cure To Working Strength.1 To 4 Days

Cure To A Solid, Thin Film*.10 To 15 Hours.

All Times Given Are Based On Working At 25°C.

Web Readily Available Near You At Local Marine & Hardware Stores.

Related Post: