S7 Tool Steel Rockwell Hardness Chart

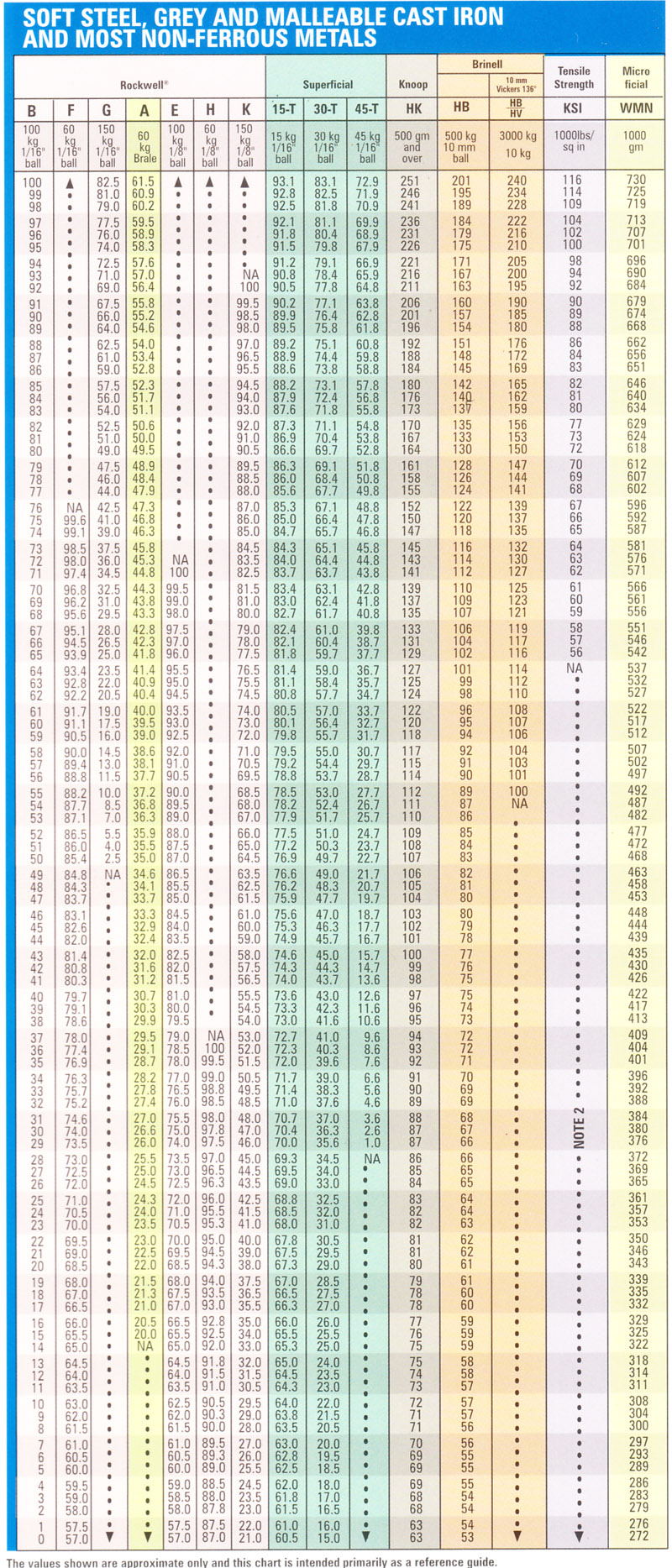

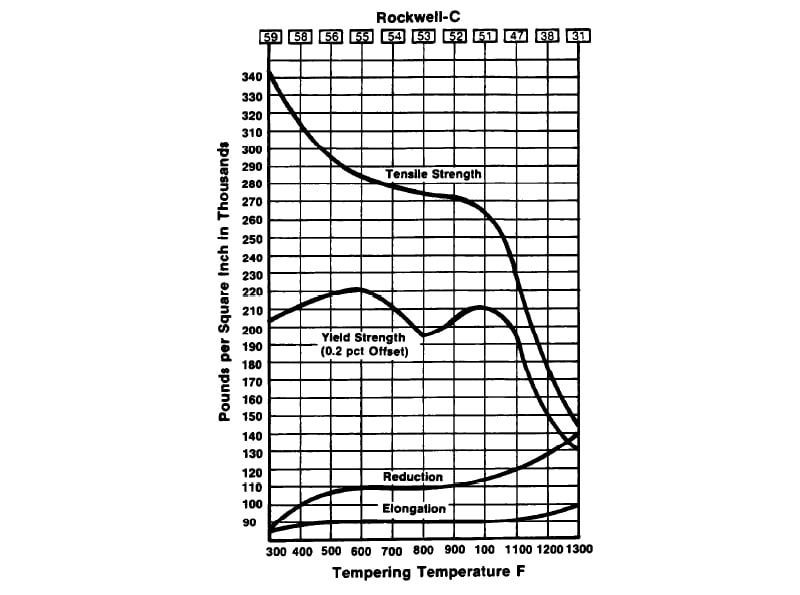

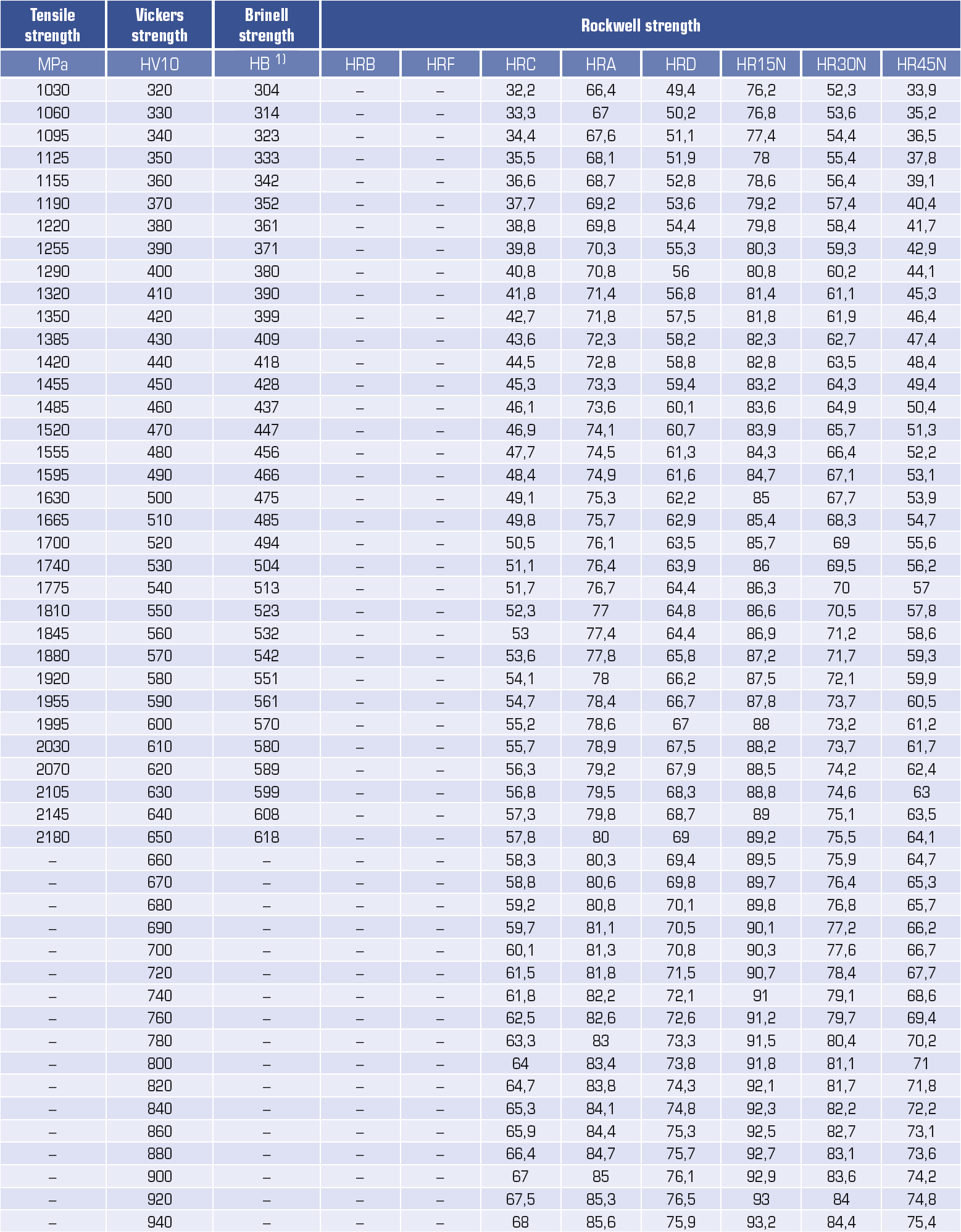

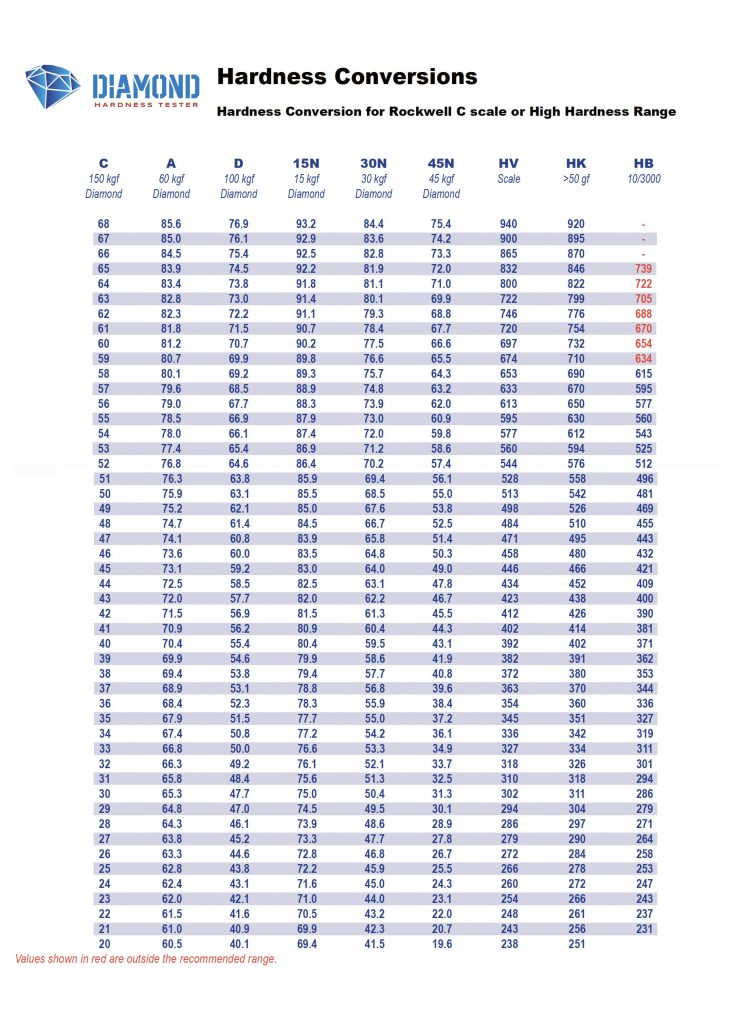

S7 Tool Steel Rockwell Hardness Chart - This process produces recast, rehardened and retempered layers on the edm surface. Hardness, rockwell c (air cooled from 941°c, 449°c temper temperature) 53: Rockwell c is measured in the unit hrc, which is the measurement used below. Hot rolled, forged, cold drawn etc. It offers toughness to withstand chipping and breaking, combined with high attainable hardness and good wear resistance. Web s7 is characterized by high impact toughness at relatively high hardness levels (55/57 hrc). 1100/1250f (595/675c), equalize, 1350/1450f (775/790c), equalize. Web assab tool steel performance comparison chart. Web hardness, rockwell c (air cooled from 941°c, 649°c temper temperature) 41: *s7 xl recommended for edming fine or intricate parts. Web recommended working hardness ranges are rc 56/58 or rc 50/52. Description cartech s7 is a general purpose air hardening tool steel having high impact and shock resistance. Two widely used tests are rockwell c and brinell. Melting onset (solidus) 1420 °c 2590 °f. Annealed hardness about bhn 187/220. Other sizes of s7 steel per customer’s requirements. However, with high hardness comes low toughness, which means that s7 is not as resistant to cracking or breaking when exposed to shock or vibration. Rockwell c is measured in the unit hrc, which is the measurement used below. *s7 xl recommended for edming fine or intricate parts. Web alloy tool steel. It offers toughness to withstand chipping and breaking, combined with high attainable hardness and good wear resistance. The combination of strength and high toughness makes s7 tool steel a candidate for a wide variety of tooling applications. Web hardness, rockwell c (air cooled from 941°c, 649°c temper temperature) 41: S7 steel is primarily used for chisels, punches, rivet sets, stamps,. However, with high hardness comes low toughness, which means that s7 is not as resistant to cracking or breaking when exposed to shock or vibration. Heat at a rate not exceeding 400°f per hour (222°c per hour). S7 tool steel is a shock resisting grade with superior impact properties combined with high toughness, machinability and size stability during heat treating.. Web hardness, rockwell c (air cooled from 941°c, 649°c temper temperature) 41: 0.283 lb/in 3 (7833 kg/m 3) specific gravity: Two widely used tests are rockwell c and brinell. Annealed hardness about bhn 187/220. It has good resistance to softening at moderately high temperatures. S7 has high impact toughness allowing it to withstand chipping and breaking while still having good wear resistance at relatively high hardness levels. It offers toughness to withstand chipping and breaking, combined with high attainable hardness and good wear resistance. Tool steels/alloys typical composition steel aisi jis din c mn si cr w mo v h13 h13 skd 61 1.2344. Or heat to 845c, hold 2hrs., cool to 760c hold 4hrs,then air cool. It offers toughness to withstand chipping and breaking, combined with high attainable hardness and good wear resistance. Web to determine the refinement produced by hardening, the fracture grain size and rockwell c hardness of s7 specimens 1 in. 0.283 lb/in 3 (7833 kg/m 3) specific gravity: The. Tool steels/alloys typical composition steel aisi jis din c mn si cr w mo v h13 h13 skd 61 1.2344 0.40 0.40 1.00 5.25 1.35 1.00 s7 s7 * 1.2357 0.50 0.75 0.25 3.25 1.40 S7 has high impact toughness allowing it to withstand chipping and breaking while still having good wear resistance at relatively high hardness levels. This combination. Rockwell c is measured in the unit hrc, which is the measurement used below. Description cartech s7 is a general purpose air hardening tool steel having high impact and shock resistance. *s7 xl recommended for edming fine or intricate parts. 1100/1250f (595/675c), equalize, 1350/1450f (775/790c), equalize. 30 x 10 6 psi (207gpa) thermal conductivity: Web recommended working hardness ranges are rc 56/58 or rc 50/52. It offers toughness to withstand chipping and breaking, combined with high attainable hardness and good wear resistance. Ultimate (uts) 2030 mpa 290 x 103 psi. Its hardness allows it to maintain sharp edges even under heavy use, making it a preferred material in the tooling industry. 74 gpa 11. Web alloy tool steel (aisi s7), carpenter s7 is a general purpose air hardening tool steel having high impact and shock resistance. 0.283 lb/in 3 (7833 kg/m 3) specific gravity: This combination of properties makes it suitable for. It offers toughness to withstand chipping and breaking, combined with high attainable hardness and good wear resistance. Or heat to 845c, hold 2hrs., cool to 760c hold 4hrs,then air cool. Web assab tool steel performance comparison chart. Its hardness allows it to maintain sharp edges even under heavy use, making it a preferred material in the tooling industry. Supply range of aisi s7 tool steel. It offers toughness to withstand chipping and breaking, combined with high attainable hardness and good wear resistance. S7 has high impact toughness allowing it to withstand chipping and breaking while still having good wear resistance at relatively high hardness levels. Web recommended working hardness ranges are rc 56/58 or rc 50/52. Annealed hardness about bhn 187/220. Web hardness, rockwell c (air cooled from 941°c, 649°c temper temperature) 41: Heat to 845c,hold for 2hours, slow cool 30c per hour to 540c then air cool. However, with high hardness comes low toughness, which means that s7 is not as resistant to cracking or breaking when exposed to shock or vibration. Rockwell c is measured in the unit hrc, which is the measurement used below.

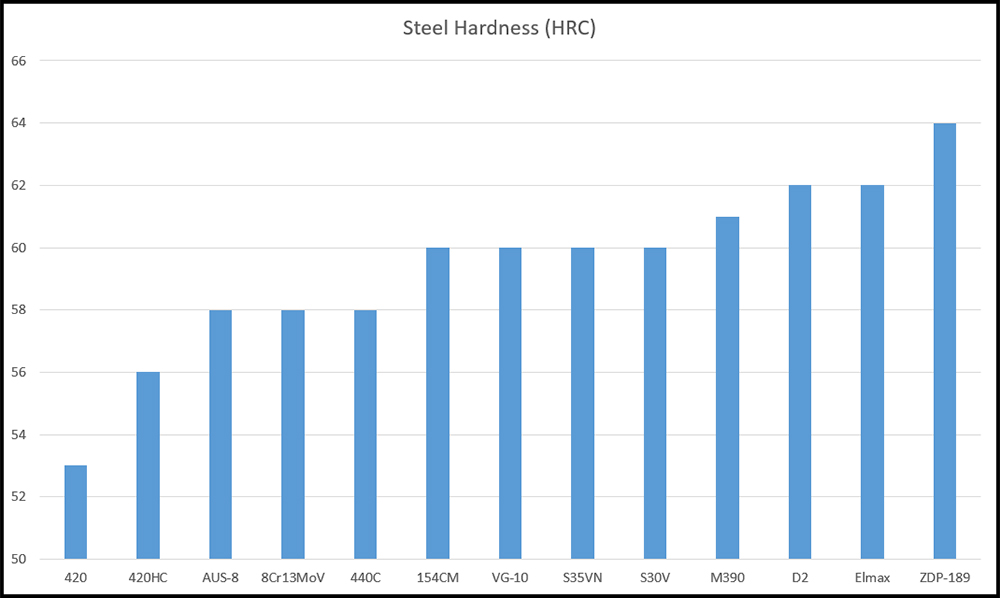

Tool Steel Rockwell Hardness Chart

Hardness Conversion Table For Steel

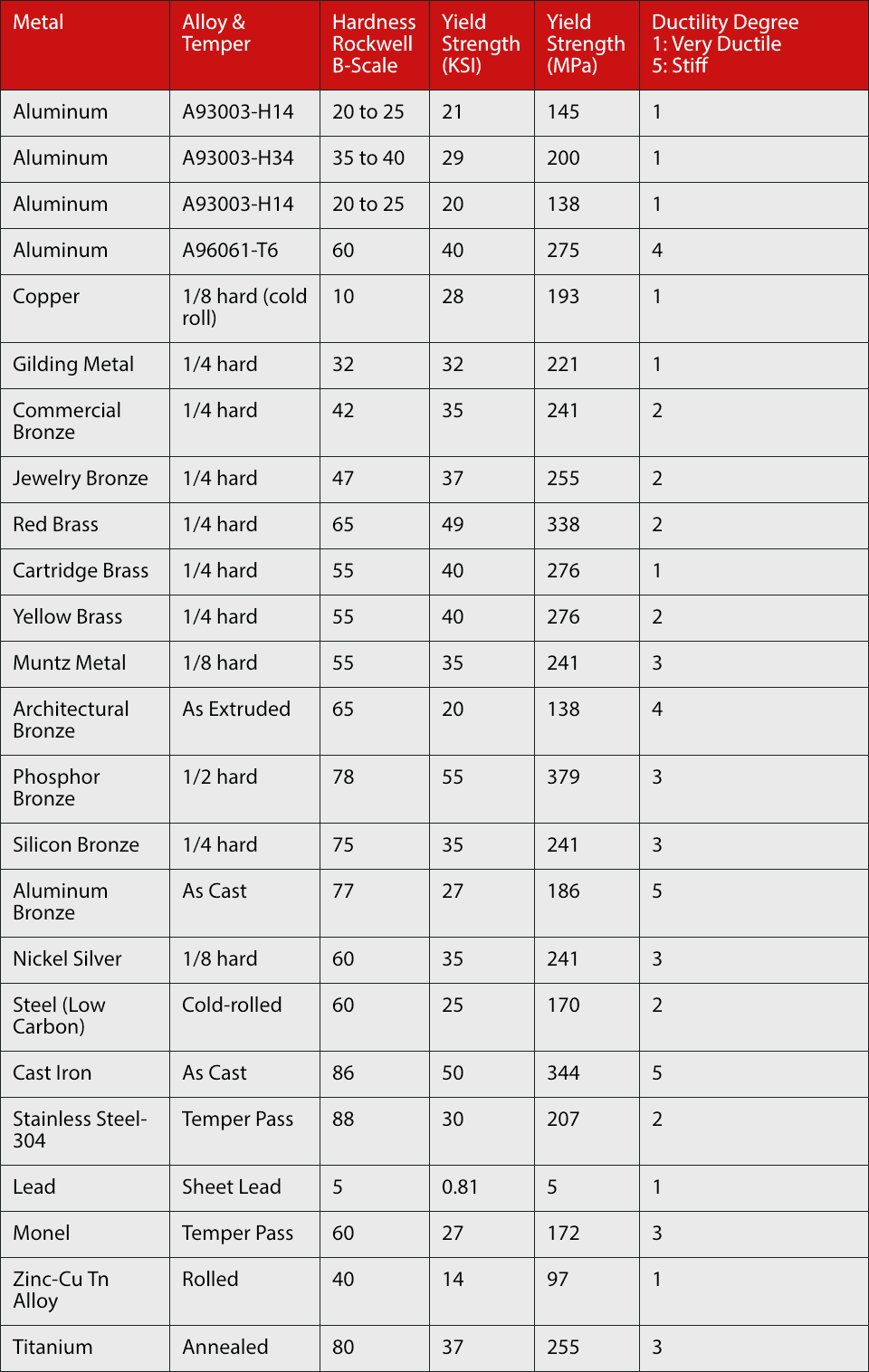

Alloy Selection Guide

S7, D2, A2 différence entre les propriétés des aciers à outils Heading

Rockwell B Hardness Scale Chart

Metal Hardness Scale Chart

Steel Rockwell Hardness Chart

Tool Steel Rockwell Hardness Chart

S7 Tool Steel Rockwell Hardness Chart

Steel Rockwell Hardness Chart

Tool Steels/Alloys Typical Composition Steel Aisi Jis Din C Mn Si Cr W Mo V H13 H13 Skd 61 1.2344 0.40 0.40 1.00 5.25 1.35 1.00 S7 S7 * 1.2357 0.50 0.75 0.25 3.25 1.40

Description Cartech S7 Is A General Purpose Air Hardening Tool Steel Having High Impact And Shock Resistance.

30 X 10 6 Psi (207Gpa) Thermal Conductivity:

Two Widely Used Tests Are Rockwell C And Brinell.

Related Post: