Sheet Metal Deep Drawing

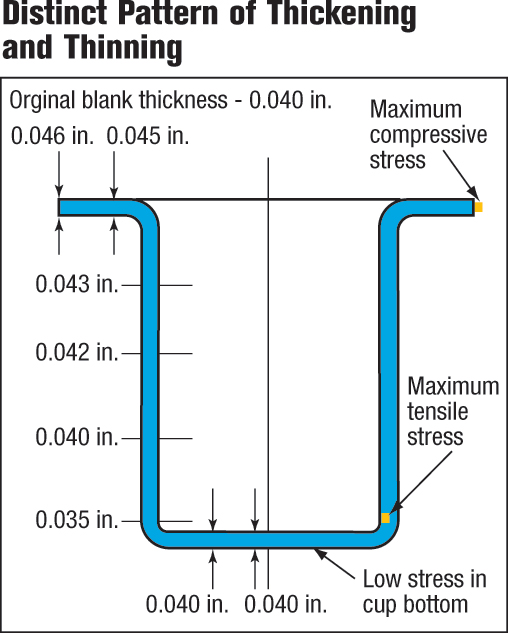

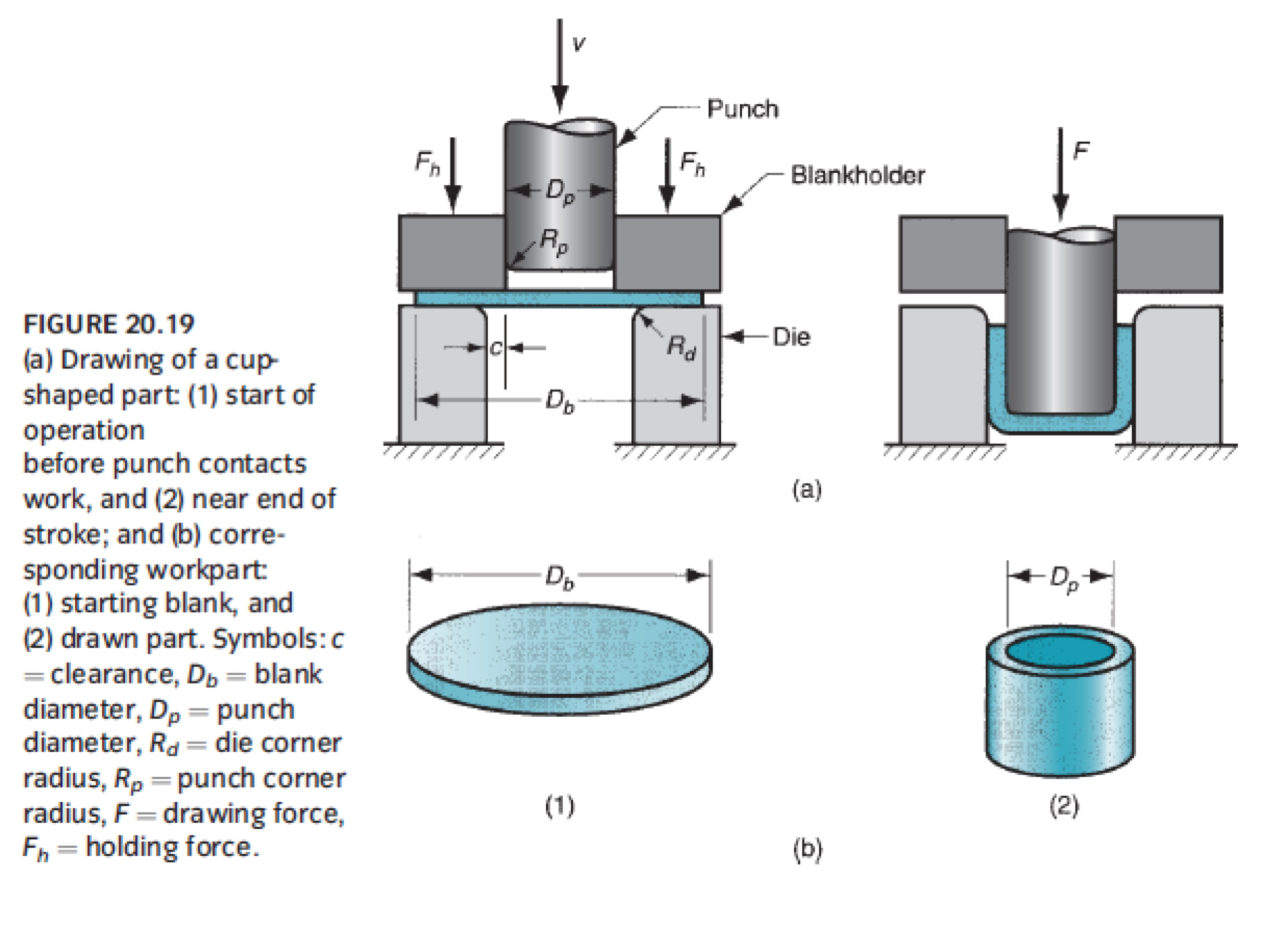

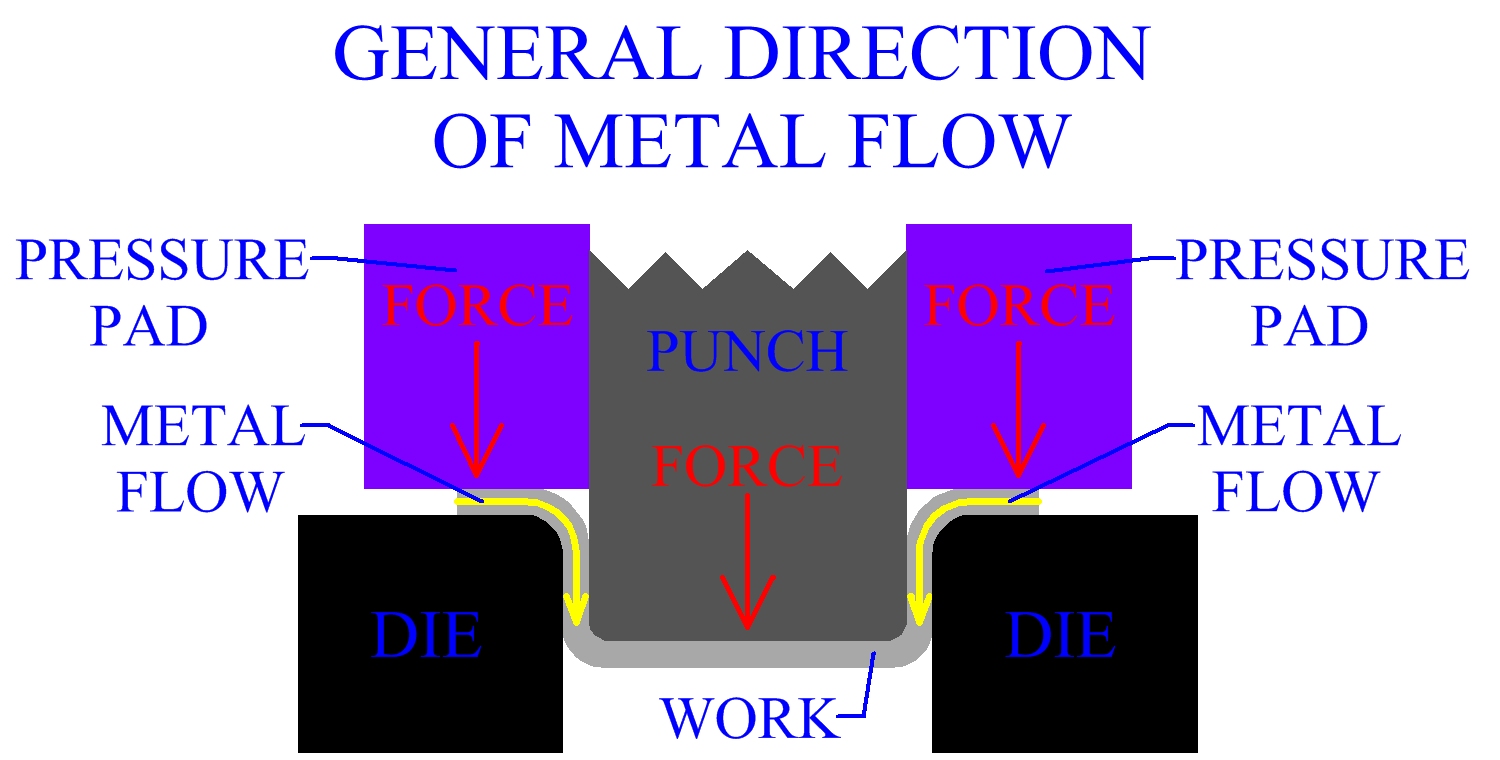

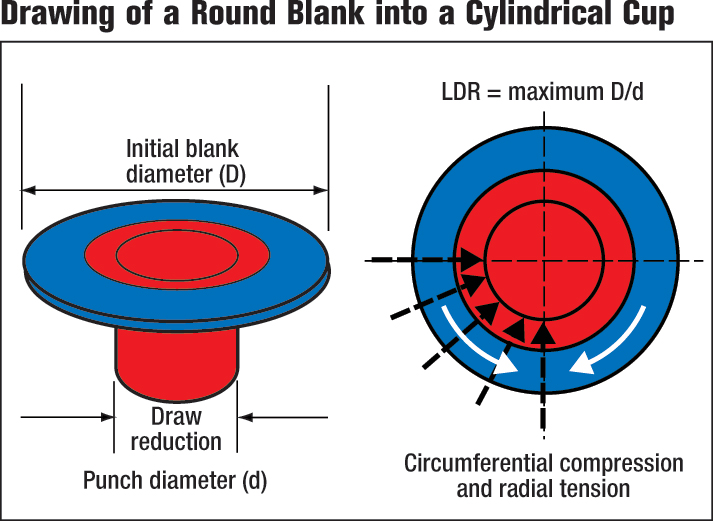

Sheet Metal Deep Drawing - Deep drawing is a processing method that uses a drawing die to press the flat blank into various open hollow parts or process the manufactured hollow parts into other shapes of hollow parts under the pressure of a press. Importance of accurate sheet metal drawings. Web deep drawing is one of the most frequently used metal forming processes. Web the deep drawing process with a rigid tool is one of the widely used forming processes, which is considered as a sheet forming process. Apart from its use in many other sectors, it is applied in the automotive industry for the manufacturing of car body parts. The depth of the drawn parts often exceeds their diameter. Web our team is highly experienced in progressive die stamping, deep drawing, piercing, forming, coining, and more to deliver quality solutions for your unique project. Web in general, deep drawing operates as a process of metal forming where the end goal is to create intricate parts with fine details. Our services our services our services. 1.when the sheet is pulled into the die cavity, the tensile force is applied to the bottom area, the radius of the punch, and the. The process is considered deep drawing when the depth of the drawn part exceeds its diameter. Deep drawing is a sheet metal forming process by which a sheet metal blank is slightly clamped along its perimeter by a blank holder and radially drawn into a forming die by use of a punch. 5.7k views 10 months ago. Web our team. [1] it is thus a shape transformation process with material retention. Web sheet metal is drawn in either hydraulic or mechanical presses. This process is the combination of metal forming process and sheet metal process. Applications of sheet metal drawing include automotive parts, aerospace components, beverage cans, and household appliances. Web deep drawing is one of the most frequently used. Deep drawing is a metal forming process for creating seamless, sheet metal parts that are closed on one end and have a depth greater than their radius. Our services our services our services. [1] it is thus a shape transformation process with material retention. Deep drawing is a process which is used to create cylindrical components from sheet metal. The. Web sheet metal is drawn in either hydraulic or mechanical presses. Apart from its use in many other sectors, it is applied in the automotive industry for the manufacturing of car body parts. Web the deep drawing process with a rigid tool is one of the widely used forming processes, which is considered as a sheet forming process. Web deep. Can deep drawing be used for all metals? The article summarizes the defects in drawing and factors considered in press selection for drawing. As mentioned, the punch and die setup is somewhat similar to a sheet metal cutting operation, such as punching or blanking. This process is the combination of metal forming process and sheet metal process. Deep drawing is. 1.when the sheet is pulled into the die cavity, the tensile force is applied to the bottom area, the radius of the punch, and the. 5.7k views 10 months ago. The definition of deep drawing. Web sheet metal is drawn in either hydraulic or mechanical presses. It finds application in various industries but is best known for its use in. Deep drawing is a metal forming process for creating seamless, sheet metal parts that are closed on one end and have a depth greater than their radius. Web deep drawing is a sheet metal forming process that involves complex material flow and force distributions. Web deep drawing is one of the most widely used processes in sheet metal forming. Two. The metal thickness, the metal type, and the blank size. Web what is deep drawing in sheet metal? Web what is deep drawing? It explains the types of dies used for drawing sheet metal and the effects of process variables and material variables on deep drawing. Apart from its use in many other sectors, it is applied in the automotive. Deep drawing is a sheet metal forming operation where sheet metal blank is drawn into hollow shapes by utilizing the combination of tensile and compressive forces. Web deep drawing is one of the most frequently used metal forming processes. Why is deep drawing used? Deep drawing is a metal forming process for creating seamless, sheet metal parts that are closed. Our services our services our services. [1] it is thus a shape transformation process with material retention. Web deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. The metal thickness, the metal type, and the blank size. Deep drawing produces a. The deep drawing process is a forming process which occurs under a combination of tensile and compressive conditions. The process is considered deep drawing when the depth of the drawn part exceeds its diameter. Web what is deep drawing? This process is the combination of metal forming process and sheet metal process. Deep drawing is a process which is used to create cylindrical components from sheet metal. Web the ultimate guide to metal deep drawing. Learn how the process works, what typical challenges are, and what you need to consider when it comes to tooling. Materials include aluminum, malleable metal, brass, bronze, carbon steel, copper, kovar® & stainless steel. Can deep drawing be used for all metals? Successful deep drawing depends on many factors. The metal thickness, the metal type, and the blank size. We specialize in all aspects of architectural sheet metal with years of experience in residential, commercial and historical landmarks. Web deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. Web in general, deep drawing operates as a process of metal forming where the end goal is to create intricate parts with fine details. Web sheet metal is drawn in either hydraulic or mechanical presses. The article summarizes the defects in drawing and factors considered in press selection for drawing.

Deep Drawing from A to Z MetalForming Magazine Article

Basics of Sheet Metal Design Consumer Hardware Guide Hardware FYI

Deep Drawing Of Sheet Metal

Deep Drawing from A to Z MetalForming Magazine Article

Deep drawing of sheet metal

Deep Drawing Sheet Metal D&H Industries

Sheet Metal Manufacturing Sinoway Industry Metal Parts

Deep Drawing Of Sheet Metal

Deep Drawing Metal Fabrication Service ABT Metals Manufacturing

Deep Drawing Of Sheet Metal

D Maximum Part Sizes With 300 Ton Press Rating & Cmm & Cad/Cam Design Capabilities.

Web The Deep Draw Sheet Metal Process Is Used To Create A Wide Range Of Products, From Simple Cylindrical Shapes To More Complex Geometries.

Deep Drawing Is The Process Of Converting A Blank Of Sheet Metal Into A Cylindrical Container With A Flat Or Hemispherical Base.

Web Our Team Is Highly Experienced In Progressive Die Stamping, Deep Drawing, Piercing, Forming, Coining, And More To Deliver Quality Solutions For Your Unique Project.

Related Post: