Steel Wool Grit Chart

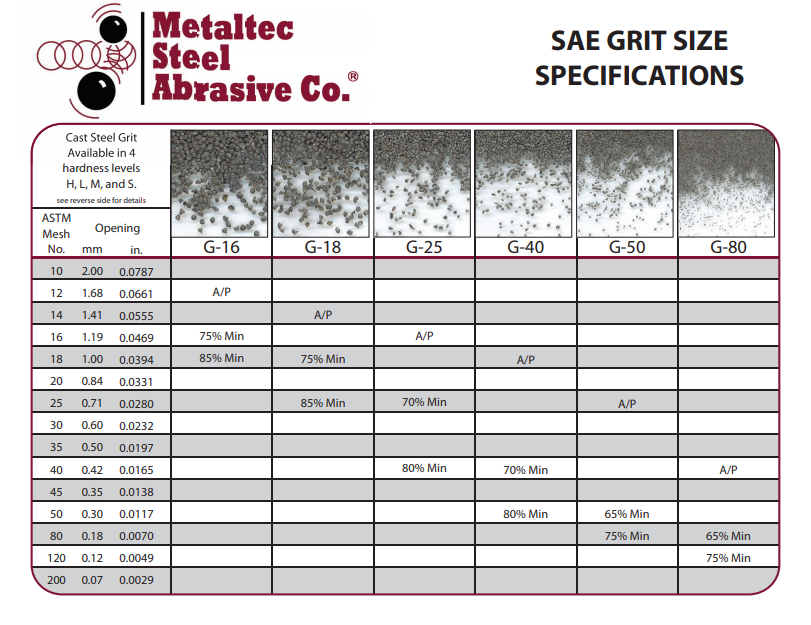

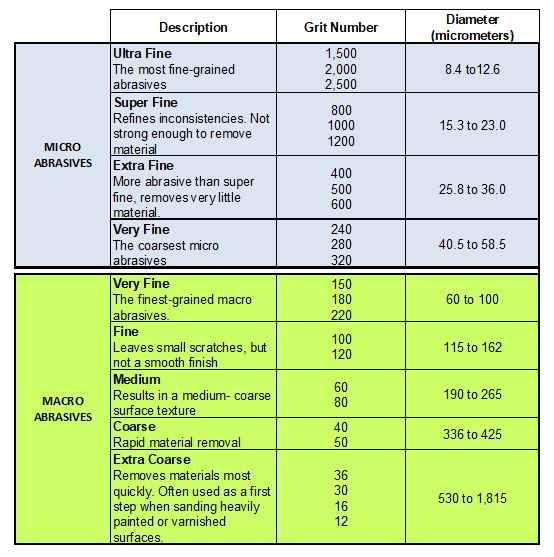

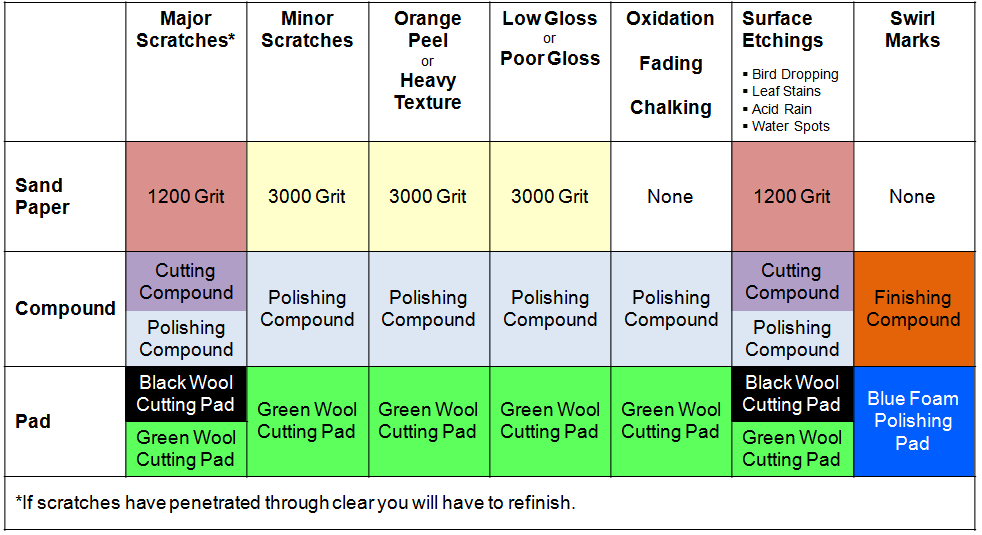

Steel Wool Grit Chart - The coarsest steel wool is grade #4. We can't speak for every single manufacturer, but here's the basic industry code: Web wood and metal • provides similar performance as steel wool grade 00 a vfn (dark maroon) • highly conformable abrasive with high cut for paint preparation and wood. The lower the grit size, the coarser the steel. Web grit size chart. Web learn about the eight grades of norton steel wool, from extra coarse #4 to super fine #0000, and how to use them for cleaning, smoothing and polishing various surfaces. Web the most important rule of following grit sequence is to move to progressively higher grit (finer) sandpaper upon each application. Web different grades of steel wool are used for various purposes, and each grade is identified by a specific grit size. 2/0 steel wool = 120 grit. Web grit sandpaper is great for precise material removal and surface smoothing, while steel wool, especially the fine #0000 grade, excels in achieving a smooth, lustrous. This is often the first grade chosen when going through the grits to prepare wood for finishing. We can't speak for every single manufacturer, but here's the basic industry code: Web 9 rows steelwool is available in 8 different levels of abrasiveness or “grades”. Web compounds and steel wool. Web grit sandpaper is great for precise material removal and surface. This is often the first grade chosen when going through the grits to prepare wood for finishing. Grit size refers to the roughness or coarseness of an. Web grades of steel wool are similar to grit in sandpaper. Web view the full range of oakey products. 3/0 steel wool = 280 grit. The grade is determined by the thickness of the wire of which the wool is made of. We can't speak for every single manufacturer, but here's the basic industry code: If you wonder what grit is 0000 steel wool equivalent to, read on! Sandpaper has various grits, so choose the right one for your needs. It’s also used to remove. Web published on march 27, 2017. 2/0 steel wool = 120 grit. Web learn about the eight grades of norton steel wool, from extra coarse #4 to super fine #0000, and how to use them for cleaning, smoothing and polishing various surfaces. 4/0 steel wool = 400 grit sandpaper. The coarsest steel wool is grade #4. 4/0 steel wool = 400 grit sandpaper. The lower the grit size, the coarser the steel. Additionally, it removes paint drips and splatters. Web different grades of steel wool are used for various purposes, and each grade is identified by a specific grit size. 2/0 steel wool = 180 grit. Sandpaper has various grits, so choose the right one for your needs. Additionally, it removes paint drips and splatters. Web published on march 27, 2017. The fine steel wool equivalent is the best alternative to fine. 2/0 steel wool = 180 grit. We can't speak for every single manufacturer, but here's the basic industry code: If you wonder what grit is 0000 steel wool equivalent to, read on! 2/0 steel wool = 180 grit. Web grades of steel wool are similar to grit in sandpaper. 2/0 steel wool = 120 grit. Refer to our extensive grade selection table. Grit size refers to the roughness or coarseness of an. Web grades of steel wool are similar to grit in sandpaper. Use it to hand sand, or with a belt or orbital sander. Web grit sandpaper is great for precise material removal and surface smoothing, while steel wool, especially the fine #0000 grade,. The following chart outlines the advantages achievable when using our products as alternatives to other cleaning, blending, deburring and finishing. 4/0 steel wool = 400 grit sandpaper. Web grit sandpaper is great for precise material removal and surface smoothing, while steel wool, especially the fine #0000 grade, excels in achieving a smooth, lustrous. Web grades of steel wool are similar. Refer to our extensive grade selection table. Unlike sandpaper, steel wool is not toxic and comes in different grades. The grade is determined by the thickness of the wire of which the wool is made of. Grit size refers to the roughness or coarseness of an. The finest steel wool is grade 0000 or 4/0. View our reference chart on choosing the right grit for your project, ranging from sanding bare wood to. The following chart outlines the advantages achievable when using our products as alternatives to other cleaning, blending, deburring and finishing. Web learn about the eight grades of norton steel wool, from extra coarse #4 to super fine #0000, and how to use them for cleaning, smoothing and polishing various surfaces. Web grit size chart. We can't speak for every single manufacturer, but here's the basic industry code: Web grit sandpaper is great for precise material removal and surface smoothing, while steel wool, especially the fine #0000 grade, excels in achieving a smooth, lustrous. 2/0 steel wool = 180 grit. Use the chart below to find the right mineral, grit coarseness and finish for your application —. It’s also used to remove minor burns from wood. The finest steel wool is grade 0000 or 4/0. This is often the first grade chosen when going through the grits to prepare wood for finishing. Web wood and metal • provides similar performance as steel wool grade 00 a vfn (dark maroon) • highly conformable abrasive with high cut for paint preparation and wood. Refer to our extensive grade selection table. Web different grades of steel wool are used for various purposes, and each grade is identified by a specific grit size. Web view the full range of oakey products. It’s commonly used for baffling cabinetry, and new wax furnishes.

Steel Wool Grit Chart

Abrasives grit size Forture Tools

Steel Grits Shiva Steel Industries (Nagpur) Limited, Nagpur

Steel Wool Grit Chart

Grit Comparison Chart Manmade Materials Metalworking

Steel Grit Great Lakes Finishing

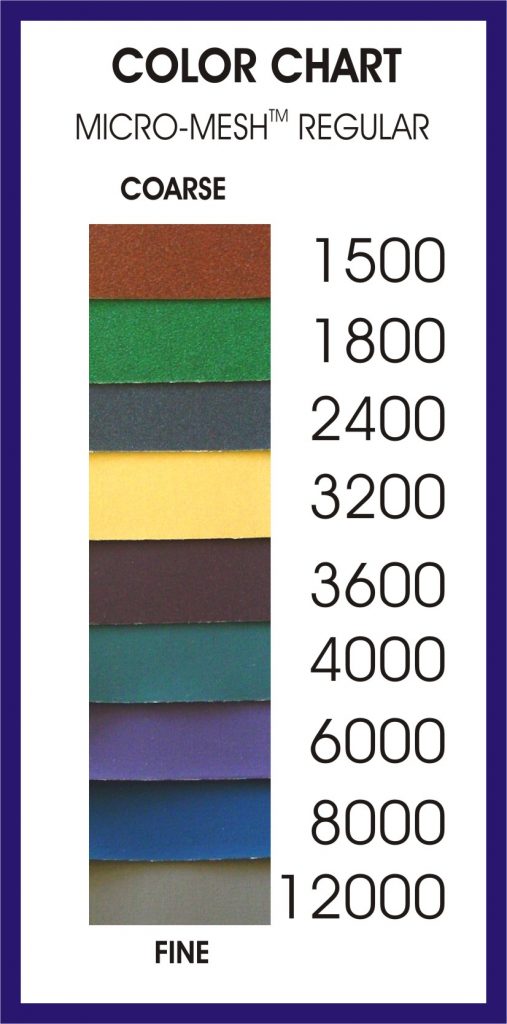

Grit Conversion Micro Surface

Grit chart of grinding wheels Forture Tools

Buffing Compound Colors Chart

Steel Wool ZIBO RIKEN MT COATED ABRASIVES CO., LTD.

The Lower The Grit Size, The Coarser The Steel.

The Grade Is Determined By The Thickness Of The Wire Of Which The Wool Is Made Of.

Grit Size Refers To The Roughness Or Coarseness Of An.

Web There Are Different Steel Wool Types, So Ensure You Get The Right One For Your Project.

Related Post: