S7 Heat Treat Chart

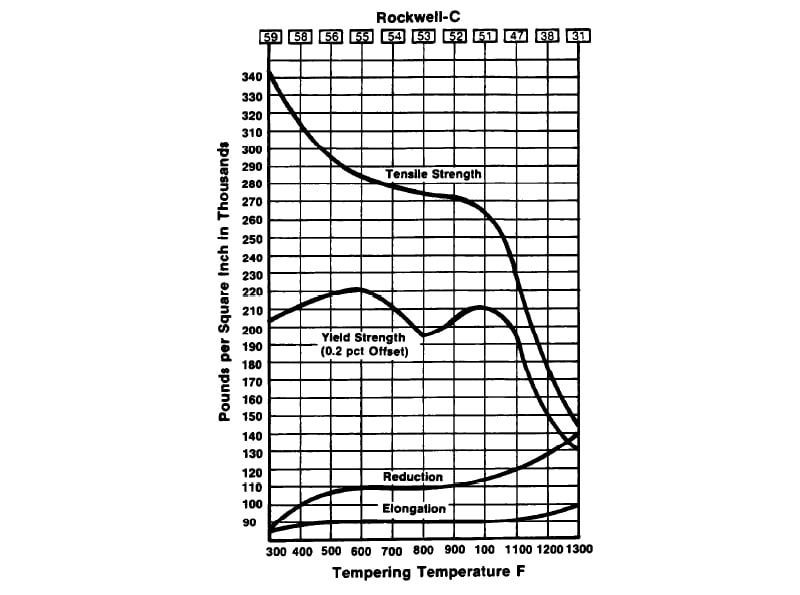

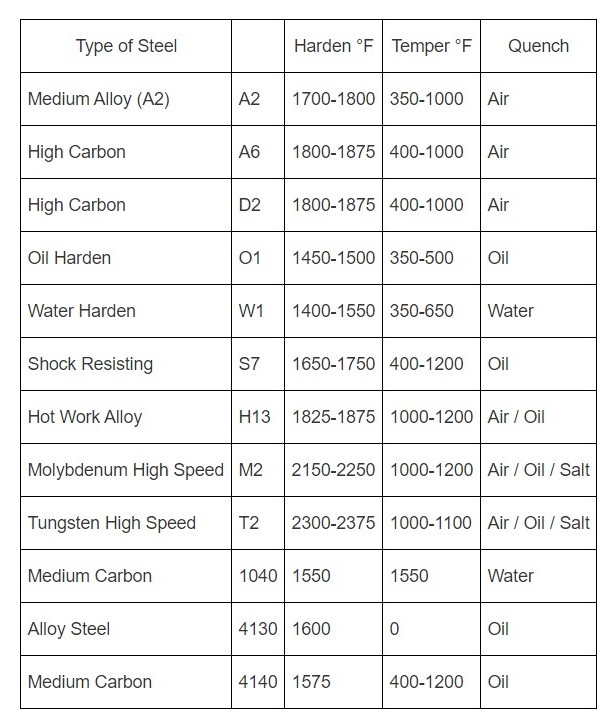

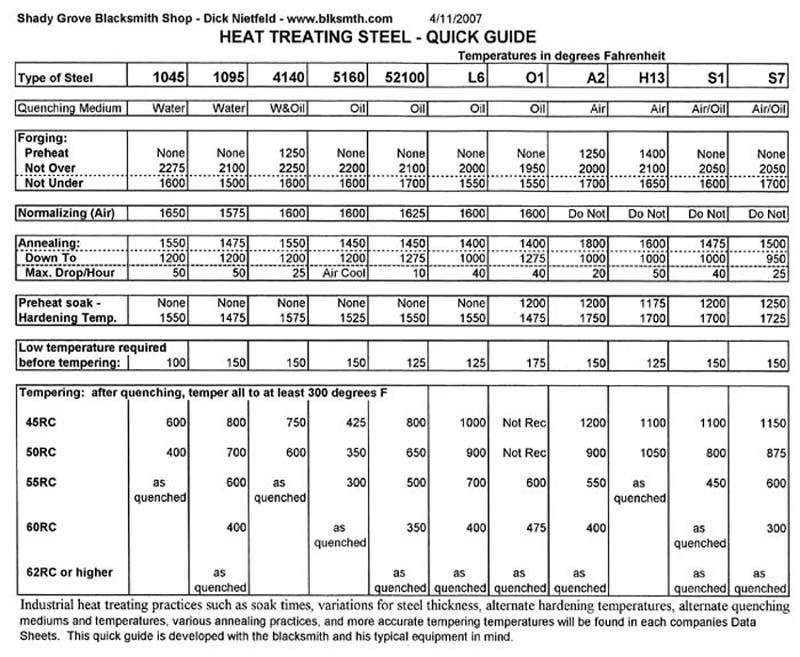

S7 Heat Treat Chart - Web heat treatment of tool steels: Web typical heat treat response. Tempering temperature 55 carburizing times and temperatures 56 carbonitriding chart 57 hardness vs. (2) hold time (minutes) (3) ouench: Strength q moderate wear resistance s7—57 hrc q high impact resistance at relatively high hardness q very high toughness to withstand. The warp issue might have to do with the overall length and thickness. Air / oil * air / endo. Web heat check resistance, & high temp. Web heat treating of tool steels 51 hardness vs. Cool slowly (50ºf per hour max) to 1100ºf and air cool to room temperature. Heat at a rate not exceeding 400°f per hour (222°c per hour). See the chemical composition, physical and mechanical properties, and equivalent materials of s7 steel. The warp issue might have to do with the overall length and thickness. Web typical heat treat response. Web heat treating of tool steels 51 hardness vs. Web march 27, 2023 | 2:55 pm. See the chemical composition, physical and mechanical properties, and equivalent materials of s7 steel. Strength q moderate wear resistance s7—57 hrc q high impact resistance at relatively high hardness q very high toughness to withstand. Web the heat treatment process for s7 tool steel typically involves three main steps: See the typical chemistry,. Web heat treating of tool steels 51 hardness vs. Stop at 1700°f and cool slowly. Web heat check resistance, & high temp. Heat at a rate not exceeding 400°f per hour (222°c per hour). Strength q moderate wear resistance s7—57 hrc q high impact resistance at relatively high hardness q very high toughness to withstand. The warp issue might have to do with the overall length and thickness. To obtain best machining properties, cool slowly to. Web typical heat treat response. Web the heat treatment process for s7 tool steel typically involves three main steps: Web s7 tool steel is a versatile formulation suitable for both cold and hot work service. Oil * air / inert / natural gas: It has good resistance to softening at. Strength q moderate wear resistance s7—57 hrc q high impact resistance at relatively high hardness q very high toughness to withstand. What forms of s7 tool steel is available at piping mart? Web heat treating of tool steels 51 hardness vs. Description cartech s7 is a general purpose air hardening tool steel having high impact and shock resistance. Web heat slowly and uniformly to 1500/1550ºf and hold for two hours. Oil * air / inert / natural gas: Web heat check resistance, & high temp. See the chemical composition, physical and mechanical properties, and equivalent materials of s7 steel. Description cartech s7 is a general purpose air hardening tool steel having high impact and shock resistance. The warp issue might have to do with the overall length and thickness. It has good resistance to softening at. Heat at a rate not exceeding 400°f per hour (222°c per hour). Mechanical properties, chemical composition, heat treat and other information. Oil * air / inert / natural gas: Let’s delve into each of these steps in. Web the heat treatment process for s7 tool steel typically involves three main steps: Mechanical properties, chemical composition, heat treat and other information. Web heat slowly and uniformly to 1500/1550ºf and hold for two hours. See the chemical composition, physical and mechanical properties, and equivalent materials of s7 steel. Web heat treatment of tool steels: It has a relatively low carbon concentration compared to d2 and a2 steels (0.45. Web heat check resistance, & high temp. (2) hold time (minutes) (3) ouench: What forms of s7 tool steel is available at piping mart? Carbon content 58 chapter 5. Air / oil * air / endo. See the typical chemistry, applications, hardening, tempering, annealing, and. Let’s delve into each of these steps in. Cool slowly (50ºf per hour max) to 1100ºf and air cool to room temperature. Web heat slowly and uniformly to 1500/1550ºf and hold for two hours. Air / oil * air / endo. (2) hold time (minutes) (3) ouench: Web heat treating of tool steels 51 hardness vs. It has a relatively low carbon concentration compared to d2 and a2 steels (0.45. Stop at 1700°f and cool slowly. Oil * air / inert / natural gas: Heat at a rate not exceeding 400°f per hour (222°c per hour). Cole, s7 is an easy tool steel to machine and heat treating is easy as well. Web the heat treatment process for s7 tool steel typically involves three main steps: Heat at a rate not exceeding 400°f per hour (222°c per hour). It has good resistance to softening at. See the typical chemistry, applications, hardening, tempering, annealing, and. The warp issue might have to do with the overall length and thickness. Strength q moderate wear resistance s7—57 hrc q high impact resistance at relatively high hardness q very high toughness to withstand.

S7, D2, A2 Difference in tool steel properties Paulo

Heat Treat Colors Of Steel Chart

Steel Heat Treat Temperature Color Chart

AISI S7 Annealing (Metallurgy) Heat Treating

Tool Steel Potential Dependent Upon Heat Treating Heat Treat Today

aisi 4340 heat treatment

Heat Treating Guide Shady Grove Blacksmith

Stainless Info AKS™

TABLE 37 HEAT TREATING (SOAKING) TEMPERATURES

4140 Alloy Steel 1.7225 SCM440 42CrMo4 OTAI Special Steel

Web Typical Heat Treat Response.

Carbon Content 58 Chapter 5.

Web Heat Treatment Of Tool Steels:

What Forms Of S7 Tool Steel Is Available At Piping Mart?

Related Post: