Tig Welding Wire Chart

Tig Welding Wire Chart - It caters to different material types and thicknesses for effective welding. Web see the chart below for recommended flow rates. The chart usually includes the current. Web what is a tig welding chart. Web learn about different types of tig welding filler rods, their properties and applications. Gas flow rates for tig welding. Web it gives a detailed description of which wire speed and voltage you’ll need for a range of metal types, wire sizes and parent metal thicknesses. Web once you’ve chosen your welding rod diameter, use the stick welding rod chart at the top of the page to find the amperage range for that specific electrode. How to choose the right tig welder. Web learn how to select the right tig welding filler rod size and composition with helpful guidelines and charts. Web it gives a detailed description of which wire speed and voltage you’ll need for a range of metal types, wire sizes and parent metal thicknesses. The amperage required when tig welding is highly affected by the type of metal you are working with and how thick. Web learn how to select the right tig welding filler rod size and. For smaw process, weaving shall be 3 times core dia. The basics of tig welding. Web view technical guides for guidance on welding various metals and selecting the right hobart brothers filler metal solution for your application. Web tig welding chart based on material and shielding gas. The type of current used will have a great effect on the penetration. For smaw process, weaving shall be 3 times core dia. Web see the chart below for recommended flow rates. Web tig welding chart based on material and shielding gas. Web view technical guides for guidance on welding various metals and selecting the right hobart brothers filler metal solution for your application. Stainless is less thermally conductive than mild steel, so. The basics of tig welding. The chart usually includes the current. Web tig welding chart based on material and shielding gas. Web tig welding allows the welder more control. Web learn how to choose the right tig filler rod for different metals and use cases. The amps required to weld stainless are about. Web in this beginner's guide, we'll cover: In making a mig wire purchase, your last decision involves the quantity of wire and how it’s housed. Web what is a tig welding chart. Web a look at each type and its uses will help the operator select the best current type for the. The type of current used will have a great effect on the penetration pattern as well. It caters to different material types and thicknesses for effective welding. Web we offer a variety of helpful welding charts and guides that you can reference online, or download as a pdf to print, distribute, or post for your welding team. Learn from ron. Web tig welding chart based on material and shielding gas. Web view technical guides for guidance on welding various metals and selecting the right hobart brothers filler metal solution for your application. Web in this beginner's guide, we'll cover: It also includes the gas flow rate. The basics of tig welding. Web view technical guides for guidance on welding various metals and selecting the right hobart brothers filler metal solution for your application. Web once you’ve chosen your welding rod diameter, use the stick welding rod chart at the top of the page to find the amperage range for that specific electrode. In making a mig wire purchase, your last decision. In making a mig wire purchase, your last decision involves the quantity of wire and how it’s housed. Web a tig welding settings chart provides essential parameters like amperage, voltage, and gas flow. Stainless is less thermally conductive than mild steel, so heat does not flow away from the weld quite so quickly. Web learn how to select the right. Web in this beginner's guide, we'll cover: The amps required to weld stainless are about. Web a tig welding settings chart provides essential parameters like amperage, voltage, and gas flow. Web learn how to tig weld with articles, videos, webinars and more. Stainless is less thermally conductive than mild steel, so heat does not flow away from the weld quite. Stainless is less thermally conductive than mild steel, so heat does not flow away from the weld quite so quickly. Web it gives a detailed description of which wire speed and voltage you’ll need for a range of metal types, wire sizes and parent metal thicknesses. Learn the key factors to consider, such as base metal compatibility,. It caters to different material types and thicknesses for effective welding. Web view technical guides for guidance on welding various metals and selecting the right hobart brothers filler metal solution for your application. How to choose the right tig welder. Browse suggested weld parameter settings for tig welding. How to choose the right mig wire for a good weld strength. Web once you’ve chosen your welding rod diameter, use the stick welding rod chart at the top of the page to find the amperage range for that specific electrode. The amps required to weld stainless are about. Web tig welding allows the welder more control. Learn from ron covell about the different tungsten electrodes available for a variety of welding applications. Use dcen (dc electrode negative is also referred to as straight polarity. Web learn how to choose the right tig filler rod for different metals and use cases. Find tips, tricks and calculators for welding different metals, equipment and techniques. It also includes the gas flow rate.

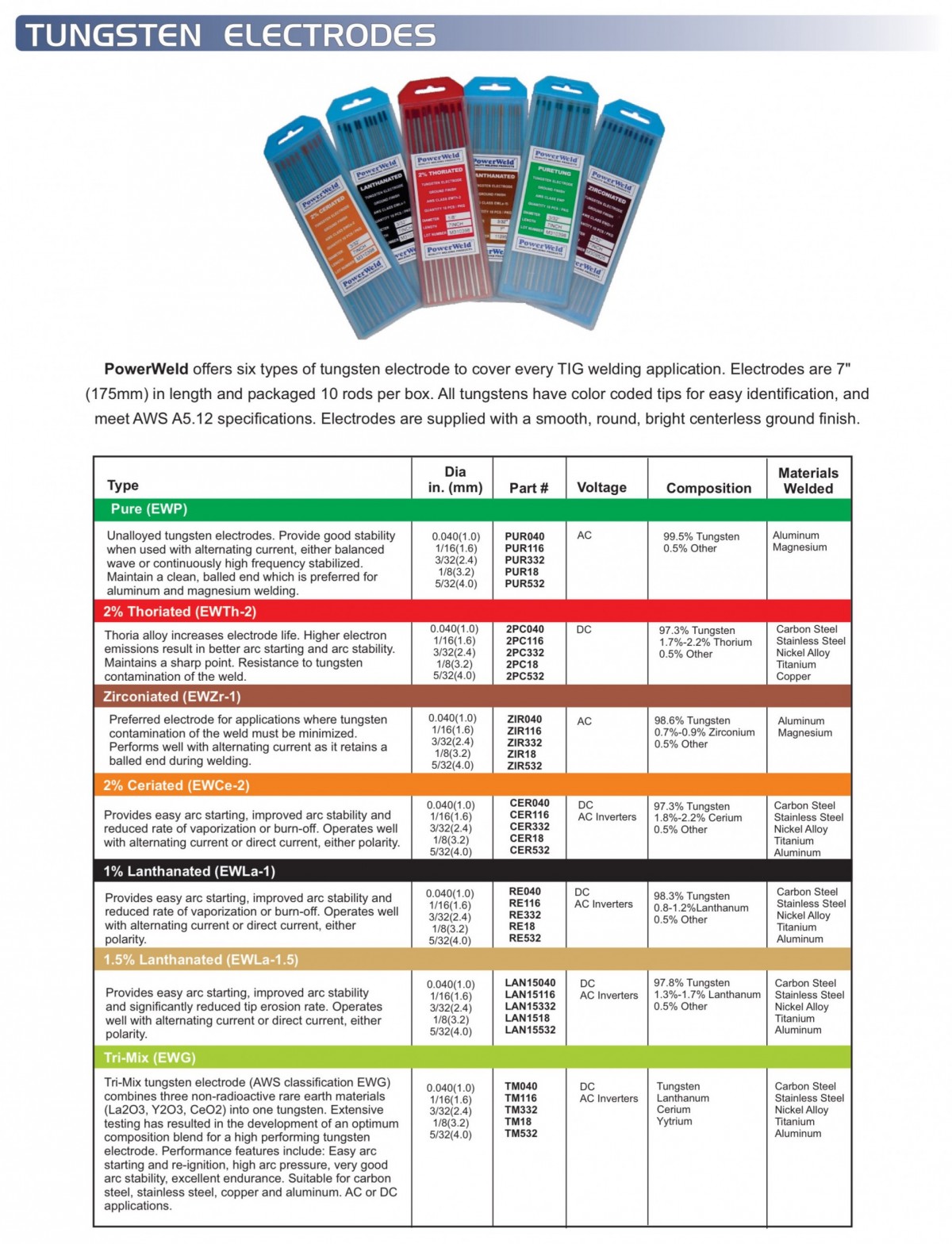

Tig Welding Tungsten Chart

TIG Welding Charts ILMO Products Company

Tig Welding Filler Rod Selection Chart Reviews Of Chart

TIG Welding Charts ILMO Products Company

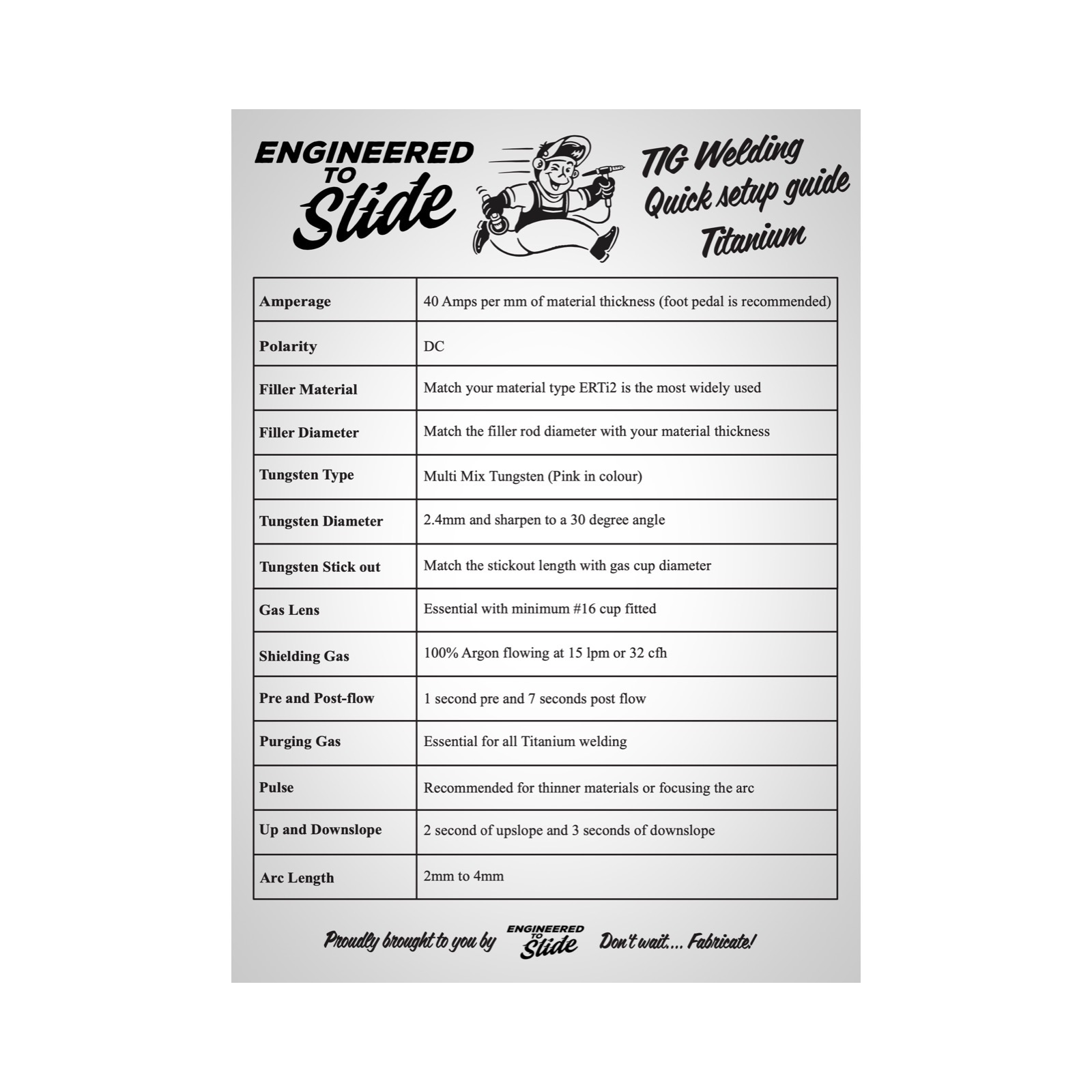

TIG Welding Charts Engineered to Slide

TIG Tungsten Electrodes Explained (with Color Chart)

Tig Welding Settings Chart Pdf

Tig Welding Rods Chart

Tig parameters chart MIG Welding Forum

tig parts breakdown chart Welding Supply

The Type Of Current Used Will Have A Great Effect On The Penetration Pattern As Well.

Web In This Beginner's Guide, We'll Cover:

For Smaw Process, Weaving Shall Be 3 Times Core Dia.

Filler Metal Can Be Either Wire Or Rod And Should Be Compatible With The Base.

Related Post: