Welding Electrodes Chart

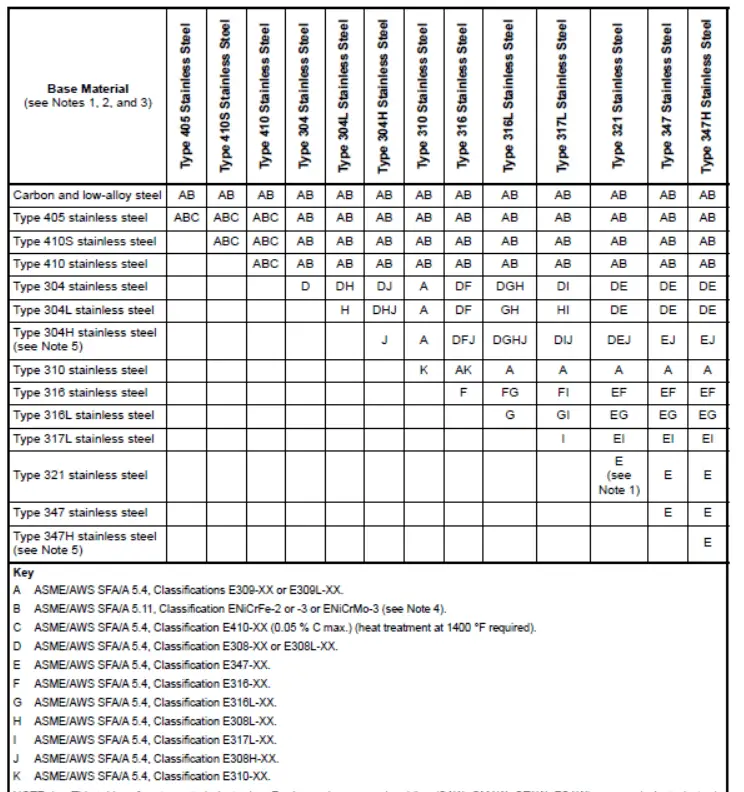

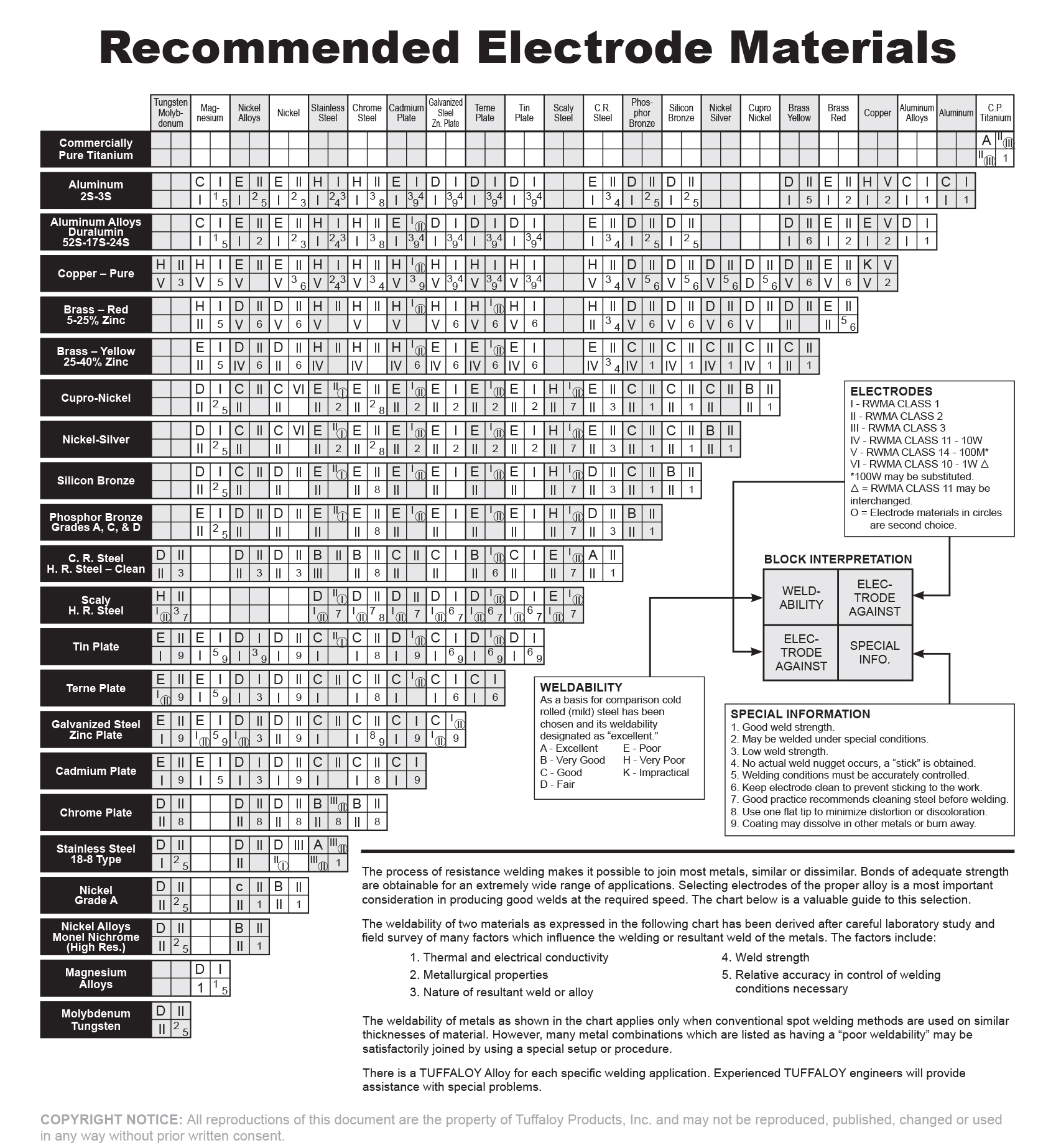

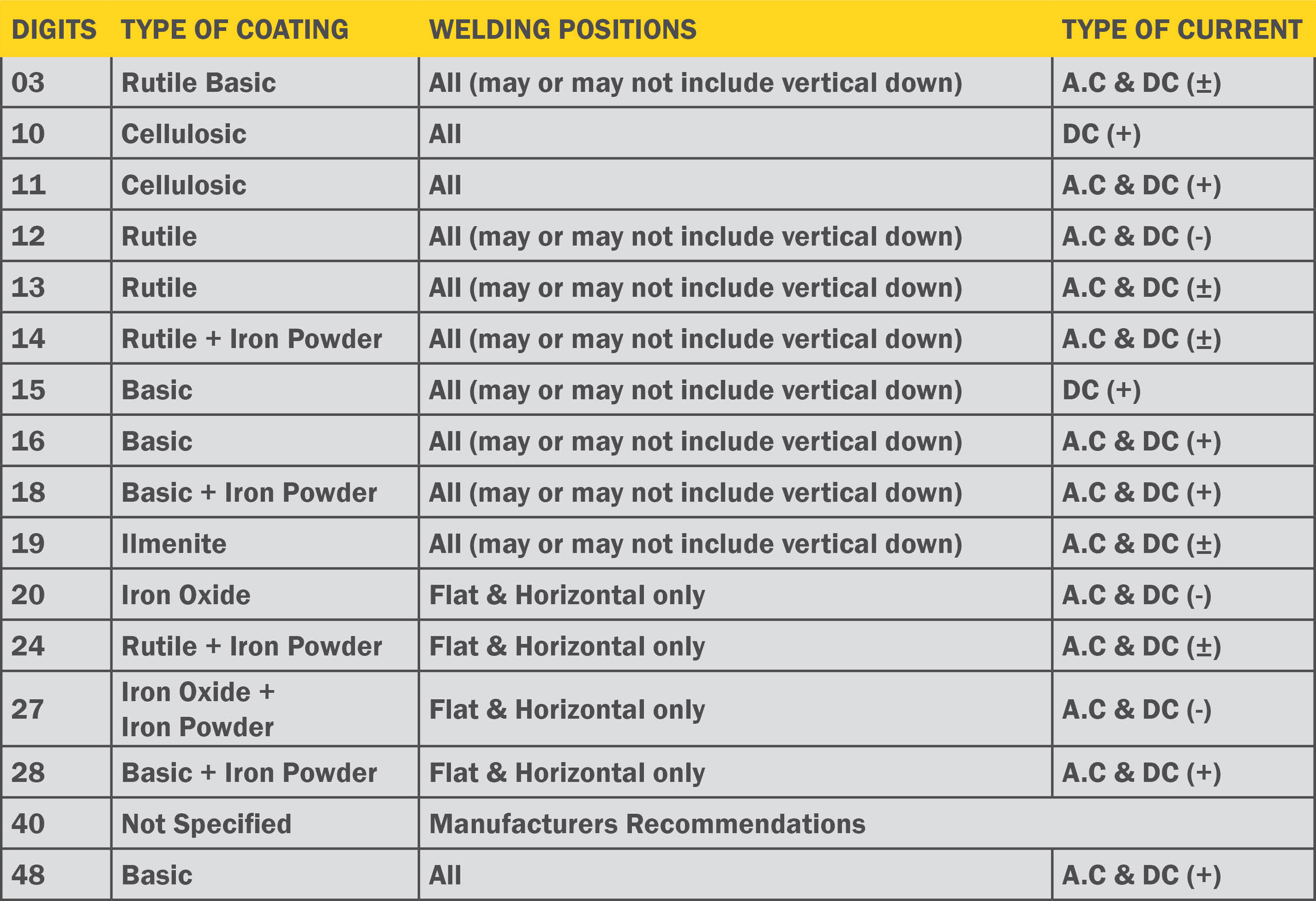

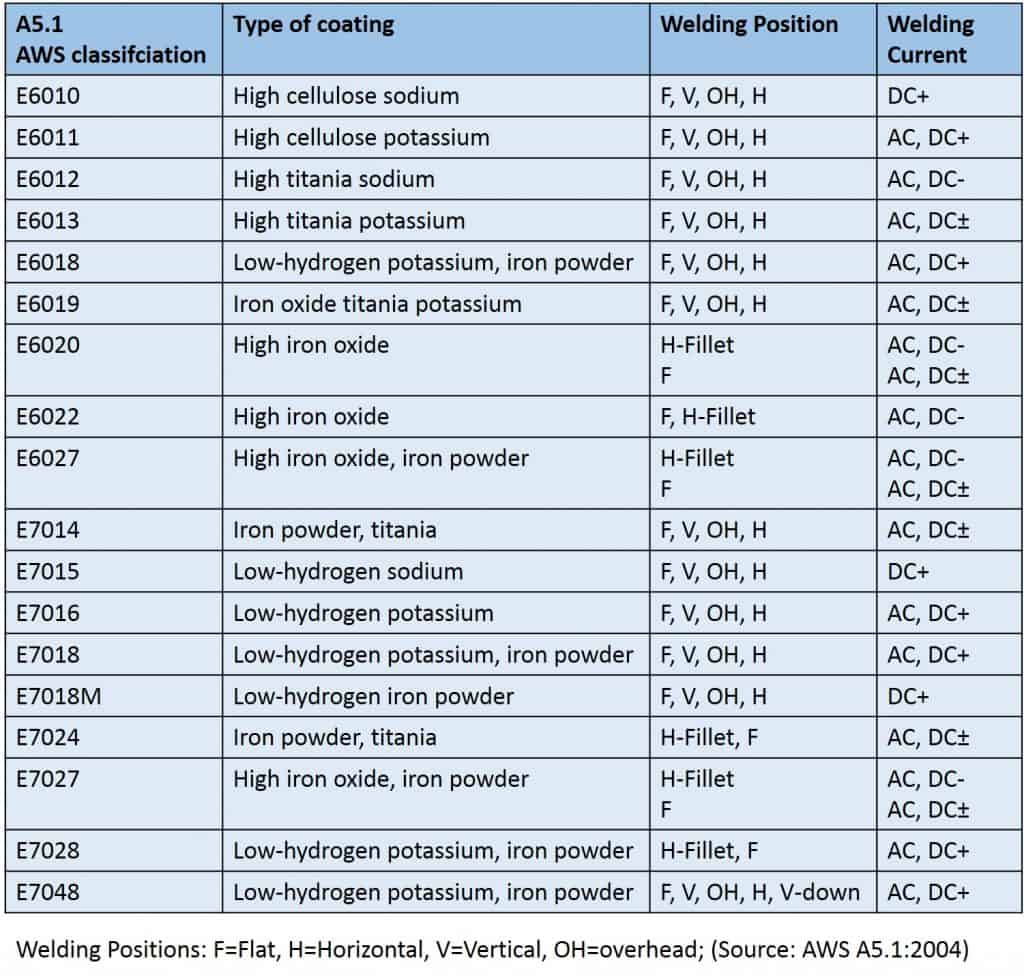

Welding Electrodes Chart - How to choose the right welding rods?. However, adjust this angle from as little as 30° to as much as 60° when required to. Web welding electrode table (chart) welding electrode symbols; Almost all fusion welding processes require welding. Web looking for a welding electrode and filler wire selection chart? Web once you’ve chosen your welding rod diameter, use the stick welding rod chart at the top of the page to find the amperage range for that specific electrode. Smooth running easy starting electrode with fast freezing slag action. Web find the perfect welding electrode for your project with our detailed comparison chart. Web the most common diameter for general purpose welding is 3/32, 1/8 inch, and 5/32 inch. Web the chart shows the proper arc electrode to be used for the various types of aisi steels. Smooth running easy starting electrode with fast freezing slag action. Web a helpful tip for beginners is to test the amperage on similar scrap metal to find the right amperage. Almost all fusion welding processes require welding. Commonly known as shielded metal arc. Web we offer a variety of helpful welding charts and guides that you can reference online, or. A slag cover is needed to protect molten or to. When molten metal is exposed to air, it absorbs oxygen and nitrogen and becomes brittle or is otherwise adversely affected. Compare models and grades to make an informed choice and. An electrode chart for arc welding is a reference guide for selecting the appropriate electrode based on the welding job. The pdf has 8 sections:. For smaw process, weaving shall be 3 times core dia. Web march 2, 2024november 30, 2023 by sohagarbin. Almost all fusion welding processes require welding. Web the color chart below summarizes the various tig tungsten electrodes you may come across: The fillet size (l) is meant to represent the base and height of the triangle used in the. However, adjust this angle from as little as 30° to as much as 60° when required to. Web the most common diameter for general purpose welding is 3/32, 1/8 inch, and 5/32 inch. Web march 2, 2024november 30, 2023 by sohagarbin. Last. The pdf has 8 sections:. Web the most common diameter for general purpose welding is 3/32, 1/8 inch, and 5/32 inch. Web usually weld with the electrode at a 45° angle (end view) from the horizontal plate. It serves as a guide for selecting the appropriate electrode. Web looking for a welding electrode and filler wire selection chart? Web find the perfect welding electrode for your project with our detailed comparison chart. An electrode chart for arc welding is a reference guide for selecting the appropriate electrode based on the welding job and. Use when you are unable to prepare a. When molten metal is exposed to air, it absorbs oxygen and nitrogen and becomes brittle or is. Web march 2, 2024november 30, 2023 by sohagarbin. * single values are maximums excepts as noted ** according to aisi steel products. For smaw process, weaving shall be 3 times core dia. Smooth running easy starting electrode with fast freezing slag action. Web the chart shows the proper arc electrode to be used for the various types of aisi steels. Web we offer a variety of helpful welding charts and guides that you can reference online, or download as a pdf to print, distribute, or post for your welding team. Web welding electrode table (chart) welding electrode symbols; Web march 2, 2024november 30, 2023 by sohagarbin. The fillet size (l) is meant to represent the base and height of the. Web find the perfect welding electrode for your project with our detailed comparison chart. Web a welding electrode chart categorizes electrodes based on factors such as material, coating, current, and position. Web the most common diameter for general purpose welding is 3/32, 1/8 inch, and 5/32 inch. When molten metal is exposed to air, it absorbs oxygen and nitrogen and. What is it & how to choose? Web looking for a welding electrode and filler wire selection chart? Web we offer a variety of helpful welding charts and guides that you can reference online, or download as a pdf to print, distribute, or post for your welding team. Web the color chart below summarizes the various tig tungsten electrodes you. Web electrode selection as per base metal with preheat, postheat and hardness details preferred alternate 1 carbon steel a 53 a106 a178 a179/192 a234 gr. Type 6011 mild steel current: However, adjust this angle from as little as 30° to as much as 60° when required to. What is it & how to choose? After that, you can weld the workpiece without defects. When molten metal is exposed to air, it absorbs oxygen and nitrogen and becomes brittle or is otherwise adversely affected. Welding carbon steels and mild steels. Smooth running easy starting electrode with fast freezing slag action. Commonly known as shielded metal arc. Last updated on jan 30 2023. Web the color chart below summarizes the various tig tungsten electrodes you may come across: Web austarc® electrode selection chart. Lincoln mig welding electrode and gas selection chart settings. How to choose the right welding rods?. Almost all fusion welding processes require welding. The fillet size (l) is meant to represent the base and height of the triangle used in the.

Welding Electrode and Filler wire Selection Charts

Welding Electrode Types Chart

TIG Welding Tungsten Electrode Selection Chart Midwest, 42 OFF

Welding Electrode Chart And Selection Weld Guru, 58 OFF

How do I select the proper electrode material for spot welding? How

Weld Electrode Chart

Selecting the Right Stick Electrode WIA

Welding Electrode Chart And Selection Weld Guru vlr.eng.br

Electrode Amperage Chart — Baker's Gas & Welding Supplies, Inc.

Weld Electrode Chart

A Welding Electrode Is Defined By Aws A3.0 Standard Welding Terms And Definitions “As A Component Of Welding Circuit Through Which Current Is.

Use When You Are Unable To Prepare A.

Web March 2, 2024November 30, 2023 By Sohagarbin.

Web Mig Welding Electrode Selection Chart.

Related Post: