Pipe Support Chart

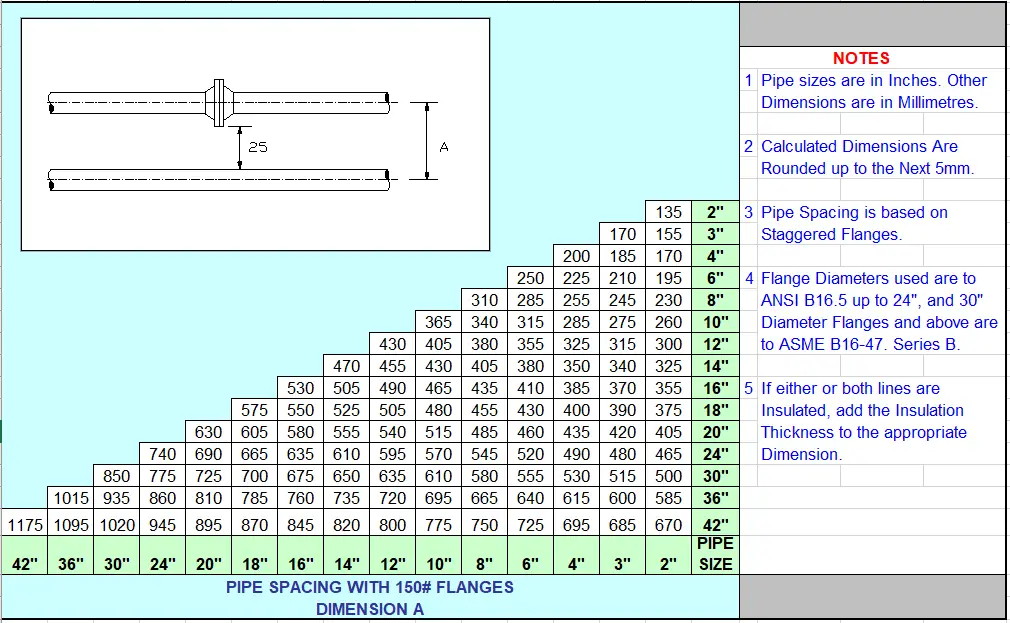

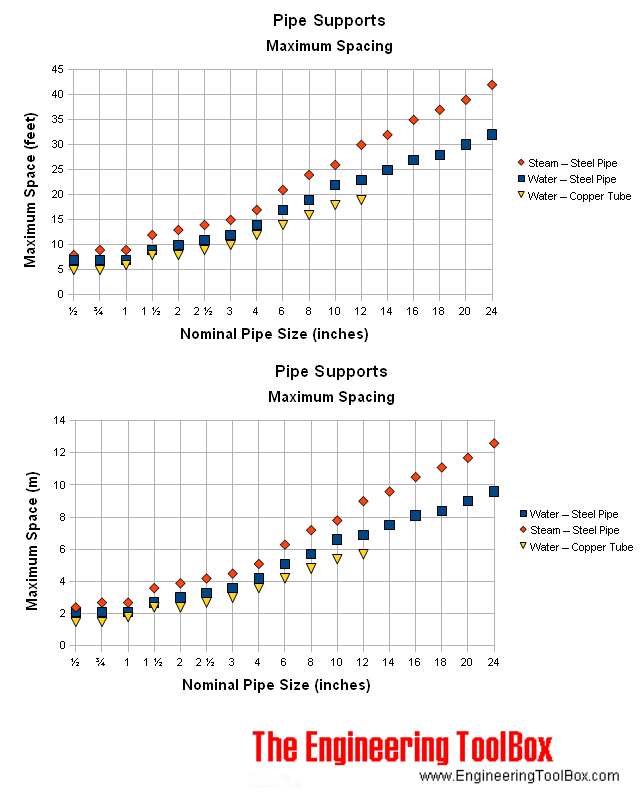

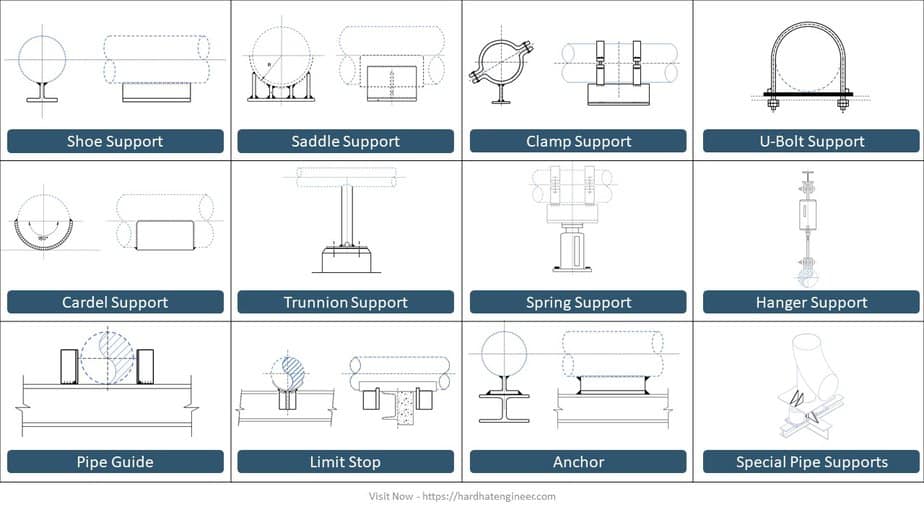

Pipe Support Chart - The document provides specifications for pipe insulation including nominal pipe size, schedule/wall thickness, temperature range, span length, and weight per meter for various pipe configurations. Pipe span charts are very nice, but not more than a guide. Web the document provides guidelines for pipe support spacing and adjustments. The calculation is applicable only for uniform pipe without any attached concentrated weight, such as a valve. Comparison of spacing required for pipe supports for various australian piping design standards. Web allowable pipe span is the maximum distance between supports or hangers that a pipe can span without excessive deflection or stress. Suggested max span for straight horizontal line ; No firm rules or limits exist which will positively fix the location of each support on a piping system. In the following image (fig. There are all kinds of formulas and techniques used to determine the amount of support required. For the static dimensioning of a pipe support, the weight which has to be carried by the clamp has. Web pipe support spacing chart as per asme b31.1 ; In this chapter, we will explore some of the most commonly used types of piping support, including pipe hangers and their subtypes. Web a pipe spacing chart provides the minimum distance. Web a pipe spacing chart provides the minimum distance between two adjacent pipes or pipelines. In the following image (fig. Web piping support is a critical component of any piping system, and various types of support mechanisms are employed to ensure the stability, safety, and functionality of pipelines. Web all pipe supports in this section are sized to fit schedule. Steam, air, gas service ; Web this pipe support spacing calculation was developed based upon equations contained in section 6.2 of pipe stress engineering published by peng engineering. Web support spacing in meter. Web support locations are dependent on pipe size, piping configuration, the location of heavy valves and fittings, and the structure that is available for the support of. There are all kinds of formulas and techniques used to determine the amount of support required. It is not applicable for the overhanging span either. Spans are based on pvc pipe filled with water and maximum sag of 2.5mm at center of span. You’ll find that your support needs vary from system to system based on configuration, pipe size, load,. Web piping support is a critical component of any piping system, and various types of support mechanisms are employed to ensure the stability, safety, and functionality of pipelines. Whenever two pipes run parallel to each other, piping designers or engineers must maintain a minimum gap between the two pipes or pipelines. There are all kinds of formulas and techniques used. You should consider the material used, wall thickness, density of the medium, isolation, etc.for really good assessment of working stresses and deflections, pipe stress calculations are needed. Steam, air, gas service ; Supports, guides, shields & saddles pipe supports, guides, shields & saddles It's an important parameter in piping design and engineering to ensure the structural. See pipe data charts. Web the selection of pipe support span by an layout engineer/support engineer/stress engineer/piping engineer varies from project to project by considering the project cost and process parameter. There are all kinds of formulas and techniques used to determine the amount of support required. Web the document provides guidelines for pipe support spacing and adjustments. Comparison of spacing required for pipe. Some steel items may be specially fabricated to fit other pipe diameters i.e. Whenever two pipes run parallel to each other, piping designers or engineers must maintain a minimum gap between the two pipes or pipelines. Steam, air, gas service ; In this chapter, we will explore some of the most commonly used types of piping support, including pipe hangers. Web this pipe support spacing calculation was developed based upon equations contained in section 6.2 of pipe stress engineering published by peng engineering. Some steel items may be specially fabricated to fit other pipe diameters i.e. I've seen several tables and charts, all with different values. Web there are a number of factors that go into calculating the amount of. Ductile iron, cast iron, etc. It recommends maximum spacing between pipe supports for horizontal steel pipes under various conditions. Web support locations are dependent on pipe size, piping configuration, the location of heavy valves and fittings, and the structure that is available for the support of the piping. There are all kinds of formulas and techniques used to determine the. Pipe support spacing table (chart) for sch 40 pvc pipes. Da = 168.3 mm, din 2448, lst = 4 m m’ = 38 kg/m 0.38 kn/m = g’ gthoer = 0.38 kn/m · 4 m 1.5 kn explanation: No firm rules or limits exist which will positively fix the location of each support on a piping system. Spans are based on pvc pipe filled with water and maximum sag of 2.5mm at center of span. Web the selection of pipe support span by an layout engineer/support engineer/stress engineer/piping engineer varies from project to project by considering the project cost and process parameter. For the static dimensioning of a pipe support, the weight which has to be carried by the clamp has. Web piping support is a critical component of any piping system, and various types of support mechanisms are employed to ensure the stability, safety, and functionality of pipelines. Some steel items may be specially fabricated to fit other pipe diameters i.e. The calculation is applicable only for uniform pipe without any attached concentrated weight, such as a valve. Placing the pipes in proper order following a pipe spacing chart provides various benefits like: June 2017 1/06/2017 uncontrolled when printed page 7 of 158 3.3 materials the preferred materials and surface finishes from which the components of pipe support assemblies shall be manufactured are given in table 1 and 2. Steam, air, gas service ; Pipe span charts are very nice, but not more than a guide. Web all pipe supports in this section are sized to fit schedule 40/80 pipe unless otherwise noted. You should consider the material used, wall thickness, density of the medium, isolation, etc.for really good assessment of working stresses and deflections, pipe stress calculations are needed. It is not applicable for the overhanging span either.

Pipe Supports

Pipe Support Spacing Chart Pdf

What You Need to Know About Supports and Hangers for CPVC Piping and

pipe branch dummy support PDF chart 1 ½" × 1 ½" to 1 ½" × 8"

What are piping supports ? Piping engineer world

Determination of Loads And Movements in Piping Supports PIPING GUIDE

Pipe Spacing Chart Pipeline Spacing Chart What Is Piping

Hangers Support Spacing and Rod Size for Horizontal Pipes

.jpg)

Determination of Loads And Movements in Piping Supports PIPING GUIDE

Types of Pipe Support Use in Oil and Gas Pipeline A Complete Overview

Support Spans Are Provided For Pipe.

Comparison Of Spacing Required For Pipe Supports For Various Australian Piping Design Standards.

Web Support Locations Are Dependent On Pipe Size, Piping Configuration, The Location Of Heavy Valves And Fittings, And The Structure That Is Available For The Support Of The Piping.

Web The Document Provides Guidelines For Pipe Support Spacing And Adjustments.

Related Post: