Tungsten Stick Out Chart

Tungsten Stick Out Chart - Get yourself close quickly by allowing the entire tapered portion to stick out past the cup. Choosing the tungsten electrode type. Tips for perfect tig welding. My stick out was no more than probably an 1/8 it was pretty short. Web electrode extension can vary from flush to no more than the inside diameter of the cup. When to break the rules. Web generate new business through innovative, and specifically designed products provide solutions to increase productivity and create repeat sales upgrade current torch setups, hoses, consumables, and accessories. Web mainly on the material thickness and the amperage needed to achieve a proper weld. Each tig welding electrode has a specific color classification that makes them easy to identify. Place the tungsten into the collet. Place the tungsten into the collet. Web keep in mind that the tungsten shouldn’t stick out further than the inner width of the ceramic cup. Setting up and preparing the welder and accessories. For example, a #7 cup is 11mm wide, so the tungsten shouldn’t sit further out than 11mm from the top of the cup. Web *click chart to. Based on the composition of the electrode, welders will find specific applications and benefits that may work best for each electrode. This product is great for maintaining consistency during the tig welding process. You do not want to let it stick out too much, but you also don’t want it touching the weld. Air cooled torches range up to 180. For example, a #7 cup is 11mm wide, so the tungsten shouldn’t sit further out than 11mm from the top of the cup. Web portable enclosed tungsten grinder. We're using (i believe) 3/32 tungsten the gray stuff and a #7 cup. When to break the rules. Tig stick out and cup sizes relationship. That's why justin decided to eliminate the human. What gas for tig welding carbon steel. Each tig welding electrode has a specific color classification that makes them easy to identify. For example, a #7 cup is 11mm wide, so the tungsten shouldn’t sit further out than 11mm from the top of the cup. We're using (i believe) 3/32 tungsten the. Web defining key terms. The inside diameter of the cup should be at least 3 times the diameter of the electrode. Choosing the right color tungsten for tig welding. Choosing the right tungsten color for your tig torch. As a general rule, you can start the sickout 1 diameter of the tungsten, and adjust accordingly. Choosing the right color tungsten for tig welding. That's why justin decided to eliminate the human. Web for welding steel the tungsten should be ground to a long point with the taper length about 2 or 3 times the diameter of the tungsten. What i like to do is use the taper as my guide for how far the electrode. Get yourself close quickly by allowing the entire tapered portion to stick out past the cup. You do not want to let it stick out too much, but you also don’t want it touching the weld. Thicker materials will require more current and thus bigger tungsten. Each tig welding electrode has a specific color classification that makes them easy to. Choosing the right color tungsten for tig welding. Choosing the tungsten electrode type. Problems with incorrect stick out length. Setting up and preparing the welder and accessories. Choosing the right tungsten color for your tig torch. This product is great for maintaining consistency during the tig welding process. Changing the distance between your welding gun and the workpiece affects the amount of resistance in the welding circuit, and a change to the resistance also alters amperage in a constant voltage process like. Leave about 1/8 to 1/4 inch sticking out of the collet (not more than. The gas lens provides a much better gas coverage than a standard shielding setup. Web what is tungsten stick out? What gas for tig welding carbon steel. The picture below illustrates this. You do not want to let it stick out too much, but you also don’t want it touching the weld. Web *click chart to download printable pdf. Web the length of the tungsten stick out should generally be no wider than the inside diameter of the nozzle. Web weldpro has a great line of tig welders for sale, but if you don't know how to correctly insert and use a tungsten electrode, you can experience lots of contamination and other weld quality. The torch should be angled in the direction of travel, providing a good distribution of heat. This will help to direct the welding gases into the weld joint and provide good shielding coverage. Tig stick out and cup sizes relationship. The long taper and sharp tip improve arc stability. What i like to do is use the taper as my guide for how far the electrode sticks out past the cup. That's why justin decided to eliminate the human. I was having a very hard time seeing the weld pool today when i was tigging for the first time. Web what’s in a tungsten and what do they do? Web generate new business through innovative, and specifically designed products provide solutions to increase productivity and create repeat sales upgrade current torch setups, hoses, consumables, and accessories. Setting up and preparing the welder and accessories. Leave about 1/8 to 1/4 inch sticking out of the collet (not more than the diameter of the nozzle, which is also called the cup). Web what is tungsten stick out? This product is great for maintaining consistency during the tig welding process.

Quickies Intro to Tungsten and Prep FabricationLife

Choose The Perfect Tungsten TIG Welding With Canaweld

Identification Tungsten Color Chart sites.unimi.it

tig welding torch setting tungsten stick out length for fillet welds

Search Result Details Welding rods, Welding tips, Welding videos

TIG Welding Tungsten Electrode Selection Chart Midwest, 42 OFF

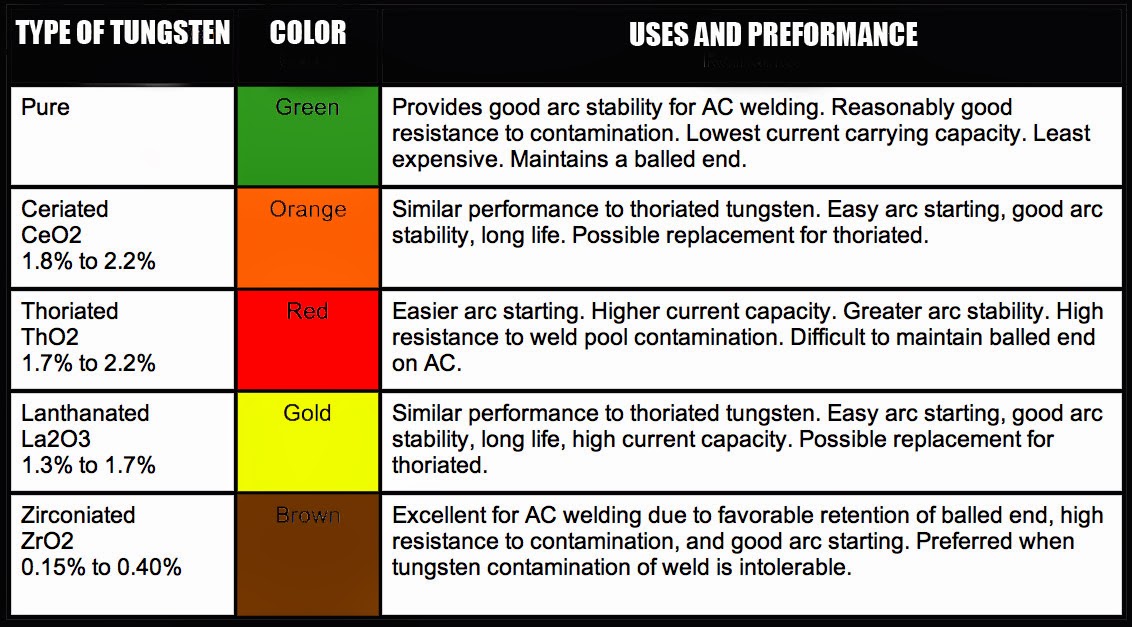

Tig Tungsten Color Chart

TIG Tungsten Electrodes Explained (with Color Chart)

TIG Tungsten Electrodes Explained (with Color Chart)

Global Tungsten Selection Chart sites.unimi.it

The Gas Lens Provides A Much Better Gas Coverage Than A Standard Shielding Setup.

The Perfect Tungsten Stick Out.

Based On The Composition Of The Electrode, Welders Will Find Specific Applications And Benefits That May Work Best For Each Electrode.

Setting Up And Preparing The Welder And Accessories.

Related Post: