Press Fit Bushing Tolerance Chart

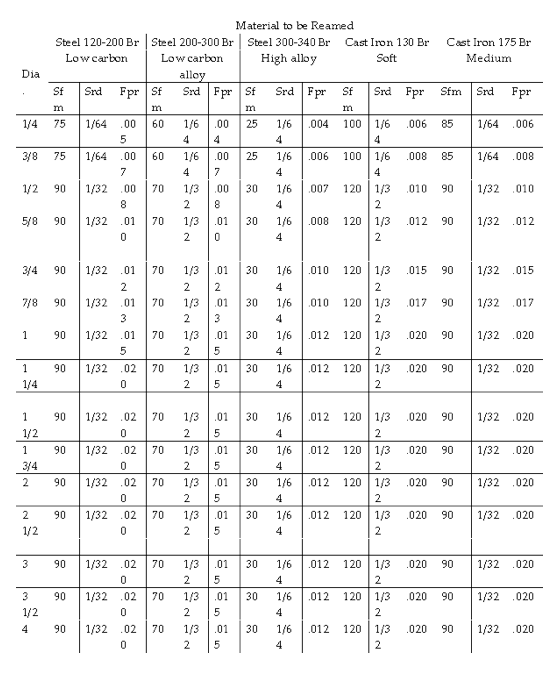

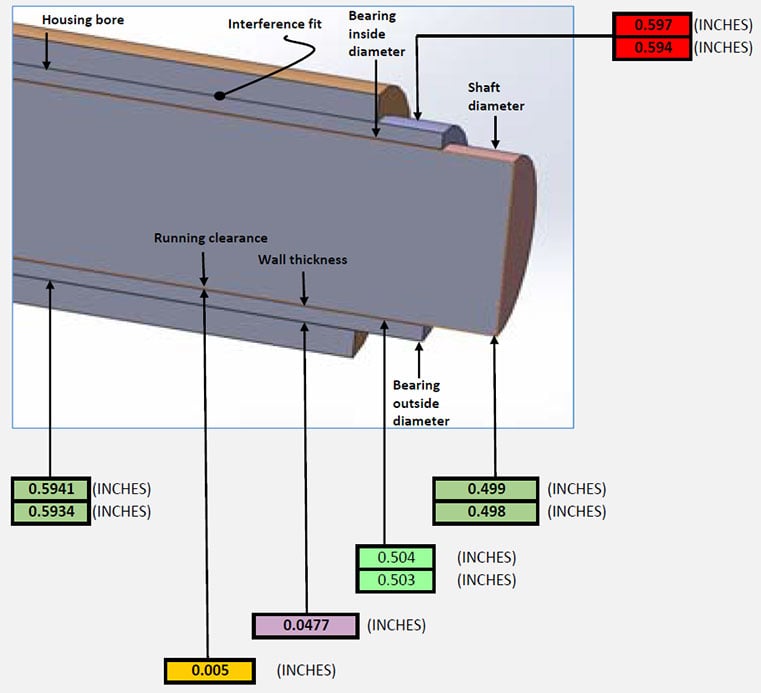

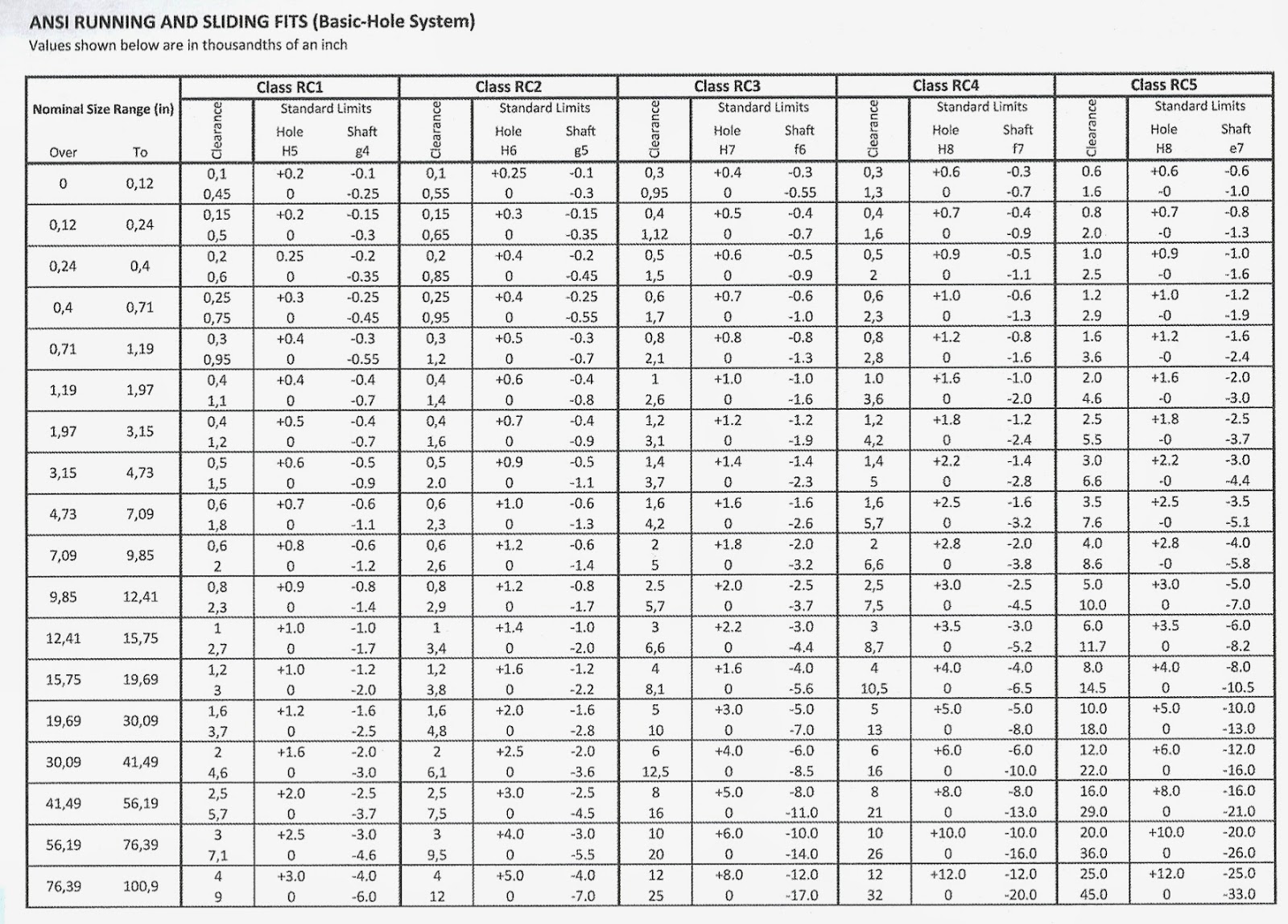

Press Fit Bushing Tolerance Chart - Preferred force shrink fits chart. Web learn about tolerance in press fit, the permissible deviation from the assigned dimensions of mating parts. See technical information on id and od tolerances, material, heat treatment, finish and more. Also, the id tolerance is 0.065 mm after installation. Web interference (press & shrink) fit calculator; The effective interference of the press fit is. Preferred tolerances and fits charts (ansi) precision measuring tools for shaft and hole measurements; Go here, for explanasions about the terms hole, shaft, ei, and. Web sliding fit driving fit press fit strong press fit shrinkage fit loose fit light roll fit roll fit 50 0 −50 −100 −150 −200 dimension tolerance h6 h7 200 150 100 50 0 −50 Bushing and plain bearings press or shrink fit design and application. Also, the id tolerance is 0.065 mm after installation. Web use this calculator to determine the proper installation hole size for standard press fit bushings. See technical information on id and od tolerances, material, heat treatment, finish and more. Preferred force shrink fits chart. Preferred tolerances and fits charts (ansi) precision measuring tools for shaft and hole measurements; Also, the id tolerance is 0.065 mm after installation. To maximize hole accuracy and minimize. Complete charts for h7/t6 press. The effective interference of the press fit is. Find your data faster with our fits calculator. Web the appropriate values for shaft seats are listed for the following tolerance classes: Preferred tolerances and fits charts (ansi) precision measuring tools for shaft and hole measurements; F5, f6, g5, g6, h5 ( table 1) h6, h8, h9, j5, j6 ( table 2) js4, js5, js6, js7, k4 ( table 3) k5, k6, m5, m6, n5 ( table 4). Find your data faster with our fits calculator. Fixing a gear and a shaft together (low torque) shaft of a flexible coupling and a gear (drive side) functional classification. Complete charts for h7/t6 press. Web class v locational interference tolerance chart for holes and bolts. Find your data faster with our fits calculator. Web in most installations diametric interference of.0005 to.0008 is adequate for installation of press fit bushings or liners. Web class v locational interference tolerance chart for holes and bolts. All tolerances classes and sizes according to standard. Web interference (press & shrink) fit calculator; Web the appropriate values for shaft seats are listed for the following tolerance classes: Web learn about tolerance in press fit, the permissible deviation from the assigned dimensions of mating parts. All tolerances classes and sizes according to standard. Bushing and plain bearings press or shrink fit design and application. See technical information on id and od tolerances, material, heat treatment, finish and more. Web class v locational interference tolerance chart for holes and. Go here, for explanasions about the terms hole, shaft, ei, and. Insertion of a suction valve and valve guide. Preferred tolerances and fits charts (ansi) precision measuring tools for shaft and hole measurements; All tolerances classes and sizes according to standard. Web the appropriate values for shaft seats are listed for the following tolerance classes: Web sliding fit driving fit press fit strong press fit shrinkage fit loose fit light roll fit roll fit 50 0 −50 −100 −150 −200 dimension tolerance h6 h7 200 150 100 50 0 −50 Preferred tolerances and fits charts (ansi) precision measuring tools for shaft and hole measurements; Find your data faster with our fits calculator. Attaching and fixing. Web the chart and diagram shows that after installation this bushing will have a total od tolerance of 0.030 mm. Web interference (press & shrink) fit calculator; All tolerances classes and sizes according to standard. Go here, for explanasions about the terms hole, shaft, ei, and es. Preferred force shrink fits chart. Find your data faster with our fits calculator. To maximize hole accuracy and minimize. See technical information on id and od tolerances, material, heat treatment, finish and more. Bushing and plain bearings press or shrink fit design and application. Insertion of a suction valve and valve guide. The effective interference of the press fit is. Hard to disassemble without damaging the components. Find out the factors influencing tolerances, tools. Preferred tolerances and fits charts (ansi) precision measuring tools for shaft and hole measurements; Complete charts for h7/t6 press. Go here, for explanasions about the terms hole, shaft, ei, and. Web engineering, manufacturing tolerance limits fits charts. Web the chart and diagram shows that after installation this bushing will have a total od tolerance of 0.030 mm. Find your data faster with our fits calculator. Find your data faster with our fits calculator. Web class v locational interference tolerance chart for holes and bolts. Fixing a gear and a shaft together (low torque) shaft of a flexible coupling and a gear (drive side) functional classification. Web in most installations diametric interference of.0005 to.0008 is adequate for installation of press fit bushings or liners. Go here, for explanasions about the terms hole, shaft, ei, and es. All tolerances classes and sizes according to standard. Attaching and fixing a bearing bushing.

Press Fit Bushing Tolerance Chart

Bushing Press Fit Tolerance Chart Best Picture Of Chart

Press Fit Interference Chart

Press Fit Bushing Tolerance Chart

Too Tight or Perfect Fit? When to Use Press Fits in Your Assemblies

Bushing Press Fit Tolerance Chart My XXX Hot Girl

How to Install and Remove a Bushing Baart Industrial Group

Bearing Selection and Achieving the Right Press Fit

Press Fit Bearing Tolerance Chart

hole sizes for pressfit bushings in unhardened steel or

Web Learn About Tolerance In Press Fit, The Permissible Deviation From The Assigned Dimensions Of Mating Parts.

Go Here, For Explanasions About The Terms Hole,.

Bushing And Plain Bearings Press Or Shrink Fit Design And Application.

Web Sliding Fit Driving Fit Press Fit Strong Press Fit Shrinkage Fit Loose Fit Light Roll Fit Roll Fit 50 0 −50 −100 −150 −200 Dimension Tolerance H6 H7 200 150 100 50 0 −50

Related Post: