Steel Alloy Chart

Steel Alloy Chart - Web steel, alloy of iron and carbon in which the carbon content ranges up to 2 percent (with a higher carbon content, the material is defined as cast iron). According to the type of alloying elements, these types of steel can be divided into: Some of the common additions to alloy steel include: Steel rebar futures fell to cny 3,520 per tonne, the lowest in two months, as markets pared expectations on future construction activity in china. Web alloy steel refers to a steel that is refined on the basis of carbon steel by adding some alloying elements (such as chromium, nickel, molybdenum, tungsten, vanadium, titanium, etc.) in order to improve the properties of the steel. Web tensile / yield strengths and ductilities for some of the plain carbon and low alloy steels are given in the following mechanical properties of steel chart. Cast iron worldwide equivalent grades: Good weldability and forming and extruding chrematistics. Temperature are indicated in the chart below. Yield strength, tensile strength and ductility values for steels at room temperature Web features of european steel and alloy database. Web carbon steels and alloy steels are designated by a four digit number, where the first digit indicates the main alloying element(s), the second digit indicates the secondary alloying element(s), and the last two digits indicate the amount of. Web tensile / yield strengths and ductilities for some of the plain carbon. This produces specific properties that are not found in. These elements commonly include manganese, nickel, chromium, molybdenum, vanadium, silicon, and boron. Web worldwide equivalent grades for steel, cast iron and alloy. The system is based on the chemical compositions of the steels and alloys. Australia ( as ) austria ( onorm, on) belgium ( nbn ) bulgaria (bds ). Web carbon steels and alloy steels are designated a four digit number, whereby the first digit indicates the main alloying element (s), the second digit indicates tg (top grade) element (s), and the last two digits indicate the amount of carbon, in hundredths of a percent ( basis points) by weight. This is an alphabetical list of alloys grouped according. Steels in general have a lower carbon content than cast irons, and lower amounts of impurities like phosphorus and sulfur. The composition chart above represents typical ranges for basic. Originally, this handbook was published in 1971 by inco, the international nickel company inc. Web aisi/sae steel numbers are indicated below. Carbon steels are regarded as steels containing not more than. According to the type of alloying elements, these types of steel can be divided into: Web worldwide equivalent grades for steel, cast iron and alloy. Web steel technical property data on over 5500 steel alloys and heat treatments, searchable by property specification, aisi, astm, sae, uns and mil spec numbers, elemental composition, and mechanical property values. Web alloy steel refers. This produces specific properties that are not found in. Web carbon steels and alloy steels are designated a four digit number, whereby the first digit indicates the main alloying element (s), the second digit indicates tg (top grade) element (s), and the last two digits indicate the amount of carbon, in hundredths of a percent ( basis points) by weight.. Web an alloy is a material made by melting one or more metals together with other elements. Web features of european steel and alloy database. Web worldwide equivalent grades for steel, cast iron and alloy. Alloy steel has other elements in its composition besides iron and carbon. Web carbon steels, alloy steels, steel compositions vary widely. Web tensile / yield strengths and ductilities for some of the plain carbon and low alloy steels are given in the following mechanical properties of steel chart. Steel rebar futures fell to cny 3,520 per tonne, the lowest in two months, as markets pared expectations on future construction activity in china. Alloy steel has other elements in its composition besides. Web alloy steel is steel that is alloyed with a variety of elements in total amounts between 1.0% and 50% by weight to improve its mechanical properties. Elements such as manganese, silicon, nickel, and chromium augment the steel's strength, toughness, and corrosion resistance. Web tensile / yield strengths and ductilities for some of the plain carbon and low alloy steels. Web alloy steel is a class of steel that, in addition to carbon, is alloyed with other elements, ranging from 1 wt.% to 50 wt.%, which are used to enhance the material’s various properties [1]. The nickel institute republished the handbook in 2021. Good weldability and forming and extruding chrematistics. Some of the common additions to alloy steel include: Web. Originally, this handbook was published in 1971 by inco, the international nickel company inc. Web an alloy is a material made by melting one or more metals together with other elements. Web worldwide equivalent grades for steel, cast iron and alloy. Temperature are indicated in the chart below. Yield strength, tensile strength and ductility values for steels at room temperature Chromium, cobalt, columbium, molybdenum, manganese, nickel, titanium, tungsten, silicon, and vanadium. Web alloy steel refers to a steel that is refined on the basis of carbon steel by adding some alloying elements (such as chromium, nickel, molybdenum, tungsten, vanadium, titanium, etc.) in order to improve the properties of the steel. Steels in general have a lower carbon content than cast irons, and lower amounts of impurities like phosphorus and sulfur. The nickel institute republished the handbook in 2021. These elements are added to enhance the steel’s mechanical properties to meet specific industrial needs. Steel / cast iron standards: This produces specific properties that are not found in. Alloy steel has other elements in its composition besides iron and carbon. Often used for general structural and automotive bodies. Web alloy steel is a class of steel that, in addition to carbon, is alloyed with other elements, ranging from 1 wt.% to 50 wt.%, which are used to enhance the material’s various properties [1]. Some alloys are listed under more than one element, since the composition of the alloy may vary such that one element is present in a higher concentration than the others.

Download PDF Steel material grades

Steel Alloy Chart

Steel Alloy Chart

List Metals used in Making Steel Alloys

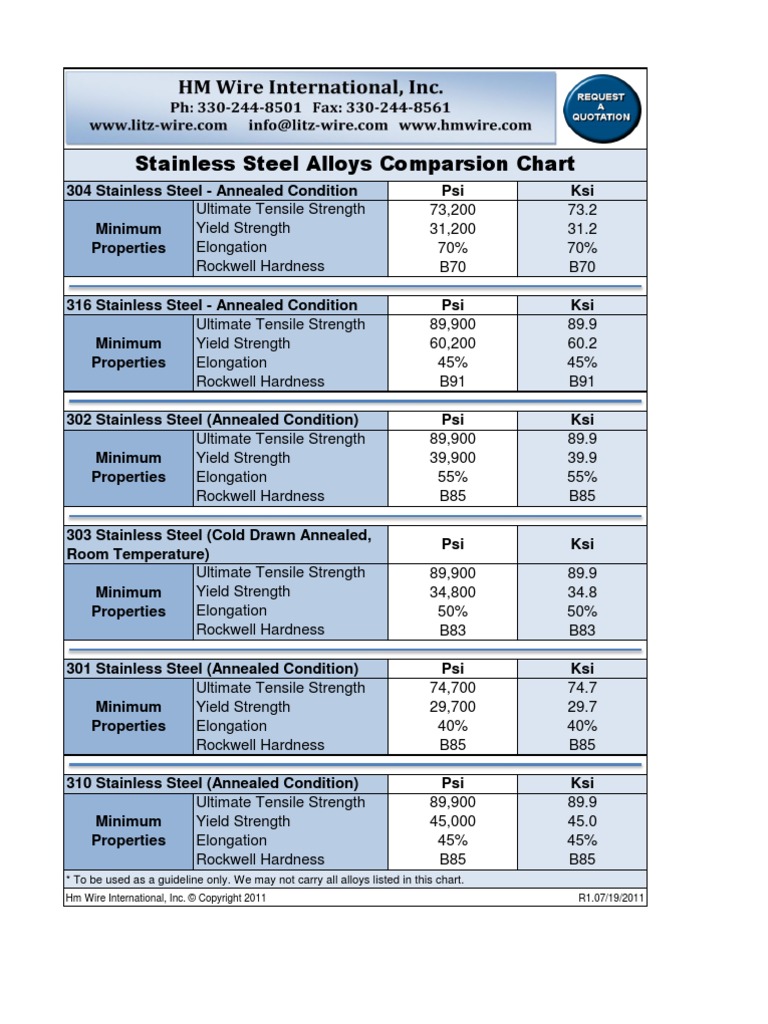

Stainless Steel Alloys Comparsion Chart Annealing (Metallurgy

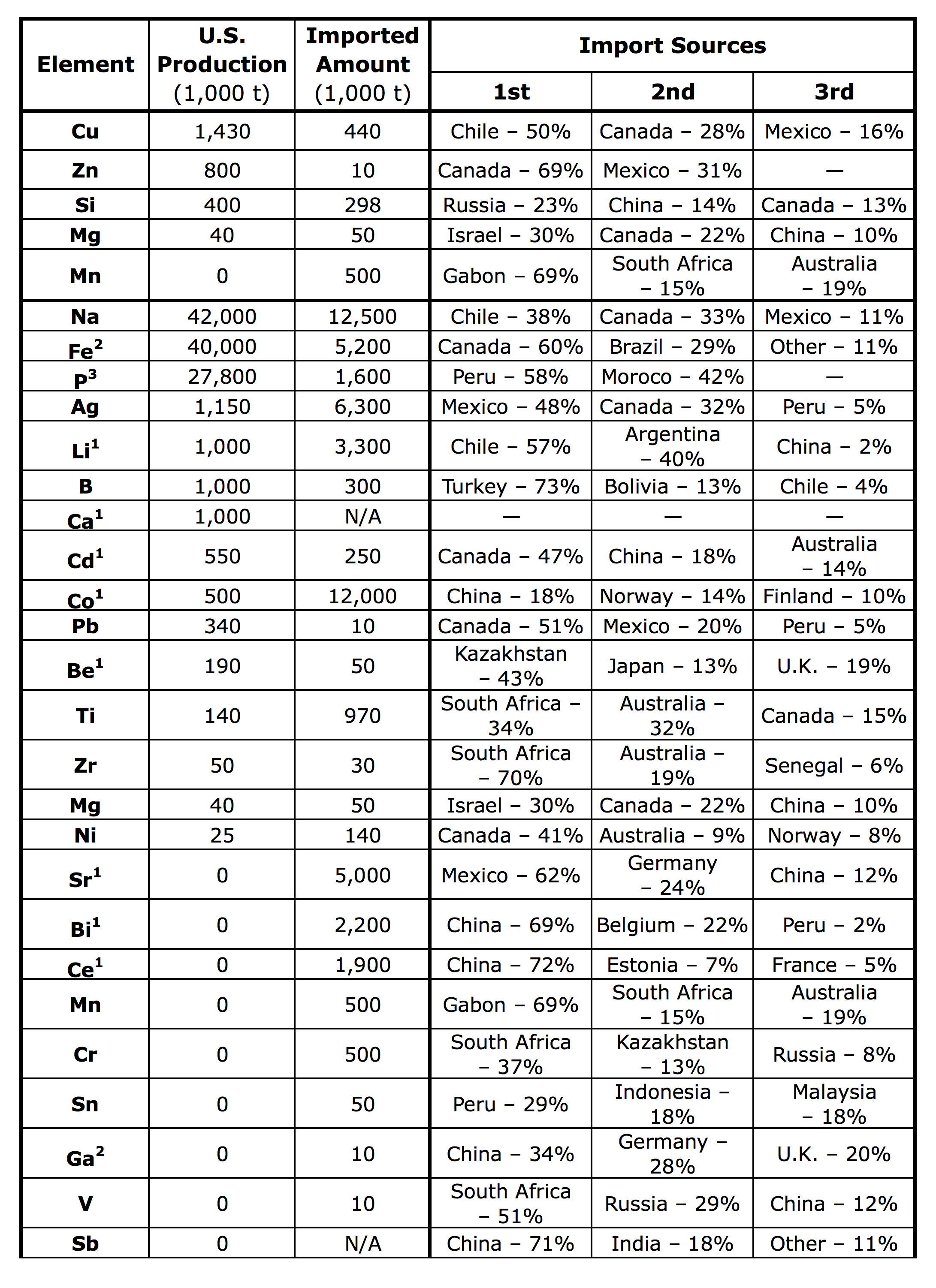

ARTICLE The Importance of Aluminum Alloying Elements and Their Sources

Luftfahrt Rauer Schlaf spülen mechanical properties of alloy steel

Alloy Steel Chart Metallic Elements Materials

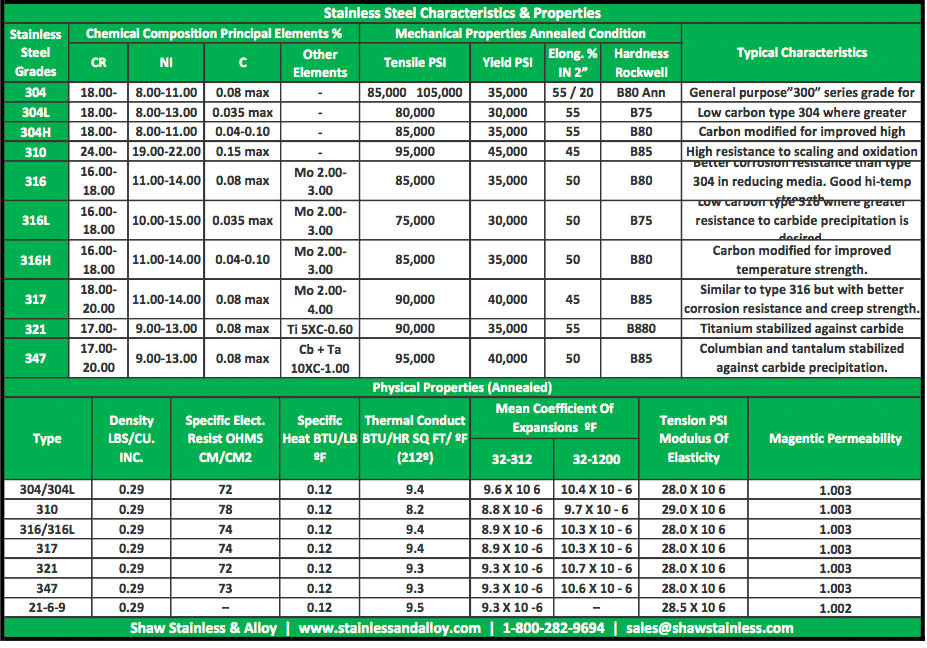

CHEMICAL COMPOSITION OF STAINLESS STEELS ALLOYS Download Table

Stainless Steel Quality Chart My XXX Hot Girl

Web Carbon Steels And Alloy Steels Are Designated By A Four Digit Number, Where The First Digit Indicates The Main Alloying Element(S), The Second Digit Indicates The Secondary Alloying Element(S), And The Last Two Digits Indicate The Amount Of.

Alloy Steel Is Made By Combining Carbon Steel With One Or Several Alloying Elements, Such As Titanium, Copper, Chromium, Aluminum, Manganese, Silicon, And Nickel.

Elements Such As Manganese, Silicon, Nickel, And Chromium Augment The Steel's Strength, Toughness, And Corrosion Resistance.

These Elements Commonly Include Manganese, Nickel, Chromium, Molybdenum, Vanadium, Silicon, And Boron.

Related Post: