Stud Torque Chart

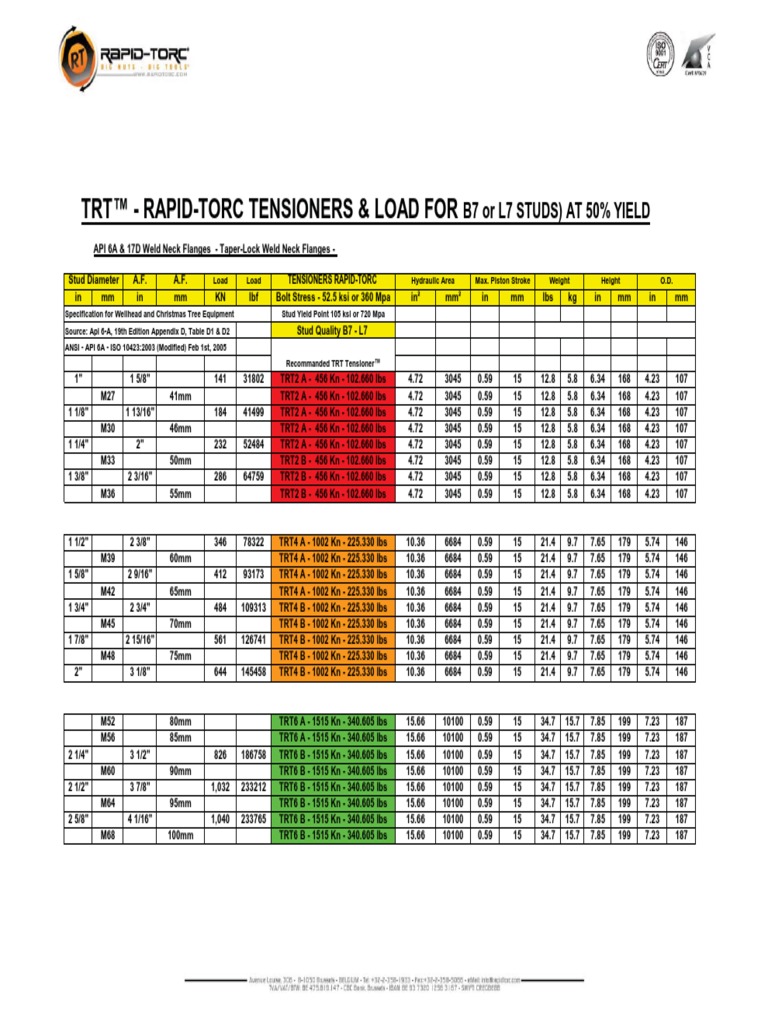

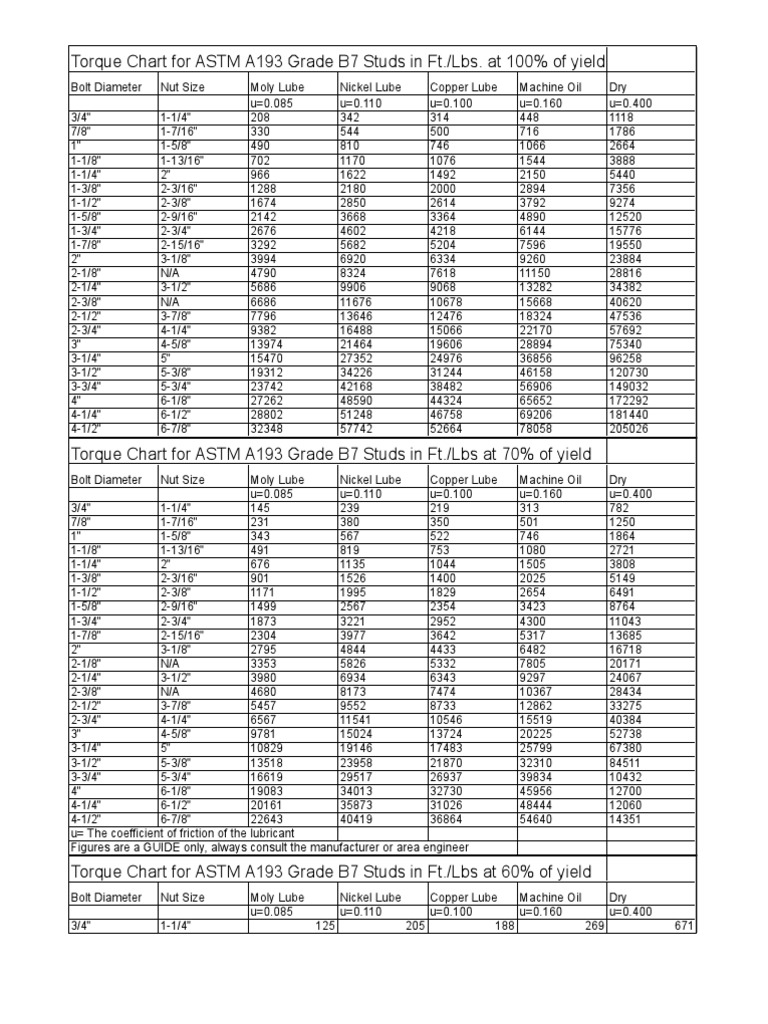

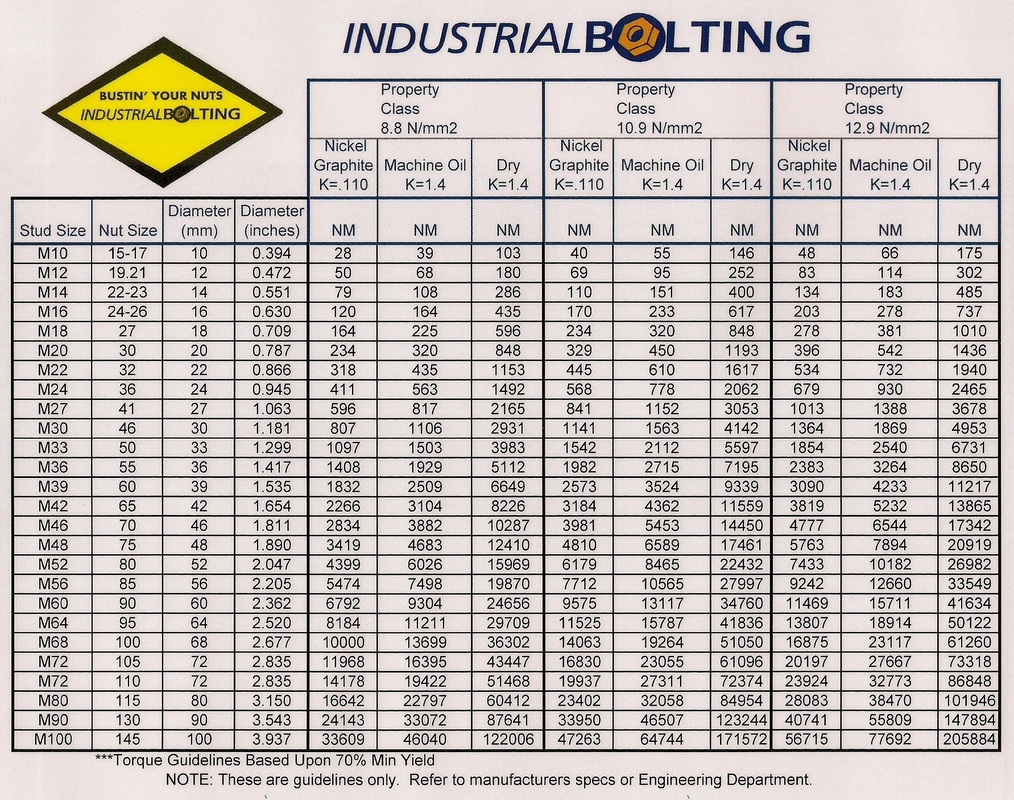

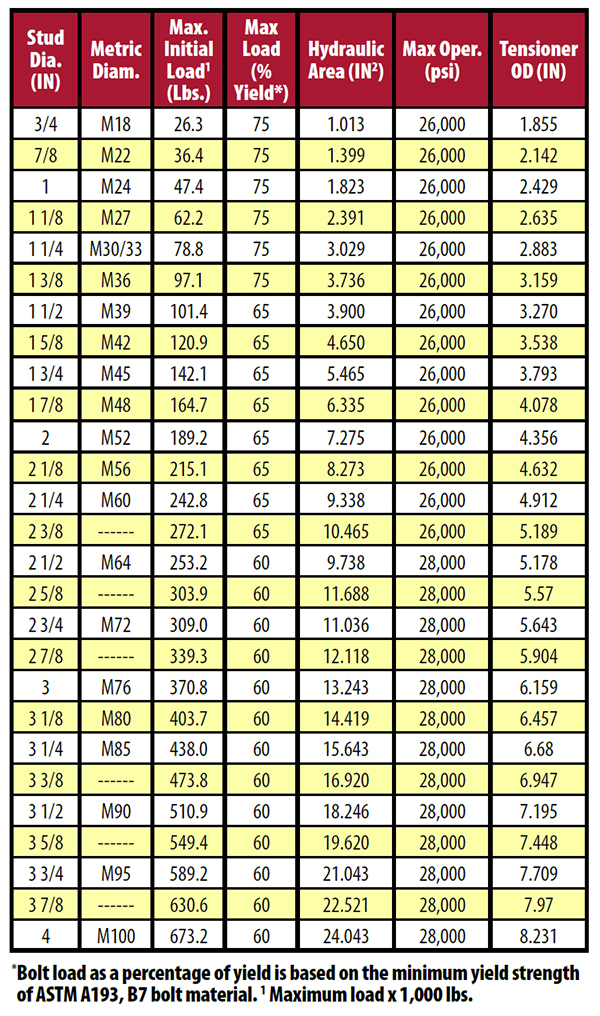

Stud Torque Chart - Thorough application of lubricant on all mating. The following suggested tightening torques provide an excellent starting point for determining torque requirements. Remember, you may need to vary these. Web the table below indicates the safe tightening torque, which may be applied to a studfast weld stud when welded to a compatible good weldable quality material. = clamp load for j429 grade 5 and 8, fnl grade 9, a574, class 4.6, 8.8, 10.9 and 12.9,. Web bolt torque chart showing suggested torque values and corresponding bolt clamping forces for various sizes and specifications of fasteners. Web in preparing this guide to torque values, the following basic assumptions have been made: New condition of flanges, studs and nuts. Web this chart is to be used a guide only, always refer to oem specifications or local engineer call alltite, inc. Any thread damage (however minor),. Tightening torque (ft lbs) galv. Web these torque values are intended for use as quidelines only & are based on perfect conditions. Web for example, the 0.18 k factor listed above is based on the following conditions: Refer to manufactures speci cations or your companies engineering. Web the table below indicates the safe tightening torque, which may be applied to. Web tightening torque for stud bolts in according to various astm standards. Refer to manufactures speci cations or your companies engineering. Web in preparing this guide to torque values, the following basic assumptions have been made: Thorough application of lubricant on all mating. Tightening torque (ft lbs) plain. New condition of flanges, studs and nuts. Web tightening torque for stud bolts in according to various astm standards. Web tightening torque (ft lbs) galv + wax. Web these torque values are intended for use as quidelines only & are based on perfect conditions. = clamp load for j429 grade 5 and 8, fnl grade 9, a574, class 4.6, 8.8,. Any thread damage (however minor),. Bolts and nuts are new, standard finish, uncoated and not lubricated*. Web bolt torque chart showing suggested torque values and corresponding bolt clamping forces for various sizes and specifications of fasteners. Web recommended torque for b7 studs (astm a193) based upon 50% yield. Torque values calculated from formula t=kdf, where coatings such as. Web torque specifications, especially for critical joints, should be determined under actual assembly conditions due to the many variables involved which are difficult to predict and. Tightening torque (ft lbs) plain. Flange bolting torque table 1 the torque tables are built on specific assumptions regarding bolt and. The following suggested tightening torques provide an excellent starting point for determining torque. New condition of flanges, studs and nuts. Bolts and nuts are new, standard finish, uncoated and not lubricated*. Web these torque values are intended for use as quidelines only & are based on perfect conditions. Stainless steel fasteners tend to gall, especially with long run downs, prevailing torque fasteners, impact. Web the stud bolt and nut torque chart shows the. = clamp load for j429 grade 5 and 8, fnl grade 9, a574, class 4.6, 8.8, 10.9 and 12.9,. Web in preparing this guide to torque values, the following basic assumptions have been made: Tightening torque (ft lbs) galv. Web find astm a193 grade b7 stud bolt torque chart at 100% of yield, 70% yield, 60% of yield, 50% of. Web recommended torque for b7 studs (astm a193) based upon 50% yield. Any thread damage (however minor),. Remember, you may need to vary these. Torque values calculated from formula t=kdf, where coatings such as. Thorough application of lubricant on all mating. New condition of flanges, studs and nuts. Torque values calculated from formula t=kdf, where coatings such as. Web in preparing this guide to torque values, the following basic assumptions have been made: Refer to manufactures speci cations or your companies engineering. Thorough application of lubricant on all mating. Stainless steel fasteners tend to gall, especially with long run downs, prevailing torque fasteners, impact. Web tightening torque for stud bolts in according to various astm standards. Refer to manufactures speci cations or your companies engineering. Thorough application of lubricant on all mating. Web torque specifications, especially for critical joints, should be determined under actual assembly conditions due to the. Web tor ue chart for astm a193 grade. Web these torque values are intended for use as quidelines only & are based on perfect conditions. = clamp load for j429 grade 5 and 8, fnl grade 9, a574, class 4.6, 8.8, 10.9 and 12.9,. Web maximum recommended tightening torque for coarse threaded metric steel bolts: Web tightening torque for stud bolts in according to various astm standards. Clamp load calculated as 75% of the yield strength for the b7 specified in astm a193. Web this chart is to be used a guide only, always refer to oem specifications or local engineer call alltite, inc. Web recommended torque for b7 studs (astm a193) based upon 50% yield. Web tightening torque (ft lbs) galv + wax. New condition of flanges, studs and nuts. Web find astm a193 grade b7 stud bolt torque chart at 100% of yield, 70% yield, 60% of yield, 50% of yield, 40% of yield and 30% of yield. Web for example, the 0.18 k factor listed above is based on the following conditions: Web torque specifications, especially for critical joints, should be determined under actual assembly conditions due to the many variables involved which are difficult to predict and. Tightening torque (ft lbs) plain. Web the stud bolt and nut torque chart shows the sequence to use, and the force to apply, to stud bolts used to tighten flanges (by flange class). Any thread damage (however minor),.Torque for B7 L7 Stud Bolts Mechanical Engineering Nature

Torque Charts Industrial Torque Tools

Torque Charts Industrial Bolting and Torque Tools

FREE 7+ Sample Bolt Torque Chart Templates in PDF MS Word

Stainless Steel Stud Bolt Torque Chart Torque Values

Torque Chart for ASTM A193 Grade B7 Studs Motor Oil Nut (Hardware)

B7 Studs Torque Specs basement wall studs

Studs Bolts Torque Charts

Torque Charts Industrial Bolting and Torque Tools

Stainless Steel Stud Bolt Torque Chart Torque Values, 60 OFF

Bolts And Nuts Are New, Standard Finish, Uncoated And Not Lubricated*.

Web The Table Below Indicates The Safe Tightening Torque, Which May Be Applied To A Studfast Weld Stud When Welded To A Compatible Good Weldable Quality Material.

The Following Suggested Tightening Torques Provide An Excellent Starting Point For Determining Torque Requirements.

Tightening Torque (Ft Lbs) Galv.

Related Post: