Tig Aluminum Filler Rod Chart

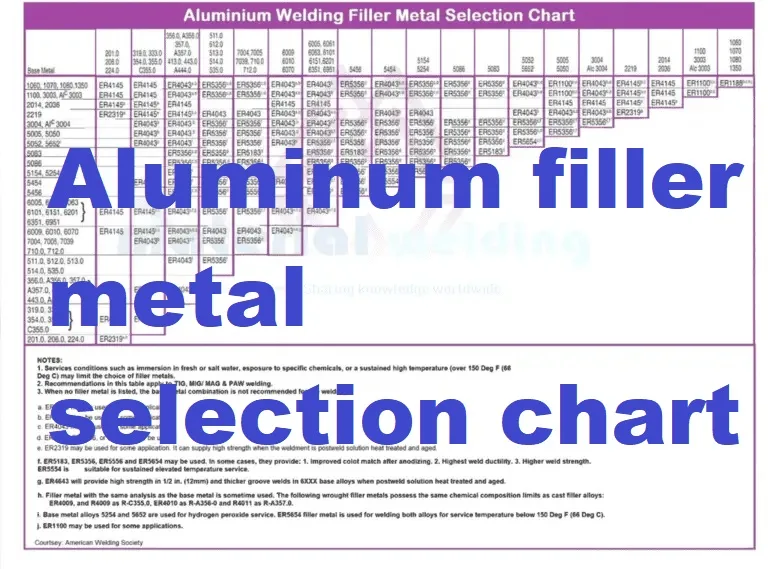

Tig Aluminum Filler Rod Chart - 4047 aluminum filler rod contains 12% silicon. Web always refer to an aluminum filler metal selection chart to choose a filler metal that is best suited for a particular application. Wire diameter control (1/10th of allowed aws specification) all these features available in a wide range of alloys. Web in this article, we will introduce an aluminum filler metal selection chart that simplifies the process of selecting the right filler metal for welding aluminum, helping you achieve a strong and reliable weld. Web whats the best size filler rod to use for tig welding? Web the use of tig welding for aluminum has many advantages for both manual and automatic processes. Er1100 gives consistent welding performance along with very good corrosion resistance. Web if the chart shows that you can use either 4043 or 5356 then there are a few more things we need to consider: But there are some guidelines. And do yourself a favor and get some 4047 aluminum filler rod for castings where porosity rares its ugly head. The following guidelines provide you with good starting points for the. There is a really good chart for selecting aluminum filler rods here. Web the use of tig welding for aluminum has many advantages for both manual and automatic processes. If service temperature will exceed 150f (65c) 5356 should not be used. Unfortunately, there is no correct answer. There is a really good chart for selecting aluminum filler rods here. Application, and the desired weld metal properties. Web for aluminum, the most commonly used filler rod is a 4043 aluminum alloy rod, and that’s the one i would recommend for most aluminum welding applications. Understanding the roles and importance of tig filler rods is crucial for anyone involved. And do yourself a favor and get some 4047 aluminum filler rod for castings where porosity rares its ugly head. Filler metal must be dry, free of oxides, grease, or other foreign matter. Stick electrode, solid mig wire, tig rods, metal cored wire and micro tig rods The following guidelines provide you with good starting points for the. Web if. Er1100 gives consistent welding performance along with very good corrosion resistance. Rules of thumb if you will. The amperage, gas flow, torch travel speed, and cup size vary, too. The following guidelines provide you with good starting points for the. How to use the chart. Web the table below shows a comprehensive overview of tig filler rods and their common applications: What is the aluminum base metal designation? The following guidelines provide you with good starting points for the. Application, and the desired weld metal properties. Web tig (tungsten inert gas) welding is a popular and versatile form of arc welding that creates strong, reliable. Web the use of tig welding for aluminum has many advantages for both manual and automatic processes. But there are some guidelines. Web if the chart shows that you can use either 4043 or 5356 then there are a few more things we need to consider: Select the proper filler rod. Er1100 is a 99% aluminum solid wire for tig. Er4043 is not used for welding applications where the weld is subjected to high shear stresses. However, aluminum is a tricky metal, so make sure you know what alloy you are welding and what the part will be used for. Web the table below shows a comprehensive overview of tig filler rods and their common applications: At temperature above 150f. Filler metal selection for aluminum welding. Web always refer to an aluminum filler metal selection chart to choose a filler metal that is best suited for a particular application. Unfortunately, there is no correct answer. Web in this article, we will introduce an aluminum filler metal selection chart that simplifies the process of selecting the right filler metal for welding. There is a really good chart for selecting aluminum filler rods here. Er4043 is not used for welding applications where the weld is subjected to high shear stresses. Filler metal selection for aluminum welding. Unfortunately, there is no correct answer. Plant and product certifications iso 9001,. It has a very good electrical conductivity. The following guidelines provide you with good starting points for the. Application, and the desired weld metal properties. Stick electrode, solid mig wire, tig rods, metal cored wire and micro tig rods Select the proper filler rod. Wire diameter control (1/10th of allowed aws specification) all these features available in a wide range of alloys. There is a really good chart for selecting aluminum filler rods here. Web whats the best size filler rod to use for tig welding? The following guidelines provide you with good starting points for the. Filler metal can be either wire or rod and should be compatible with the base alloy. Web always refer to an aluminum filler metal selection chart to choose a filler metal that is best suited for a particular application. Plant and product certifications iso 9001,. At temperature above 150f this alloy is. Er1100 gives consistent welding performance along with very good corrosion resistance. Er4043 is not used for welding applications where the weld is subjected to high shear stresses. It is therefore essential to have the answers to some basic questions prior to the selection of the most appropriate filler metal. Web er1100 tig & mig filler wire welding rod. 4047 aluminum filler rod contains 12% silicon. Unfortunately, there is no correct answer. And do yourself a favor and get some 4047 aluminum filler rod for castings where porosity rares its ugly head. The amperage, gas flow, torch travel speed, and cup size vary, too.

Tig Filler Rod Sizes

Tig Aluminum Filler Rod Chart

TIG Welding Charts ILMO Products Company

Tig Welding Rod Chart

Tig Welding Aluminum Filler Rod

Aluminum Filler Alloy Selection Chart PDF Welding Construction

How Do I Calculate How Much Welding Rod I Need

Tig Welding Filler Rod Selection Chart Reviews Of Chart

Aluminum filler metal selection charts

TIG Welding Charts ILMO Products Company

If Service Temperature Will Exceed 150F (65C) 5356 Should Not Be Used.

Application, And The Desired Weld Metal Properties.

What Is The Aluminum Base Metal Designation?

Web Shop Aluminum Tig Rods For Aluminum To Aluminum Welding At Airgas Today From Radnor™️, Alcotec Wire Company, Harris® And Hobart®.

Related Post: