Piping Span Chart

Piping Span Chart - Pressure in pipe is 20 bar at atmospheric temperature using the procedure described above. Proper pipe support span is as important as the selection of support. Click to print our line sheet. This chart should only be used as a general guide. Web pipe support span (spacing) guideline. Stress and deflection are calculated as functions of the pipes' section properties and the weights applied to the pipes. Web special pipe supports (sps) piping support standards and codes. Whenever two pipes run parallel to each other, piping designers or engineers must maintain a minimum gap between the two pipes or pipelines. Overdoing can impact your budget, and underdoing impacts plant safety. Web pipe dimension chart (11×17) click to print our pipe dimension chart. Pressure in pipe is 20 bar at atmospheric temperature using the procedure described above. Use our ansi pipe chart to determine the nominal pipe size, wall thickness, weight and schedule designations. Web pipe dimension chart (11×17) click to print our pipe dimension chart. It's an important parameter in piping design and engineering to ensure the structural integrity and safety of. The maximum pipe support spacing is dependant on the maximum allowable deflection or sag in the piping and the maximum permissible stress. The distance between two consecutive support is defined as the support span. Pipe allowable support span as per asme b31.3, asme b31.1. As we’ve pointed out, there are various factors that contribute to support requirements that you will. Click to print our line sheet. The span is the distance between two points where a pipe is supported, such as at. Proper pipe support span is as important as the selection of support. To absorb excessive line vibrations. Pipe support span or spacing. Web of the 57 stainless steels recognized as standard by the american iron and steel institute (aisi), those most commonly used in piping systems are the austenitic alloys represented by aisi types 304, 304l, 316 and 316l. Web special pipe supports (sps) piping support standards and codes. Web a pipe spacing chart provides the minimum distance between two adjacent pipes. Web special pipe supports (sps) piping support standards and codes. Web pipe dimension chart (11×17) click to print our pipe dimension chart. Let us calculate the maximum support span for transporting water through a seamless stainless steel pipe (astm a 312 tp 316 l) of 300 nps through a distance of 15 km. You should consider the material used, wall. Click to print our line sheet. Web of the 57 stainless steels recognized as standard by the american iron and steel institute (aisi), those most commonly used in piping systems are the austenitic alloys represented by aisi types 304, 304l, 316 and 316l. Calculate spacing between pipes on a pipe rack based on dimensional standard asme b16.5 and b16.47. Web. = 0.3239 m [2] = 20 bar. Pipe span charts are very nice, but not more than a guide. Web of the 57 stainless steels recognized as standard by the american iron and steel institute (aisi), those most commonly used in piping systems are the austenitic alloys represented by aisi types 304, 304l, 316 and 316l. Web the given standard. Pipe allowable support span as per asme b31.3, asme b31.1. Web special pipe supports (sps) piping support standards and codes. In case of weaker thickness (often in the range of stainless steel) the. Pipe support arrangement in pipe rack. Web allowable pipe span is the maximum distance between supports or hangers that a pipe can span without excessive deflection or. Web special pipe supports (sps) piping support standards and codes. Click to print our line sheet. Proper pipe support span is as important as the selection of support. I've seen several tables and charts, all with different values. It's an important parameter in piping design and engineering to ensure the structural integrity and safety of a piping system. The span is the distance between two points where a pipe is supported, such as at. I've seen several tables and charts, all with different values. As we’ve pointed out, there are various factors that contribute to support requirements that you will need to take into account for each system you create. To absorb excessive line vibrations. Let us calculate. The various functions that pipe support serves are as follows: The distance between two consecutive support is defined as the support span. Web a pipe spacing chart provides the minimum distance between two adjacent pipes or pipelines. Determination of pipe support location. = 0.3239 m [2] = 20 bar. As we’ve pointed out, there are various factors that contribute to support requirements that you will need to take into account for each system you create. Web allowable pipe span is the maximum distance between supports or hangers that a pipe can span without excessive deflection or stress. Web pipespans is a spreadsheet program written to determine the maximum stress and deflection of a pipe. Web pipe support span (spacing) guideline. Web online piping spacing calculator. Pipe support span or spacing. In case of weaker thickness (often in the range of stainless steel) the. Web piping system selection and applications.1. Pipe support arrangement in pipe rack. Proper pipe support span is as important as the selection of support. Pipe allowable support span as per asme b31.3, asme b31.1.

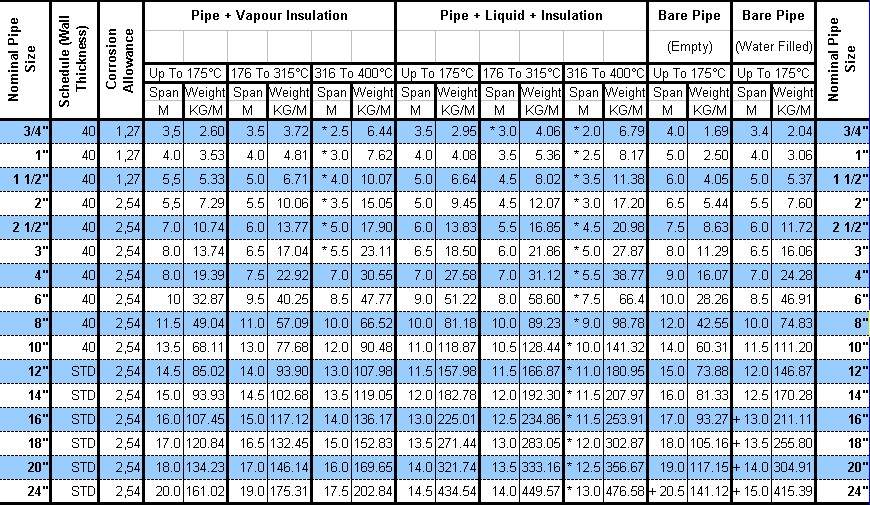

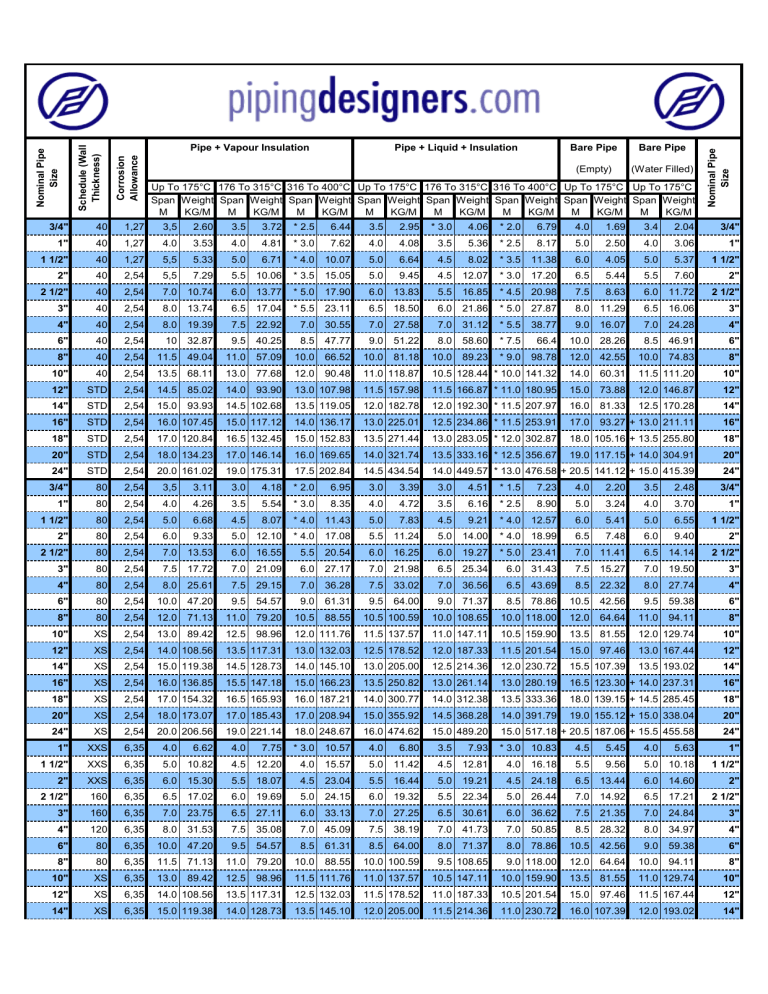

Allowable Pipe Span Chart

Pipe Span Chart Pipe (Fluid Conveyance) Civil Engineering

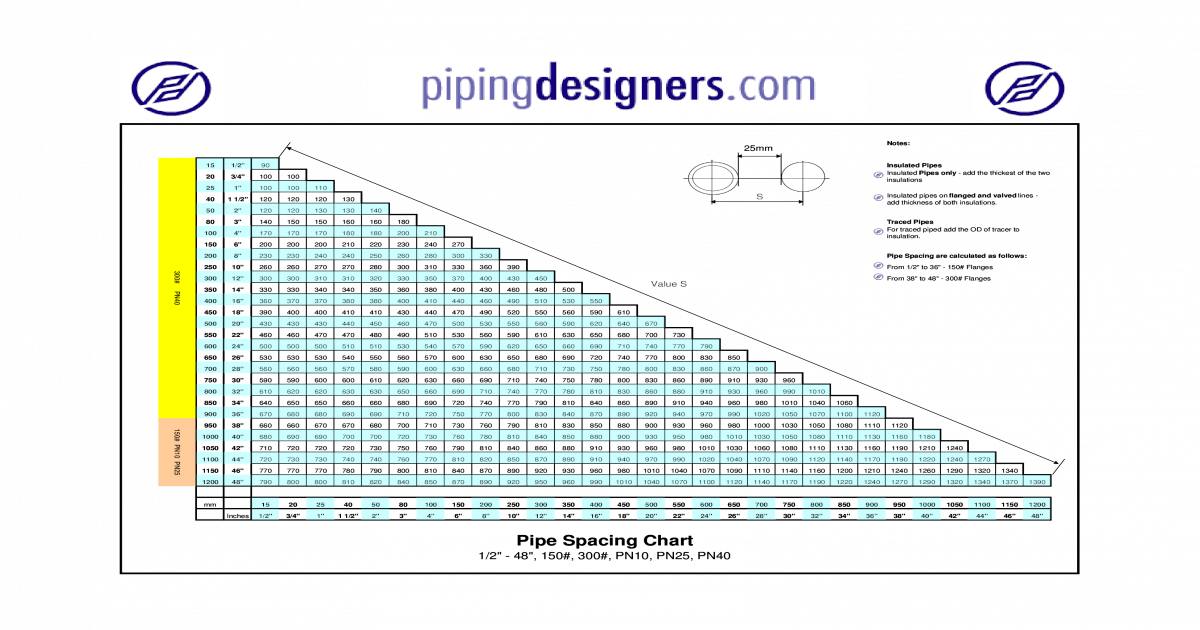

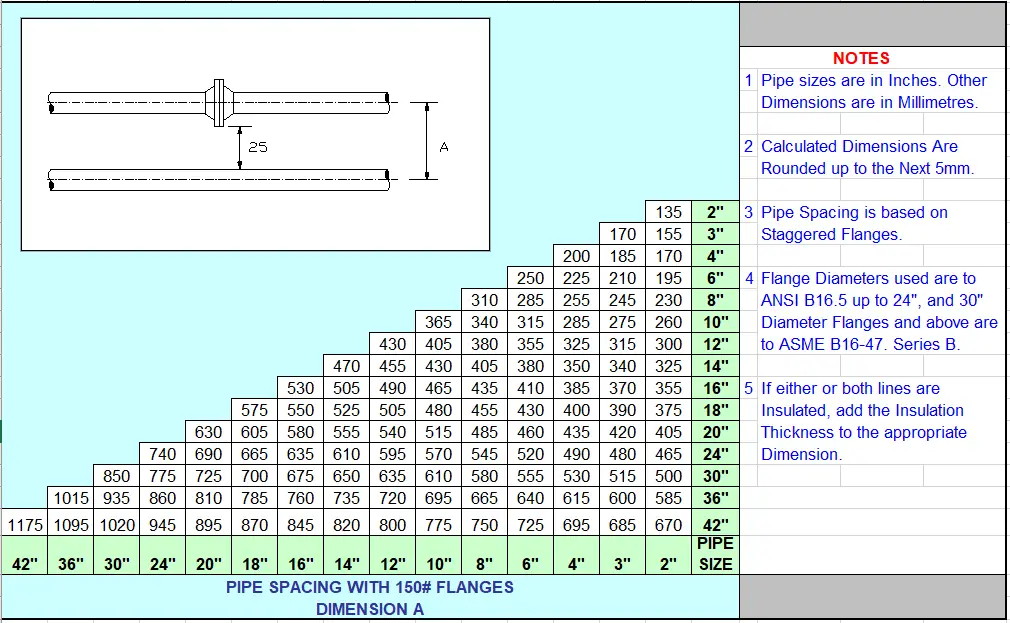

Pipe Spacing Chart Piping Designers . Spacing 15mm · Pipe Spacing

Pipe Span Chart Pipe (Fluid Conveyance) Chemical Engineering

pipe span chart

Pipe Span Chart

Pipe Span Chart PDF Pipe (Fluid Conveyance) Civil Engineering

The maximum steel pipe support spacing California

Piping Spacing Chart

What are piping supports ? Piping engineer world

Distance Between Steel Pipe Supports.

Web Of The 57 Stainless Steels Recognized As Standard By The American Iron And Steel Institute (Aisi), Those Most Commonly Used In Piping Systems Are The Austenitic Alloys Represented By Aisi Types 304, 304L, 316 And 316L.

Web Allowable Spans Are Based On A Maximum Bending Stress Of 41.37 Mpa (6000 Psi) Or A Maximum Deflection Of 12.7 Mm (0.5In).

Pipe Span Charts Are Very Nice, But Not More Than A Guide.

Related Post: