Weld Positions Chart

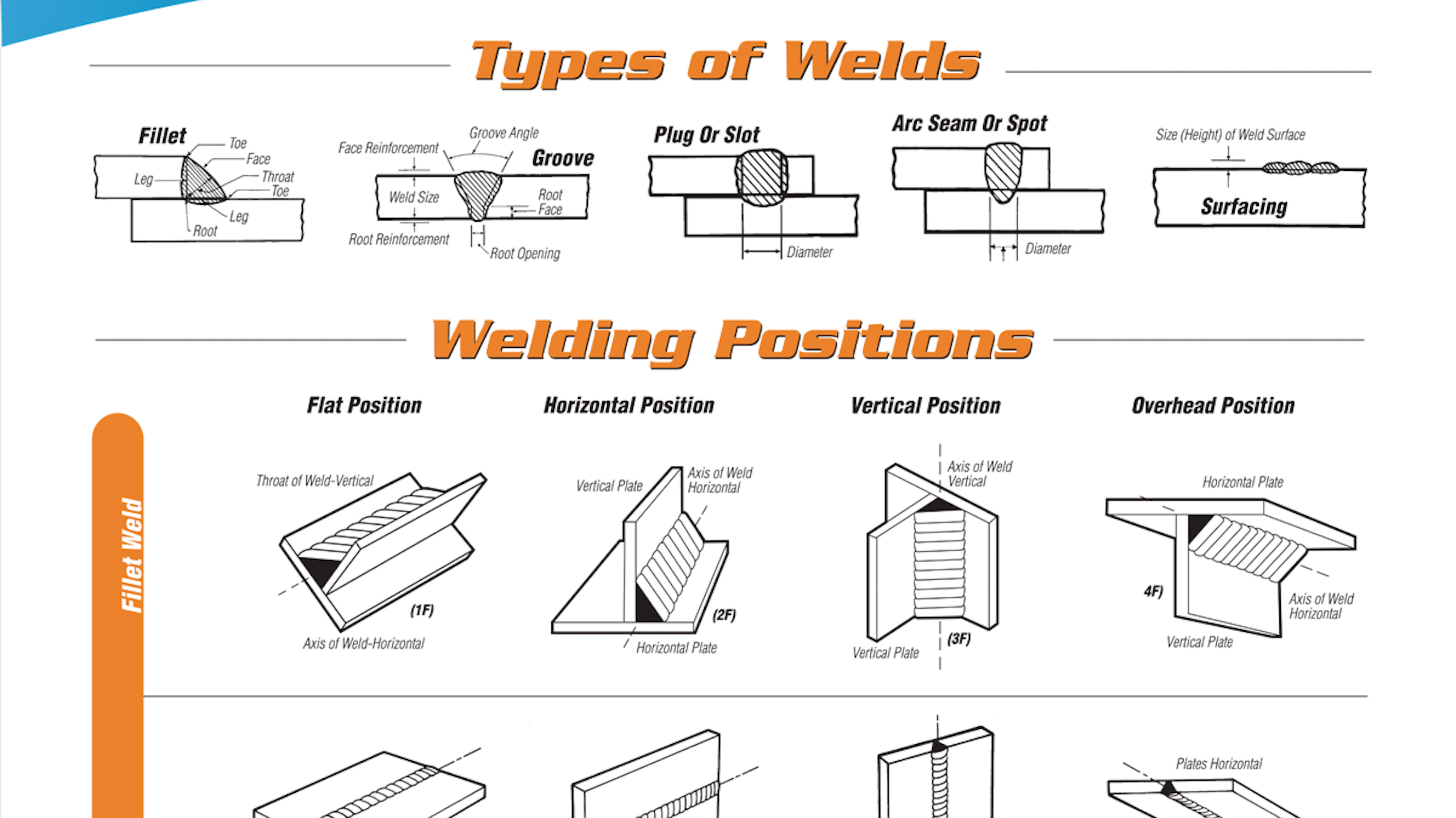

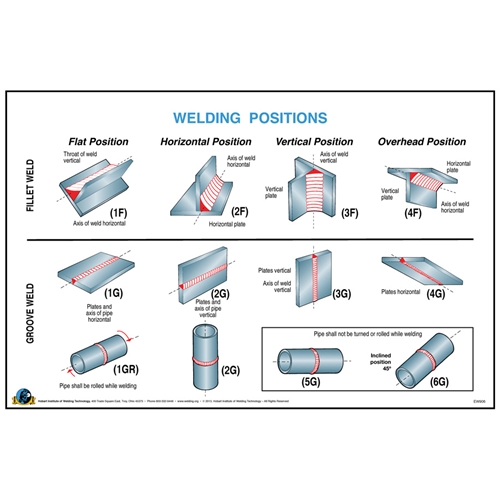

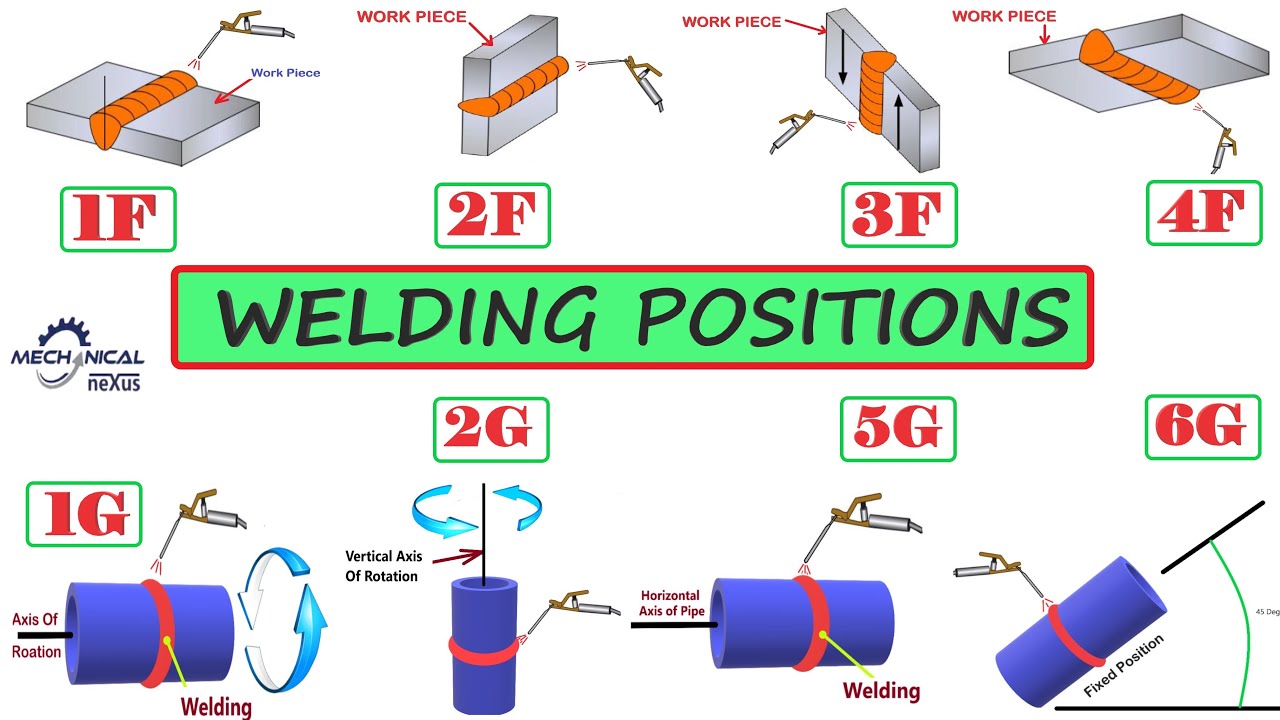

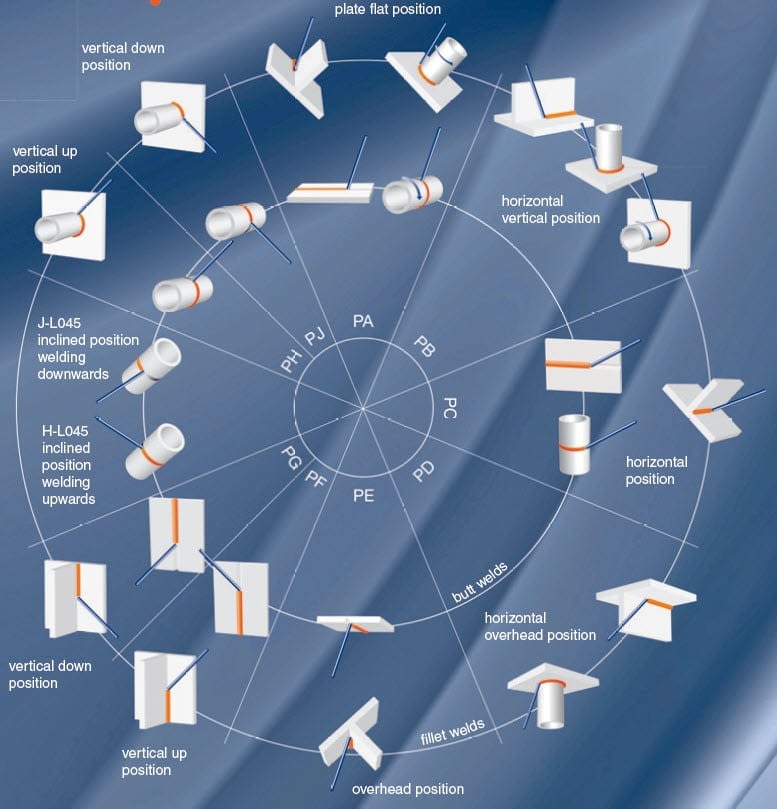

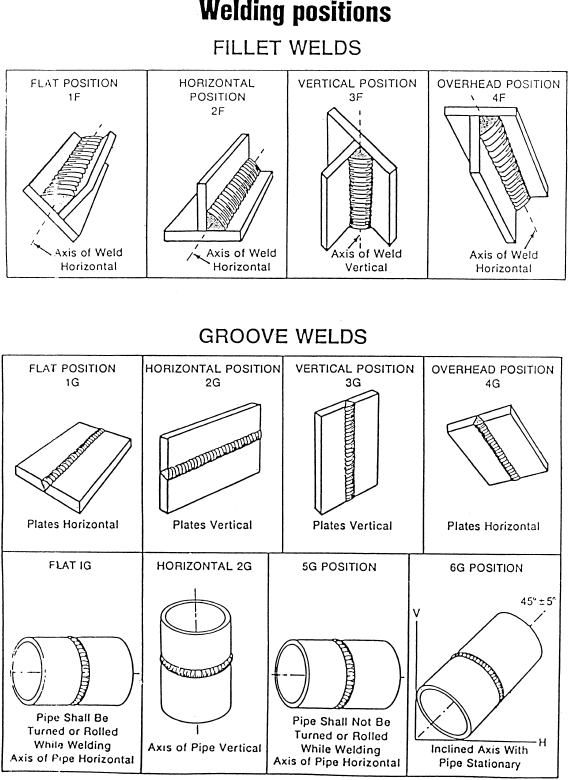

Weld Positions Chart - Web welders can use the welding position chart to learn new techniques. Web the four major welding positions: The following image in fig. Web understanding the four basic welding positions can help you choose the right filler metal and welding process for your job. Web iso 6947 welding position chart. Knowing this alphanumeric system will help you make the right weld every time. Any conversation around welding starts with a discussion on the welding position of the weld face. The position chart is especially helpful when welding in difficult positions. Web even though there is a lot to learn, you are lucky since you’ve stumbled upon us. Each welding position requires specific techniques to ensure efficient and successful welding. We’re going to tell you everything you need to know about each of the welding positions we’ve just mentioned. Iso 6947 and aws welding positions. Web to achieve more excellent welding quality, professional organizations (asme, aws, iso, jwes) make rules and classifications of welding positions. Unique letters designate fillet and groove welds (image credit: The chart helps welders understand the. En iso 6947 and asme use the same welding positions, but with different labels. These include the flat (1g/1f/pa), horizontal (2g/2f/pc/pb), vertical (3g/5g), and overhead (4g/4f) positions. A weld in the flat position is the easiest weld joint to perform. The welding position at the groove joint and the welding position at the fillet joint. Web the standardized alphanumeric system. Web flat position (1g and 1f) in the flat position, the axis of the weld joint is horizontal and the weld is made on the top side of the joint. Iso 6947 and aws welding positions. It reveals four welding positions and joint types such as 1g, 2g, 3g, 4g, 5g and 6g/6gr. Flat position (1g welding position or 1f. Welding positions according to the iso 6947. Any conversation around welding starts with a discussion on the welding position of the weld face. Just type your email below! Let’s get into the specifics, shall. Knowing this alphanumeric system will help you make the right weld every time. The following image in fig. The welding position at the groove joint and the welding position at the fillet joint. En iso 6947 and asme use the same welding positions, but with different labels. Flat position (1g welding position or 1f welding position) horizontal position (2g welding position or 2f welding position) The chart also helps welders choose the best. 1 shows the welding positions used during welding. Flat, vertical, horizontal, and overhead. Web the four basic welding positions are: Web the standardized alphanumeric system shown below is used to specify a fillet weld or a groove weld, and whether the weld is to take place in the flat, horizontal, vertical or overhead position. Four basic welding positions defined by. Four basic welding positions defined by the american welding society. Web jasic welding & cutting inverters 2024. The most common type of weld you will do is a fillet weld and a groove weld, and you can accomplish these welds in all four positions. Web the four major welding positions: Iso 6947 and aws welding positions. These include the flat (1g/1f/pa), horizontal (2g/2f/pc/pb), vertical (3g/5g), and overhead (4g/4f) positions. Web there are four different welding positions that can be defined as follows: Web understanding the four basic welding positions can help you choose the right filler metal and welding process for your job. The following image in fig. Web know all types of welding positions and. Web flat position (1g and 1f) in the flat position, the axis of the weld joint is horizontal and the weld is made on the top side of the joint. Flat, horizontal, vertical, and overhead. Generally, the pipe welding position is divided into two types: Iso 6947 and aws welding positions. Chart showing welding positions in accordance with bs en. Horizontal, flat, vertical, overhead, and inclined. Welds with a 1 are flat position, 2 is horizontal, 3 is vertical and 4 is overhead. Four basic welding positions defined by the american welding society. Web a welding position chart is a comprehensive guide outlining the positions in which a welder can operate. A weld in the flat position is the easiest. Web pick up your free welding symbols hand chart that we made! Unique letters designate fillet and groove welds (image credit: The most common type of weld you will do is a fillet weld and a groove weld, and you can accomplish these welds in all four positions. (note, downloadable versions are below the table for printing.) (found this page useful? The chart also helps welders choose the best position for a particular weld. Web the four basic welding positions are: Welding positions according to the iso 6947. Web iso 6947 welding position chart. 1 shows the welding positions used during welding. Weld joint positions for plate. Web the american welding society has defined the four basic welding positions as shown below. Each welding position requires specific techniques to ensure efficient and successful welding. Flat, horizontal, vertical, and overhead. Each welding position may require different techniques, parameters and preparation to achieve the best results. The position chart is especially helpful when welding in difficult positions. Web jasic welding & cutting inverters 2024.

Welding Positions Chart Jasic Welding Inverters

Welding position in accordance with EN ISO 6947 — Capilla

Welding Types and Positions poster Fleet Maintenance

Welding Positions Wall Poster Hobart Institute of Welding Technology

WELDING POSITIONS FLAT POSITION HORIZONTAL POSITION VERTICAL

Weld Position Diagram Australian Welding Solutions

Xa00152120 Welding Positions Eng New Iso June 2010

Printable Welding Charts

Weld Positions

What are the 5 MIG Welding Positions A Definitive Guide

The Four Basic Weld Positions For Plate Are:

Web Flat Position (1G And 1F) In The Flat Position, The Axis Of The Weld Joint Is Horizontal And The Weld Is Made On The Top Side Of The Joint.

Generally, The Pipe Welding Position Is Divided Into Two Types:

The Individual Welding Positions As Per Iso 6947 Standards Are The:

Related Post: