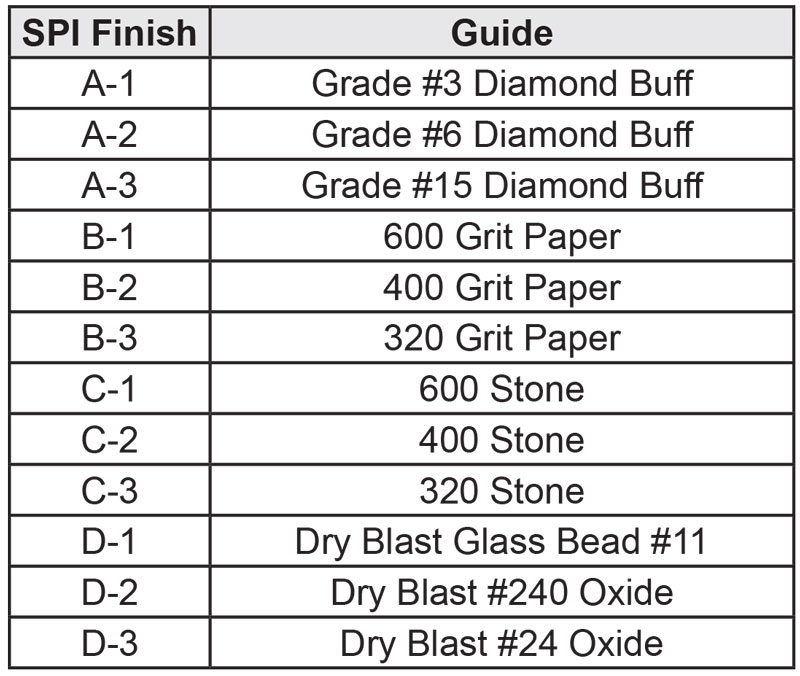

Spi Finish Chart

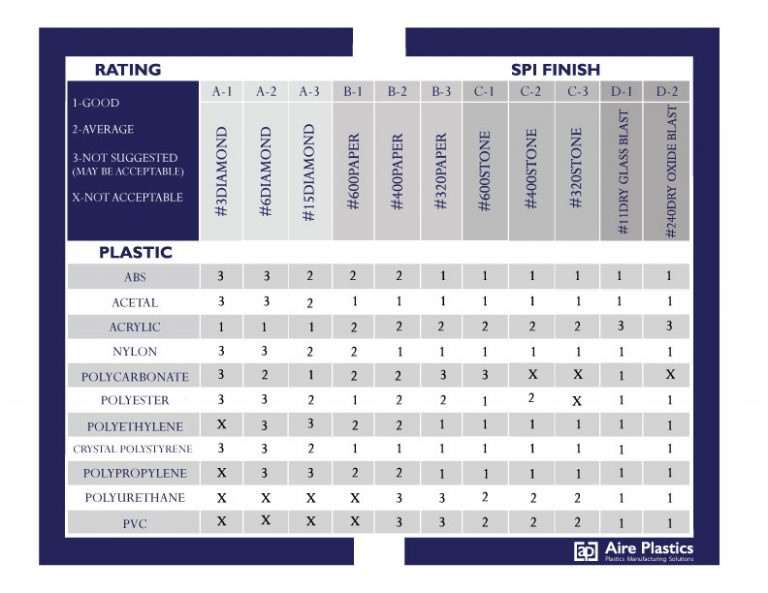

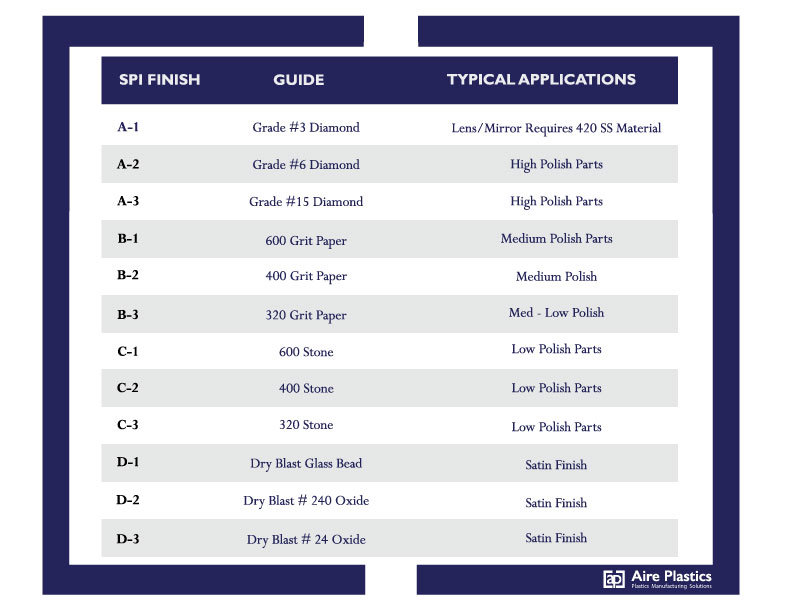

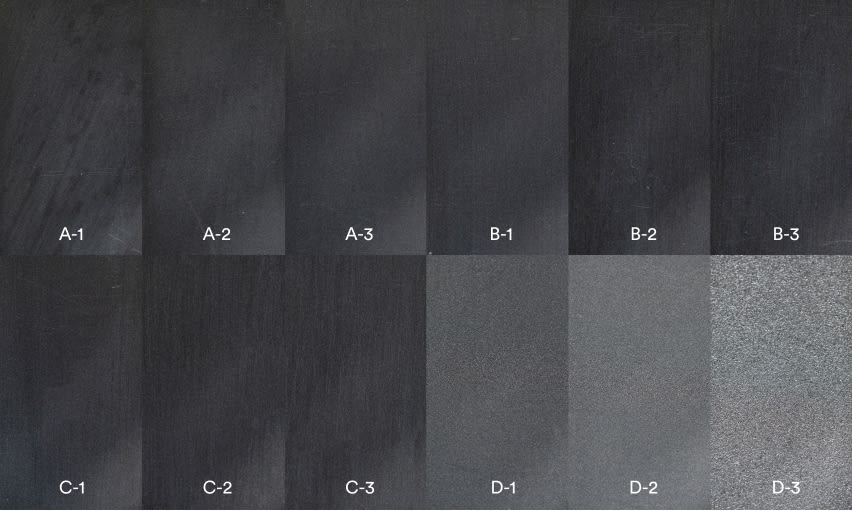

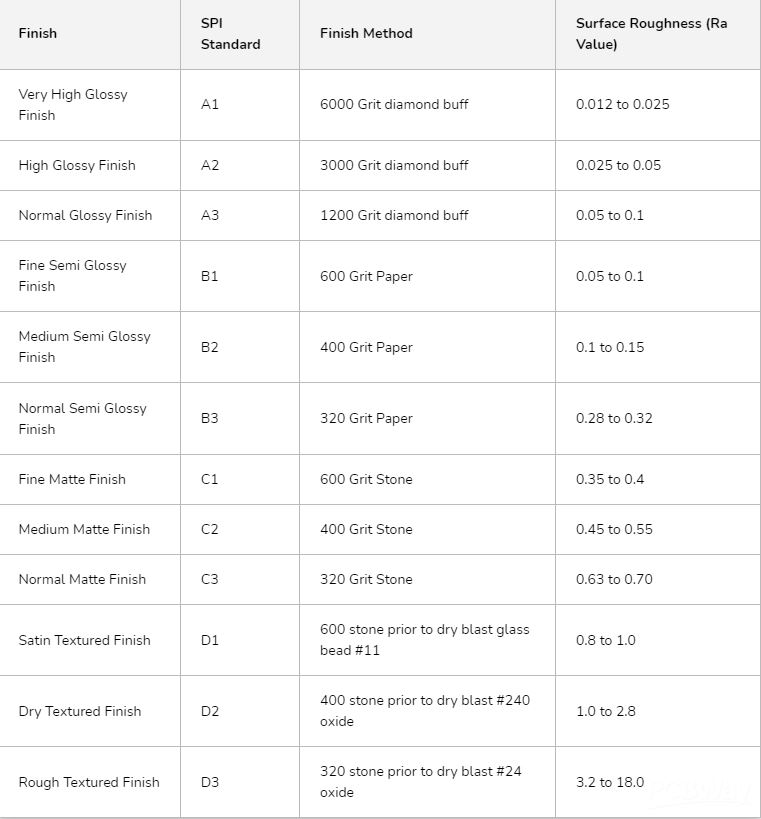

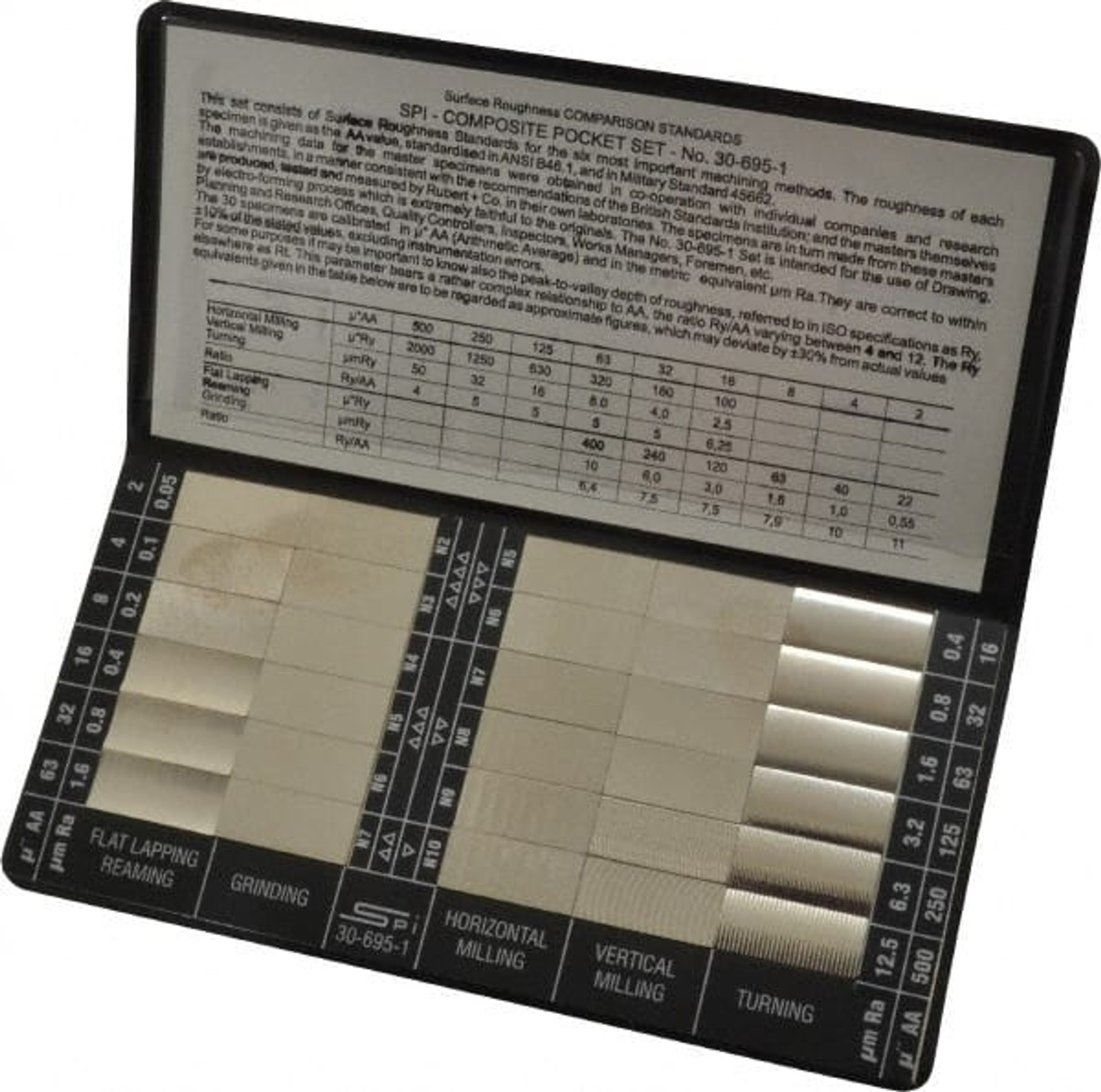

Spi Finish Chart - Surface finish is a critical aspect of injection molded parts. Web spi mold finish guide, spi mold finish standards, plastic surface finish standards, spi surface finish chart, plastic injection molded parts surface finishes, surface roughness. Quality verified by apple, samsung, space. Web the society of plastics industry (spi) has set several standard finishing procedures that result in different part surface finishes. English (us) spi surface finishes are. Web spi surface finish chart for roughness technology. Grade #3, 6000 grit diamond buff : 25+ available plastics to choose. Web spi standard finishing method roughness average ra (um) super high glossy ; Web learn everything about spi finish, the american standard for plastic injection molds with 12 grades from a1 to d3. Web spi mold finish guide, spi mold finish standards, plastic surface finish standards, spi surface finish chart, plastic injection molded parts surface finishes, surface roughness. Web the society of plastics industry (spi) has set several standard finishing procedures that result in different part surface finishes. Web spi surface finish chart. Web these standardized finishes are called spi mold finishes. We. For injection molds that do not need. 25+ available plastics to choose. Web spi mold finish guide, spi mold finish standards, plastic surface finish standards, spi surface finish chart, plastic injection molded parts surface finishes, surface roughness. Web finish spi* standard finishing method typical surface roughness ra (μm) super high glossy finish: What is the vdi 3400 standard? Web there are twelve grades of finishes specified by the spi in four categories that range from shiny to dull. For injection molds that do not need. The first step with mold polishing is to find an area in the shop that is clean and is away from other machining and polishing operations. We will focus on various spi surface. Web the spi mold finish standards are pretty straightforward. English (us) spi surface finishes are. What is the vdi 3400 standard? Web complete 12 spi surface finish grades: From spi a1 to spi d3. The first step with mold polishing is to find an area in the shop that is clean and is away from other machining and polishing operations. Quality verified by apple, samsung, space. Web spi surface finish chart for roughness technology. Web there are twelve grades of finishes specified by the spi in four categories that range from shiny to dull.. For injection molds that do not need. Web spi standard finishing method roughness average ra (um) super high glossy ; Web these standardized finishes are called spi mold finishes. Web there are twelve grades of finishes specified by the spi in four categories that range from shiny to dull. Web finish spi* standard finishing method typical surface roughness ra (μm). The first step with mold polishing is to find an area in the shop that is clean and is away from other machining and polishing operations. Web spi mold finish guide, spi mold finish standards, plastic surface finish standards, spi surface finish chart, plastic injection molded parts surface finishes, surface roughness. The mold can be textured with. Web the type. See the spi finish chart, the finishing methods, the. Grade #3, 6000 grit diamond buff : Web the most common finishes used include those from the society of the plastics industry (spi), which are a set of standard mold finishes starting from heavily. Web there are twelve grades of finishes specified by the spi in four categories that range from. Web complete 12 spi surface finish grades: The spi mold finish ratings allow you to specify a general mold surface finish. Web the society of plastics industry (spi) has set several standard finishing procedures that result in different part surface finishes. Surface finish is a critical aspect of injection molded parts. Quality verified by apple, samsung, space. See the spi finish chart, the finishing methods, the. Grade #3, 6000 grit diamond buff : Surface finish is a critical aspect of injection molded parts. The mold finish, in particular, directly impacts the surface quality and appearance of the. Web the type of metal, amount of material, and condition of your mold determine the type of finishing stones required. The mold can be textured with. Each grade has different requirements for allowable deviation from perfect,. Web learn everything about spi finish, the american standard for plastic injection molds with 12 grades from a1 to d3. The mold finish, in particular, directly impacts the surface quality and appearance of the. Quality verified by apple, samsung, space. Web there are twelve grades of finishes specified by the spi in four categories that range from shiny to dull. Samples of each polish type can be purchased through the spi store; 25+ available plastics to choose. Web spi mold finish guide, spi mold finish standards, plastic surface finish standards, spi surface finish chart, plastic injection molded parts surface finishes, surface roughness. Web these standardized finishes are called spi mold finishes. Web what are spi surface finishes? Surface finish is a critical aspect of injection molded parts. Web spi surface finish chart. Web the type of metal, amount of material, and condition of your mold determine the type of finishing stones required to get your stoning marks to 600 grit or finer. What’s the best spi surface finish for your injection molded part? Web this mold level chart describes all twelve spi surface finishes, including the finishing method and typical surface roughness.

Spi Surface Finish Chart

spi surface finish Plastopia

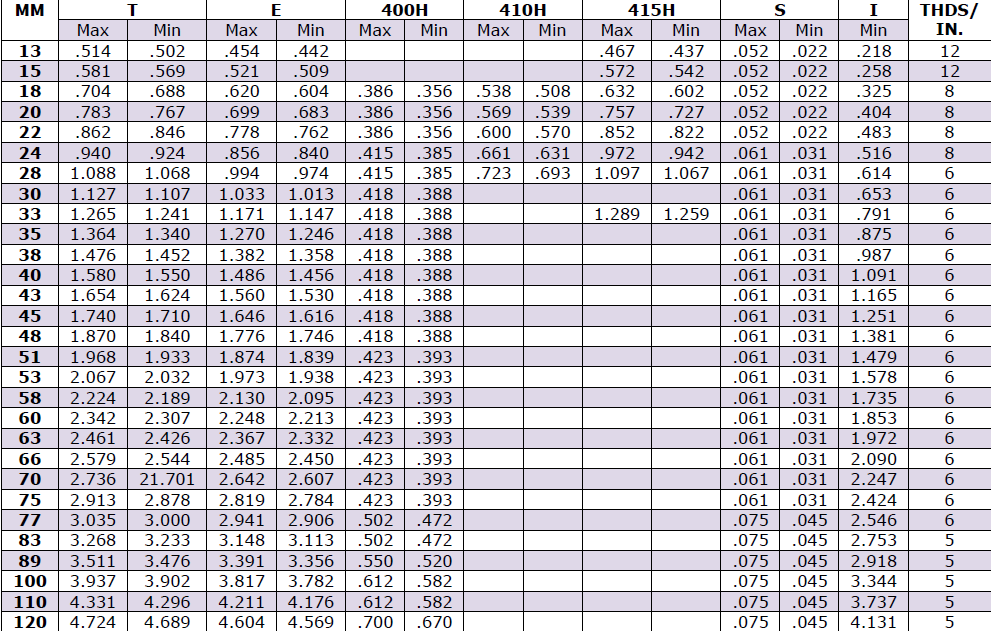

Neck Finish Information MJS Packaging

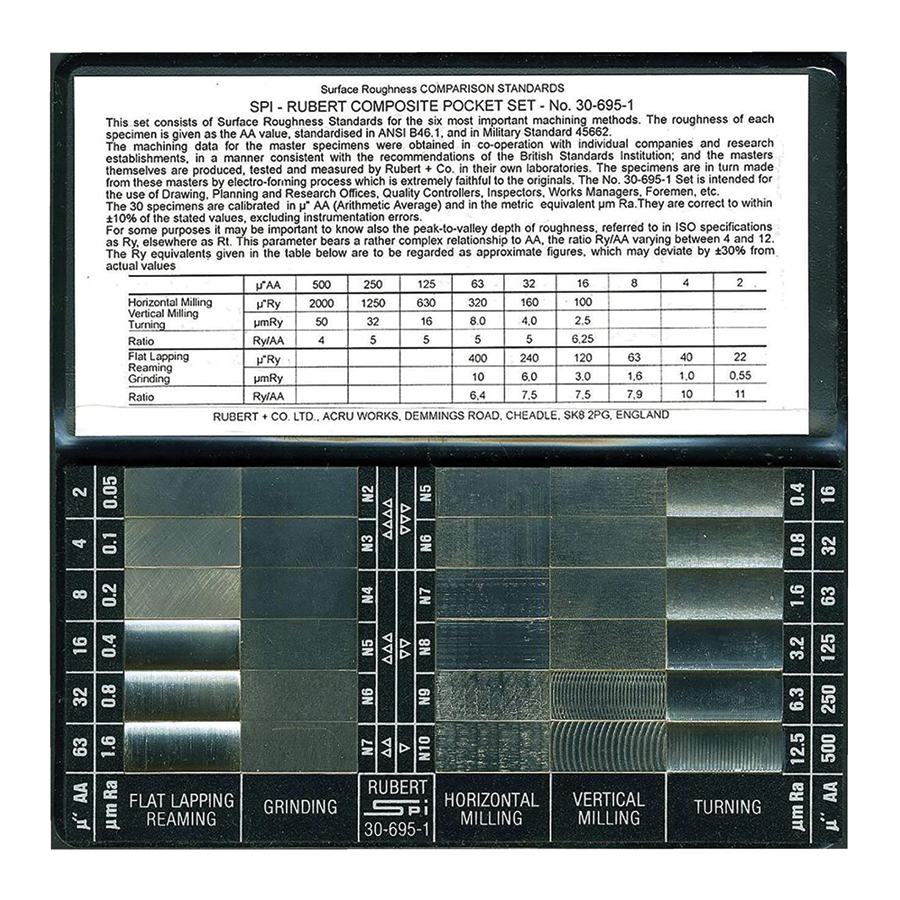

SPI® Surface Roughness Standards Sets WEB 306951

SPI Mold Finish Guide and Guidelines Injection Molding Texas

Spi Surface Finish Chart

Spi Surface Finish Chart

SPI Mold Finish Surface Finish For Injection Molded Parts Injection

SPI surface finish standard with metal scale SPI Surface Finish

SPI Surface Roughness Standards, Surface Finish Comparator 306951

We Will Focus On Various Spi Surface Finishes, Roughness Values And Recommendations For Plastic Parts.

For Injection Molds That Do Not Need.

Grade #3, 6000 Grit Diamond Buff:

What Is The Vdi 3400 Standard?

Related Post: