Weld Fillet Size Chart

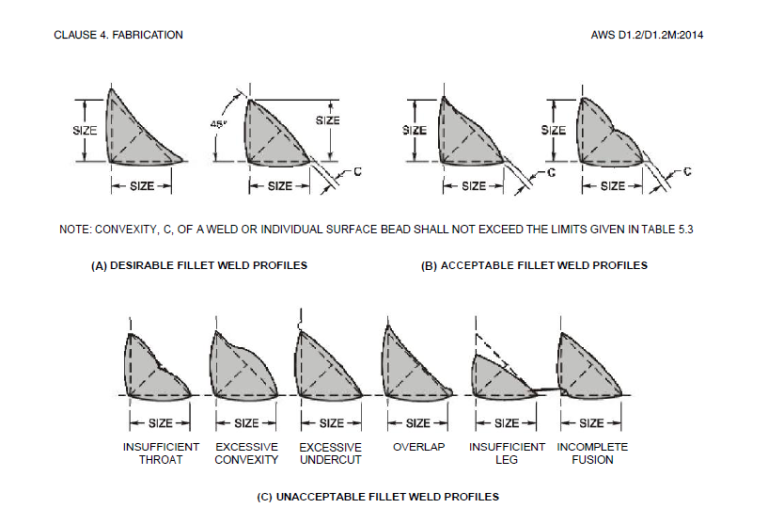

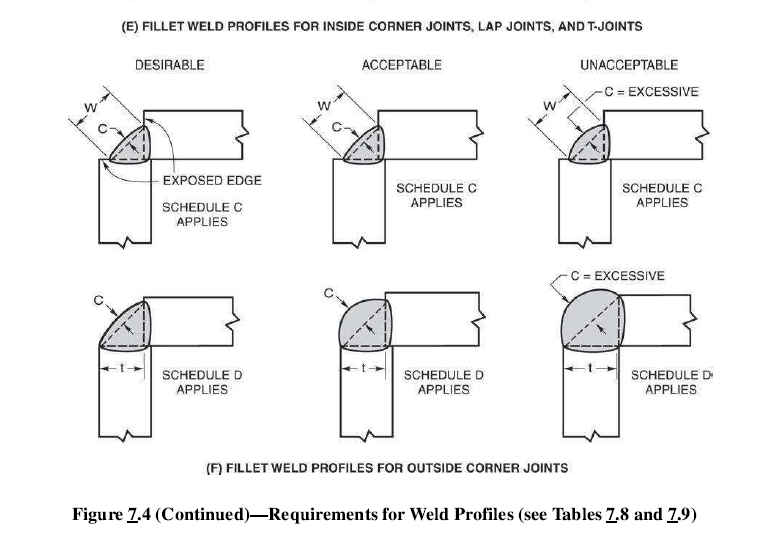

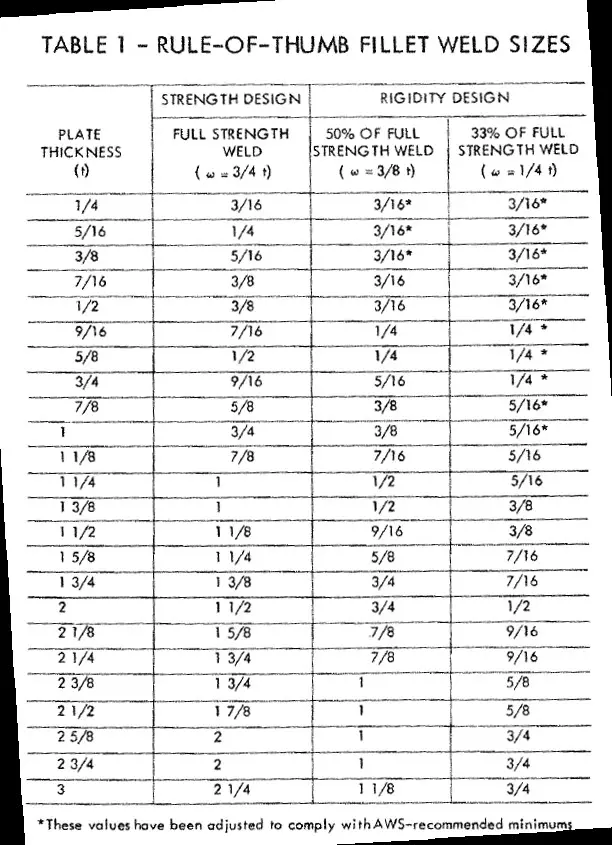

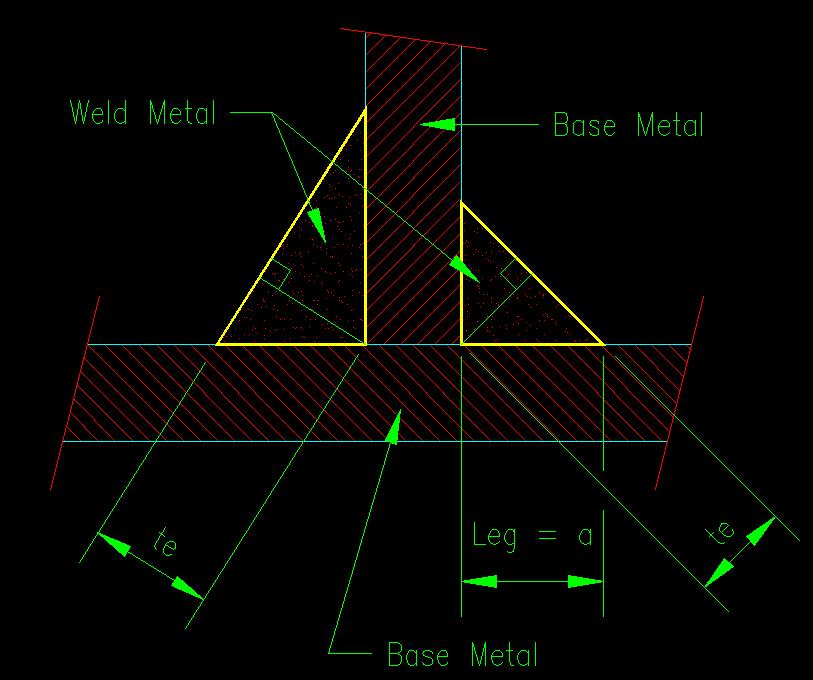

Weld Fillet Size Chart - You can use fillet weld size formula to calculate the fillet weld size. Web fillet weld is specified by a size known as either throat size (given as a) or leg length (given as z). Maximum size of fillet weld. What is the weld size tolerance? Web weld sizes should be determined based on structural requiremnts and specified. Web accurately determining the size of a fillet weld is crucial for ensuring the structural integrity and performance of welded components. Acceptance criteria clauses for weld profile in aws. A = nominal throat thickness. Welder qualification tests acceptance criteria. However, for heavier metal thicknesses, such as 5/16 inch and thicker, the minimum size fillet weld should be. You can use fillet weld size formula to calculate the fillet weld size. Web a fillet weld symbol can be used with an arrow side (below reference line) other side (above reference line) significance or on both sides (both sides of the reference line.) when a fillet weld is required on both sides of the reference line it is called. Over specified fillet welds or oversized fillet welds. What is the weld size tolerance? This blog here answers your questions about: If a print calls for a ¼” fillet weld and in production you make a 5/16” fillet weld, you are overwelding by 56%! Many fabricators can lower their welding costs significantly if they paid close attention to weld sizes. Web a simple calculator that converts between throat thickness and leg length. This blog here answers your questions about: S = deep penetration throat thickness. Many fabricators can lower their welding costs significantly if they paid close attention to weld sizes. Web the american welding society (aws) welding code specifies minimum fillet weld sizes for various thicknesses of base metal. A = nominal throat thickness. Welder qualification tests acceptance criteria. What does the minimum size of fillet weld depend on? Web fillet weld is specified by a size known as either throat size (given as a) or leg length (given as z). Common joint designs for fillet welds. Web drawings by specifying essential design information such as weld dimensions, quality level, etc. Web (1) the size of an equal leg fillet weld is the leg length of the largest inscribed right isosceles triangle. It assumes a symmetrical, mitre, fillet. Methods for the calculation of fillet weld sizes are explained here. Web rule of thumb for fillet weld sizes. The joint preparation and welding process(es) are then determined by the production unit in order to meet the specified requirements. The maximum size of the fillet weld will be= 0.7 x t, where ‘t’ is the base metal thickness. Maximum size of fillet weld. Methods for the calculation of fillet weld sizes are explained here. If a print calls for. S = deep penetration throat thickness. International standards do not generally provide requirements or guidance on minimum fillet weld sizes. Web a fillet weld symbol can be used with an arrow side (below reference line) other side (above reference line) significance or on both sides (both sides of the reference line.) when a fillet weld is required on both sides. If a print calls for a ¼” fillet weld and in production you make a 5/16” fillet weld, you are overwelding by 56%! Web aws design handbook for calculating fillet weld sizes. What is the required fillet weld size for structures ? Web rule of thumb for fillet weld sizes | welding answers. Maximum size of fillet weld. Web fillet weld is specified by a size known as either throat size (given as a) or leg length (given as z). This blog here answers your questions about: Web weld sizes should be determined based on structural requiremnts and specified. Web the aws defines a fillet weld as: This section will cover the process of calculating fillet weld sizes. Web the size of a fillet weld should be calculated by the designer of the welded structure, based on the nature and magnitude of applied loads, on the material and on the design basis. Web accurately determining the size of a fillet weld is crucial for ensuring the structural integrity and performance of welded components. Web (1) the size of. The maximum size of the fillet weld will be= 0.7 x t, where ‘t’ is the base metal thickness. Web as a rough estimate, a minimum gap of around 1/16 inch (1.6 mm) is common for many welding applications. Web the size of an unequal leg fillet weld is the shorter leg length of the largest right triangle that can be inscribed within the fillet weld cross section. This blog here answers your questions about: If a print calls for a ¼” fillet weld and in production you make a 5/16” fillet weld, you are overwelding by 56%! S = deep penetration throat thickness. Web aws design handbook for calculating fillet weld sizes. The american institute of steel construction specifies minimum fillet weld sizes based on the thickness of the material being welded. Web (1) the size of an equal leg fillet weld is the leg length of the largest inscribed right isosceles triangle. If so, please consider making any planned purchases through these links to or to support collie welding at no cost to yourself.) Web rule of thumb for fillet weld sizes | welding answers. International standards do not generally provide requirements or guidance on minimum fillet weld sizes. Web the american welding society (aws) welding code specifies minimum fillet weld sizes for various thicknesses of base metal. 2.4 fillet welds 2.4.1 effective throat Web weld sizes should be determined based on structural requiremnts and specified. Welder qualification tests acceptance criteria.

Fillet Weld Size Chart

How It Works How do you determine the adequate size of a fillet weld

Fillet Weld Size Chart

Fillet Weld Sizes as per AWS D1.1 & AWS D1.2

Minimum Size of Fillet Welds CISCICCA

Fillet Weld Sizes as per AWS D1.1 & AWS D1.2 AQC Inspection

Rule Of Thumb For determining the Fillet Weld Size

Fillet weld in lap joint IDEA StatiCa

Max size fillet weld in T joint. Welding, Bonding & Fastener

Effective Area & Size

Web A Fillet Weld Symbol Can Be Used With An Arrow Side (Below Reference Line) Other Side (Above Reference Line) Significance Or On Both Sides (Both Sides Of The Reference Line.) When A Fillet Weld Is Required On Both Sides Of The Reference Line It Is Called A Double Fillet Weld.

Common Joint Designs For Fillet Welds.

The Minimum Fillet Size Requirement.

What Is The Tolerance For Fillet Weld Sizes As Per Aws D1.1 ?

Related Post: