Sheet Metal Bend Radius Chart

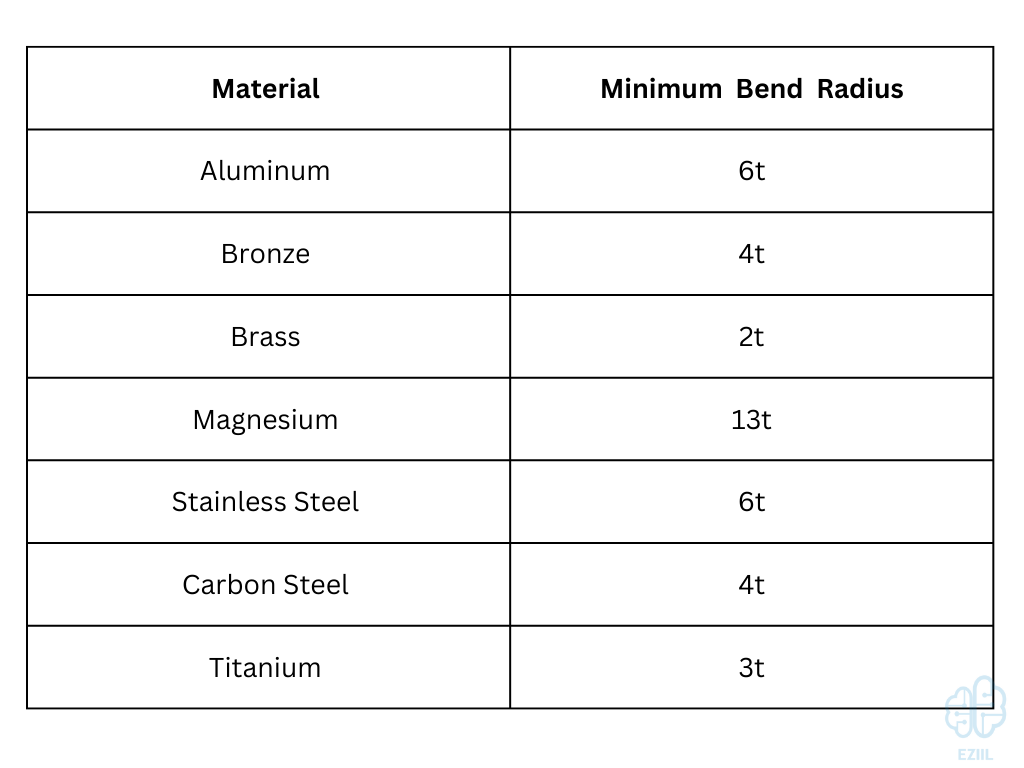

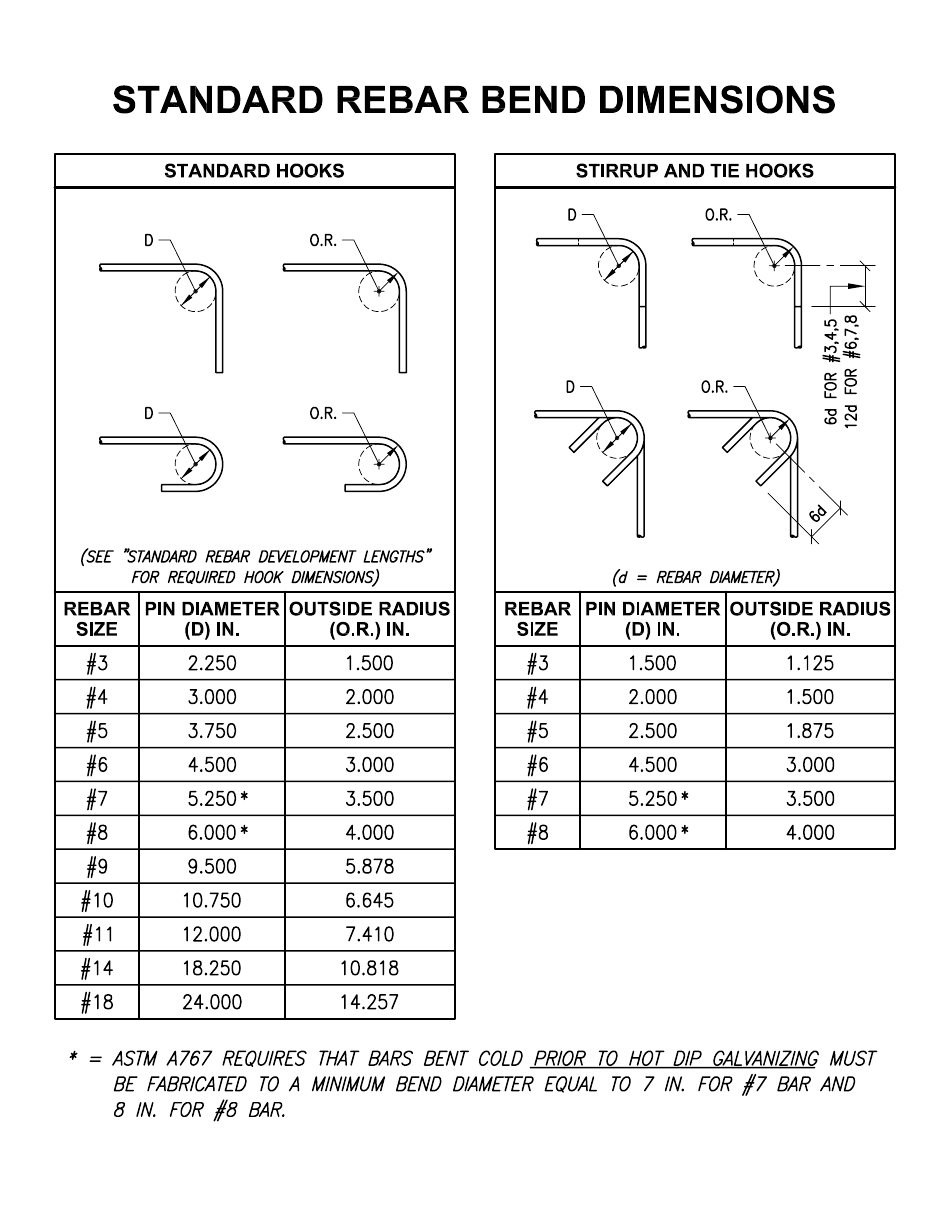

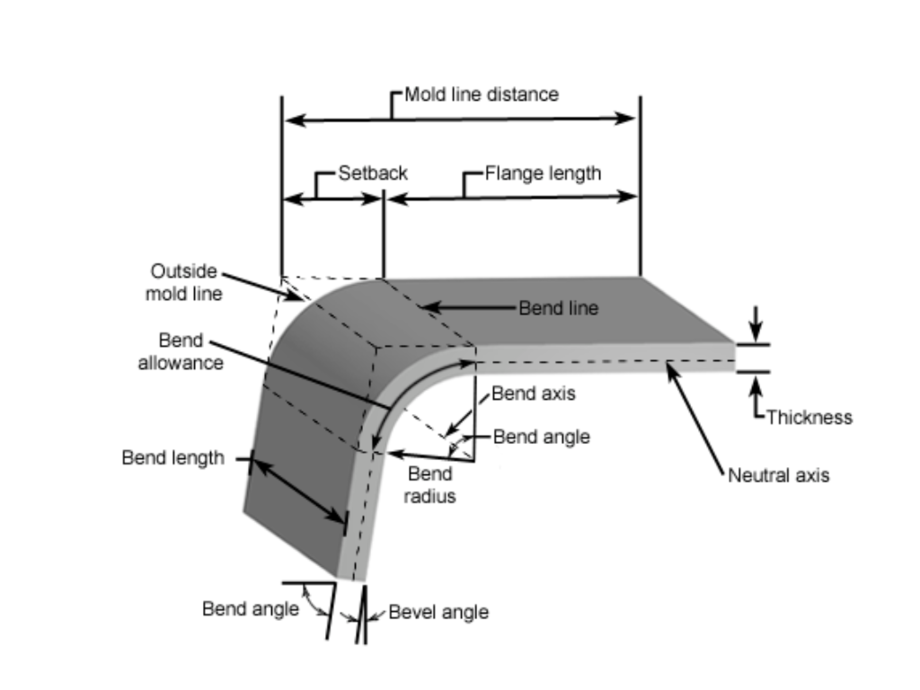

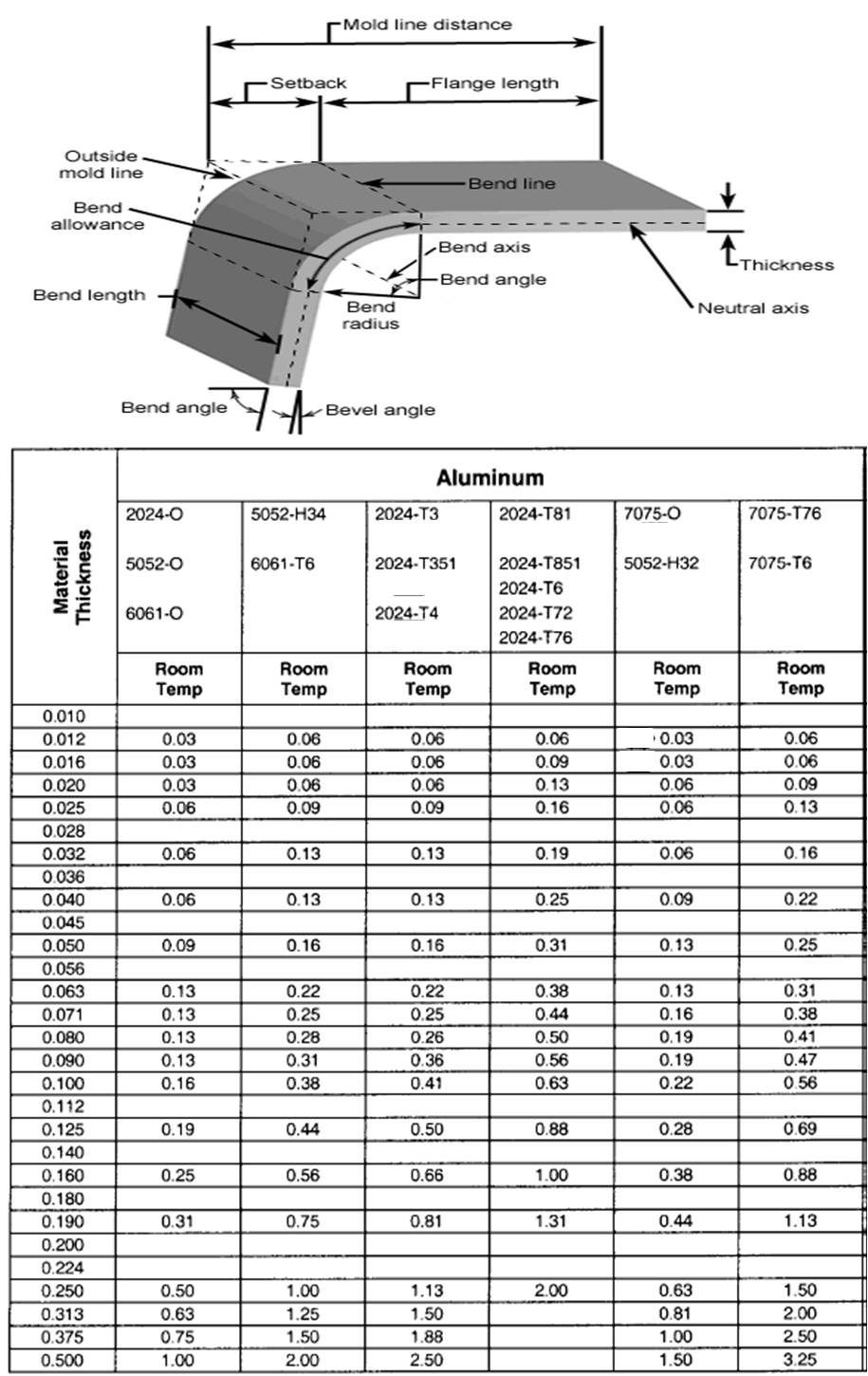

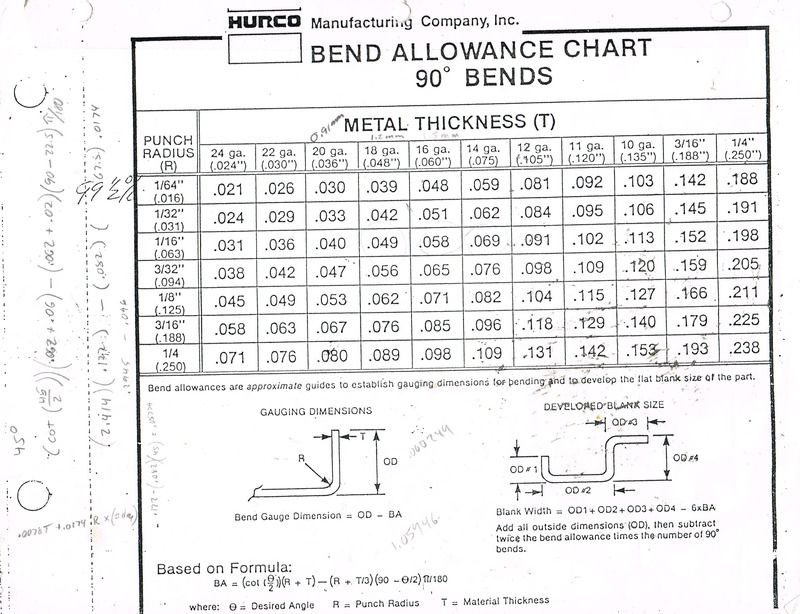

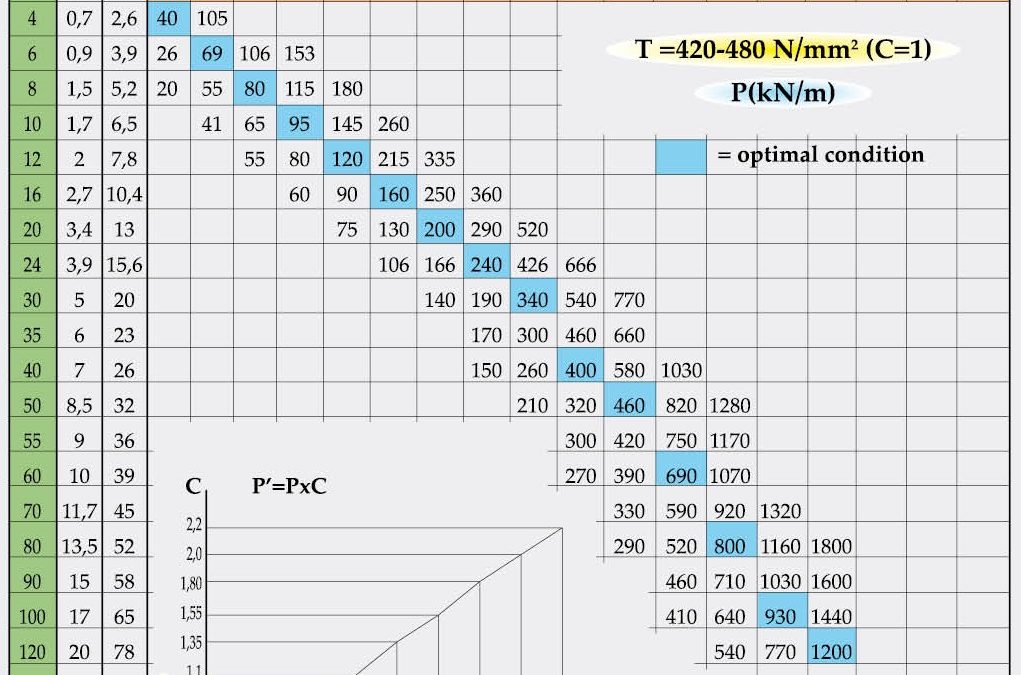

Sheet Metal Bend Radius Chart - Web find the recommended minimum bend radius for different thicknesses and types of sheet metal materials. Web sheet metal and plastic bending calculator. Web table of contents. The length of the neutral axis is calculated as a. Web a sheet metal bend radius chart is a valuable tool that provides engineers and fabricators with essential information. Find out how to choose bend radii and minimum bend sizes for different materials and tooling combinations. When the radius is less than recommended, this can cause material flow problems in soft material. Use the tables and diagrams to optimize your design a… 2 sheet metal part design for manufacturing tip. We go beyond the general rules of sheet metal. Thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse bending,. The length of the neutral axis is calculated as a. Thickness (s) [mm] length [mm] bending angle [degrees] type of bending. Input material thickness and and inner radius to get the k factor, y factor, neutral layer. The lower v. Thickness (s) [mm] length [mm] bending angle [degrees] type of bending. It is useful for sheet metal designers as it specifies the bend. Web the air force bending chart is a chart showing the tonnage used for bending different thickness sheet metal. 2 sheet metal part design for manufacturing tip. Web ba = [ (0.017453 × inside radius) + (0.0078. Input material thickness and and inner radius to get the k factor, y factor, neutral layer. The material thickness will be measured in decimal. Web a sheet metal bend radius chart is a valuable tool that provides engineers and fabricators with essential information. Web sheet metal bending radius refers to the minimum radius that can be applied to a sheet. The chart also shows the v width radius and angle. Web sheet metal bending radius refers to the minimum radius that can be applied to a sheet metal component where its flange originates from. 1.5 times the thickness of the sheet. 2 sheet metal part design for manufacturing tip. The material thickness will be measured in decimal. Web table of contents. 1.5 times the thickness of the sheet. Web the tables below show bend radii and minimum bend sizes for materials and tooling combinations stocked by protocase. Web a sheet metal bend radius chart is a valuable tool that provides engineers and fabricators with essential information. The material thickness will be measured in decimal. 2 sheet metal part design for manufacturing tip. It typically lists various materials and their. It is useful for sheet metal designers as it specifies the bend. The charts show the bend radius measured to the inside of the bend. Use the tables and diagrams to optimize your design a… Web sheet metal and plastic bending calculator. Input material thickness and and inner radius to get the k factor, y factor, neutral layer. The material thickness will be measured in decimal. The chart also shows the v width radius and angle. When the radius is less than recommended, this can cause material flow problems in soft material. Web sheet metal bending radius refers to the minimum radius that can be applied to a sheet metal component where its flange originates from. 2.0.1 unable to unfold part, sheet. The length of the neutral axis is calculated as a. Web bend allowance is dependent on the inside formed radius. 1 time the thickness of the sheet. Web the tables below show bend radii and minimum bend sizes for materials and tooling combinations stocked by protocase. The charts show the bend radius measured to the inside of the bend. The material thickness will be measured in decimal. (2) sheet metal bending allowance table (iron, aluminum, copper) note: Use sendcutsend’s bending calculator to input your desired material and. 2 sheet metal part design for manufacturing tip. (2) sheet metal bending allowance table (iron, aluminum, copper) note: The lower v die opening determines the inside radius (i.r.) of a formed part. The charts show the bend radius measured to the inside of the bend. The inside radius for mild. 1 time the thickness of the sheet. Web sheet metal and plastic bending calculator. Web the air force bending chart is a chart showing the tonnage used for bending different thickness sheet metal. Web find the minimum bend radius for different materials and thicknesses based on the inside die and punch radius. 2 sheet metal part design for manufacturing tip. 1 common bend radius design mistakes. The chart also shows the v width radius and angle. Web the tables below show bend radii and minimum bend sizes for materials and tooling combinations stocked by protocase. The charts show the bend radius measured to the inside of the bend. Input material thickness and and inner radius to get the k factor, y factor, neutral layer. Web (1) bend allowance chart for 88° & 90° bending. 2.0.1 unable to unfold part, sheet. Use sendcutsend’s bending calculator to input your desired material and the units of measurement for your design to get the. Web ba = [ (0.017453 × inside radius) + (0.0078 × material thickness)] × bend angle, which is always complementary. When the radius is less than recommended, this can cause material flow problems in soft material. Web in steel between 0.5 and 0.8 in.

Sheet Metal Bend Radius Full Guide Chart

Bend radius / SolidWorks / more brackets Sling2

Predicting an airformed sheet metal inside bend radius

Bending Stainless Steel Tubing Effective Processes and Considerations

Radius die tubing bend chart retarea

Sheet Metal Bend Radius Full Guide Chart

Bend Radius Chart Sheet Metal

Sheet Metal Bending Design Tips, Bend Allowance, K Factor Fractory

General Sheet Metal Bends Radius for No +/ Factor Practical

Sheet Metal Bend Chart

Web A Sheet Metal Bend Radius Chart Is A Valuable Tool That Provides Engineers And Fabricators With Essential Information.

It Typically Lists Various Materials And Their.

The Lower V Die Opening Determines The Inside Radius (I.r.) Of A Formed Part.

Find Out How To Choose Bend Radii And Minimum Bend Sizes For Different Materials And Tooling Combinations.

Related Post: