Ring And Pinion Pattern Chart

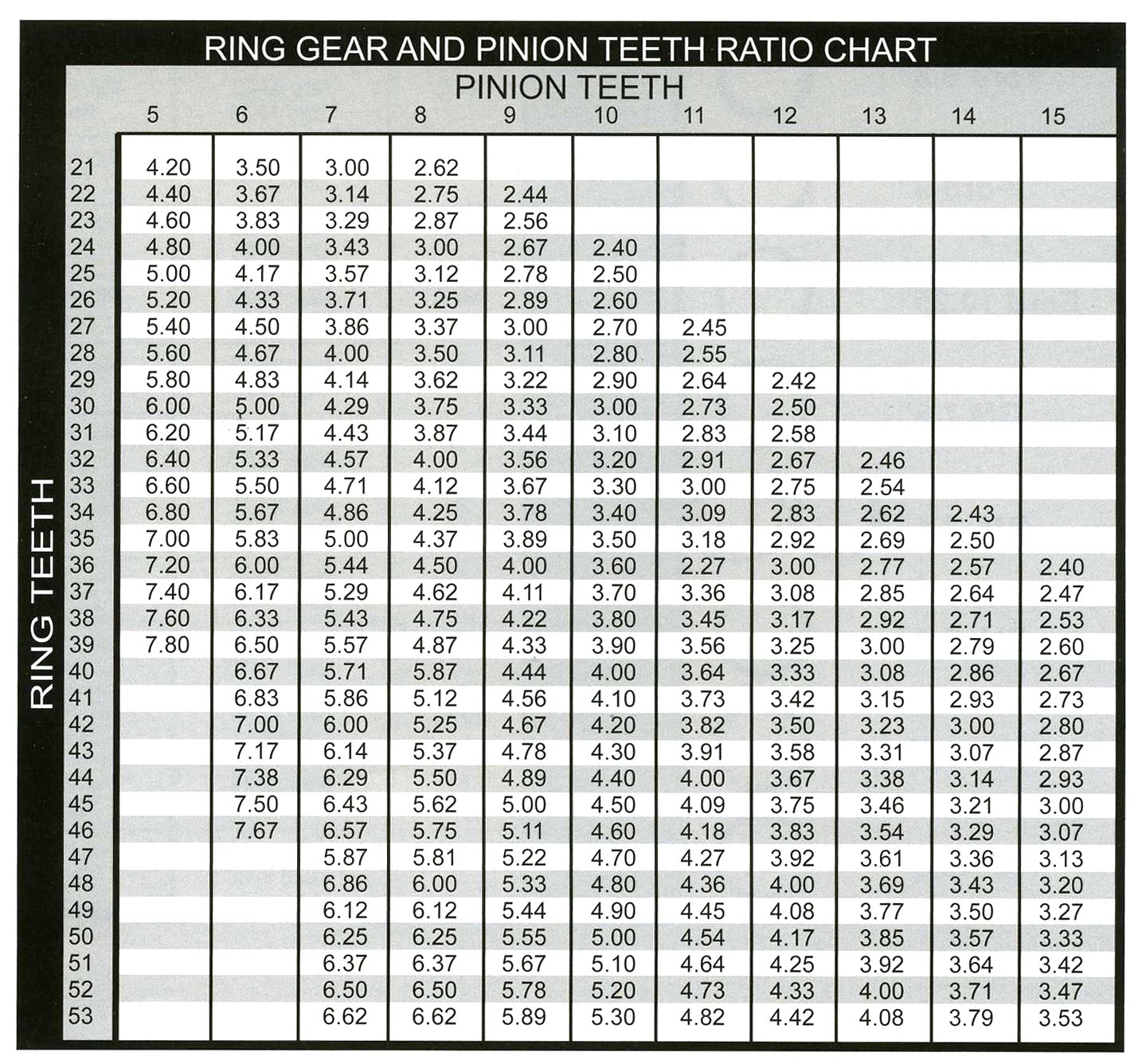

Ring And Pinion Pattern Chart - The toe of the gear is the portion of the tooth surface at the end towards the center. Is it prematurely worn or chipped teeth? Rotate the ring gear several times by hand and inspect the ring gear teeth. Or an ominous clunking sound? Web reading and interpreting gear patterns can be very confusing if they aren't obvious patterns. The ratio is the number of teeth on the ring gear divided by the number of teeth on the pinion gear. Web in general, pattern movements can be summarized this way: Congratulations on your purchase of a new g/2 ring and pinion set. Web shallow pinion position, with correct backlash, moves the pinion further from the ring gear. The pattern refers to how the ring gear and pinion gears mesh. Bearing preload, total turning preload, and ring gear backlash. Is it prematurely worn or chipped teeth? The final pinion position will be verified by using the gear contact pattern method described as follows: We live in a global economy and the parts we are working with, oem or aftermarket, are being sourced all over the world. Web we can determine. If the pattern is heavy on the “heel” (outboard area of the ring gear teeth), add shims. Web ring and pinion gear tooth pattern. (1) paint ring gear teeth with a marking compound to both the drive and coast side. So, if the ring gear has 41 teeth and the pinion has 11 teeth, the ratio is 3.73:1 (41 divided. Or an ominous clunking sound? Web reading and interpreting gear patterns can be very confusing if they aren't obvious patterns. Ring and pinion gear pattern is one of the most valuable tools for determining if a differential is properly set up. Moving the pinion gear closer to the carrier will move the drive side pattern closer to the flank and. Or an ominous clunking sound? Web randys worldwide is the leading supplier in the united states for differential gears, axles, installation kits, small parts, tools, lockers, limited slips, drivelines, and more. Drive pattern moves toward the top of the tooth (face contact) and toward the heel. Web ring & pinion tooth pattern interpretation. Web reading and interpreting gear patterns can. Web we can determine how gears mesh by changing how close the pinion gear is to the ring gear centerline. This gear set has been manufactured to provide extended gear life when properly installed in the correct application. Rotate the ring gear several times by hand and inspect the ring gear teeth. Drive pattern moves toward the top of the. This chart illustrates different patterns and adjustments. Web the numbers are more accurately written out as 3.08:1, 3.73:1, or 4.10:1. Proper ring gear to pinion gear contact pattern is critical for quiet and trouble free gear set operation. Web ring and pinion gear tooth pattern. Enter code yt30off on our sponsor's checkout. Web ring & pinion tooth pattern interpretation. These symptoms can be signs of a fairly serious problem with your ring and pinion gears, so it’s time to consult with the doctor—the gear doctor. Web what grinds your gears? Is it prematurely worn or chipped teeth? The toe of the gear is the portion of the tooth surface at the end. Web what is the difference? Congratulations on your purchase of a new g/2 ring and pinion set. Disregard the pattern’s position to the tooth’s heel (ring gear outside diameter) or toe (ring gear inside diameter). The pattern refers to how the ring gear and pinion gears mesh. The final pinion position will be verified by using the gear contact pattern. (10) 3/8x24 or 7/16x20 rh cover bolts: 1.625 / 29 ring gear bolts: Drive pattern moves toward the top of the tooth (face contact) and toward the heel. There is a process used when reassembling a differential that optimizes ring gear and pinion tooth contact. Web shallow pinion position, with correct backlash, moves the pinion further from the ring gear. The ratio is the number of teeth on the ring gear divided by the number of teeth on the pinion gear. Drive pattern moves toward the top of the tooth (face contact) and toward the heel. Begin by setting proper pinion. The procedure involves changing the pinion position via shims in the carrier and repositioning the carrier. The final pinion. These symptoms can be signs of a fairly serious problem with your ring and pinion gears, so it’s time to consult with the doctor—the gear doctor. The procedure involves changing the pinion position via shims in the carrier and repositioning the carrier. The toe of the gear is the portion of the tooth surface at the end towards the center. Web ring gear and pinion tooth pattern interpretation. Web the pattern’s position to the tooth face (ridge/top land) and flank (valley/root) indicates pinion depth. Moving the pinion gear closer to the carrier will move the drive side pattern closer to the flank and slightly toward the toe. (10) 3/8x24 or 7/16x20 rh cover bolts: (2) rotate ring gear one complete revolution in both directions while load is being applied with a large screwdriver or simular tool between the carrier casting and differential case flange. Web shallow pinion position, with correct backlash, moves the pinion further from the ring gear. If the pattern is heavy on the “heel” (outboard area of the ring gear teeth), add shims. Or an ominous clunking sound? This video was created to give people a basic understanding of how to read gear patterns when. 158k views 2 years ago. Disregard the pattern’s position to the tooth’s heel (ring gear outside diameter) or toe (ring gear inside diameter). Web in general, pattern movements can be summarized this way: This chart illustrates different patterns and adjustments.

Ring and pinion pattern? Bronco Forum Full Size Ford Bronco Forum

Weber_Ring_Gear_Contact_Pattern_Interpretation.pdf Gear Tooth

The Easiest Way to Read Ring & Pinion Contact Patterns YouTube

How to Read and Interpret Gear Patterns (Ring and Pinion) YouTube

Ring paint/ pinion IH8MUD Forum

Figure 83. Proper piniontodifferential ring gear tooth contact pattern.

Ring & pinion set up, Jantz Engineering advanced masters course

Ring and Pinion Pattern Help! Ford Bronco Forum

RING AND PINION TOOTH CONTACT PATTERN...mine with pic MGB & GT Forum

Ring and Pinion Gear Ratio Calculation Chart Quadratec

Congratulations On Your Purchase Of A New G/2 Ring And Pinion Set.

(1) Paint Ring Gear Teeth With A Marking Compound To Both The Drive And Coast Side.

Web Ring & Pinion Tooth Pattern Interpretation.

8.5 / 216Mm Pinion Diameter / Spline:

Related Post: