Stainless Steel Bolt Torque Chart

Stainless Steel Bolt Torque Chart - Web bolt torque chart reference guides include grade 2, b7, a307, a325, grade 8, a490, and grade 5. While fastenal has used reliable sources and testing to determine these values, there are many variables that will effect the results and the use of this information is at sole risk of the user. Web most aisi stainless steels are identified by a system of numbers in either 200, 300, or 400 series. For a307 grade a, 75% of 36,000 psi is utilized. Web the following data tables are designed to be used as general guidance when installing stainless steel fasteners. Web remember, you may need to vary these numbers somewhat based on the individual joint or the amount of fastener lubrication. Web if lubrication has been applied to the bolt and/or the nut (other than the normal protective oil film), multiply the recommended torque by the appropriate factor shown in the table. 5)stainless steel fasteners tend to gall while being tightened. The following torque values are suggested maximums based upon actual lab testing on clean and dry or near dry fasteners. Stainless steel fasteners tend to gall, especially with long run downs, prevailing torque fasteners, impact drivers, and lack of lubrication. * this table is recommended for use as a guide only. Web the following data tables are designed to be used as general guidance when installing stainless steel fasteners. Stainless steel fasteners tend to gall, especially with long run downs, prevailing torque fasteners, impact drivers, and lack of lubrication. While all care has been taken with its preparation, no responsibility. = clamp load for j429 grade 5 and 8, fnl grade 9, a574, class 4.6, 8.8, 10.9 and 12.9, the clamp loads are listed at 75% of the proof loads specified by the standard. Stainless steel fasteners tend to gall, especially with long run downs, prevailing torque fasteners, impact drivers, and lack of lubrication. The above data is based on. All material included in this chart is advisory only, and its use by anyone. Web torque and pullout load. Stainless steel fasteners tend to gall, especially with long run downs, prevailing torque fasteners, impact drivers, and lack of lubrication. Web torque values stainless steel bolt table chart. Therefore, using the correct installation torque is. Testing is done to various bolts and metal plates, torqueing them until the point of failure. Web torque values for a2 or a4 metric stainless steel fasteners. Around 640 torque tables were developed for unc, unf, and m fasteners. Stainless steel fasteners tend to gall, especially with long run downs, prevailing torque fasteners, impact drivers, and lack of lubrication. Required. This applies to ‘grades’ a1, a2, a3, a4 and a5. * this table is recommended for use as a guide only. 5)stainless steel fasteners tend to gall while being tightened. All material included in this chart is advisory only, and its use by anyone. This shows torque values in nm for property classes 50, 70 and 80 as shown in. Use of its content by anyone is the sole responsibility of that person and they assume all risk. * this table is recommended for use as a guide only. Bolt and nut are both phosphated; Stainless steel fasteners tend to gall, especially with long run downs, prevailing torque fasteners, impact drivers, and lack of lubrication. In developing this information, fastenal. Web bolt torque chart reference guides include grade 2, b7, a307, a325, grade 8, a490, and grade 5. All material included in this chart is advisory only, and its use by anyone. Web check bolt torque chart online, view bolt torque chart stainless steel and m30 stainless steel bolt torque. Use of its content by anyone is the sole responsibility. Stainless steel fasteners tend to gall, especially with long run downs, prevailing torque fasteners, impact drivers, and lack of lubrication. Web bolt torque chart reference guides include grade 2, b7, a307, a325, grade 8, a490, and grade 5. Web torque values stainless steel bolt table chart. The above data is based on a dry installation and should not be used. Required torque = torque recommended x 0.75. Web remember, you may need to vary these numbers somewhat based on the individual joint or the amount of fastener lubrication. To construct a securely assembled joint using bolts or machine screws, the fasteners must be tightened to develop the proper amount of clamping force. Web values given represent the torque required to. Web values given represent the torque required to induce a tension in the bolt corresponding to approximately 65% of its proof load. Recommended bolt torque values for stainless steel and nonferrous fasteners (inch series). Around 640 torque tables were developed for unc, unf, and m fasteners. Aft fasteners is your trusted source for fastener information. 5)stainless steel fasteners tend to. Stainless steel fasteners tend to gall, especially with long run downs, prevailing torque fasteners, impact drivers, and lack of lubrication. Special analysis and proprietary stainless steels are identified by trade names, some of which may resemble aisi numbers. Web torque and pullout load. Web stainless steel bolt and machine screw torque reference. The above data is based on a dry installation and should not be used for a lubricated installation. Required torque = torque recommended x 0.75. The risk of galling or thread seizing can be reduced by: While all care has been taken with its preparation, no responsibility is accepted for the Web the following data tables are designed to be used as general guidance when installing stainless steel fasteners. All material included in this chart is advisory only, and its use by anyone. Web torque values stainless steel bolt table chart. 5)stainless steel fasteners tend to gall while being tightened. Web torque values for a2 or a4 metric stainless steel fasteners. For a307 grade a, 75% of 36,000 psi is utilized. Different lengths of thread engagement were analyzed Bolt and nut are both phosphated;

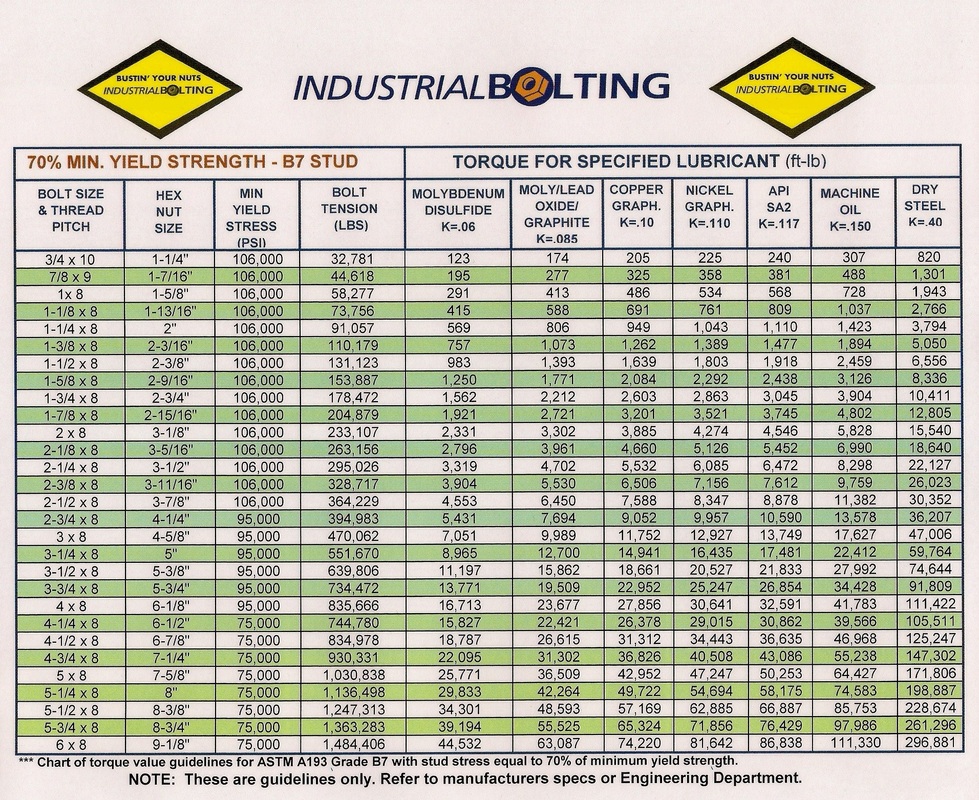

Torque Charts Industrial Torque Tools

Stainless Steel 316 Bolts and A4 S31600 Stud/ Hex Bolt/ Nuts/ Fasteners

Stainless Steel Torque Chart Website of julisalt!

FREE 7+ Sample Bolt Torque Chart Templates in PDF MS Word

FREE 7+ Sample Bolt Torque Chart Templates in PDF MS Word

304 Stainless Steel Metric Bolt Torque Chart A Visual Reference of

A270 Stainless Steel Hex Head Bolt A2 70 Bolt Torque & Size Chart

FREE 7+ Sample Bolt Torque Chart Templates in PDF MS Word

Metric Stainless Bolt Torque Chart

FREE 7+ Sample Bolt Torque Chart Templates in PDF MS Word

Web Remember, You May Need To Vary These Numbers Somewhat Based On The Individual Joint Or The Amount Of Fastener Lubrication.

This Table Is Offered As The Suggested Maximum Torque Values For Threaded Products And Is Only A Guide.

Web If Lubrication Has Been Applied To The Bolt And/Or The Nut (Other Than The Normal Protective Oil Film), Multiply The Recommended Torque By The Appropriate Factor Shown In The Table.

Web Bolt Torque Chart Reference Guides Include Grade 2, B7, A307, A325, Grade 8, A490, And Grade 5.

Related Post: