Plastic Melting Temperature Chart

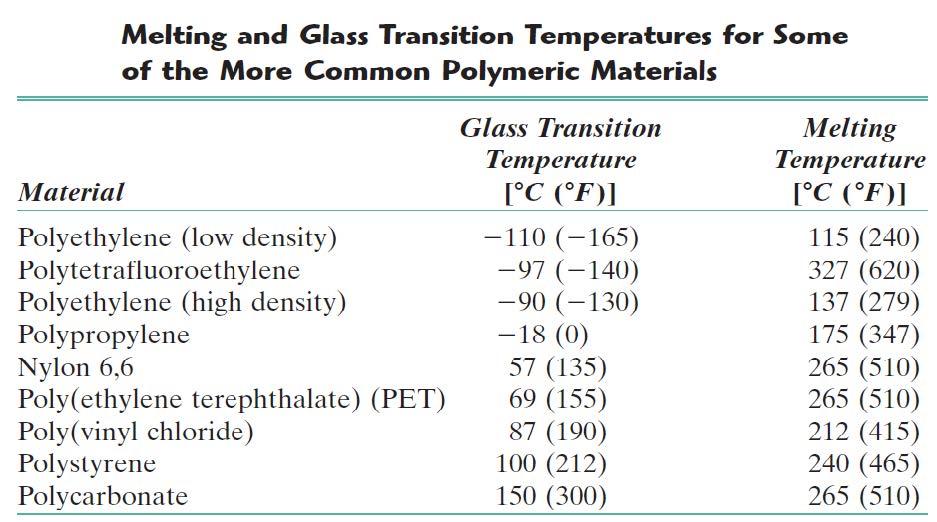

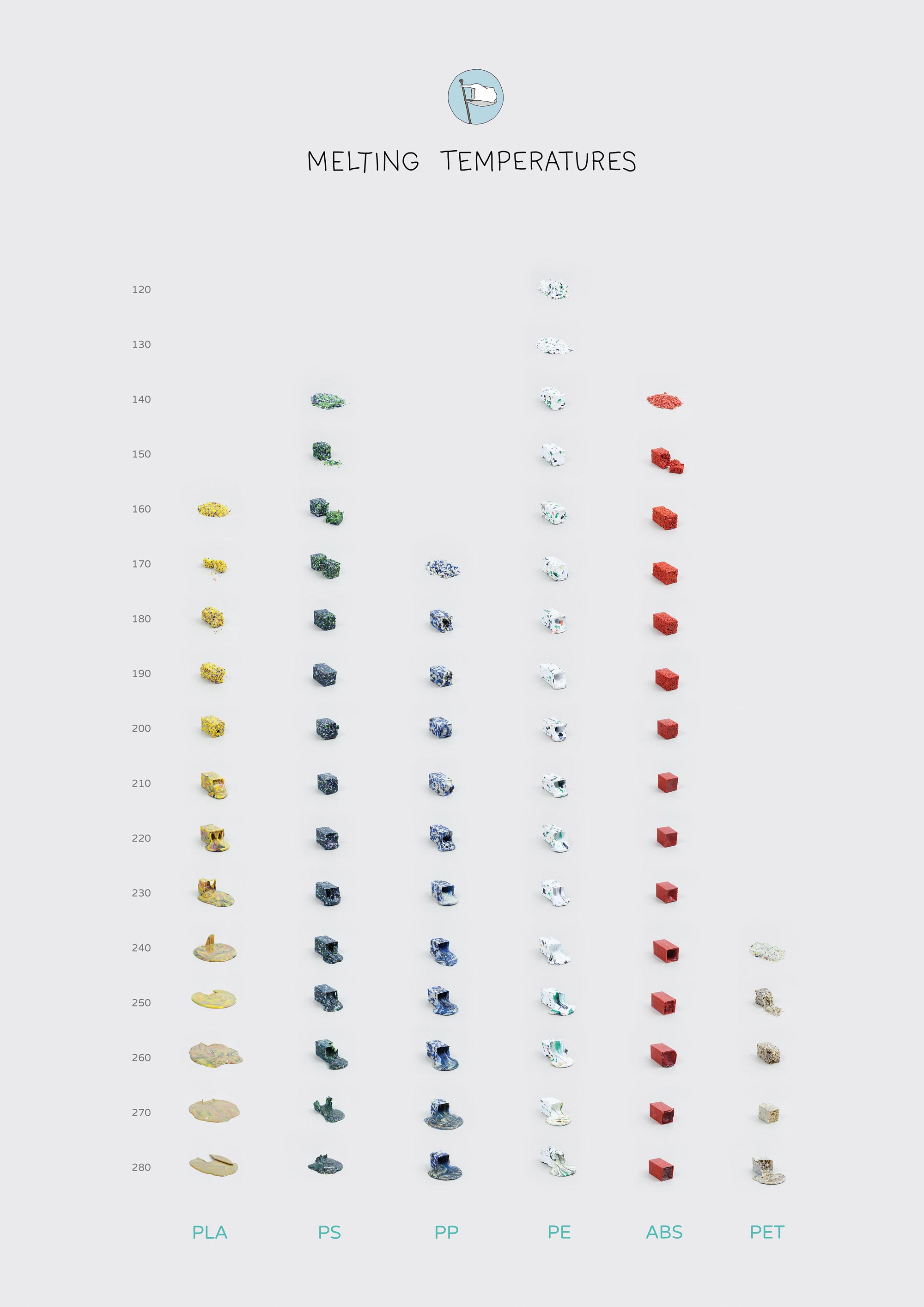

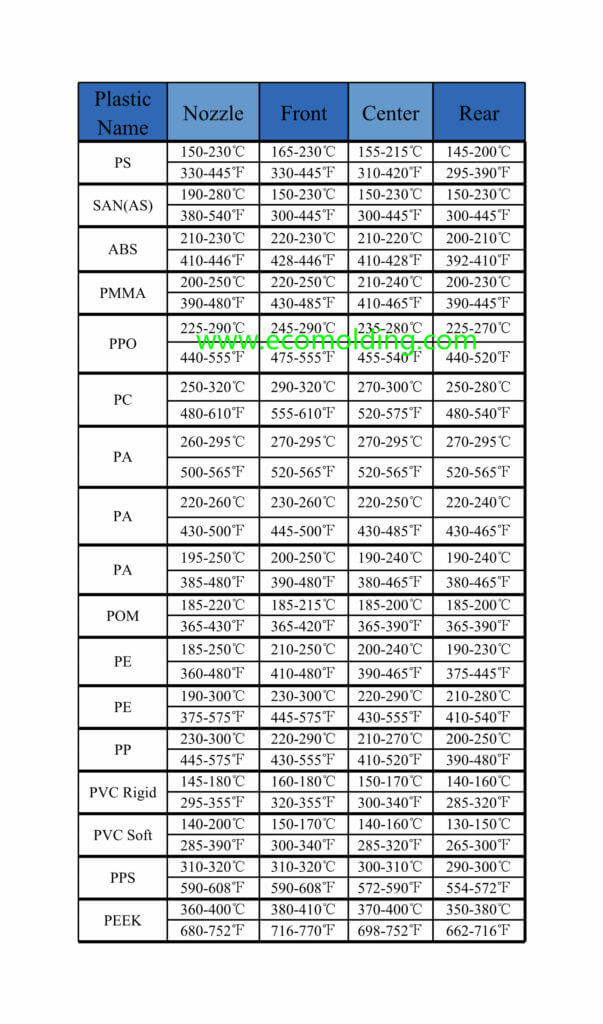

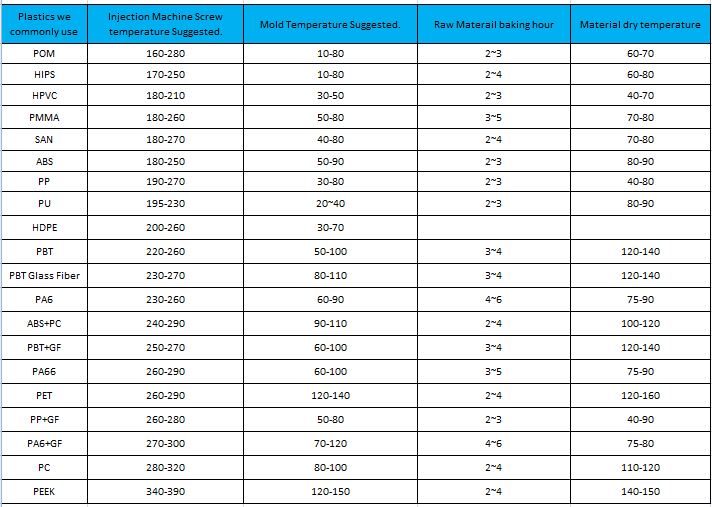

Plastic Melting Temperature Chart - • soften over a wide temperature range. Get in the right group what is most important to the application? (1 atm = 101,325 pa) click on the icon to switch between degrees celsius (°c) and degrees fahrenheit (°f) units. Preheat the oven to around 300 °f (149 °c). When exposed to colder temperatures, polypropylene plastic begins to degrade more quickly. Web the melting point of plastic refers to the temperature at which it transitions from a solid to a liquid state. A homogenous melt is required for consistent part quality, but achieving it requires balancing a number of factors, including barrel usage and temperature as well as screw speed, backpressure and residence time. Web below is a comprehensive chart to the melting and molding temperatures of various plastic materials: Web unlock the secrets of optimal plastic melt and mould temperatures. The flexural strength of injection molding materials. The flexural strength of injection molding materials. Web the melting point of plastic refers to the temperature at which it transitions from a solid to a liquid state. Detailed temperature ranges for common plastics. Manufacturers often incorporate additives into thermoplastics, such as pigments, plasticizers, or stabilizers, to modify the material's properties, including its melting point. The tensile strength of injection. Tips on how to safely melt plastic. Ratings based on five minute tests using 600 watts of power on exposed, empty labware. Web melt preparation part 1: (1 atm = 101,325 pa) click on the icon to switch between degrees celsius (°c) and degrees fahrenheit (°f) units. • soften over a wide temperature range. Web plastic material melt & mould temperatures chart. • soften over a wide temperature range. Tips on how to safely melt plastic. It is available in different crystalline structures, referred to as hdpe, ldpe, and lldpe. Web find out the perfect pp plastic from more than 13000 commercial grades present in our database. Web find out the perfect pp plastic from more than 13000 commercial grades present in our database. Tips on how to safely melt plastic. What is melting point of plastics? On the other hand, ice (solid h 2 o) is a molecular compound whose molecules are held together by hydrogen bonds, which is effectively a strong example of an interaction. Use temp., or expose labware to chemicals which heating cause to attack the plastic or be rapidly absorbed. 3.1 thermal analysis of pp, pmma and pvc. Web table list for plastic melting temperature and mold temp. Web pla's melting point typically ranges between 150°c and 180°c, although this varies depending on the specific grade of pla and whether the material. Web pla's melting point typically ranges between 150°c and 180°c, although this varies depending on the specific grade of pla and whether the material has any additives. Get in the right group what is most important to the application? Use temp., or expose labware to chemicals which heating cause to attack the plastic or be rapidly absorbed. This temperature will. The flexural strength of injection molding materials. Polymer materials have high plasticity that enables them to mold, press easily, and even extrude. Detailed temperature ranges for common plastics. When exposed to colder temperatures, polypropylene plastic begins to degrade more quickly. Web find out the perfect pp plastic from more than 13000 commercial grades present in our database. Polymer materials have high plasticity that enables them to mold, press easily, and even extrude. The plastic material melt & mould temperatures chart is an essential tool in the field of plastic manufacturing, providing vital data on the optimal temperatures required to melt and mold various types of. This temperature will gradually melt the plastic. Use temp., or expose labware. Numerous industries use polyethylene, particularly hdpe and ldpe, for a variety of purposes. Discuss the melting point of all the mainstream plastics with a defined table. (1 atm = 101,325 pa) click on the icon to switch between degrees celsius (°c) and degrees fahrenheit (°f) units. Web pla's melting point typically ranges between 150°c and 180°c, although this varies depending. Web table list for plastic melting temperature and mold temp. Web (flashpoint of pvc) what is plastic? Web unlock the secrets of optimal plastic melt and mould temperatures. A “flat heat profile” is generally recommended when developing a molding process with a new resin. It is a commodity plastic with. 3.1 thermal analysis of pp, pmma and pvc. The plastic will absorb and retain significant amounts of heat resulting in an unexpectedly hot surface. What is mold temperature of plastics? Its main ingredient is polymer, a type of organic compound. Tips on how to safely melt plastic. Web the melting point of plastic refers to the temperature at which it transitions from a solid to a liquid state. Polymer materials have high plasticity that enables them to mold, press easily, and even extrude. When exposed to colder temperatures, polypropylene plastic begins to degrade more quickly. 1.2 thermal analysis by differential scanning calorimetry. However, you will need to be patient with the melting. Web plastic material selection guide (at curbell plastics) 1. This critical characteristic determines the conditions under which plastic can be shaped, recycled, and utilized in various applications. Get in the right group what is most important to the application? On the other hand, ice (solid h 2 o) is a molecular compound whose molecules are held together by hydrogen bonds, which is effectively a strong example of an interaction between two permanent dipoles. Range for different plastics like abs, hdpe, pp, ps, pet, pvc, pa, pmm, acetal,etc Web comprehensive guide on polyethylene (pe) polyethylene (pe) is one of the most popular thermoplastic materials.

Plastic Melting Temperature Chart

The Basics of Plastic · Precious Plastic Toolbox

What is the best injection molding

:max_bytes(150000):strip_icc()/Highperformance_thermoplastics_en-58d93d655f9b58468394f718.png)

High Temperature Thermoplastics

Melting temperatures of plastics. Download Scientific Diagram

Material & Mold Temperature information in injection molding

Material Melt and Mould Temperature Chart PlastikCity Temperature

Plastic Melting Temperature Chart

Solved Table below shows the melting and glass transition

Mastering Plastic Material Melt & Mould Temperatures Essential Tips

• Soften Over A Wide Temperature Range.

Web Plastic Material Melt & Mould Temperatures Chart.

The Plastic Material Melt & Mould Temperatures Chart Is An Essential Tool In The Field Of Plastic Manufacturing, Providing Vital Data On The Optimal Temperatures Required To Melt And Mold Various Types Of.

• Bond Well Using Adhesives Or Solvents.

Related Post: