Sublimation Printable Heat Press Temperature Guide

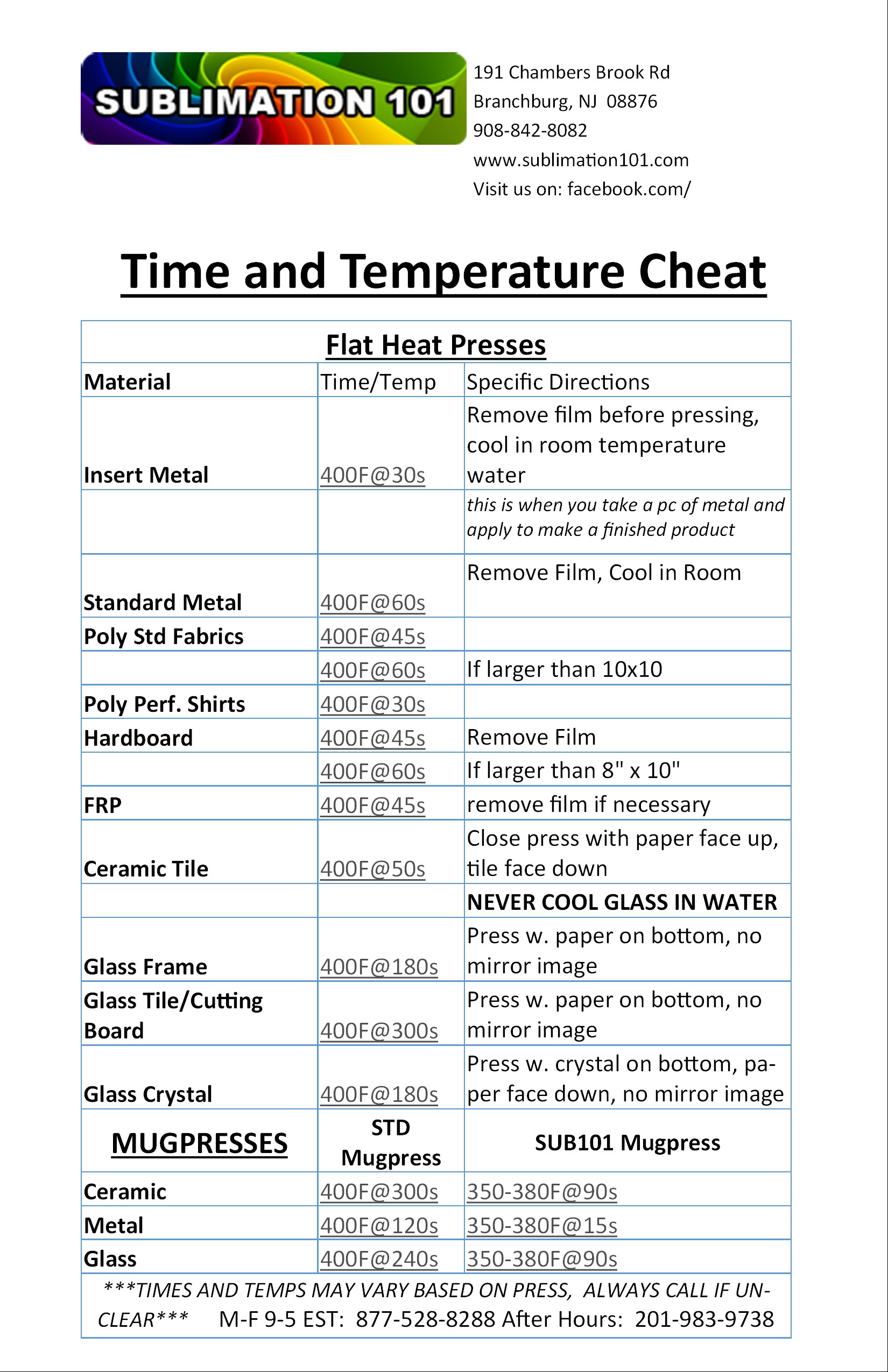

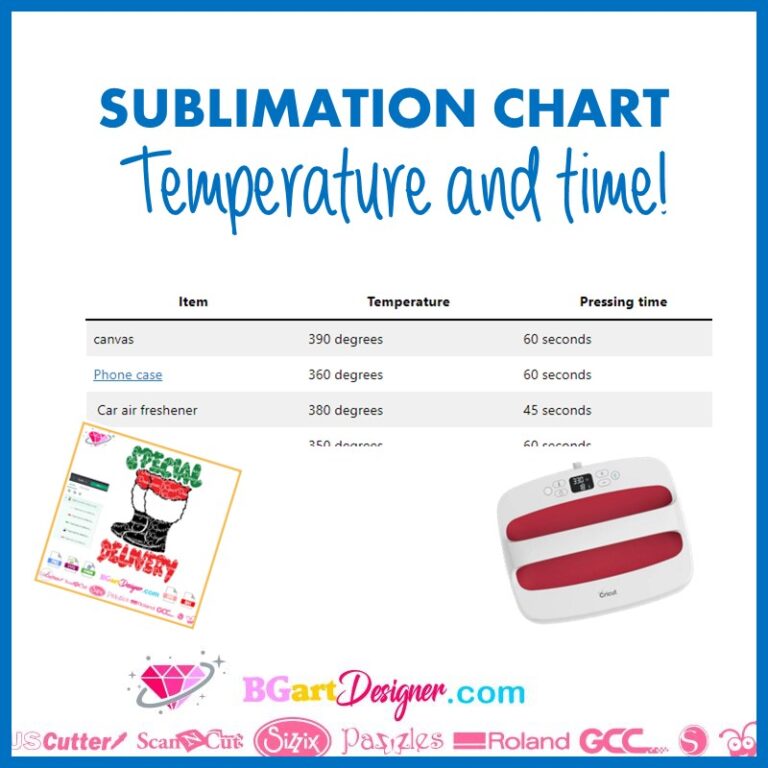

Sublimation Printable Heat Press Temperature Guide - First, you need to find the type of substrate you’re printing on. Lifetime warranty on the heating element. Cricut easypress mini chart downloads. The hard, slick surface of stainless steel requires higher temperatures sustained over greater dwell durations with plenty of pressure to. What temperature and time are right for the surface you are pressing? Then, you need to find the appropriate temperature and pressure for that substrate. So let’s talk about common sublimation heat press settings and how to determine times, temperatures, and pressures for different materials. For example, cotton requires less time than polyester. Adjust the time according to the material you’re using. It demands precision in temperature. What temperature and time are right for the surface you are pressing? Transfer should be slightly larger than film and placed face down on the substrate (adhesive side down). If not, please use the heat press instructions or the values written in this table as a guide. First, you need to find the type of substrate you’re printing on. From. For more info about sublimation printing, visit elmlib.org/sublimation. For heat press temperature and time settings, please refer to the recommended values of the material if available. You can usually find this information in the product manual or on the manufacturer’s website. I created different versions of the chart so you can grab whichever one you need. Tips for cchieving the. Web simply click “user guide” for more info. Cricut easypress chart for heat and time settings. Select options to view instructions. Web the online heat guide gives you different options depending on your machine and whether you’re using a towel or an easypress mat. What temperature and time are right for the surface you are pressing? Producing quality end products is a matter of suitable substrates, a calibrated heat press, smart color management, following manufacturer guidelines, testing and practice! 1 year warranty on the heat press. The following chart should serve only as a starting place. Then, you need to find the appropriate temperature and pressure for that substrate. The hard, slick surface of stainless steel. 1 year warranty on the heat press. Producing quality end products is a matter of suitable substrates, a calibrated heat press, smart color management, following manufacturer guidelines, testing and practice! Then, you need to find the appropriate temperature and pressure for that substrate. I created different versions of the chart so you can grab whichever one you need. Just click. Cricut easypress mini chart downloads. 1 year warranty on the heat press. Web the online heat guide gives you different options depending on your machine and whether you’re using a towel or an easypress mat. What temperature and time are right for the surface you are pressing? For example, cotton requires less time than polyester. Web the online heat guide gives you different options depending on your machine and whether you’re using a towel or an easypress mat. Web in this comprehensive heat press guide, we provide a variety of recommended heat press settings for dtf printing, sublimation printing, heat transfer vinyl, screen printed vinyl, and laser transfer paper. 1 year warranty on the heat. It demands precision in temperature. 30 seconds to 4 minutes, depending on the substrate. For example, cotton requires less time than polyester. Or you plan to apply the heat transfer vinyl for sublimation first on cotton, then you need to set the temperature at 266 to 284°f for htv vinyl. This press guide provides our recommended time, temperature, and pressure. Web what temperature should i set my heat press to? Tips for cchieving the best sublimation results. What temperature do i put my heat press on for sublimation? Web simply click “user guide” for more info. Producing quality end products is a matter of suitable substrates, a calibrated heat press, smart color management, following manufacturer guidelines, testing and practice! The following chart should serve only as a starting place. Web table of contents. Web press into silicon pad. What temperature do i put my heat press on for sublimation? Web sublimation heat press settings. Temperature and time will vary based on sublimation blank. Always warm up your heat press before printing the design. I created different versions of the chart so you can grab whichever one you need. This requires more than just quality designs; Lifetime warranty on the heating element. For heat press temperature and time settings, please refer to the recommended values of the material if available. The following chart should serve only as a starting place. The following chart should serve only as a starting place. For more info about sublimation printing, visit elmlib.org/sublimation. Select options to view instructions. Transfer should be slightly larger than film and placed face down on the substrate (adhesive side down). The following chart should serve only as a starting place. More material settings on back side. This press guide provides our recommended time, temperature, and pressure settings for sublimating sawgrass inks by substrate material. 380°f to 400°f (193°c to 204°c) time: It demands precision in temperature.

Sublimation Printable Heat Press Temperature Guide

Sublimation Temperature Guide Cheat Sheet Temperature Etsy

Printable Cheat Sheets for Sublimation Heat Press Temperature Etsy

Sublimation Heat Press Temperature Chart A Complete Guide

Cheat Sheet Printable Heat Press Temperature Guide

Printable Cheat Sheets for Sublimation Heat Press Temperature Settings

Sublimation Temperature Guide Cheat Sheet Temperature Etsy

Heat Press Temperature Guide Sublimation and HTV Angie Holden The

Printable Heat Press Temperature Guide

Sublimation temperature and time chart

Producing Quality End Products Is A Matter Of Suitable Substrates, A Calibrated Heat Press, Smart Color Management, Following Manufacturer Guidelines, Testing And Practice!

Or You Plan To Apply The Heat Transfer Vinyl For Sublimation First On Cotton, Then You Need To Set The Temperature At 266 To 284°F For Htv Vinyl.

Web Press Into Silicon Pad.

Tips For Cchieving The Best Sublimation Results.

Related Post: