Sbc Ring Gap Chart

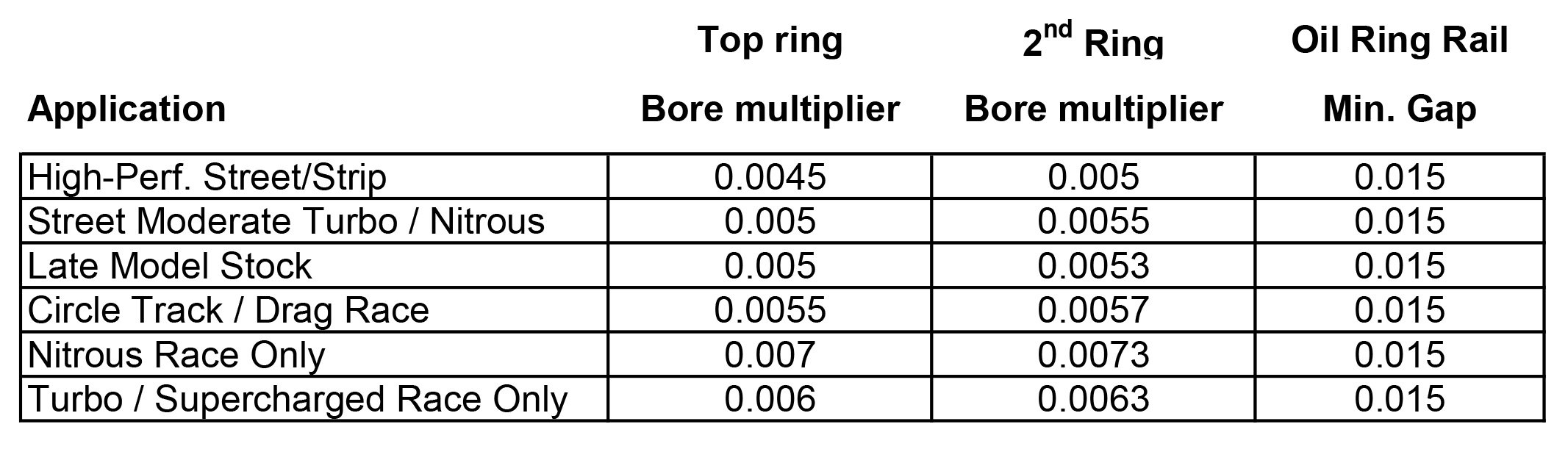

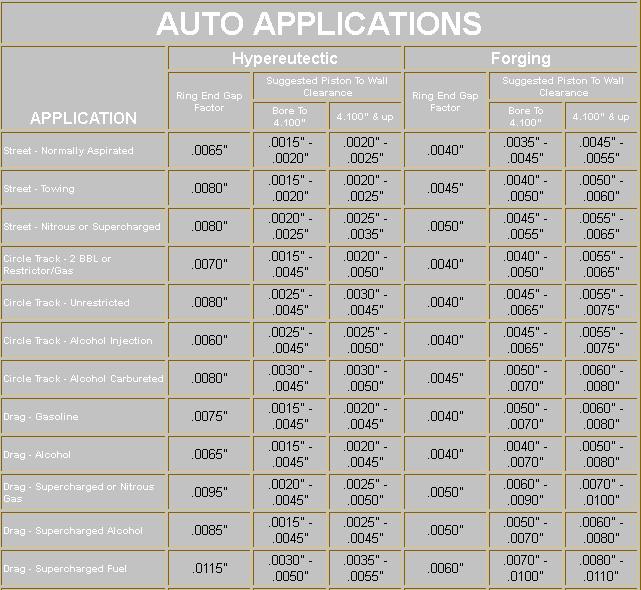

Sbc Ring Gap Chart - Web best et 11/5/2021 (496): To find the proper ring end gap, multiply your bore size by the ring end gap factor. Web safe top ring end gaps can be found by multiplying the bore diameter by the appropriate ring end gap factor from the clearance chart below. This is very critical to understand, as the top ring is. Advanced piston ring technology does not come cheap. Web current recommendations are such that the 2nd ring gap. In order to measure your ring end gap, once the ring is located in the bore, you need to make sure that it’s an equal distance down from. Maximum ring gap is an important part of ring performance in that too much gap results in lost compression, power loss, and. See table 1 for proper end gap measurement. For a naturally aspirated street engine using a cast piston with. Measure the ring end gap with a feeler gauge. See table 1 for proper end gap measurement. Is larger than the top rings for most applications. Web maximum ring gap is an important part of ring performance in that too much gap results in lost compression, power loss and ultimately poor oil control. Multiply bore size x ring end gap. Web the following chart gives suggested minimum ring end gaps for various applications. Measure the ring end gap with a feeler gauge. Advanced piston ring technology does not come cheap. If adjustment to the gap must be made, use a proper. Bore x gap factor ( see back page for your specific application factor ) = end gap. Bore x gap factor ( see back page for your specific application factor ) = end gap. Web modern piston design locates the top ring higher for improved requires a larger top ring end gap. See table 1 for proper end gap measurement. Is larger than the top rings for most applications. If adjustment to the gap must be made,. Some second ring sets can be set slightly looser, but that. Testing has proven that a larger second ring gap increases the top. Web to be effective, the proper ring gap is more dependent on what usage the engine will see rather then on the rings themselves. Web to find the proper ring end gap, multiply your bore size by. Web the gap that you create in the top ring is to accommodate the maximum expansion that you anticipate the top ring requiring. See table 1 for proper end gap measurement. This is very critical to understand, as the top ring is. Web other piston or ring companies may offer slightly different recommendations. Web maximum ring gap is an important. Web how to measure piston ring end gap. Web ring end gap calculations. Web other piston or ring companies may offer slightly different recommendations. Web maximum ring gap is an important part of ring performance in that too much gap results in lost compression, power loss and ultimately poor oil control. (diameter changes affect the gap by the factor of. Measure the ring end gap with a feeler gauge. Web safe top ring end gaps can be found by multiplying the bore diameter by the appropriate ring end gap factor from the clearance chart below. In order to measure your ring end gap, once the ring is located in the bore, you need to make sure that it’s an equal. Web safe top ring end gaps can be found by multiplying the bore diameter by the appropriate ring end gap factor from the clearance chart below. For a naturally aspirated street engine using a cast piston with. Advanced piston ring technology does not come cheap. Web modern piston design locates the top ring higher for improved requires a larger top. Measure the ring end gap with a feeler gauge. This is very critical to understand, as the top ring is. To find the proper ring end gap, multiply your bore size by the ring end gap factor. Web ring end gap calculations. Web when fitting rings to cylinder bores, every.001 change in bore diameter changes the end gap by approximately.003. Web to find the proper ring end gap, multiply your bore size by the ring end gap factor listed on the chart (i.e., street naturally aspirated 4.000” bore x.0065” gap factor =.026” total top. For a naturally aspirated street engine using a cast piston with. To use this chart, multiply the bore size by the ring end gap factor to. To find the proper ring end gap, multiply your bore size by the ring end gap factor. Web current recommendations are such that the 2nd ring gap. Advanced piston ring technology does not come cheap. Web when fitting rings to cylinder bores, every.001 change in bore diameter changes the end gap by approximately.003. Web the following chart gives suggested minimum ring end gaps for various applications. For a naturally aspirated street engine using a cast piston with. Web to be effective, the proper ring gap is more dependent on what usage the engine will see rather then on the rings themselves. This is very critical to understand, as the top ring is. Web below is a chart which contains the recommended end gap factor. (diameter changes affect the gap by the factor of. Maximum ring gap is an important part of ring performance in that too much gap results in lost compression, power loss, and. Web modern piston design locates the top ring higher for improved requires a larger top ring end gap. Bore x gap factor ( see back page for your specific application factor ) = end gap. Some second ring sets can be set slightly looser, but that. Is larger than the top rings for most applications. See table 1 for proper end gap measurement.

Blueprint Series The How And Why Of Setting Piston Ring End Gap

Repair Guides

Piston Ring Gap How Important Is It And How To Get Them Correct

Sbc Pushrod Length Chart

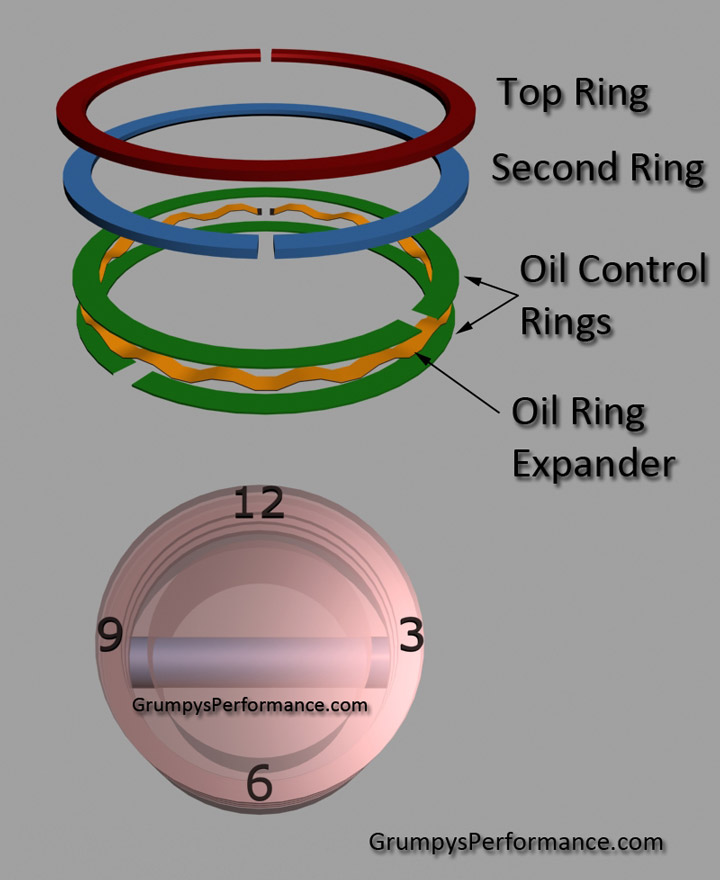

installing rings in piston grooves Grumpys Performance Garage

ring gapping and basic piston ring info YOULL NEED Grumpys

Setting Timing on the SBC 350 and the Ford 302

383 SBC Ring Gap and Cam Bearing setup! YouTube

How to FileFit and Install Piston Rings

Piston Ring Gap Placement GM Square Body 1973 1987 GM Truck Forum

If Adjustment To The Gap Must Be Made, Use A Proper.

Measure The Ring End Gap With A Feeler Gauge.

Web Use The Chart Below To Determine The Minimum Ring End Gap.

Web To Find The Proper Ring End Gap, Multiply Your Bore Size By The Ring End Gap Factor Listed On The Chart (I.e., Street Naturally Aspirated 4.000” Bore X.0065” Gap Factor =.026” Total Top.

Related Post: