Steel Material Hardness Chart

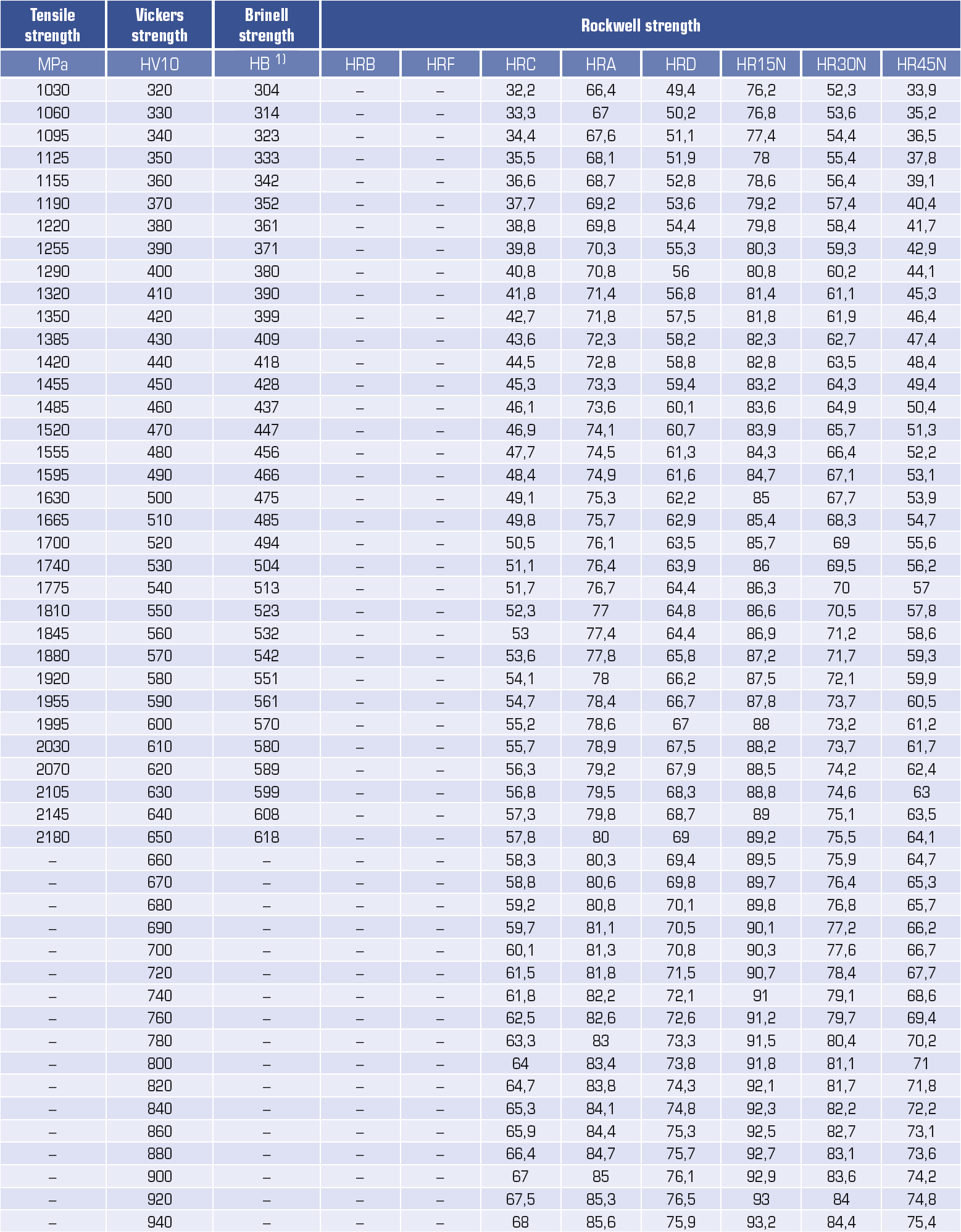

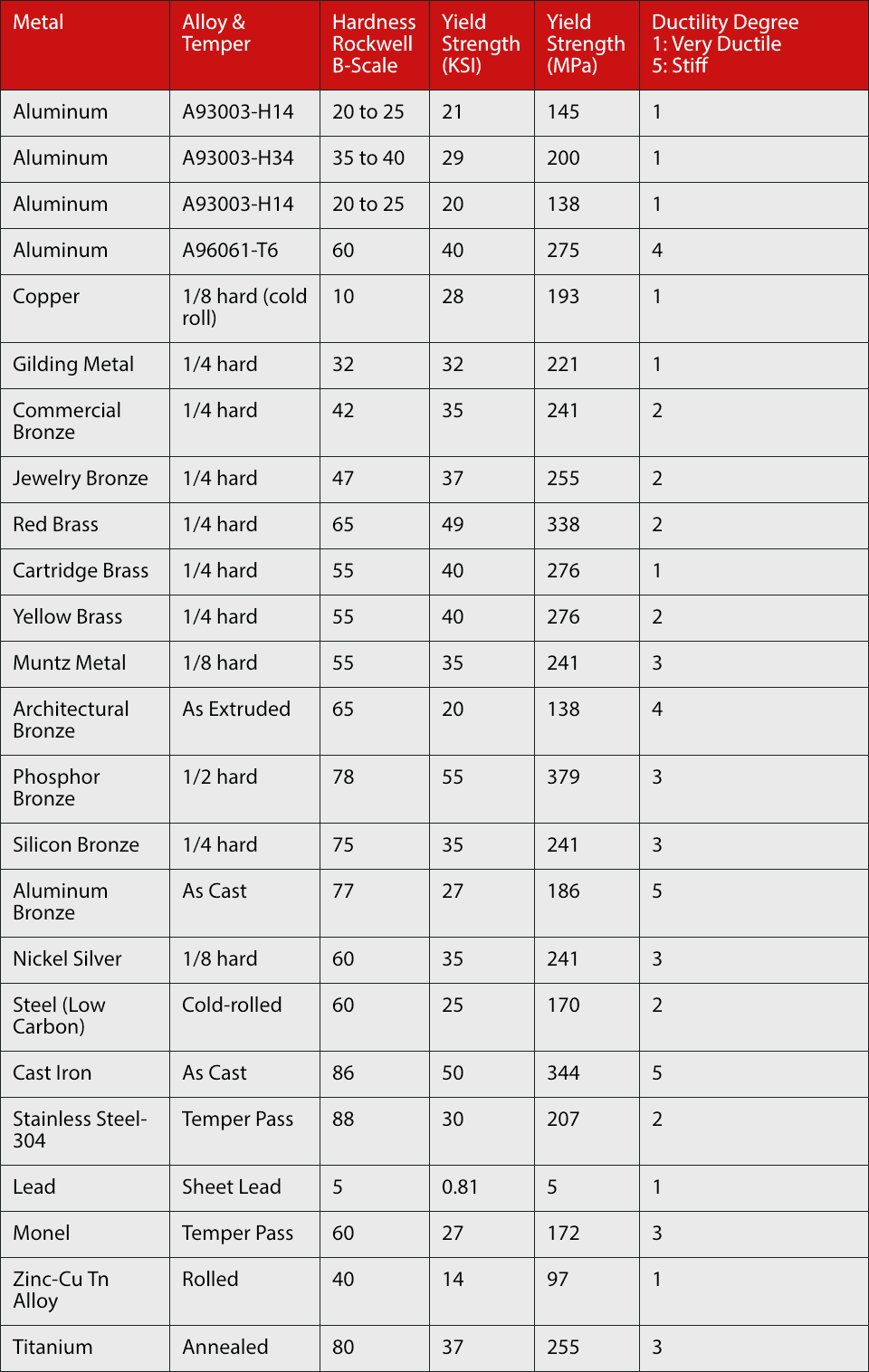

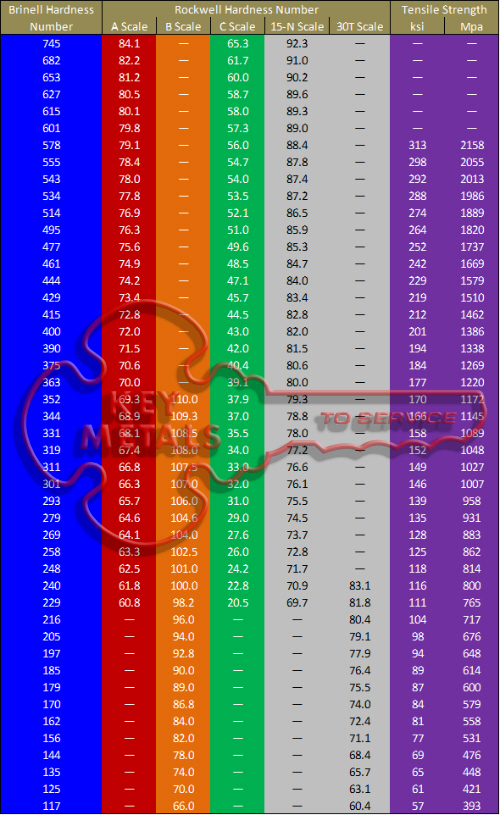

Steel Material Hardness Chart - Vickers, brinell and rockwell hardness as well as tensile strength in steel and cast steel. When measuring hardness using the rebound method, the hardness value represents the extent of the metal’s elastic deformation function. Web the brinell hardness test consists of indenting the test material with a 10mm diameter hardened steel or tungsten ball subjected to a load of 3000 kg. For softer materials, there are alternate scales using a 1500 kg or 500 kg load to. Depending on the testing method used, conventionally, there are brinell (hb), rockwell (hrc), vickers (hv), and leeb (hl) hardness measurements, among which hb and hrc are most commonly used. The most common scale for this qualitative test is mohs scale, which is used in mineralogy. These conversion charts are provided for guidance only as each scales uses different methods of measuring hardness. Web here we collect the metal strength chart (tensile, yield strength, hardness, and density included) and mechanical properties chart of common metals of different grades for your reference. Scratch hardness is the measure of how resistant a sample is to permanent plastic deformation due to friction from a sharp object. The symbol for metal hardness (hardness) is h. When measuring hardness using the rebound method, the hardness value represents the extent of the metal’s elastic deformation function. Web the brinell hardness test consists of indenting the test material with a 10mm diameter hardened steel or tungsten ball subjected to a load of 3000 kg. Web this table shows approximate hardness of steel using brinell, rockwell b and c. The most common scale for this qualitative test is mohs scale, which is used in mineralogy. Depending on the testing method used, conventionally, there are brinell (hb), rockwell (hrc), vickers (hv), and leeb (hl) hardness measurements, among which hb and hrc are most commonly used. Web there are three main types of hardness measurements: Scratch hardness is the measure of. Web the brinell hardness test consists of indenting the test material with a 10mm diameter hardened steel or tungsten ball subjected to a load of 3000 kg. Web there are three main types of hardness measurements: Web the hardness value indicates a material’s ability to resist plastic deformation caused by the intrusion of another object. The rockwell hardness test is. The table values are guide values. The symbol for metal hardness (hardness) is h. Depending on the testing method used, conventionally, there are brinell (hb), rockwell (hrc), vickers (hv), and leeb (hl) hardness measurements, among which hb and hrc are most commonly used. The most common scale for this qualitative test is mohs scale, which is used in mineralogy. Web. When measuring hardness using the rebound method, the hardness value represents the extent of the metal’s elastic deformation function. Web here we collect the metal strength chart (tensile, yield strength, hardness, and density included) and mechanical properties chart of common metals of different grades for your reference. For softer materials, there are alternate scales using a 1500 kg or 500. Web this table shows approximate hardness of steel using brinell, rockwell b and c and vickers scales. The symbol for metal hardness (hardness) is h. Depending on the testing method used, conventionally, there are brinell (hb), rockwell (hrc), vickers (hv), and leeb (hl) hardness measurements, among which hb and hrc are most commonly used. Vickers, brinell and rockwell hardness as. When measuring hardness using the rebound method, the hardness value represents the extent of the metal’s elastic deformation function. The symbol for metal hardness (hardness) is h. The most common scale for this qualitative test is mohs scale, which is used in mineralogy. Scratch hardness is the measure of how resistant a sample is to permanent plastic deformation due to. Web this table shows approximate hardness of steel using brinell, rockwell b and c and vickers scales. Vickers, brinell and rockwell hardness as well as tensile strength in steel and cast steel. Web the hardness value indicates a material’s ability to resist plastic deformation caused by the intrusion of another object. The rockwell hardness test is suitable for a wide. Web the brinell hardness test consists of indenting the test material with a 10mm diameter hardened steel or tungsten ball subjected to a load of 3000 kg. The table values are guide values. Web this table shows approximate hardness of steel using brinell, rockwell b and c and vickers scales. These conversion charts are provided for guidance only as each. Web the brinell hardness test consists of indenting the test material with a 10mm diameter hardened steel or tungsten ball subjected to a load of 3000 kg. When measuring hardness using the rebound method, the hardness value represents the extent of the metal’s elastic deformation function. The most common scale for this qualitative test is mohs scale, which is used. These conversion charts are provided for guidance only as each scales uses different methods of measuring hardness. Web the brinell hardness test consists of indenting the test material with a 10mm diameter hardened steel or tungsten ball subjected to a load of 3000 kg. Depending on the testing method used, conventionally, there are brinell (hb), rockwell (hrc), vickers (hv), and leeb (hl) hardness measurements, among which hb and hrc are most commonly used. Vickers, brinell and rockwell hardness as well as tensile strength in steel and cast steel. The rockwell hardness test is suitable for a wide range of materials, using a. Web the hardness value indicates a material’s ability to resist plastic deformation caused by the intrusion of another object. Scratch hardness is the measure of how resistant a sample is to permanent plastic deformation due to friction from a sharp object. Web here we collect the metal strength chart (tensile, yield strength, hardness, and density included) and mechanical properties chart of common metals of different grades for your reference. For softer materials, there are alternate scales using a 1500 kg or 500 kg load to. The most common scale for this qualitative test is mohs scale, which is used in mineralogy. Web there are three main types of hardness measurements: The symbol for metal hardness (hardness) is h.

Metal Hardness Scale Chart

Product Detail Nachi America

Metal Hardness Scale Chart

Metal Hardness Zahner — Innovation and Collaboration to Achieve the

Hardness Chart Key Metals

Is there a source that simplifies hardness levels of naturally

Hardness comparison table WS STAHL

What is steel?

9 STEEL MATERIAL GRADES PDF * Materials

ASTM A27 Steel Metal Casting Resources

When Measuring Hardness Using The Rebound Method, The Hardness Value Represents The Extent Of The Metal’s Elastic Deformation Function.

The Table Values Are Guide Values.

Web This Table Shows Approximate Hardness Of Steel Using Brinell, Rockwell B And C And Vickers Scales.

Related Post: