Tig Weld Amperage Chart

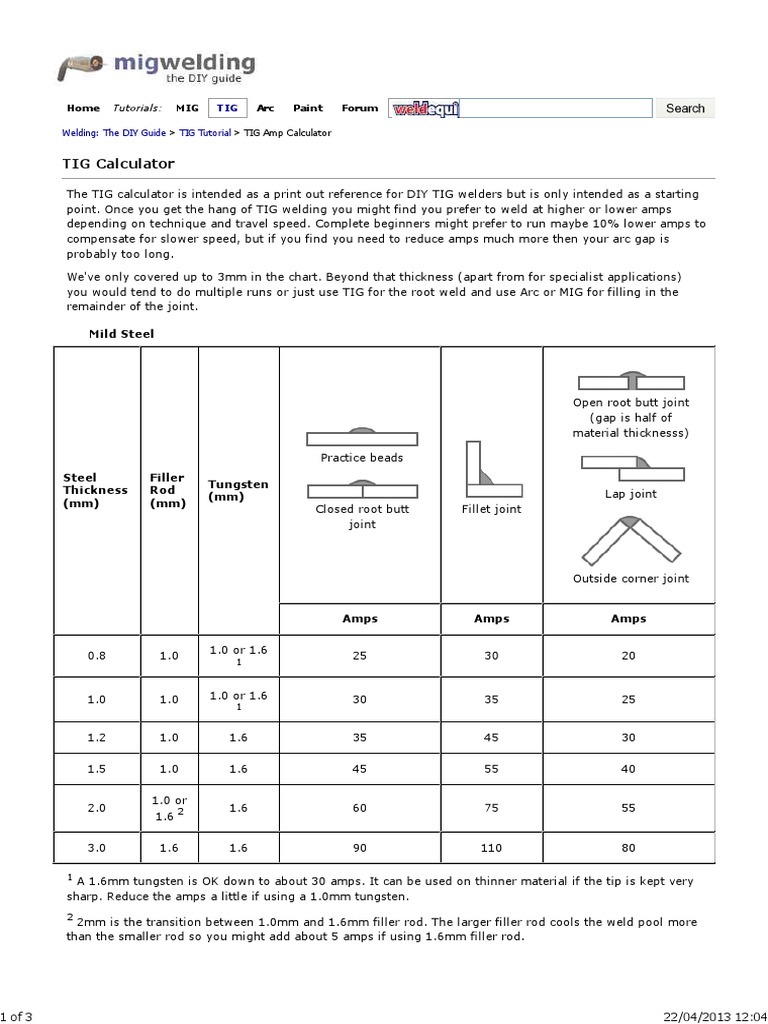

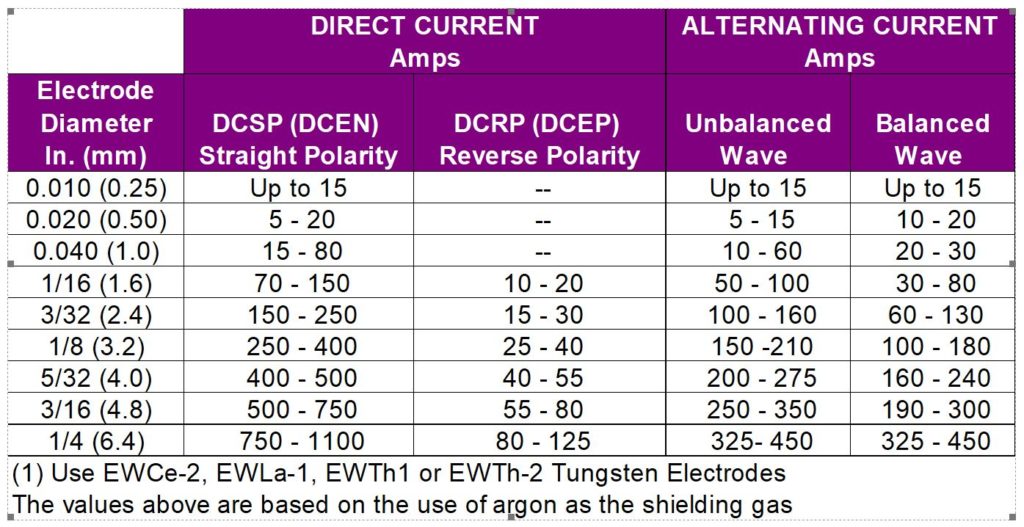

Tig Weld Amperage Chart - By using the chart, welders can determine the optimal settings for their welding machine based on the material they are welding and the desired weld size. Whether you’re working on steel, aluminum, or stainless steel, this tool provides you with tailored recommendations for electrode size, type, and amperage, ensuring that your welds meet the highest standards. Although midwest tungsten service only provides 1/16, 3/32, and 1/8 electrodes, some projects call for a slightly bigger diameter, such as 5/32 or 3/16. Web the document provides a tig welding amp calculator chart for mild steel and stainless steel in thicknesses ranging from 0.8mm to 3mm. The chart provides a visual representation of the required settings, making it easy for welders to select the right amperage, depending on the material, joint type, electrode size, and welding position. Tungsten diameter and cup size. It caters to different material types and thicknesses for effective welding. It notes that the chart provides starting point amps that may need adjusting based on technique and travel speed. Web setting the amperage on a welding machine, whether stick (smaw), mig (gmaw) (*typically uses voltage setting), or tig (gtaw), depends on some key variables such as application and base material, welding process, and electrode. The charts are intended as a starting point for beginner and intermediate tig welders. Web empower your tig welding projects with our free online tig welding calculator. Tig welding, or tungsten inert gas welding, demands precision and control over various settings for optimal results. Web a tig welding settings chart provides essential parameters like amperage, voltage, and gas flow. It lists recommended amperages for. Whether you’re working on steel, aluminum, or stainless steel, this. Filler metal must be dry, free of oxides, grease, or other foreign matter. Web tig welding amperage chart. Understanding the relationship between the amperage and functionality of tig welding is of significant importance. Web printable charts shiowing the amps and tungstons you might select for various thiknesses, joint types and materials. Web for beginners it’s recommended to stick with a. According to these charts, mild steel requires the most amperage (not aluminum), and also the fastest travel speed. Whether you’re working on steel, aluminum, or stainless steel, this tool provides you with tailored recommendations for electrode size, type, and amperage, ensuring that your welds meet the highest standards. This document provides a tig welding amp calculator chart for mild steel. Web the exact amperage of a tig welder depends on the type of metal, type of project, and thickness of the material you are working on. The type of current used will have a great effect on the penetration pattern as well as the bead configuration. Filler metal must be dry, free of oxides, grease, or other foreign matter. Web. Filler metal can be either wire or rod and should be compatible with the base alloy. This document provides a tig welding amp calculator chart for mild steel and stainless steel. By using the chart, welders can determine the optimal settings for their welding machine based on the material they are welding and the desired weld size. Web the use. How to read the chart. Characteristics of current types for tig welding. It lists recommended amperages for. Once you determine these three main variables, you can set your welding machine and start. Click here for helpful charts for tig welding based on amperage, materials, sizes, shielding gasses, and more. See the chart below for current ranges of all sizes. By using the chart, welders can determine the optimal settings for their welding machine based on the material they are welding and the desired weld size. Browse suggested weld parameter settings for tig welding. Download the app version of the weld setting calculator for easy reference! Web the exact amperage. Web a look at each type and its uses will help the operator select the best current type for the job. Web welders are often looking for a good reference detailing recommended amperage levels based on tungsten welding electrode size and type. Although midwest tungsten service only provides 1/16, 3/32, and 1/8 electrodes, some projects call for a slightly bigger. Filler metal can be either wire or rod and should be compatible with the base alloy. If you get the amperage right, you can get welding results of the desired quality. Characteristics of current types for tig welding. It notes that the chart provides starting point amps that may need adjusting based on technique and travel speed. Web tig welding. Web a tig welding settings chart provides essential parameters like amperage, voltage, and gas flow. Tungsten diameter and cup size. Web if you aren’t sure which type of electrode to buy then look at our comparison of 6010 vs 6011 vs 6013 vs 7018 vs 7024. Filler metal can be either wire or rod and should be compatible with the. Web the exact amperage of a tig welder depends on the type of metal, type of project, and thickness of the material you are working on. Web if you aren’t sure which type of electrode to buy then look at our comparison of 6010 vs 6011 vs 6013 vs 7018 vs 7024. Web the use of tig welding for aluminum has many advantages for both manual and automatic processes. How to choose welding rod amperage. Web tig torch connection diagrams. Web welders are often looking for a good reference detailing recommended amperage levels based on tungsten welding electrode size and type. The charts are intended as a starting point for beginner and intermediate tig welders. By using the chart, welders can determine the optimal settings for their welding machine based on the material they are welding and the desired weld size. This document provides a tig welding amp calculator chart for mild steel and stainless steel. Adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. Browse suggested weld parameter settings for tig welding. Web below you will find manuals, guides, and fact sheets for our large variety of ck tig welding products and accessories. It notes that the chart provides starting point amps that may need adjusting based on technique and travel speed. I looked in the stickies, but didn't see any charts for how much amperage to use when using a. It lists recommended amperages for. If you get the amperage right, you can get welding results of the desired quality.

TIG Welding Charts ILMO Products Company

Electrode Amperage Chart Baker's Gas & Welding Supplies, Inc.

Aluminum Tig Welding Settings Chart

TIG Welding Amp Charts Welding Building Materials

Tig Welding Settings Chart Pdf

Tig parameters chart MIG Welding Forum

Download Tig Welding Aluminum Amperage Chart Pics All About Welder

Tig Welding Amperage Chart

TIG Welding Charts ILMO Products Company

Tig Weld Amp Chart

Tungsten Diameter And Cup Size.

Web For Beginners It’s Recommended To Stick With A 3/32” Diameter Tungsten.

Web Empower Your Tig Welding Projects With Our Free Online Tig Welding Calculator.

Amperage Chart For Different Metals And Their Thickness.

Related Post: