Tig Torch Size Chart

Tig Torch Size Chart - Depending on your amperage needs and your budget, there are always several good. Web use this quick reference chart to identify the type of tig torch that suit your machine. The type of current used will have a great effect on the penetration pattern as well as the bead configuration. The actual amperage capability may vary from manufacturer, ambient temperature, welding position, the heat reflected by the welded material, and other variables. Refer to the charts below for the proper connector to match your machines setup. Tig stands for tungsten inert gas and is also known as gas tungsten arc welding (gtaw). Adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. Cup sizes typically range from #4 (1/4 inch or 6.4 mm) to #12 (3/4 inch or 19 mm). These, generally, are in numerical order, in that 9 is the smallest size torch and 26 is the largest. Water cooled torches range up to 320 amps with a recommended max. In those days power sources were transformer based, and pure tungsten could accommodate welding in the ac mode, which is the standard for. The actual amperage capability may vary from manufacturer, ambient temperature, welding position, the heat reflected by the welded material, and other variables. Web tig torch connection diagrams. Web a small air cooled tig torch rated for 125. All this make any sense to anyone? Web from the torch bodies, through all the various types of tig gas nozzle, to the wide range of handles. This article will help break down the basics for you when it comes to selecting your first torch. Which torch body is suitable for what? Web a look at each type and its. Depending on your amperage needs and your budget, there are always several good. Web what is tig welding? The chart below has been designed to help the torch selection process easier by visually highlighting each torches capabilities. Web tig welding was developed to efficiently join aluminum and magnesium alloys, and pure tungsten made sense at the time, since it has. Web tig welding was developed to efficiently join aluminum and magnesium alloys, and pure tungsten made sense at the time, since it has the highest melting temperature of all metals. I have a lot of torches. Web air cooled torches range up to 180 amps with a recommended max. Cup sizes typically range from #4 (1/4 inch or 6.4 mm). With these reliable torches, you’ll be able to manage your most demanding applications while minimizing overheating to get the job done. Web a look at each type and its uses will help the operator select the best current type for the job. Web from the torch bodies, through all the various types of tig gas nozzle, to the wide range. The actual amperage capability may vary from manufacturer, ambient temperature, welding position, the heat reflected by the welded material, and other variables. Standard tig torches with valve. All this make any sense to anyone? Which torch body is suitable for what? But what exactly are the differences between all these tig torches, and what does each one do? The actual amperage capability may vary from manufacturer, ambient temperature, welding position, the heat reflected by the welded material, and other variables. Let’s go over the differences between the two, so you can decide on the right torch for your welding needs. Web what is tig welding? Web tig welding cup size refers to the diameter of the ceramic or. Web when it comes to tig torches, there are two main types to choose from: This article will help break down the basics for you when it comes to selecting your first torch. Tungsten inert gas (tig) welding is the process in which an arc is formed between a tungsten electrode and the workpiece to join the metals together. I. Adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. • facilitate arc starting • increase arc stability • improve current carrying capacity of the electrode • reduce the risk of weld contamination • increase electrode life We need a lot less flow in tig welding. The actual amperage capability may vary from manufacturer, ambient. Depending on your amperage needs and your budget, there are always several good. Web tig welding cup size refers to the diameter of the ceramic or glass cup that directs shielding gas flow around the welding arc. Tungsten inert gas (tig) welding is the process in which an arc is formed between a tungsten electrode and the workpiece to join. Do you find a large or small handle easier to hold? Tig stands for tungsten inert gas and is also known as gas tungsten arc welding (gtaw). In those days power sources were transformer based, and pure tungsten could accommodate welding in the ac mode, which is the standard for. Web what is tig welding? All this make any sense to anyone? Cup sizes typically range from #4 (1/4 inch or 6.4 mm) to #12 (3/4 inch or 19 mm). • facilitate arc starting • increase arc stability • improve current carrying capacity of the electrode • reduce the risk of weld contamination • increase electrode life Web when it comes to tig torches, there are two main types to choose from: Web from the torch bodies, through all the various types of tig gas nozzle, to the wide range of handles. What metal are you welding? Web air cooled torches range up to 180 amps with a recommended max. The chart below has been designed to help the torch selection process easier by visually highlighting each torches capabilities. Let’s go over the differences between the two, so you can decide on the right torch for your welding needs. Web a small air cooled tig torch rated for 125 amps is called a #9 style. Choosing the correct size depends on material thickness, joint type, and desired weld bead profile. See the chart below for current ranges of all sizes.

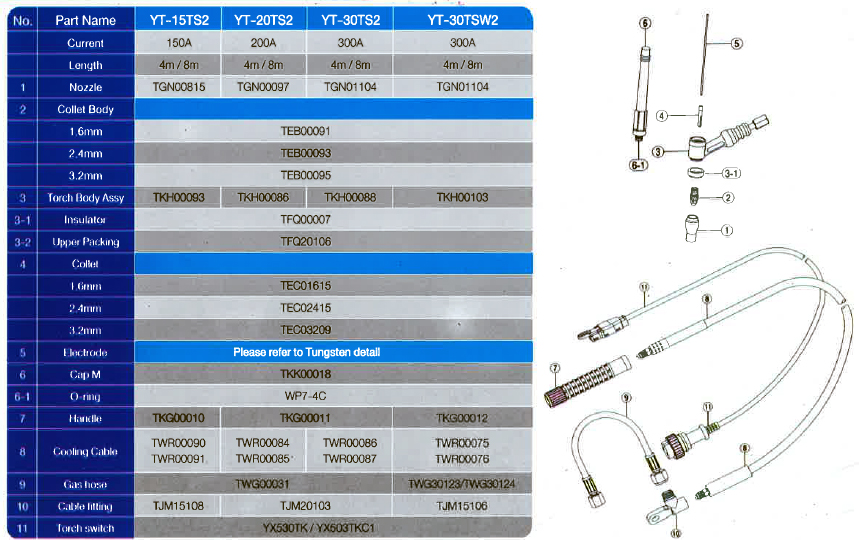

Tig Torch Welding machine

A Better TIG Experience Hot Rod Network

Tig Torch Sizes Chart

/9_20_consumables_setup-1.png?width=4500&name=9_20_consumables_setup-1.png)

BINZEL BASICS TIG torch selection, consumables setup & care & maintenance.

Tig Torch Size Chart

/17_18_26_consumables_setup.png?width=3210&name=17_18_26_consumables_setup.png)

BINZEL BASICS TIG torch selection, consumables setup & care & maintenance.

Tig Torch Size Chart

CK20/CK25 Flex Head TIG Torch WaterCooled 250 Amp TIG Welder CK

Tig Torch Size Guide

Fl130 & FL150 130 150 Amp FlexLoc Swivel Head TIG Torch CK

Web For Beginners It’s Recommended To Stick With A 3/32” Diameter Tungsten.

Web The Table Below Summarizes The Key Specifications And Applications Of The Different Tig Torch Sizes:

With These Reliable Torches, You’ll Be Able To Manage Your Most Demanding Applications While Minimizing Overheating To Get The Job Done.

Web Tig Welding Was Developed To Efficiently Join Aluminum And Magnesium Alloys, And Pure Tungsten Made Sense At The Time, Since It Has The Highest Melting Temperature Of All Metals.

Related Post: