Sfm Chart For Milling

Sfm Chart For Milling - Web speeds and feeds are the cutting variables used in every milling operation and vary for each tool based on cutter diameter, operation, material, etc. Click here to download a printable pdf file containing these formulas. Web these guidelines may require possible variations to achieve optimum results. Are you using a harvey tool? Web theory behind surface feet per minute: Milling surface feet per minute = (rpm x tool diameter) / 3.82 turning surface feet per minute = 0.262 x part diameter x rpm 10xx, 11xx, 12xx, a36 ≤ 28 rc 800 700 500 0.0010 0.0020 0.0025 0.0030 0.0035 steel medium/high carbon steels, alloy steels: Web select your material in the iso colored chart. Low & plain carbon, alloy & tool steels (<286 hb) <30 hrc. Web the best online speeds and feeds calculator. Web recommended cutting speed and feed. Diameter x 3.14159 (pi) = distance cutter travels every revolution. Web sfm to rpm chart (inch) find the required rpm according to your tool’s diameter and sfm Your job is to fill in the blue boxes, Adjust the cutting speed and/or feed rate based on your cutting conditions. Below are variable abbreviations and formulas for many common milling operations. Nominal hardnes s of the material. Web how do you calculate sfm in machining? Web sfm chart for uncoated end mill feeds and speeds: In the future we will be adding data for hss and cobalt end mills. Web sfm ipt *(baseline) cutting diameter engaged cutting diameter material hardness 25% 50% 100% 5/16 3/8 1/2 5/8 3/4 p steel free machining & low carbon: Master milling efficiency the most important aspect of milling with end mills is to run the tool at the proper rpm (revolutions per minute or spindle speed) and ipm (inches per minute or feed. Greater radial depths of cut (more than.5 x diameter), the lower range of surface speeds (sfm) should be used. Web speed and feed chart for threadmills. Web this page gives cutting speeds for turning, milling, and drilling of several different materials. Web select your material in the iso colored chart. Web how do you calculate sfm in machining? Web determine the spindle speed (rpm) and feed rate (ipm) for a milling operation, as well as the cut time for a given cut length. Web these guidelines may require possible variations to achieve optimum results. Low & plain carbon, alloy & tool steels (<286 hb) <30 hrc. For woc equal to.5 x diameter on profiling applications, decrease feed by. Axial depth of cut = ad. A short overhang of the cutting tool. Adjust the cutting speed and/or feed rate based on your cutting conditions. When cutting an internal thread, the linear feed rate needs to be reduced to compensate for the ratio of the tool's cutting diameter to the major diameter being cut. Understanding the right speeds and feeds. Web sfm to rpm chart (inch) find the required rpm according to your tool’s diameter and sfm Start with the recommended rpm, cutting speed, vc (sfm) and feed rate, fz (in/tooth). This calculator is designed to coincide with standard feed and speed charts for various materials and carbide end mills. Cutting speed for aluminum, brass, bronze, cast iron, magnesium, copper,. Never exceed the maximum rpm rating of the cutter body. Low & plain carbon, alloy & tool steels (<286 hb) <30 hrc. Web this page gives cutting speeds for turning, milling, and drilling of several different materials. Adjust the cutting speed and/or feed rate based on your cutting conditions. 10xx, 11xx, 12xx, a36 ≤ 28 rc 800 700 500 0.0010. Depths of cut (more than.5 x diameter) the lower range of surface speeds (sfm) should be used axial depth of cut: Click here for speeds and feeds specific to your tool. Start with the recommended rpm, cutting speed, vc (sfm) and feed rate, fz (in/tooth). Axial depth of cut = 1.5 x tool dia. Diameter x 3.14159 (pi) = distance. Axial depth of cut = ad. Distance cutter travels every revolution x 12 = distance traveled in feet.(sf) chart is recommending how far your cutter should travel per minute in feet. Web theory behind surface feet per minute: Diameter x 3.14159 (pi) = distance cutter travels every revolution. Click on the speeds in the above table to get better precision. In the future we will be adding data for hss and cobalt end mills. Web sfm to rpm chart (inch) find the required rpm according to your tool’s diameter and sfm Web the speed estimation is given for an ideal situation: Click here to download a printable pdf file containing these formulas. Distance cutter travels every revolution x 12 = distance traveled in feet.(sf) chart is recommending how far your cutter should travel per minute in feet. Web speeds and feeds are the cutting variables used in every milling operation and vary for each tool based on cutter diameter, operation, material, etc. It includes a calculator to figure the spindle speed required. Below are variable abbreviations and formulas for many common milling operations. Diameter x 3.14159 (pi) = distance cutter travels every revolution. If this condition exists, convential milling should be used and feed per tooth should be reduced by 50% Click on the speeds in the above table to get better precision for specific parameters. A short overhang of the cutting tool. Cutting speed for turning, drilling, reaming, and end milling. Axial depth of cut = 1.5 x tool dia. Web speed and feed chart for threadmills. This calculator is designed to coincide with standard feed and speed charts for various materials and carbide end mills.Speed And Feed Chart For Milling

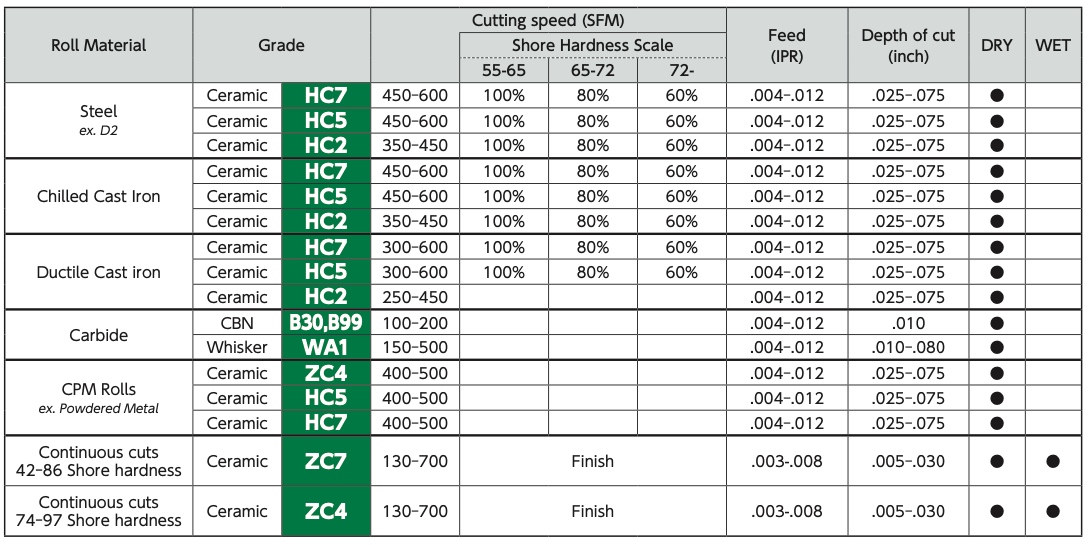

Tech Tips for Machining Hardened Materials with Ceramic and CeramiX

Session 2 Milling Formulas for Speed & Feed Calculations Milling

Kennametal Solid Carbide Drill Selection Guide and Dimensions

Drill Speed Chart For Steel

carbide end mill speed and feed chart Bamil

fab academy 2018

Cutting Speed (Vc) SFM Stainless Steel Steel

Sfm Chart For Turning Labb by AG

SFM Chart Surface, It cast, Speed

Web Recommended Cutting Speed And Feed.

Web Here Is The Chart With The Recommended Cutting Speed For Different Materials.

Web This Page Gives Cutting Speeds For Turning, Milling, And Drilling Of Several Different Materials.

Start With The Recommended Rpm, Cutting Speed, Vc (Sfm) And Feed Rate, Fz (In/Tooth).

Related Post: