Small Block Chevy Valve Adjustment Chart

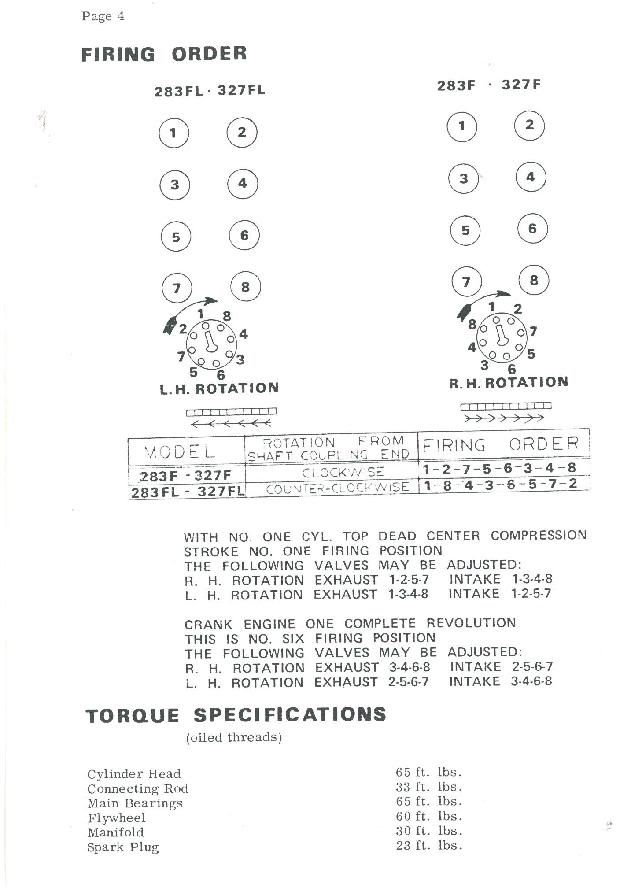

Small Block Chevy Valve Adjustment Chart - Web here we show you how to set valve lash on a small block chevy using a hydraulic lift camshaft in just eight steps. 44k views 3 years ago. Loosen the rocker slightly (if using roller rockers there is typically a. 602k views 4 years ago. Web here's a pic of a static valve adjustment sequence i constructed for a buddy. Remember, the opposite is engine firing order dependent. You only have to rotate the crank 90° for each adjustment. Starting with #1 cylinder, turn the engine over until the exhaust pushrod just begins to move up. This article uses the small and big block chevy engines as the example, so this would be the #6 cylinder. This is generally around 0.040 inches inboard. The video also briefly talks about firing. This is generally around 0.040 inches inboard. For other engines you will use the firing order that matches your engine to create a similar chart. This works on all engines with adjustable valve train. This chart is based upon opposite cylinders of your firing order. Web how can to tell when to adjust valves on a small block chevy. Starting with #1 cylinder, turn the engine over until the exhaust pushrod just begins to move up. The pushrod positioned the rocker over the valve, guided by. Step by step valve adjustment.more. Web here's a pic of a static valve adjustment sequence i constructed for a. This will place the hydraulic lifter plunger half way through it's travel. I crank the engine over two full revolutions, and i can no longer feel any compression on #1. After the engine has been thoroughly warmed up the valves may be adjusted with the engine shut of as follows: Web adjust intake #5 and exhaust #2. Most performance valve. You only have to rotate the crank 90° for each adjustment. I'm adjusting the valves on my 69 camaro, hydralic flat tappet. Step by step valve adjustment.more. 602k views 4 years ago. Why oil and fluid analysis makes your engine and transmission healthier. After the engine has been thoroughly warmed up the valves may be adjusted with the engine shut of as follows: This is generally around 0.040 inches inboard. I'm adjusting the valves on my 69 camaro, hydralic flat tappet. A more detailed explanation follows below the chart. Everyone thinks their way is the right way, which it very well. This chart is based upon opposite cylinders of your firing order. There is a ton of information out there for adjusting valves, and it can be very confusing at times. With engine in position to fire number 1 cylinder the following valves may be adjusted: This method doesn’t rely on any knowledge of a particular engine’s firing order. The video. For other engines you will use the firing order that matches your engine to create a similar chart. Web then, simply adjust the two valves on the companion cylinder. Web first, view this simple chart below for small and big block chevy engines. Why oil and fluid analysis makes your engine and transmission healthier. Loosen the rocker slightly (if using. There is a ton of information out there for adjusting valves, and it can be very confusing at times. That should automatically call for an sbc valve adjustment. Starting with #1 cylinder, turn the engine over until the exhaust pushrod just begins to move up. For hydraulic lifters you back the rocker of till you have ply, then you take. This chart is based upon opposite cylinders of your firing order. Web valve adjustment procedure for small and big block chevy. Web here we show you how to set valve lash on a small block chevy using a hydraulic lift camshaft in just eight steps. There is a ton of information out there for adjusting valves, and it can be. Remember, the opposite is engine firing order dependent. This chart is based upon opposite cylinders of your firing order. I adjust the half the intake and exhaust valves. Web you adjust #2,5,6,7, exhaust & #3,4,6,8, intake. A more detailed explanation follows below the chart. This chart is based upon opposite cylinders of your firing order. For hydraulic lifters you back the rocker of till you have ply, then you take out all the slack between the push rod & rocker, then you tighten the rocker nut half a turn. I adjust the half the intake and exhaust valves. Everyone thinks their way is the right way, which it very well. This method doesn’t rely on any knowledge of a particular engine’s firing order. For other engines you will use the firing order that matches your engine to create a similar chart. I crank the engine over two full revolutions, and i can no longer feel any compression on #1. I set the engine to tdc on #1, i can feel the compression blow on my thumb. Most performance valve jobs place the seat closer to the edge of the valve to improve flow. Starting with #1 cylinder, turn the engine over until the exhaust pushrod just begins to move up. That should automatically call for an sbc valve adjustment. This will place the hydraulic lifter plunger half way through it's travel. Web stem diameter (1) should be obvious, but look for the overall length (2), margin (3), head diameter (4), back angle and radius (5), seat width and angle (6), and back cut angle (7). Web adjust intake #5 and exhaust #2. Web using a long handled ratchet or breaker bar attached to the crank bolt, turn the engine over in the clockwise direction. This works on all engines with adjustable valve train.

How to Adjust Valves on A 350 Chevy (Explained)

sbc intake and exhaust valve Valve adjustment, Truck repair, Lashes

Small Block Chevy Valve Adjustment Chart

Small Block Chevy Valve Adjustment Chart

How to Adjust Valves on A 350 Chevy (Explained)

Small Block Chevy Valve Adjustment Chart

Small Block Chevy Valve Adjustment Chart

Small Block Chevy Valve Adjustment Chart

Small Block Chevy Valve Adjustment Chart

Best Way To Adjust Sbc Valves The gray tower

With Engine In Position To Fire Number 1 Cylinder The Following Valves May Be Adjusted:

The Pushrod Positioned The Rocker Over The Valve, Guided By.

Go Across The Top Row First, And Then The Bottom Row (Left To Right) By Putting The Corresponding Valve Above Or Below The Target Valve (The One You're Adjusting) At Teeter.

Remember, The Opposite Is Engine Firing Order Dependent.

Related Post: