Tig Welding Tungsten Chart

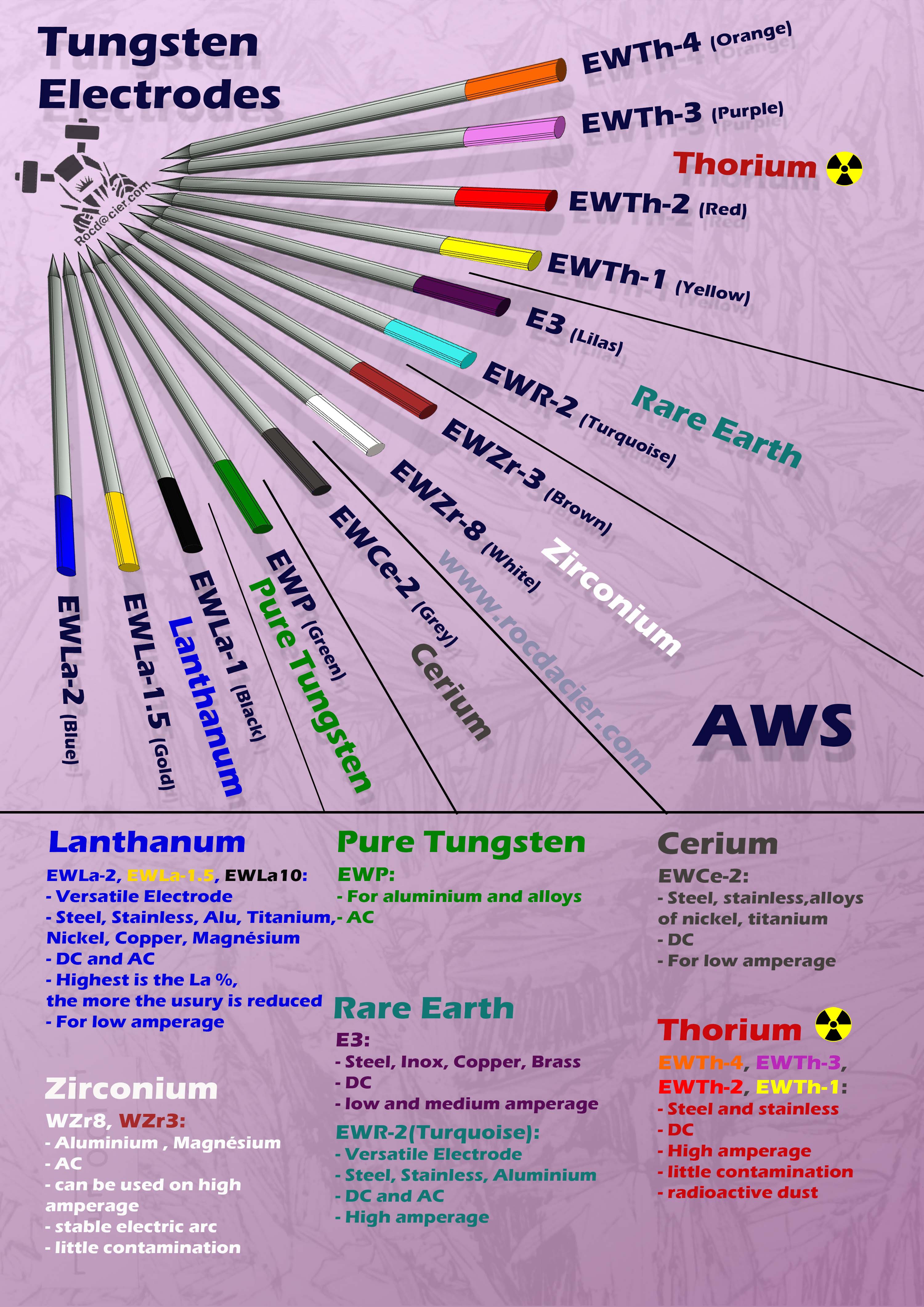

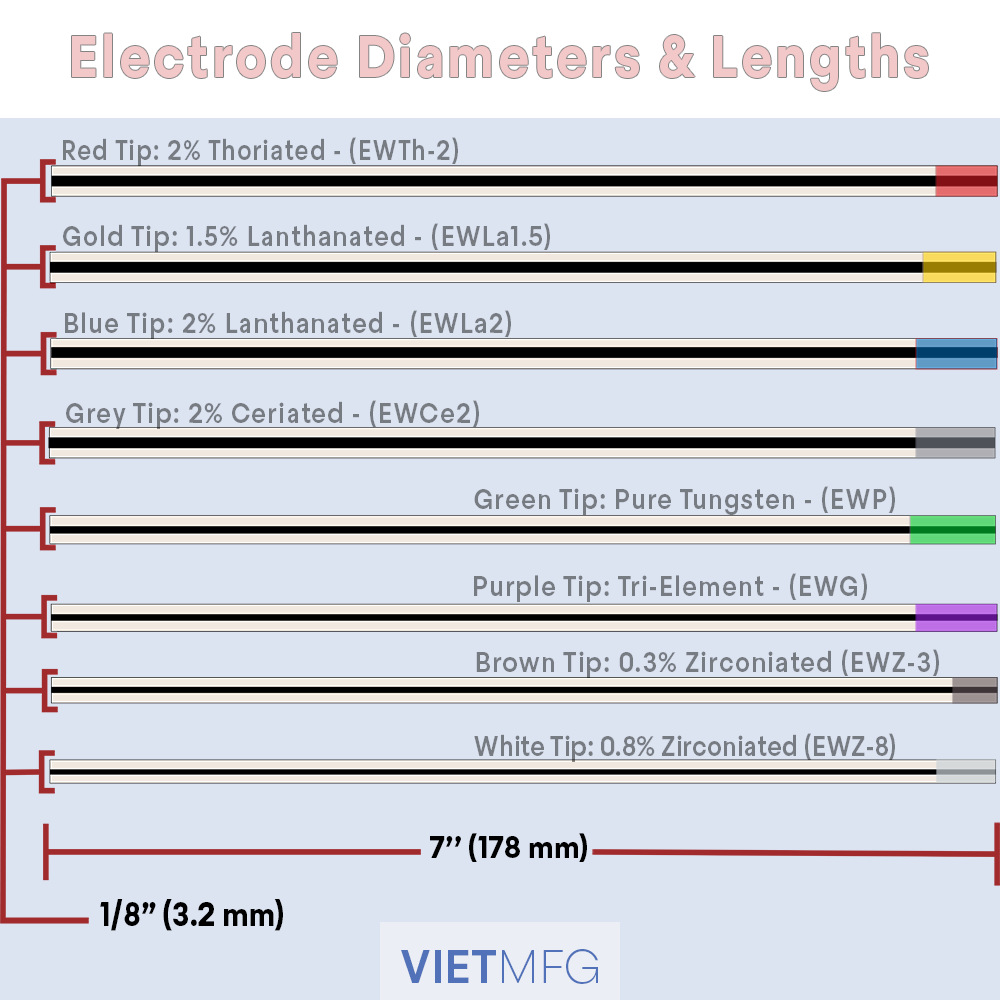

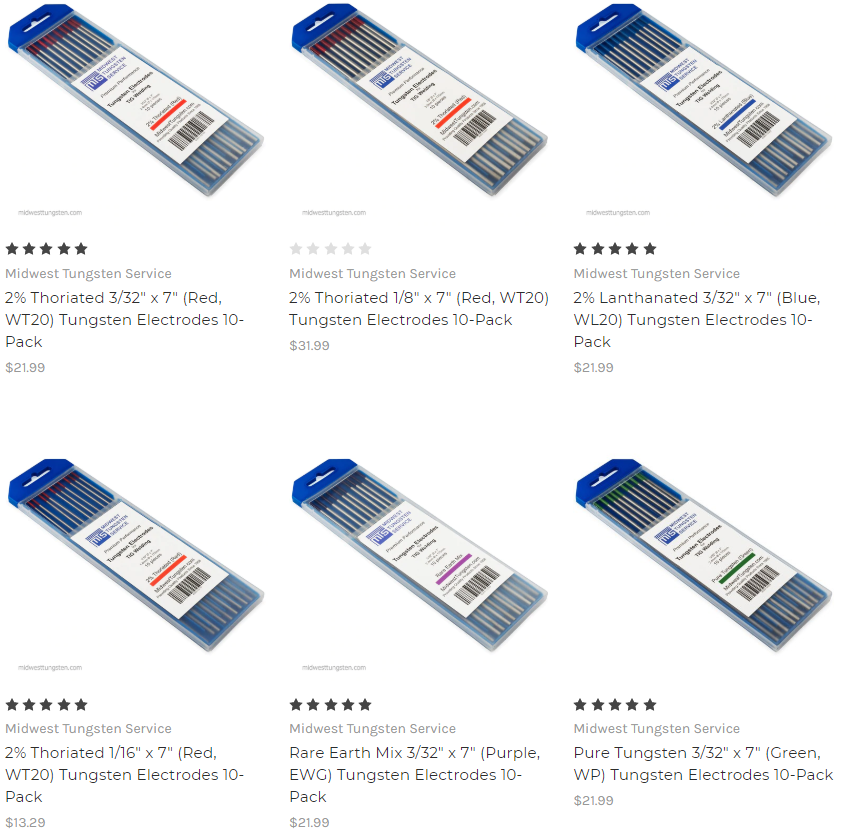

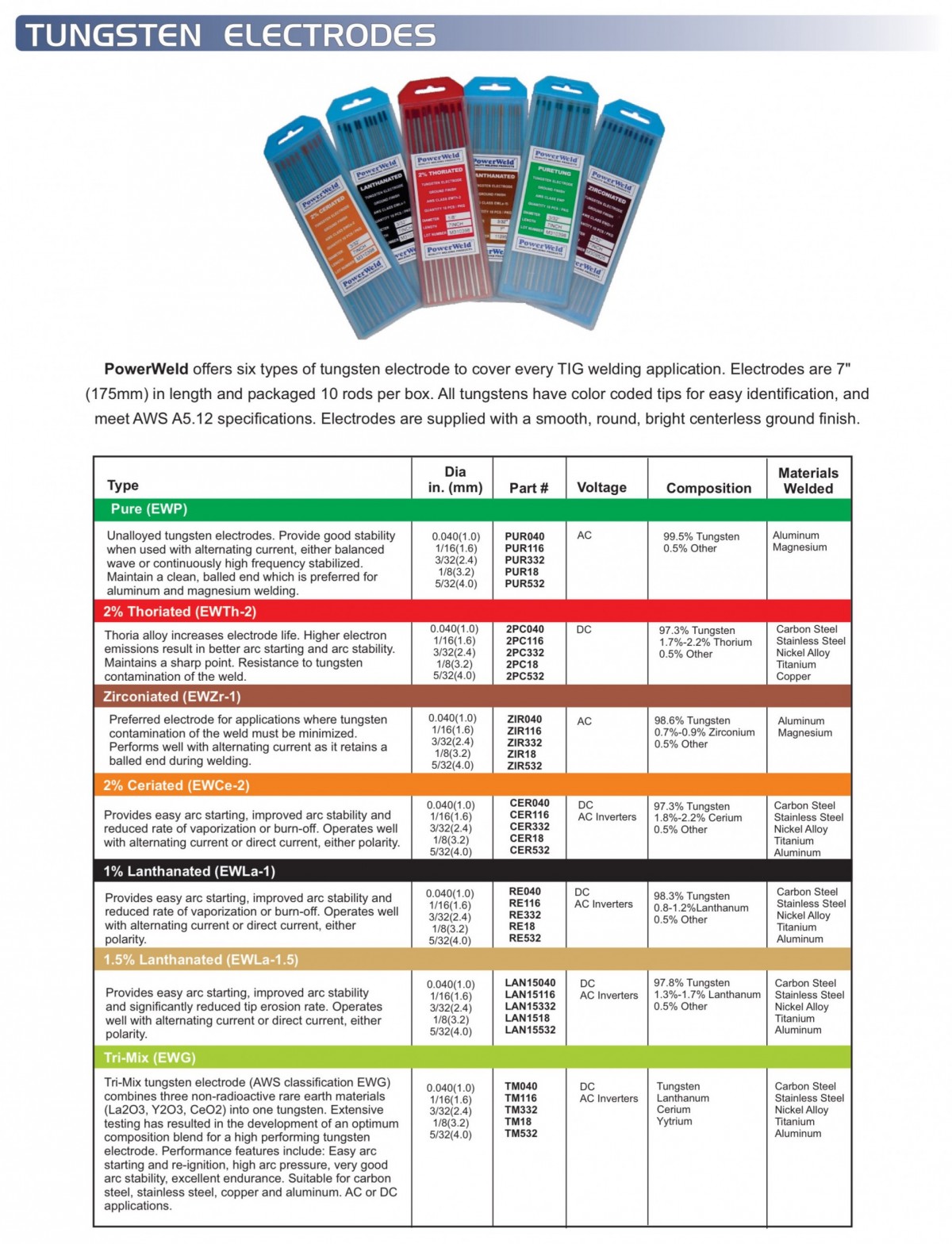

Tig Welding Tungsten Chart - Pure tungsten electrodes provide good stability when welding with alternating (“ac”) but may be used with direct current (“dc”) and argon or helium. Tig welding electrodes usually contain small quantities of metallic oxides which can offer increase arc stability, facilitate arc starting, increase electrode l Tungsten diameter (mm) material thickness (mm) amperage (amps) 1.6. Web in this article, we will explore the world of tig tungsten electrodes, their types, and usage, with the help of a color chart for easy reference. As we progress through this guide of tig welding electrodes, it’s important to know that there are several tig welding tungsten options that have the ability to weld a wide range of amperage with both dc and ac for aluminum. Selecting the right tungsten electrode is an essential part of tig welding. The current polarity, power source, thickness of the material, and metal type play a role in tungsten selection. Compare the types, usages, and benefits of different electrodes for various metals and applications. See the chart below for current ranges of all sizes. Based on the composition of the electrode, welders will find specific applications and benefits that may work best for each electrode. Ceriated or lanthanated tungsten for ac tig? Web 7 premium electrode varieties. Web the proper electrode selection depends on many variables, including the type of weld, the composition of the material being welded, and the amperage level, among other factors. Good arc stability for ac. Web how to choose the best tungsten for ac tig welding. Web electrode diameter affects welding performance and weld bead shape. The table below is the recommended tig tungsten size for welding material of a wide range of thicknesses. Web mechanized tig welding mechanized tig welding encompasses a wide spectrum of applications such as precision bellows welding using.040 diameter tungsten electrode at 1.0 ampere up to high speed tube mills welding. Web what are the main types of tungstens used for welding? Characteristics of current types for tig welding. Adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. Web electrode diameter affects welding performance and weld bead shape. Many of our customers are often looking for a good reference for which electrode type to choose. Web the proper electrode selection depends on many variables, including the type of weld, the composition of the material being welded, and the amperage level, among other factors. Selecting the right tungsten electrode is an essential part of tig welding. Choosing the right color tungsten for tig welding. Dc straight polarity dc reverse polarity ac high frequency selecting correct torch. Web in this article, we will explore the world of tig tungsten electrodes, their types, and usage, with the help of a color chart for easy reference. Many of our customers are often looking for a good reference for which electrode type to choose while welding different metals. Based on the composition of the electrode, welders will find specific applications. Thoriated 1.7 to 2.2% lanthanated 1.3 to 1.7% zirconiated.15 to.40% color code. Print this selection chart and keep it in your work area as a useful reference when selecting the tungsten material for your next project. Web electrode diameter affects welding performance and weld bead shape. Web the size of the tungsten electrode must, thus, be based on the choice. Here is a brief roundup: Maximizing the benefits of inverter technology in ac tig welding depends on many factors. We break down the different tungsten colors and explain when you should use each one. Click the chart to get the full size. Web *click chart to download printable pdf. Ceriated or lanthanated tungsten for ac tig? Selecting the right tungsten electrode is an essential part of tig welding. Web *click chart to download printable pdf. This electric arc generates intense heat, which, in turn, melts the base metal, creating a weld pool. Click the chart to get the full size. The current polarity, power source, thickness of the material, and metal type play a role in tungsten selection. A precise yet consistent electrode will have a Web mechanized tig welding mechanized tig welding encompasses a wide spectrum of applications such as precision bellows welding using.040 diameter tungsten electrode at 1.0 ampere up to high speed tube mills welding with a.250. Web the color chart below summarizes the various tig tungsten electrodes you may come across: Web for beginners it’s recommended to stick with a 3/32” diameter tungsten. Tig welding electrodes usually contain small quantities of metallic oxides which can offer increase arc stability, facilitate arc starting, increase electrode l Selecting the right tungsten electrode is an essential part of tig. Thoriated 1.7 to 2.2% lanthanated 1.3 to 1.7% zirconiated.15 to.40% color code. Web this information applies only to the selection and preparation of electrodes for gas tungsten arc welding (gtaw), also known as tungsten inert gas (tig) welding and plasma arc welding (paw). We need a lot less flow in tig welding. As we progress through this guide of tig welding electrodes, it’s important to know that there are several tig welding tungsten options that have the ability to weld a wide range of amperage with both dc and ac for aluminum. Web in this article, we will explore the world of tig tungsten electrodes, their types, and usage, with the help of a color chart for easy reference. Tungsten diameter and cup size. Nearly sixty years of experience have gone into producing these premium quality tig welding tungsten electrodes, and you benefit from that experience. Web electrode diameter affects welding performance and weld bead shape. A precise yet consistent electrode will have a Many of our customers are often looking for a good reference for which electrode type to choose while welding different metals. Here is a brief roundup: Compare the types, usages, and benefits of different electrodes for various metals and applications. Print this selection chart and keep it in your work area as a useful reference when selecting the tungsten material for your next project. Tig welding electrodes usually contain small quantities of metallic oxides which can offer increase arc stability, facilitate arc starting, increase electrode l Luckily, each tungsten stick has a color code applied to one end, which identifies the material type of the tungsten. However, the following chart may serve as a general guide.

Tig Tungsten Color Chart

Tig Tungsten Electrode Chart

Tungsten Electrode Selection Chart

TIG Welding Tungsten Electrode Selection Chart Midwest Tungsten Service

Choose The Perfect Tungsten TIG Welding With Canaweld

The different types of electrodes used in orbital TIG welding

Tig Welding Tungsten Chart

Tig Tungsten Chart Labb by AG

TIG Tungsten Electrodes Explained (with Color Chart)

![Tips For Selecting Tungsten Electrodes [TIG Welding]](https://weldingpros.net/wp-content/uploads/2020/04/tungsten-electrodes.jpg)

Tips For Selecting Tungsten Electrodes [TIG Welding]

Web Thoriated 2% (Red Tipped) Ceriated 2% (Grey Tipped) Lanthanated 1.5% (Gold Tipped) Zirconiated 0.8% (White Tipped) Rare Earth (Purple Tipped) Tungsten Guide.

See The Chart Below For Current Ranges Of All Sizes.

Web Tig Electrodes Color Chart.

The Table Below Is The Recommended Tig Tungsten Size For Welding Material Of A Wide Range Of Thicknesses.

Related Post: