Tig Weld Chart

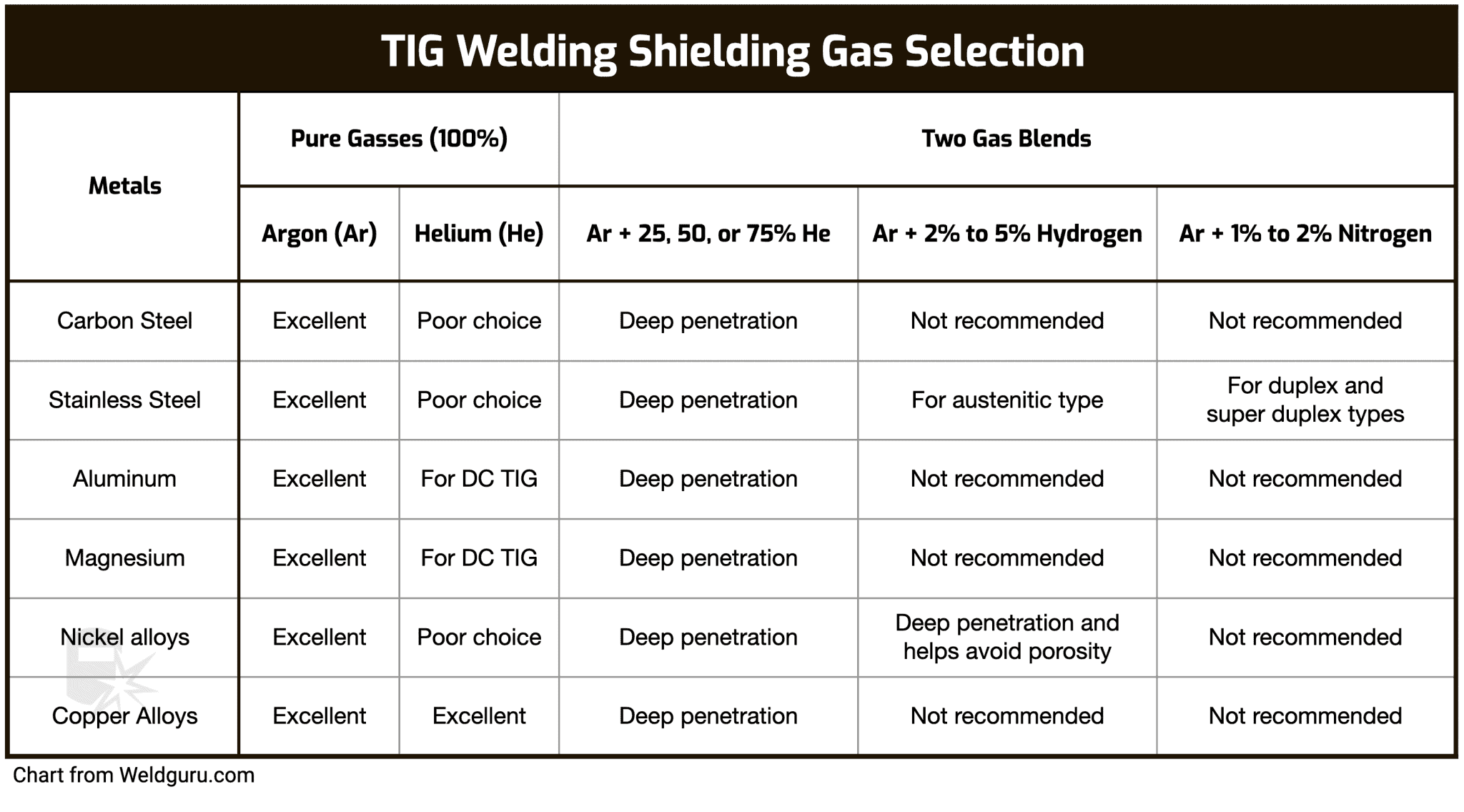

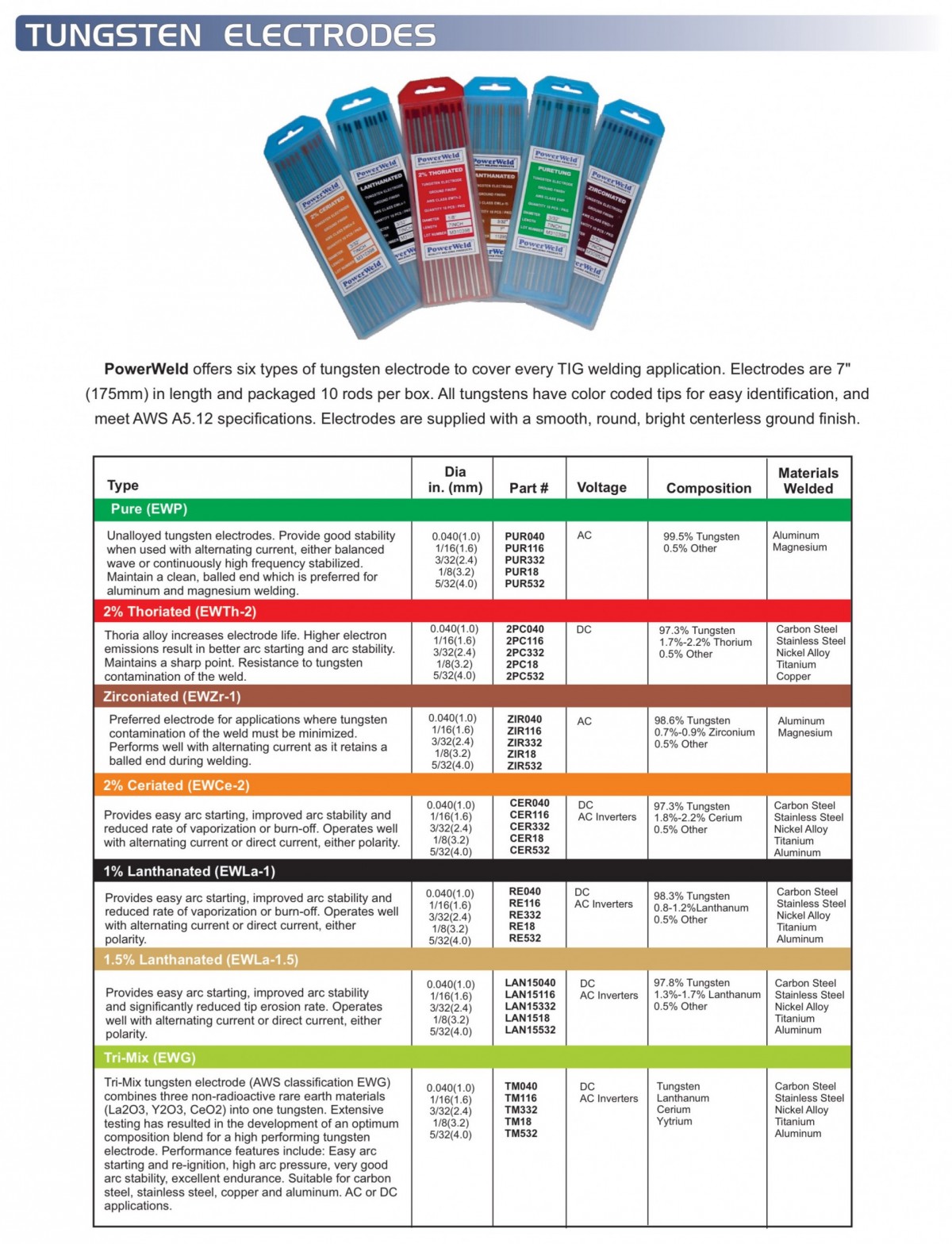

Tig Weld Chart - Web follow requirements in osha 1910.252 (a) (2) (iv) and nfpa 51b for hot work and have a fire watcher and extinguisher nearby. Web the use of tig welding for aluminum has many advantages for both manual and automatic processes. Tungsten inert gas (tig) welding is the process in which an arc is formed between a tungsten electrode and the workpiece to join the metals together. Web what metal are you welding? Read and understand the safety data sheets (sdss) and the manufacturer’s instructions for adhesives, coatings, cleaners, consumables, coolants, degreasers, fluxes, and metals. Web tig welding filler rod chart. And even two dissimilar metals. The amperage required when tig welding is highly affected by the type of metal you are working with and how thick that metal is. Gas flow rates for tig welding. Tig welding, or tungsten inert gas welding, demands precision and control over various settings for optimal results. Web a tig welding settings chart provides essential parameters like amperage, voltage, and gas flow. Read and understand the safety data sheets (sdss) and the manufacturer’s instructions for adhesives, coatings, cleaners, consumables, coolants, degreasers, fluxes, and metals. Tig welding, or tungsten inert gas welding, demands precision and control over various settings for optimal results. Web the use of tig welding. Pure tungsten electrodes provide good stability when welding with alternating (“ac”) but may be used with direct current (“dc”) and argon or. Web see the chart below for recommended flow rates. Tig welding is a complex and precise process that requires the right tools and techniques to be used correctly. Filler metal must be dry, free of oxides, grease, or. Web the color chart below summarizes the various tig tungsten electrodes you may come across: Web what metal are you welding? / all about tungsten in tig welding: Web follow requirements in osha 1910.252 (a) (2) (iv) and nfpa 51b for hot work and have a fire watcher and extinguisher nearby. If you’re new to tig welding, the process of. Tig welding, or tungsten inert gas welding, demands precision and control over various settings for optimal results. If you’re new to tig welding, the process of selecting the correct settings can be overwhelming. Web a tig welding settings chart provides essential parameters like amperage, voltage, and gas flow. The three main types of metals typically worked on with a tig. Browse suggested weld parameter settings for tig welding. Tig welding, or tungsten inert gas welding, demands precision and control over various settings for optimal results. Web view technical guides for guidance on welding various metals and selecting the right hobart brothers filler metal solution for your application. Web a tig welding chart visually represents the welding parameters needed to achieve. Web the color chart below summarizes the various tig tungsten electrodes you may come across: Whether you’re working on steel, aluminum, or stainless steel, this tool provides you with tailored recommendations for electrode size, type, and amperage, ensuring that your welds meet the highest standards. Ron covell explains the different tig tungsten options, the tungsten color code and how to. Print this selection chart and keep it in your work area as a useful reference when selecting the tungsten material for your next project. Web once you’ve chosen your welding rod diameter, use the stick welding rod chart at the top of the page to find the amperage range for that specific electrode. The three main types of metals typically. Use ac (alternating current) when welding aluminum and magnesium. It caters to different material types and thicknesses for effective welding. Web view technical guides for guidance on welding various metals and selecting the right hobart brothers filler metal solution for your application. Print this selection chart and keep it in your work area as a useful reference when selecting the. Click the chart to get the full size. Tig welding is a complex and precise process that requires the right tools and techniques to be used correctly. For mild steel, it recommends running 10% lower amps for complete beginners. Pure tungsten electrodes provide good stability when welding with alternating (“ac”) but may be used with direct current (“dc”) and argon. Web the document provides a tig welding amp calculator chart for mild steel and stainless steel in thicknesses ranging from 0.8mm to 3mm. The amperage that you choose from the range will come down to a few different factors, but you should use a high amperage on thicker metal and low amperage on thinner metal. Web a tig welding chart. Whether you’re working on steel, aluminum, or stainless steel, this tool provides you with tailored recommendations for electrode size, type, and amperage, ensuring that your welds meet the highest standards. Web empower your tig welding projects with our free online tig welding calculator. Tungsten electrode current ranges 8. The chart usually includes the current range, polarity, filler metal type, shielding gas type, and tungsten electrode size. The amperage required when tig welding is highly affected by the type of metal you are working with and how thick that metal is. Web a tig welding settings chart provides essential parameters like amperage, voltage, and gas flow. It notes that the chart provides starting point amps that may need adjusting based on technique and travel speed. Web tig welding filler rod chart. Filler metal must be dry, free of oxides, grease, or other foreign matter. Read and understand the safety data sheets (sdss) and the manufacturer’s instructions for adhesives, coatings, cleaners, consumables, coolants, degreasers, fluxes, and metals. Pure tungsten electrodes provide good stability when welding with alternating (“ac”) but may be used with direct current (“dc”) and argon or. Web tig welding tungsten electrode selection chart. Web tig welding chart based on material and shielding gas. Web tig welding amp charts. The amperage that you choose from the range will come down to a few different factors, but you should use a high amperage on thicker metal and low amperage on thinner metal. Web the use of tig welding for aluminum has many advantages for both manual and automatic processes.

What Gas Should You Use for TIG Welding? (with Chart)

Tig Welding Rods Chart

TIG Welding Charts ILMO Products Company

MIG vs TIG vs Stick Welding UNIMIG Welding Guides & Tutorials

The 25+ best Tig welding process ideas on Pinterest Mig welding

TIG Tungsten Electrodes Explained (with Color Chart)

TIG Welding Charts ILMO Products Company

Aluminum Tig Welding Settings Chart

Tig Welding Settings Chart Pdf

Tig Welding Tungsten Chart

It Caters To Different Material Types And Thicknesses For Effective Welding.

Web See The Chart Below For Recommended Flow Rates.

Print This Selection Chart And Keep It In Your Work Area As A Useful Reference When Selecting The Tungsten Material For Your Next Project.

Tig Welding Can Be Used To Weld Aluminium, Copper, Titanium Etc.

Related Post: