Silage Bag Capacity Chart

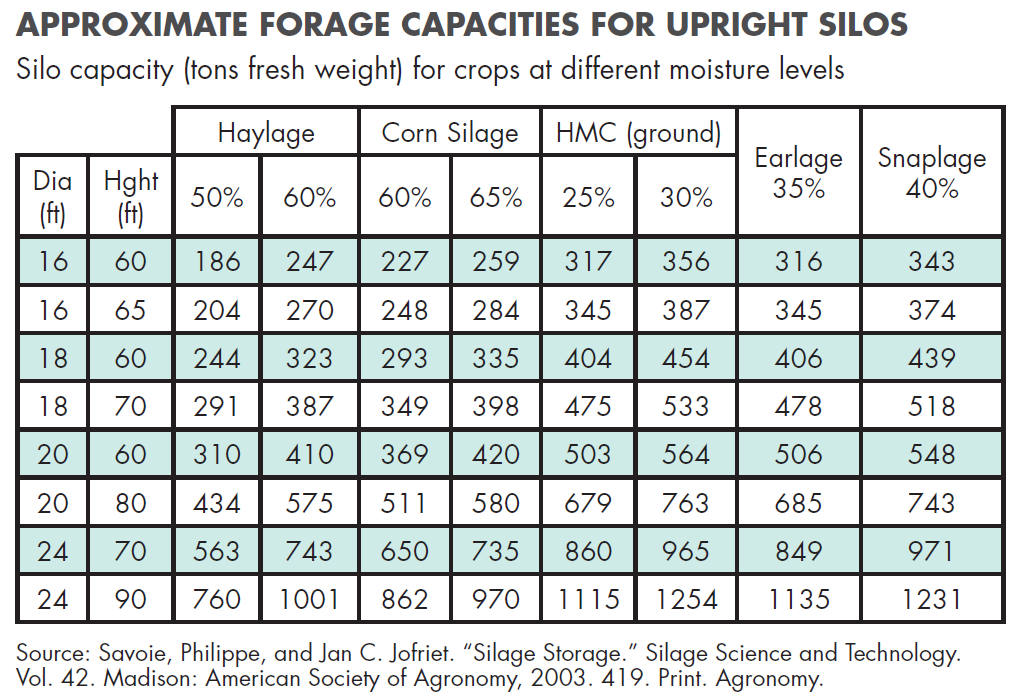

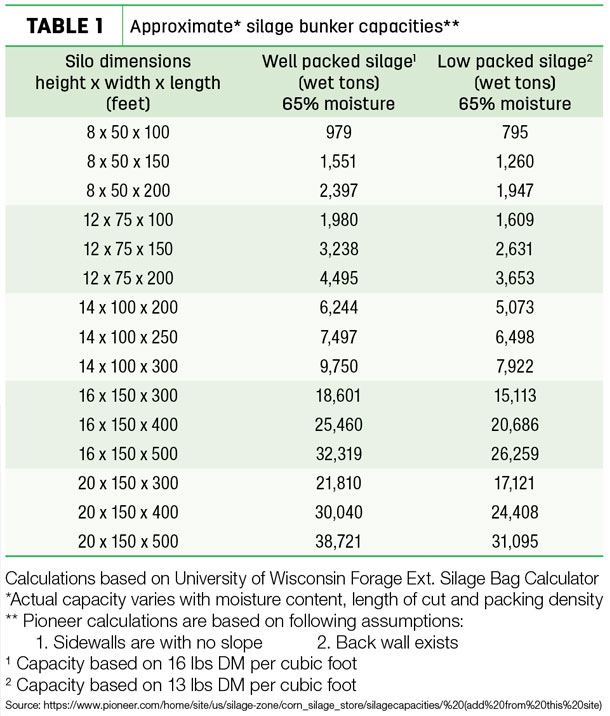

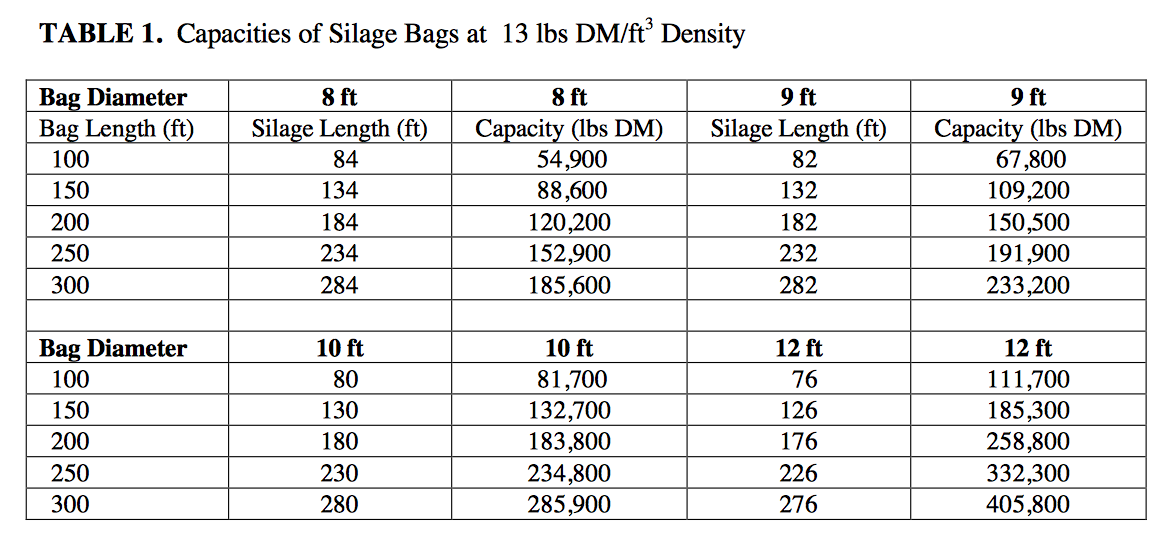

Silage Bag Capacity Chart - The machinery needed for filling the bags is the only thing you’ll need. V = 3.14 × (d2 ÷ 4) × l. Begin by downloading the silo bag capacity spreadsheet: Web for corn silage the recommended tlc is 3/8 inch without a processor or 1/2 to 3/4 inch with a processor. Web with modern high capacity silage baggers, grain baggers, and grain bag extractors, filling an agflex storage bag in the field saves you time, labor, storage, and fuel costs. Silage is the end product of the fermentation of a high moisture crop (40 to 80% water). Click here to download chart. Web when full length bags are used, the length of silage is the bag length minus the unused portion needed to seal each end of the bag. Exact tons or bushels are based on length of cut, moisture, variety, and pack density. Table 1 has been developed to show silo bag capacity based on the following assumptions. Packing silage into the bags may be accomplished via. This spreadsheet was developed to determine the number and size of silage storage bags and a pad upon which to place them for hay crop, whole plant corn crop and ground high moisture corn. We frequently get questions about the amount of silage in a silo bag. Of length, and the. The first record of a containment structure or “silo” in the u.s. See the calculations of various capacities. The amount of specific silages that can be stored in each bag varies with forage species, dry matter content and bag capacity. Click here to download chart. Web visualize how much of the slope would need to be “folded back” on itself. *actual capacity varies with moisture content, length of cut and packing density. See the calculations of various capacities. Today, our formulation features the latest in polymers science coupled with the most advanced manufacturing process. These numbers are estimated values only to provide a guide on total capacity. V = 3.14 × (d2 ÷ 4) × l. Begin by downloading the silo bag capacity spreadsheet: V = 3.14 × (d2 ÷ 4) × l. Click here to download chart. Web visualize how much of the slope would need to be “folded back” on itself to square up the sides of the pile to determine average width. Silage bags have the least infrastructure necessary to store and maintain. Silage is the end product of the fermentation of a high moisture crop (40 to 80% water). Exact tons or bushels are based on length of cut, moisture, variety, and pack density. Web the dry matter density can vary from bag to bag and is based on machine type and adjustment as well as forage type. Improvements were also seen. V = volume (ft3) spacespaciid =. Web silage dry matter intake by 4 percent and milk yield by 2.6 pounds per cow per day (shown below). Exact tons or bushels are based on length of cut, moisture, variety, and pack density. Web with these designs, longer bags can potentially be used. 1 capacity based on 16 lbs. Click here to download chart. The quantity of dry matter in the bag is the volume multiplied times the dry matter density. V = 3.14 × (d2 ÷ 4) × l. This spreadsheet requires microsoft excel. Web with modern high capacity silage baggers, grain baggers, and grain bag extractors, filling an agflex storage bag in the field saves you time,. Web silage bag capacity. Our silage bags are produced using a unique resin, resulting in a bag that: The first record of a containment structure or “silo” in the u.s. 2 capacity based on 13 lbs. Web approximate silage bunker, pile and bag capacities. V = 3.14 × (d2 ÷ 4) × l. Is during the late 1800s. See the calculations of various capacities. Packing silage into the bags may be accomplished via. Begin by downloading the silo bag capacity spreadsheet: Pioneer strategic account manager jim smith is back for another installment of the silage zone to help you get the most out of your silage storage. Web silage dry matter intake by 4 percent and milk yield by 2.6 pounds per cow per day (shown below). 2 capacity based on 13 lbs. Our silage bags are produced using a unique. Silage bags have the least infrastructure necessary to store and maintain silage. Safely minimize shrink and preserve quality in storing silage. One way to estimate this value is to calculate the volume in the bag and multiply by its density. The best way to measure total capacity is weighing each load before storing forage or grain. Speed up your grain harvest by filling an agflex bag in the field instead of trucking grain long distances for storage. Web the dry matter density can vary from bag to bag and is based on machine type and adjustment as well as forage type. The first record of a containment structure or “silo” in the u.s. The volume of a round bag is calculated as: Begin sampling whole plant moisture when the corn kernel contains about 80% milk. Of length, and the necessary silage bunker cover width. Web with modern high capacity silage baggers, grain baggers, and grain bag extractors, filling an agflex storage bag in the field saves you time, labour, storage, and fuel costs. We frequently get questions about the amount of silage in a silo bag. Plantarum mtd/1 per g of feed Calculations based on university of wisconsin forage ext. Lallemand animal nutrition www.lallemandanimalnutrition.com tel: Web with these designs, longer bags can potentially be used.

Silage Bag Capacity Charts Online Shopping

Details more than 74 bag capacity calculator best esthdonghoadian

Up North Plastics Silage Bags Bag Man, LLC Agricultural Sales

Details 54+ silage bags vs bunkers latest in.cdgdbentre

Silage Bag Capacity Chart

Silage Inform Nutrition

Up North Plastics Silage Bags Bag Man, LLC Agricultural Sales

Silage Bag Capacity Chart

Silage Bag Capacity

Approximate Silage Bunker, Pile and Bag Capacities

Speed Up Your Grain Harvest By Filling An Agflex Bag In The Field Instead Of Trucking Grain Long Distances For Storage.

The Quantity Of Dry Matter In The Bag Is The Volume Multiplied Times The Dry Matter Density.

Silage Is The End Product Of The Fermentation Of A High Moisture Crop (40 To 80% Water).

This Spreadsheet Requires Microsoft Excel.

Related Post: