V Belt Tension Chart

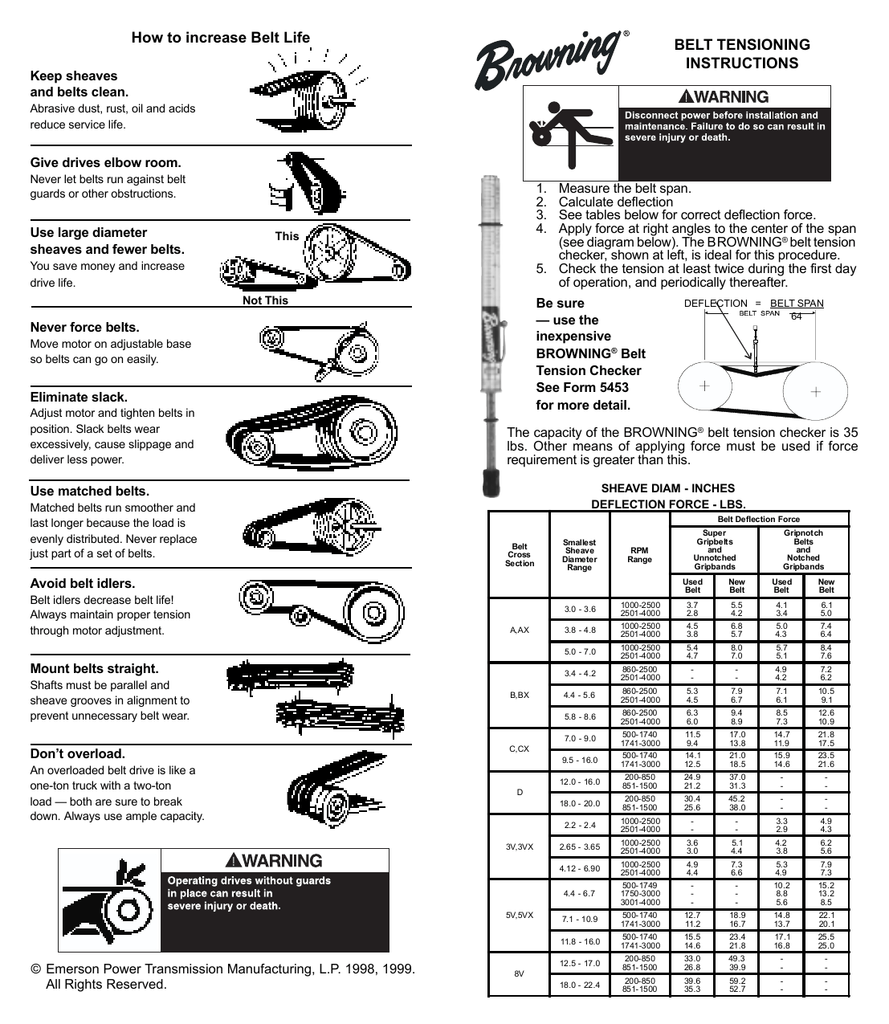

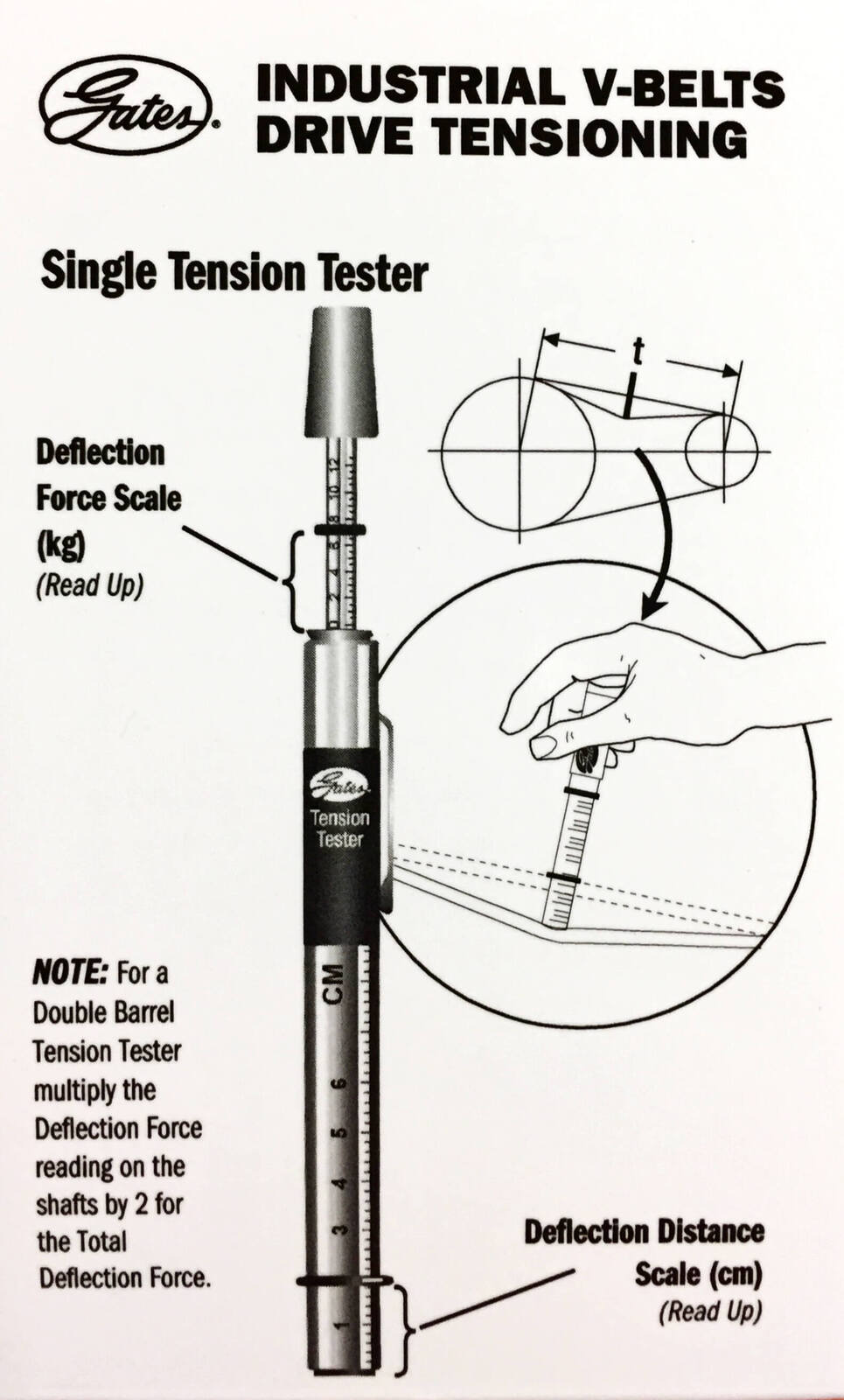

V Belt Tension Chart - Apply force at right angles to the center of the span (see diagram below). Web the updated version cap 6.0, with a new look, allows for quick and clear drive design and calculation. Web the amount of force required to deflect the belt should compare with the deflection forces noted in the chart below. Web table 1 gives general tensioning values for a particular belt cross section in relation to the pulley diameter. Tight side tension (pounds) t2 : Although they have been around for a long time, belts are still a very. All belts do not feel the same when properly tensioned. How you tension a belt at installation will determine how long the. Belt speed (feet per minute) t1 : Small sheave initial diameter range (inches) retensioning maximum minimum 12.1 12.0 15.6. Ideal tension is the lowest tension at which the belt will not slip under peak load. The browning® belt tension checker,. However, notice the differences in cord. See tables below for correct deflection force. Although they have been around for a long time, belts are still a very. How you tension a belt at installation will determine how long the. Calculate your gates powergrip belt drive tension to determine the proper center distance, tension force, deflection distance and more to. Belt speed (feet per minute) t1 : For the total design of power transmission belt, we recommend our application designing program for belts, it can be downloaded at:.. Ideal tension is the lowest tension at which the belt will not slip under peak load. Web table 1 gives general tensioning values for a particular belt cross section in relation to the pulley diameter. All belts do not feel the same when properly tensioned. Apply force at right angles to the center of the span (see diagram below). Tight. Calculate your gates powergrip belt drive tension to determine the proper center distance, tension force, deflection distance and more to. Tight side tension (pounds) t2. All belts do not feel the same when properly tensioned. See tables below for correct deflection force. Tight side tension (pounds) t2 : However, notice the differences in cord. Using a carlisle tensiometer (part no. When you install a new set of belts, use the gauge to establish correct. For the total design of power transmission belt, we recommend our application designing program for belts, it can be downloaded at:. Web the updated version cap 6.0, with a new look, allows for quick. Web the updated version cap 6.0, with a new look, allows for quick and clear drive design and calculation. All belts do not feel the same when properly tensioned. Web take a look at the accompanying chart (figure 1). Belt speed (feet per minute) t1 : Ideal tension is the lowest tension at which the belt will not slip under. Ideal tension is the lowest tension at which the belt will not slip under peak. Web table 1 gives general tensioning values for a particular belt cross section in relation to the pulley diameter. Ideal tension is the lowest tension at which the belt will not slip under peak load. See tables below for correct deflection force. How you tension. Using a carlisle tensiometer (part no. All belts do not feel the same when properly tensioned. Web table 1 gives general tensioning values for a particular belt cross section in relation to the pulley diameter. Different options for calculation are available to the user: Web the amount of force required to deflect the belt should compare with the deflection forces. However, notice the differences in cord. Web the updated version cap 6.0, with a new look, allows for quick and clear drive design and calculation. All belts do not feel the same when properly tensioned. Belt speed (feet per minute) t1 : Using a carlisle tensiometer (part no. Web the amount of force required to deflect the belt should compare with the deflection forces noted in the chart below. See tables below for correct deflection force. Tight side tension (pounds) t2 : Different options for calculation are available to the user: Small sheave initial diameter range (inches) retensioning maximum minimum 12.1 12.0 15.6. Calculate your gates powergrip belt drive tension to determine the proper center distance, tension force, deflection distance and more to. For the total design of power transmission belt, we recommend our application designing program for belts, it can be downloaded at:. However, notice the differences in cord. Ideal tension is the lowest tension at which the belt will not slip under peak load. All belts do not feel the same when properly tensioned. Using a carlisle tensiometer (part no. Small sheave initial diameter range (inches) retensioning maximum minimum 12.1 12.0 15.6. The browning® belt tension checker,. How you tension a belt at installation will determine how long the. Web take a look at the accompanying chart (figure 1). Web the updated version cap 6.0, with a new look, allows for quick and clear drive design and calculation. Web the amount of force required to deflect the belt should compare with the deflection forces noted in the chart below. Belt speed (feet per minute) t1 : See tables below for correct deflection force. Although they have been around for a long time, belts are still a very. When you install a new set of belts, use the gauge to establish correct.

Gates TENSIONCARD Pocket VBelt Tension Guide ubicaciondepersonas

V Belt Tension Chart Pdf

Fenner Wedge & VBelt Tensioning Instructions.pdf Belt (Mechanical

V Belt Tensioning Chart

Gates V Belt Tension Chart

Fenner V Belt Tension Chart

Browning Belt Tensioning InstructionsForm 8082

Reliable VBelt Drive Operation 20170602 Engineered Systems Magazine

Gates Pocket VBelt Tension Guide

Pdf V Belt Tension Chart chegos.pl

Tight Side Tension (Pounds) T2 :

Different Options For Calculation Are Available To The User:

Ideal Tension Is The Lowest Tension At Which The Belt Will Not Slip Under Peak.

Apply Force At Right Angles To The Center Of The Span (See Diagram Below).

Related Post: