Six Sigma Control Chart

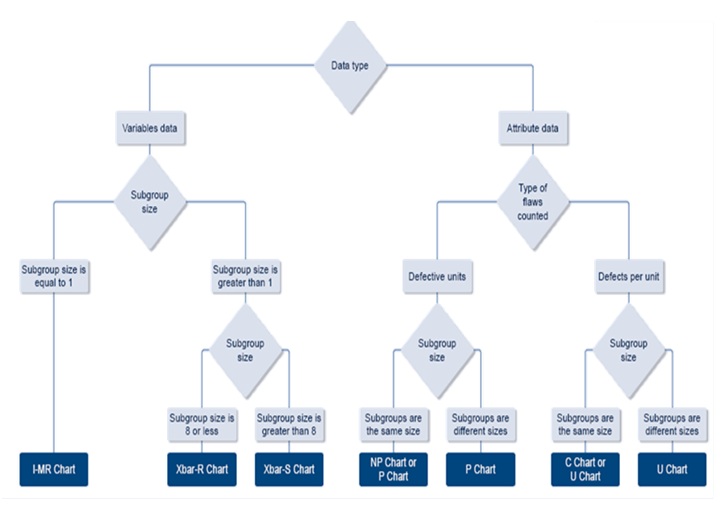

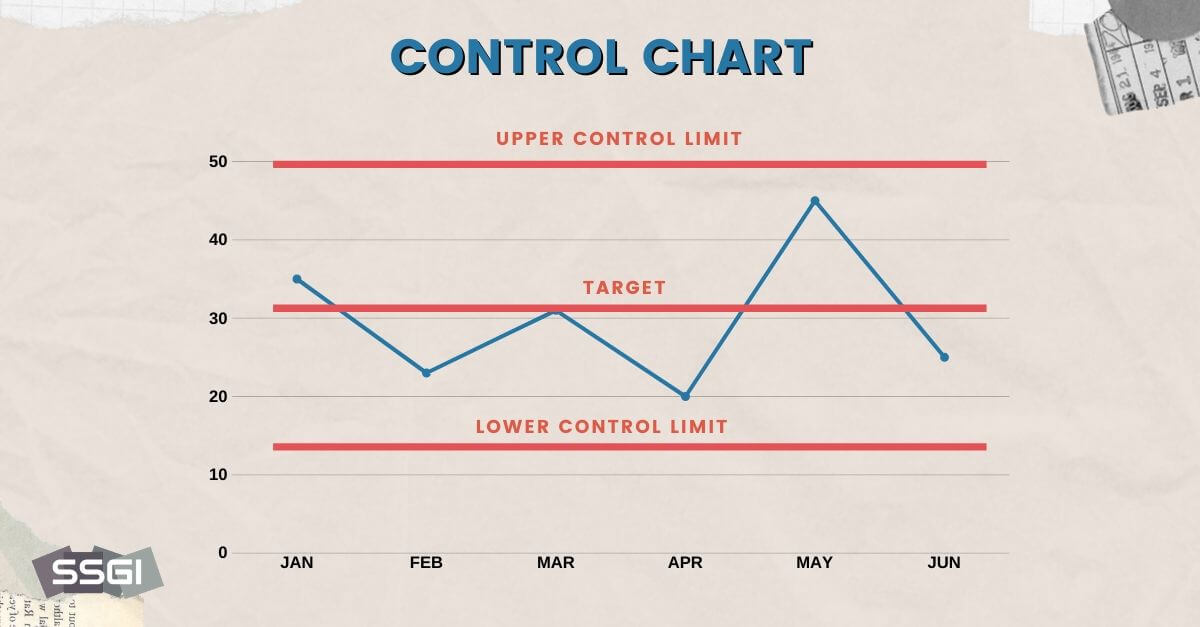

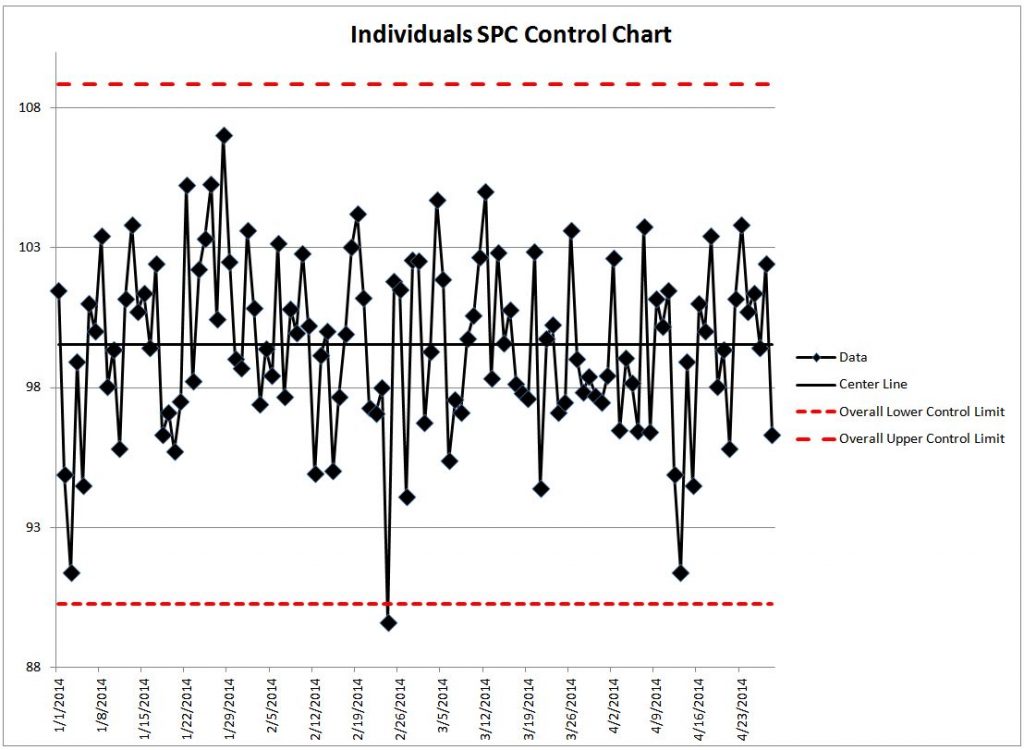

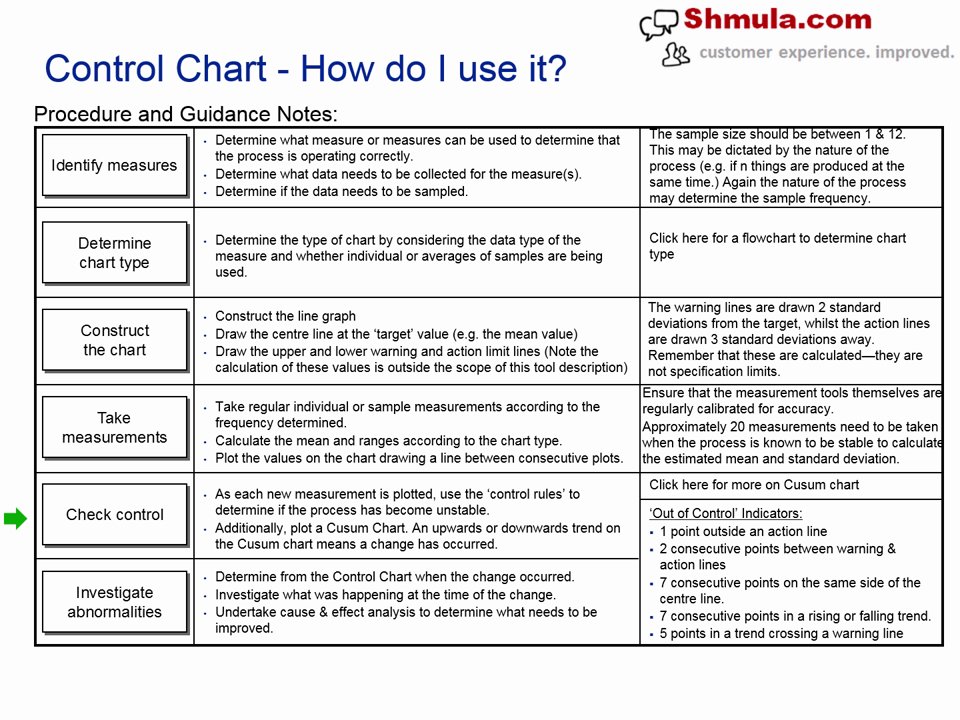

Six Sigma Control Chart - In this tutorial, we will explore the concept of six sigma, the importance of control charts, and the types of control charts used in six sigma. Web control charts are a key tool used in the six sigma methodology. Web six sigma control charts are an essential tool in the six sigma methodology, allowing businesses to monitor their processes and identify any variations or defects. It aims at achieving process stability and enhancing overall quality. Web control charts are time charts designed to display signals or warnings of special cause variation. Web the six sigma control chart is vital to the six sigma methodology. It also plays a role as a tool for ongoing control of a process. This way, you can easily see variation. Web in a six sigma project, we can use a control chart at the starting of the project as well as at the improve phase to implement some necessary improvement steps and adopt some corrective measures to keep the project under control. A control chart always has a central line for the average, an upper line for the upper control limit, and a lower line for the lower control limit. The remainder of this article will focus on the different types of centering and dispersion charts. Web control charts are crucial six sigma tools that help organizations monitor processes, identify variations, and drive improvements. Web in a six sigma project, we can use a control chart at the starting of the project as well as at the improve phase to. Web control charts are a key tool used in the six sigma methodology. A control chart always has a central line for the average, an upper line for the upper control limit, and a lower line for the lower control limit. Creating a control chart requires a graph that covers a period of time, a center line that shows the. A control chart always has a central line for the average, an upper line for the upper control limit, and a lower line for the lower control limit. Web the main focus of control charts is to detect and monitor the process variation. The control chart was invented by walter shewhart at bell labs in 1920. Web control charts stand. There are many types of spc control charts, though centering charts are used most often. Data are plotted in time order. Special cause variation, as distinct from common cause variation, refers to changes in process performance due to sporadic or rare events indicating that a process is not “in control.”. Web the control chart is a graphical display of quality. The remainder of this article will focus on the different types of centering and dispersion charts. Web control chart detects and monitors process variation over time. Data for the control chart can be selected randomly or over a specified time period. Control charts are a great tool for monitoring your processes over time. In six sigma studies, we read control. Web control charts are a key tool used in the six sigma methodology. Web the main focus of control charts is to detect and monitor the process variation. Control charts are a great tool for monitoring your processes over time. • lcl line shows the lower control limit. This allows us to see how the process behaves over time. Web six sigma control charts are known as process behavior charts. Web some of the more common control charts are the xbar and r chart, imr chart, p and np charts, and c and u charts. There are many types of spc control charts, though centering charts are used most often. Keep those six sigma dmaic improvements. It also plays. Web the control chart is a graph used to study how a process changes over time. An ideal example in this context can be a. Then prepare a control plan and reaction to remain an effective mechanism to monitor and control the process. Web the descriptions below provide an overview of the different types of control charts to help practitioners. Web the control chart is a graphical display of quality characteristics that have been measured or computed from a sample versus the sample number or time. The remainder of this article will focus on the different types of centering and dispersion charts. There are many types of spc control charts, though centering charts are used most often. In six sigma. The charts help us track process statistics over time and help us understand the causes of the variation. The remainder of this article will focus on the different types of centering and dispersion charts. Web the primary statistical process control (spc) tool for six sigma initiatives is the control chart — a graphical tracking of a process input or an. Web the primary statistical process control (spc) tool for six sigma initiatives is the control chart — a graphical tracking of a process input or an output over time. Web the control chart is a graphical display of quality characteristics that have been measured or computed from a sample versus the sample number or time. Web control chart detects and monitors process variation over time. Web six sigma control charts are an essential tool in the six sigma methodology, allowing businesses to monitor their processes and identify any variations or defects. Web in a six sigma project, we can use a control chart at the starting of the project as well as at the improve phase to implement some necessary improvement steps and adopt some corrective measures to keep the project under control. An ideal example in this context can be a. Then prepare a control plan and reaction to remain an effective mechanism to monitor and control the process. Web the descriptions below provide an overview of the different types of control charts to help practitioners identify the best chart for any monitoring situation, followed by a description of the method for using control charts for analysis. Web a six sigma control chart is a simple yet powerful tool for evaluating the stability of a process or operation over time. Keep those six sigma dmaic improvements. Control charts are a great tool for monitoring your processes over time. A control chart always has a central line for the average, an upper line for the upper control limit, and a lower line for the lower control limit. In six sigma studies, we read control charts in the control phase, like the statistical process cont control chart (spc chart). Control charts help a user to identify special causes of variation, shifts, trends and cycles. Special cause variation, as distinct from common cause variation, refers to changes in process performance due to sporadic or rare events indicating that a process is not “in control.”. Web the main focus of control charts is to detect and monitor the process variation.

Six Sigma DMAIC Process Control Phase Control Chart Selection

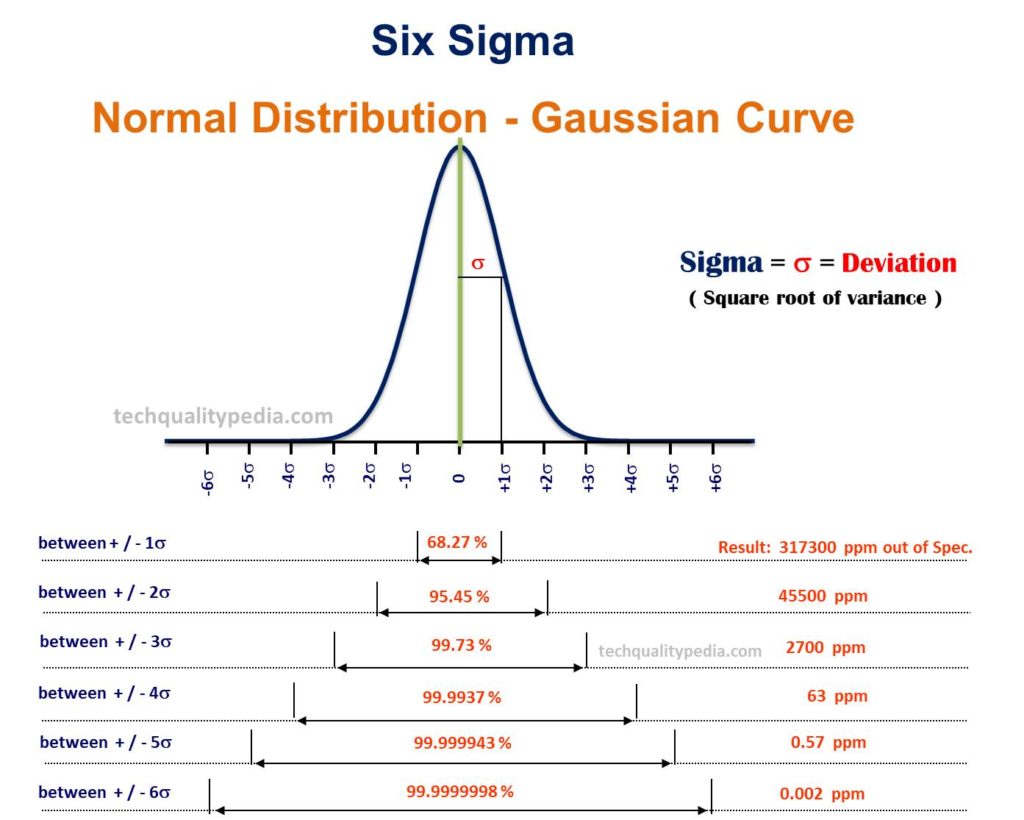

What is Six Sigma? Six Sigma Levels Methodology Tools

Lean Six Sigma The Definitive Guide (2020) SSGI

Six Sigma

6 Sigma Control Chart Introduction Toolkit from Leanscape

6 Sigma Control Chart Introduction Toolkit from Leanscape

Control chart Lean Manufacturing and Six Sigma Definitions

Control Chart Rules Six Sigma A Visual Reference of Charts Chart Master

Six Sigma Control Charts

What is Control Charts in Six Sigma and How to Create them?

It Can Be Collected As Single Data Points Or Rational Subgroups Of Data.

Creating A Control Chart Requires A Graph That Covers A Period Of Time, A Center Line That Shows The Results Of A Process During That Time, And Upper And Lower Control Limits That Indicate Whether Process.

Know How To Use A Control Chart Along With The Advantages Of Implementing Six Sigma Chart.

It Also Plays A Role As A Tool For Ongoing Control Of A Process.

Related Post: