Torque Spark Plugs Chart

Torque Spark Plugs Chart - If threads are lubricated, the torque value. When installing the spark plug, finger tighten until the gasket or tapered seat make contact with the cylinder head, then give it the recommended turn or angle. Web use a torque wrench to tighten spark plugs following manufacturer’s recommendations, or refer to the torque chart in the autolite spark plug catalog if you don’t have a torque wrench. However, it is possible to tighten the plugs satisfactorily without a torque wrench. Web ensure proper spark plug installation for optimal engine performance. Web refer to your vehicle’s owner’s manual or a torque specification chart, such as the one provided by champion auto parts, to determine the correct torque for your spark plugs. This short video gives a great insight into the importance of using the correct torque setting when replacing spark plugs. Clean threaded spark plug holes in cylinder heads. Denso always recommends using a torque wrench to achieve the correct installation torque setting. Learn about torque requirements and gap specifications. Web it’s best to check the torque specs of the spark plugs you use to determine how tight they should be. If threads are lubricated, the torque value. Improper torquing can lead to damage. Web installation torque is a measure of force acting on an object, which causes that object to rotate during installation. Web installing spark plugs without a. Web it is extremely important that the correct torque is applied when installing spark plugs. 23 ± 3nm (17 ± 2.2 ft/lb) Hand tighten the spark plug until it seats. Web it’s best to check the torque specs of the spark plugs you use to determine how tight they should be. Most are represented in the chart below. If threads are lubricated, the torque value. Most are represented in the chart below. Web recommended torque specifications all engine manufacturers have recommended torque specifications for spark plug installation. Web spark plugs should be torqued to manufacturers’ specifications. May cause airtight leakage or break of the mounting screws due to the the caulking of the insulator and housing become loosened. Hand tighten the spark plug until it seats. When installing a new spark plug, always follow the instructions listed in the engine manufacturer's literature. Web it is extremely important that the correct torque is applied when installing spark plugs. Web refer to your vehicle’s owner’s manual or a torque specification chart, such as the one provided by champion auto parts,. Web installing spark plugs without a torque wrench it is always best to use a torque wrench to install spark plugs. If threads are lubricated, the torque value. Use a torque wrench to tighten the spark plugs to the specified torque. Improper installation may cause poor performance, and even result in engine damage. As a result the metal shell will. However, it is possible to tighten the plugs satisfactorily without a torque wrench. Improper installation may cause poor performance, and even result in engine damage. These suggestions are for spark plugs with new gaskets.) spark plug thread / seat tightening procedure Any good for performance gains, or just a. Improper torquing can lead to damage. Web use a torque wrench to tighten spark plugs following manufacturer’s recommendations, or refer to the torque chart in the autolite spark plug catalog if you don’t have a torque wrench. Even though it is made by ngk the information can be used for any brand of spark plug. 31 ± 2nm (23 ± 1.5 ft/lb) motorsport engines: Denso always. If a torque wrench is not available, however, you may use this chart as a guide. These suggestions are for spark plugs with new gaskets.) spark plug thread / seat tightening procedure Web torque is one of the most critical aspects of spark plug installation. Web it is essential to tighten a spark plug to the specified turning angle or. First, screw in the plug finger tight until the gasket meets the cylinder head. Tighten new or reused gasket spark plugs as follows: This short video gives a great insight into the importance of using the correct torque setting when replacing spark plugs. Install the new plug finger tight, and complete the installation with a torque wrench. How does the. Hand tighten the spark plug until it seats. The installation torque values shown above apply to new spark plugs without lubricating the threads. Any good for performance gains, or just a. When installing a new spark plug, always follow the instructions listed in the engine manufacturer's literature. 23 ± 3nm (17 ± 2.2 ft/lb) Learn about torque requirements and gap specifications. *use rem37by when encountering lead fouling. Web use a torque wrench to tighten spark plugs following manufacturer’s recommendations, or refer to the torque chart in the autolite spark plug catalog if you don’t have a torque wrench. Spark plug thread = m12 x 1.25. Web the recommended torque specification for spark plugs is typically listed in the owner’s manual, or it can be obtained from the spark plug manufacturer. As a result the metal shell will deform. Spark plug thread = m14 x 1.25. If a torque wrench is not available, however, you may use this chart as a guide. Web installation torque is a measure of force acting on an object, which causes that object to rotate during installation. Web refer to your vehicle’s owner’s manual or a torque specification chart, such as the one provided by champion auto parts, to determine the correct torque for your spark plugs. This short video gives a great insight into the importance of using the correct torque setting when replacing spark plugs. The information provided below has been estimated for standard engines: The table on this page gives the recommended torque for proper spark plug installation. Torque directly affects the spark plugs' ability to transfer heat out of the combustion chamber. When installing the spark plug, finger tighten until the gasket or tapered seat make contact with the cylinder head, then give it the recommended turn or angle. Web without a doubt, the best method is to use a torque wrench to tighten the spark plugs to specification.

Torque Chart Tightening Torque Installation Instructions for E3 Spark

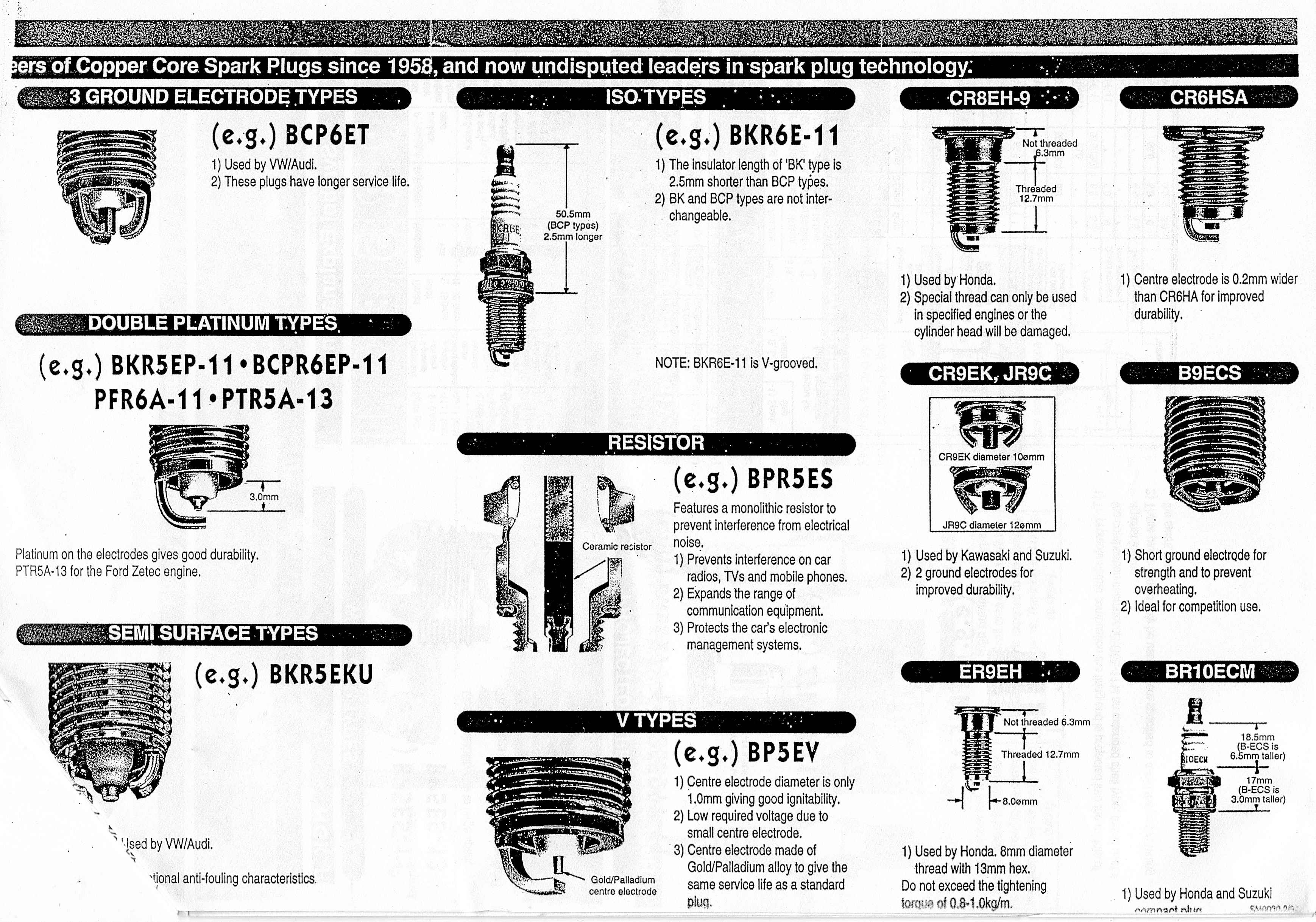

NGK PLUGS DATA SHEETS

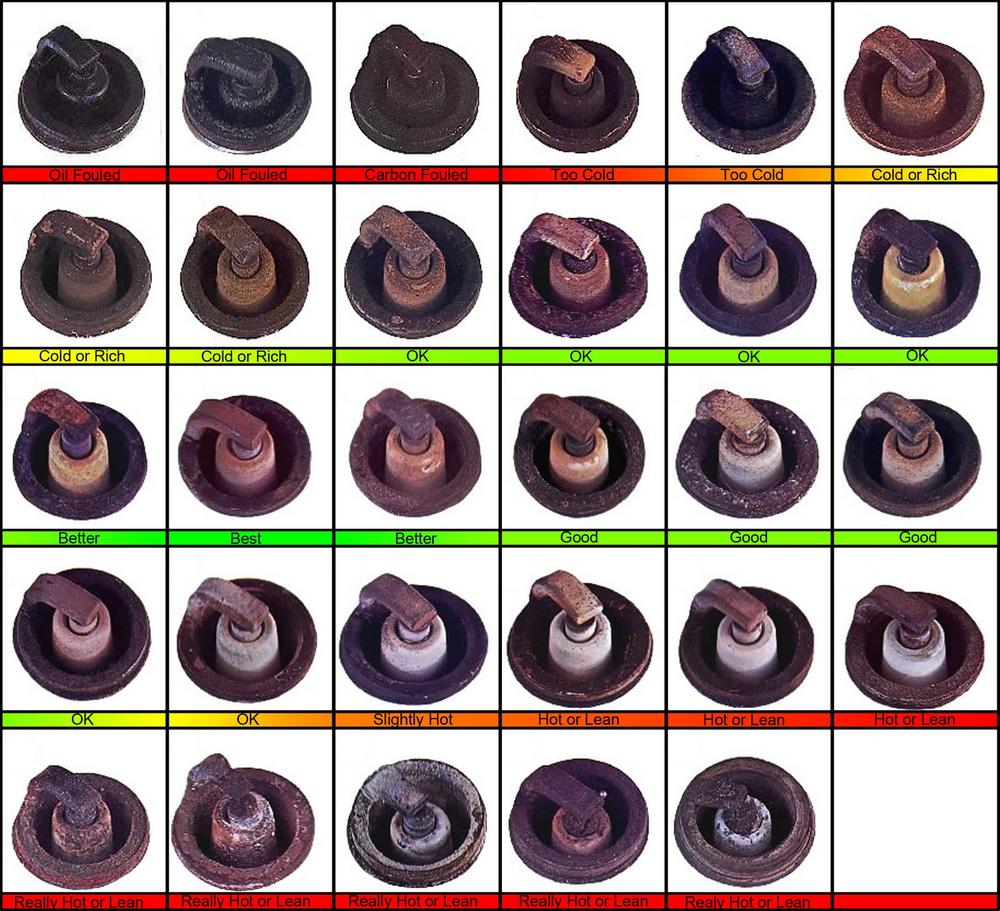

Lean Spark Plug Reading Chart

4DIYers Spark Plug Torque Chart

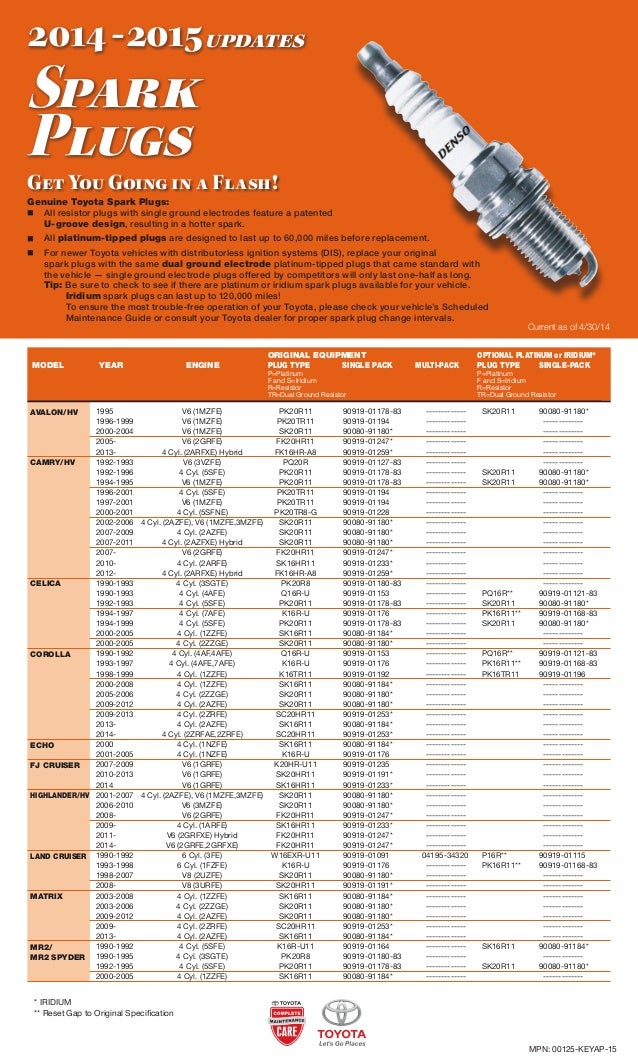

Toyota Spark Plugs Chart Haley Toyota Of Roanoke

![How Tight Should Spark Plugs Be? [Including Chart] Drill and Driver](https://www.drillanddriver.com/wp-content/uploads/2022/04/How-Tightly-Do-Spark-Plugs-Have-To-Be.jpg)

How Tight Should Spark Plugs Be? [Including Chart] Drill and Driver

Ngk Spark Plug Chart

How Tight Should Spark Plugs Be? (See Torque Chart) In The Garage

Ac Delco Spark Plug Torque Chart

Spark Plug Gap Chart The Ultimate Guide Dona

We Strongly Recommend Using The Manual.

Clean Threaded Spark Plug Holes In Cylinder Heads.

Web It Is Essential To Tighten A Spark Plug To The Specified Turning Angle Or Torque Setting.

Applying The Right Torque When Fitting Spark Plugs Is Critical To Ensuring A Secure Fastening;

Related Post: