Solder Melting Temperature Chart

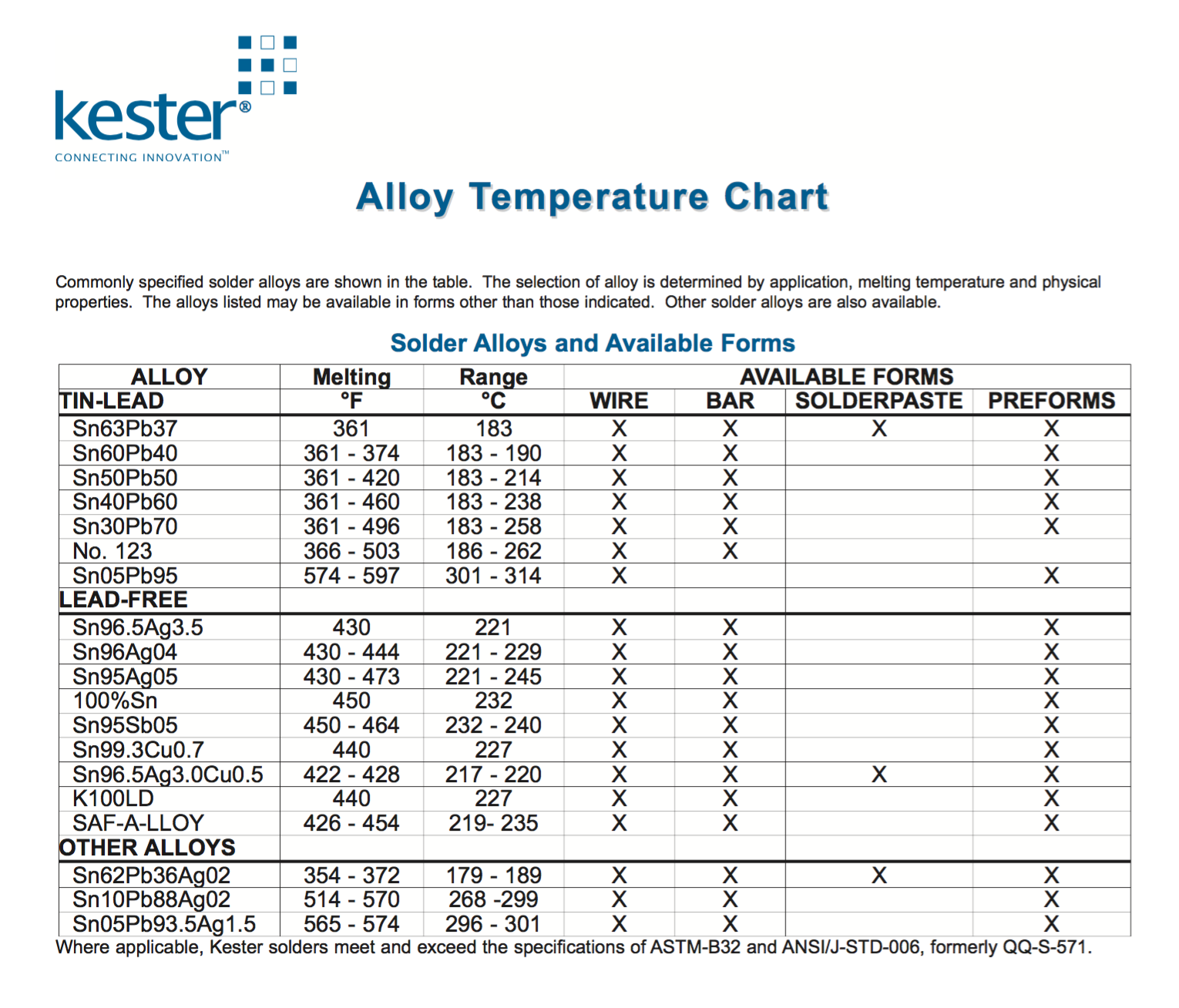

Solder Melting Temperature Chart - This can be used for several applications, and the temperatures they can reach vary depending on the solder and their intended purpose. Web when assembling a piece start with the highest melting point solder. In this article, i will cover some topics to help you better understand these practical tools. When choosing a solder alloy, there are a few questions that need to be answered. The selection of alloy is determined by application, melting temperature and physical properties. This temperature chart shows the different solders that are available and their melting temperatures. What are the types of soldiers and their melting points? Web this guide covers the significance of the melting point of solder, why it’s important, factors affecting it, common solder alloys, and tools for measuring solder melting temperature. These values are for some of the most common solders. Choosing the best silver solder for jewelry depends on your project and process. The choice of specific solder alloys depends on their melting point, chemical reactivity, mechanical properties, toxicity, and other properties. The higher the zinc content, the lower the melting temperature. Web this guide covers the significance of the melting point of solder, why it’s important, factors affecting it, common solder alloys, and tools for measuring solder melting temperature. Other solder alloys. Commonly specified solder alloys are shown in the table. These values are for some of the most common solders. Your soldering iron is also important. The selection of alloy is determined by application, melting temperature and physical properties. Web solders comprise dozens of alloy compositions, with melting points as low as 90° to as high as 400°c. As you progress through assembly use a lower temperature solder. What type/size does the power need to be for the smallest feature in the application? What are the types of soldiers and their melting points? Other solder alloys are also available. Web a composition of tin (30%) and lead (70%) turns into liquid at a higher temperature of 491°f (255°c). And the hotter the iron tip, the higher the risk of burning your fingers, if care isn’t taken. These values are for some of the most common solders. This can be used for several applications, and the temperatures they can reach vary depending on the solder and their intended purpose. Web this guide covers the significance of the melting point. For instance, the sn10/pb88/ag2 alloy containing 88% lead has a 570°f (299°c) melting point. These values are for some of the most common solders. Selecting a soldering temperature for your iron. Web most solder melts around 180 to 190 degrees celsius, that is 360 to 370 degrees fahrenheit. Commonly specified solder alloys are shown in the table. In this article, i will cover some topics to help you better understand these practical tools. And the hotter the iron tip, the higher the risk of burning your fingers, if care isn’t taken. The choice of specific solder alloys depends on their melting point, chemical reactivity, mechanical properties, toxicity, and other properties. The alloys listed may be available in. This is a critical factor to consider when soldering, as using a solder with the wrong melting point can lead to weak or incomplete joints. This temperature chart shows the different solders that are available and their melting temperatures. Selecting a soldering temperature for your iron. Soldering irons use a resistor to generate heat to melt solder. The selection of. Web a composition of tin (30%) and lead (70%) turns into liquid at a higher temperature of 491°f (255°c) due to the high lead concentration. National institute of standards and technology. The selection of alloy is determined by application, melting temperature and physical properties. To avoid conspicuous solder lines, use the highest temperature solder feasible. Web this chart includes the. The choice of specific solder alloys depends on their melting point, chemical reactivity, mechanical properties, toxicity, and other properties. Web this guide covers the significance of the melting point of solder, why it’s important, factors affecting it, common solder alloys, and tools for measuring solder melting temperature. National institute of standards and technology. What are the types of soldiers and. Other solder alloys are also available. The choice of specific solder alloys depends on their melting point, chemical reactivity, mechanical properties, toxicity, and other properties. When choosing a solder alloy, there are a few questions that need to be answered. Save this chart for quick reference. For instance, the sn10/pb88/ag2 alloy containing 88% lead has a 570°f (299°c) melting point. Web solders comprise dozens of alloy compositions, with melting points as low as 90° to as high as 400°c. Web when assembling a piece start with the highest melting point solder. Web most solder melts around 180 to 190 degrees celsius, that is 360 to 370 degrees fahrenheit. Other solder alloys are also available. Web melting temperatures of solder are determined by the zinc content: This temperature chart shows the different solders that are available and their melting temperatures. This article will explore different solder types and their melting points. What are the types of soldiers and their melting points? The selection of alloy is determined by application, melting temperature and physical properties. The selection of alloy is determined by application, melting temperature and physical properties. Solder is a metallic material that is used to connect metal workpieces. Web do you have little or no experience in soldering? For instance, the sn10/pb88/ag2 alloy containing 88% lead has a 570°f (299°c) melting point. The alloys listed may be available in forms other than those indicated. Your soldering iron is also important. When choosing a solder alloy, there are a few questions that need to be answered.

Solder Melting Point Chart

Silver Solder Melting Temperature Chart

Solder Melting Point Chart

Eutectic vs Leadfree solder Iron Tip temperature Japanpeuf

Solder Melting Point Chart

kester solder melting points

soldering Bismuth or Indium solder how do they compare?

Solder Melting Temperature Chart

Silver Solder Melting Temperature Chart

Silver Solder Melting Temperature Chart

In This Article, I Will Cover Some Topics To Help You Better Understand These Practical Tools.

What Type/Size Does The Power Need To Be For The Smallest Feature In The Application?

A Soldering Iron Melting Solder To Join Two Wires.

Soldering Irons Use A Resistor To Generate Heat To Melt Solder.

Related Post: