R Chart Formula

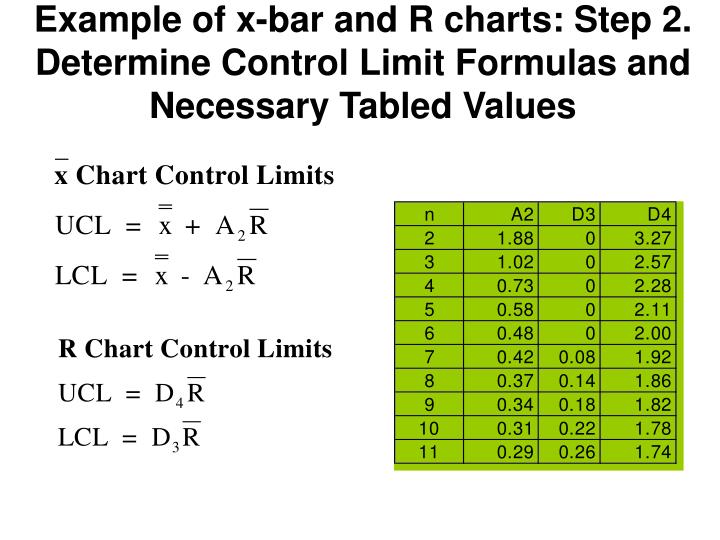

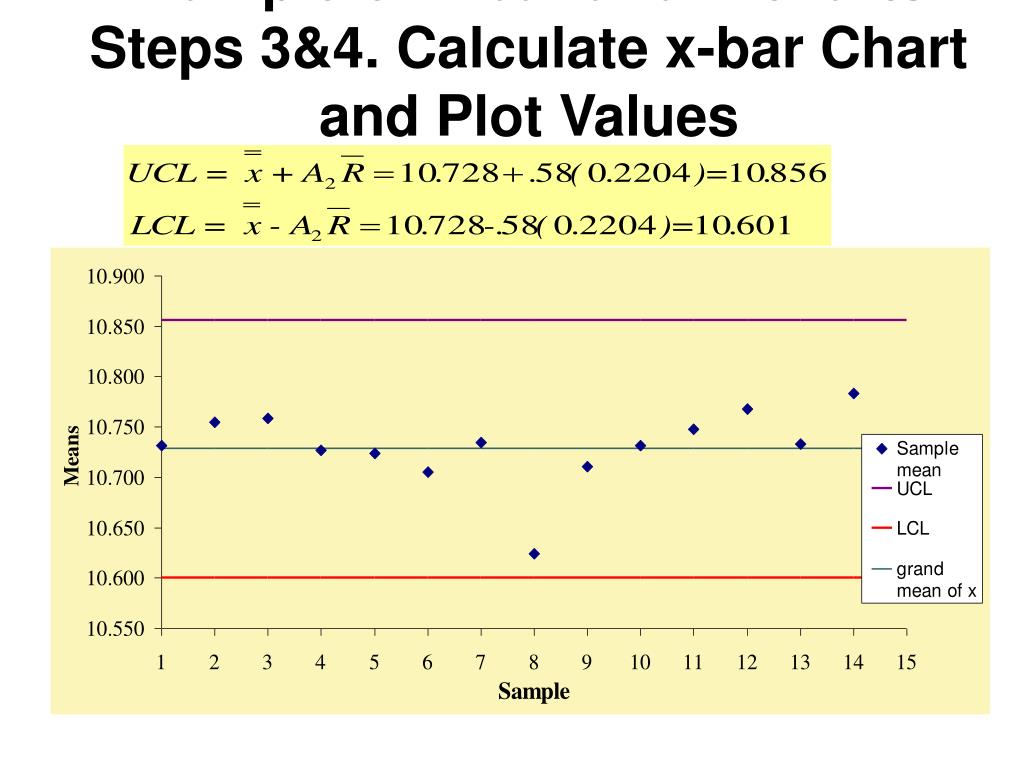

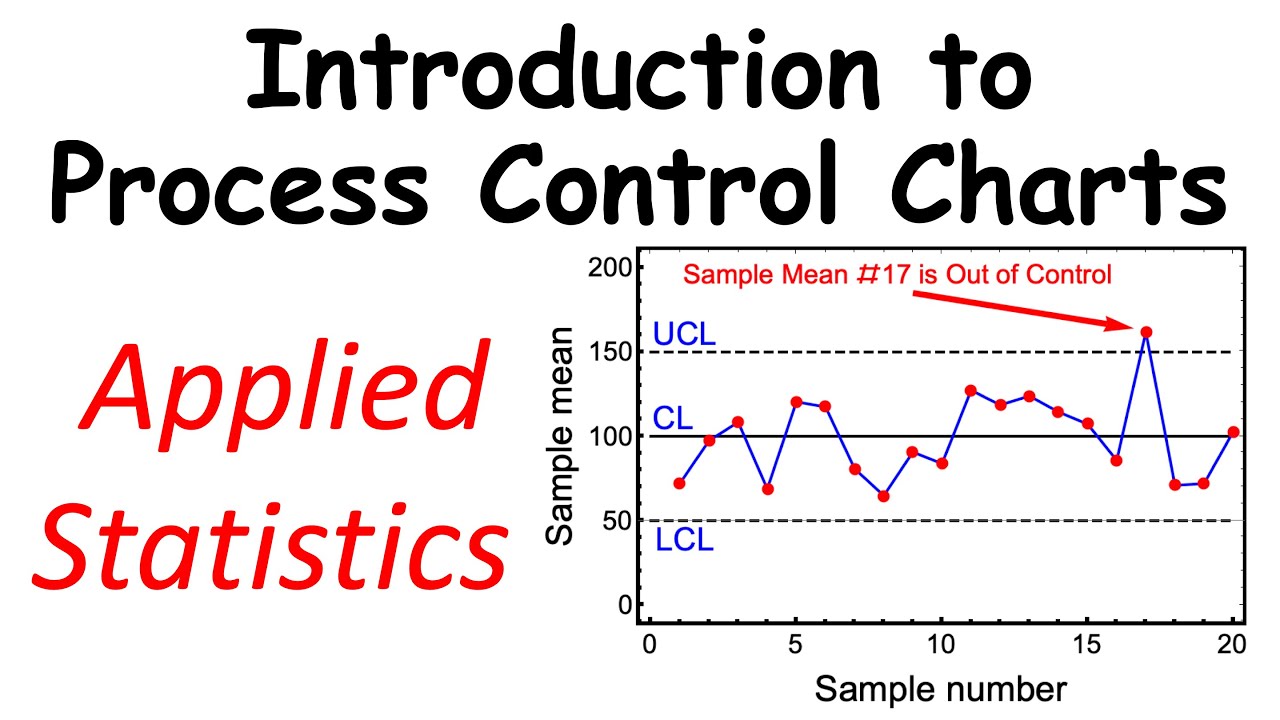

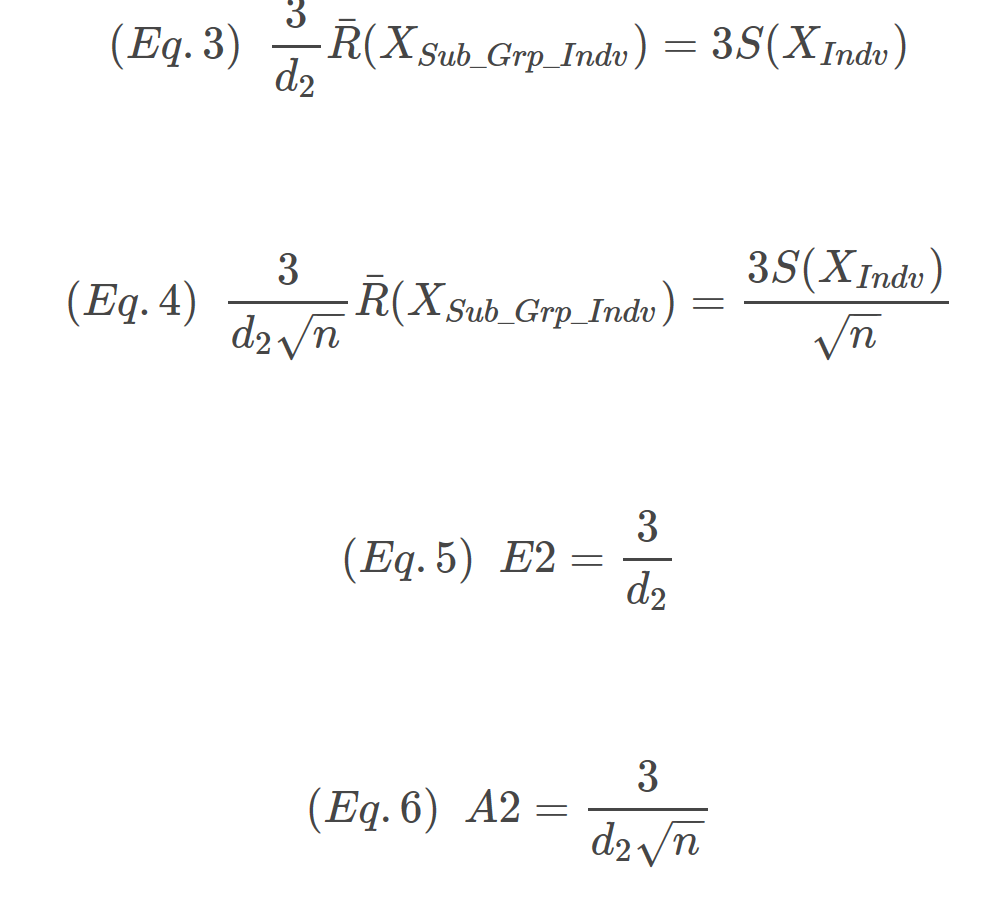

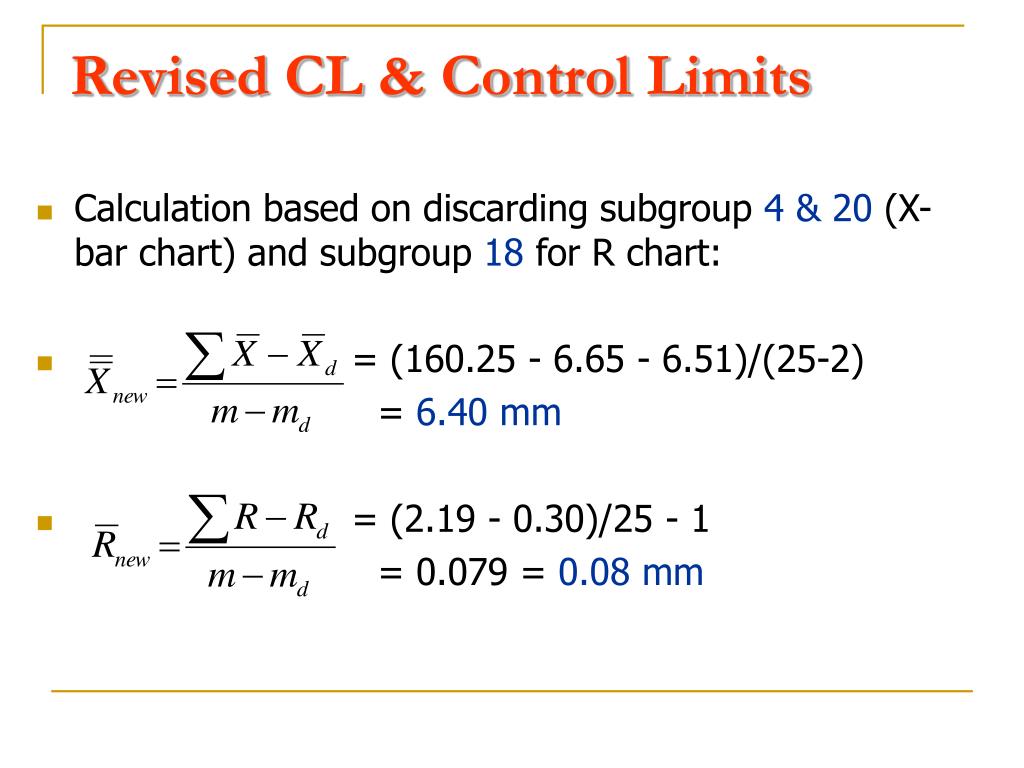

R Chart Formula - The and r chart plots the mean value for the quality characteristic across all units in the sample, , plus the range of the quality characteristic across all units in the sample as follows: U c lr = d4 ¯r u c l r = d 4 r ¯. For a sample size, n, of less than 7 the lower limit is zero. We can supply a vector or matrix to this function. If we supply a vector, the plot will have bars with their heights equal to. U chart for rate of defects. If the r chart is out of control, then the control limits on the xbar. The chart actually consists of a pair of charts: Select the method or formula of your choice. Is your process in control? Web the control chart basics, including the 2 types of variation and how we distinguish between common and special cause variation, along with how to create a ra. If we supply a vector, the plot will have bars with their heights equal to. The and r chart plots the mean value for the quality characteristic across all units in the. We can supply a vector or matrix to this function. For a sample size, n, of less than 7 the lower limit is zero. Parameter for test 1 (the default value is 3 for analyses that allow custom values. The and r chart plots the mean value for the quality characteristic across all units in the sample, , plus the. The value is 3 for analyses that do not allow custom values.) σ. This causes the x chart. Parameter for test 1 (the default value is 3 for analyses that allow custom values. Is your process in control? If the subgroup size is one, the. The xmr chart is a great statistical process control (spc) tool that can help you answer this question, reduce waste, and increase. Is your process in control? The chart actually consists of a pair of charts: Web bar plots can be created in r using the barplot() function. We can supply a vector or matrix to this function. Web below are the x bar r chart formula that used in the qi macros for both range & avg (xbar) charts. U c lr = d4 ¯r u c l r = d 4 r ¯. Look at the r chart first; If the r chart is out of control, then the control limits on the xbar. Lc lr. Web the r chart is used to evaluate the consistency of process variation. Is your process in control? $$ then an estimate of \(\sigma\) can be. Web let \(r_1, \, r_2, \, \ldots, r_k\), be the ranges of \(k\) samples. If each set of n rows represents a group, enter the. P chart for proportion of defective units. Web let \(r_1, \, r_2, \, \ldots, r_k\), be the ranges of \(k\) samples. Subgroups should be formed to minimize the amount of variation within a subgroup. The xmr chart is a great statistical process control (spc) tool that can help you answer this question, reduce waste, and increase. Web the control chart. Web bar plots can be created in r using the barplot() function. Look at the r chart first; The xmr chart is a great statistical process control (spc) tool that can help you answer this question, reduce waste, and increase. U chart for rate of defects. Web the r chart is used to evaluate the consistency of process variation. If the subgroup size is one, the. Web below are the x bar r chart formula that used in the qi macros for both range & avg (xbar) charts. One to monitor the process standard deviation (as approximated by the sample moving range) and another to monitor the process mean, as is done with the $${\displaystyle {\bar {x}}}$$ and s. The chart actually consists of a pair of charts: Web r = the absolute value of the difference between successive pairs of measurements. The value is 3 for analyses that do not allow custom values.) σ. The average range is $$ \bar{r} = \frac{r_1 + r_2 +. Look at the r chart first; U c lr = d4 ¯r u c l r = d 4 r ¯. $$ then an estimate of \(\sigma\) can be. The and r chart plots the mean value for the quality characteristic across all units in the sample, , plus the range of the quality characteristic across all units in the sample as follows: = average of the moving ranges. The average range is $$ \bar{r} = \frac{r_1 + r_2 +. Subgroups should be formed to minimize the amount of variation within a subgroup. If we supply a vector, the plot will have bars with their heights equal to. Web let \(r_1, \, r_2, \, \ldots, r_k\), be the ranges of \(k\) samples. The chart actually consists of a pair of charts: Web bar plots can be created in r using the barplot() function. Web the r chart is used to evaluate the consistency of process variation. Is your process in control? In the formulas above, you see mention of the constants a2, d4,. P chart for proportion of defective units. Web the control chart basics, including the 2 types of variation and how we distinguish between common and special cause variation, along with how to create a ra. Lc lr = d3 ¯r l c l r = d 3 r ¯.

How to plot xbar and r bar chart in excel crosspasa

Xbar And R Chart Formula And Constants The Definitive vrogue.co

PPT X AND R CHART EXAMPLE INCLASS EXERCISE PowerPoint Presentation

What is common to each of the formulas on the xbar and rcharts. On

PPT X AND R CHART EXAMPLE INCLASS EXERCISE PowerPoint Presentation

Statistical Process Control Charts for the Mean and Range X Bar Charts

Estimating Control Chart Constants with R

Xbar and R Chart Formula and Constants The Definitive Guide

PPT Control Charts for Variables PowerPoint Presentation, free

PPT Chapter 17 PowerPoint Presentation, free download ID5953193

Look At The R Chart First;

For A Sample Size, N, Of Less Than 7 The Lower Limit Is Zero.

If The R Chart Is Out Of Control, Then The Control Limits On The Xbar.

If Each Set Of N Rows Represents A Group, Enter The.

Related Post: