Pipe Flange Charts Sizes

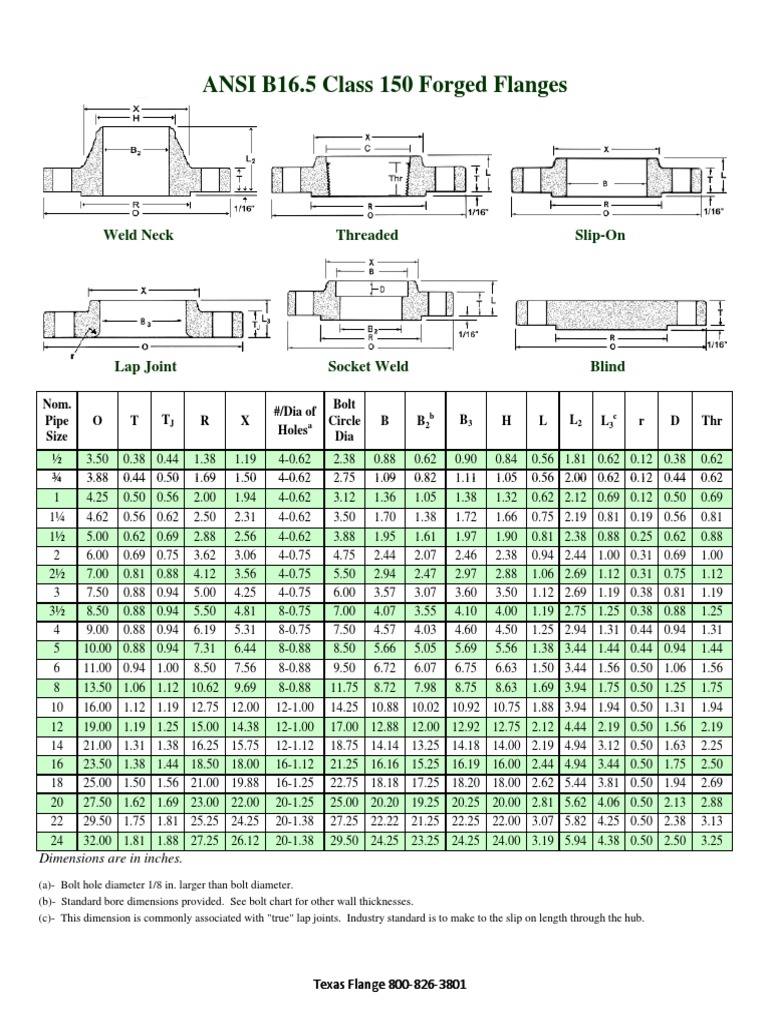

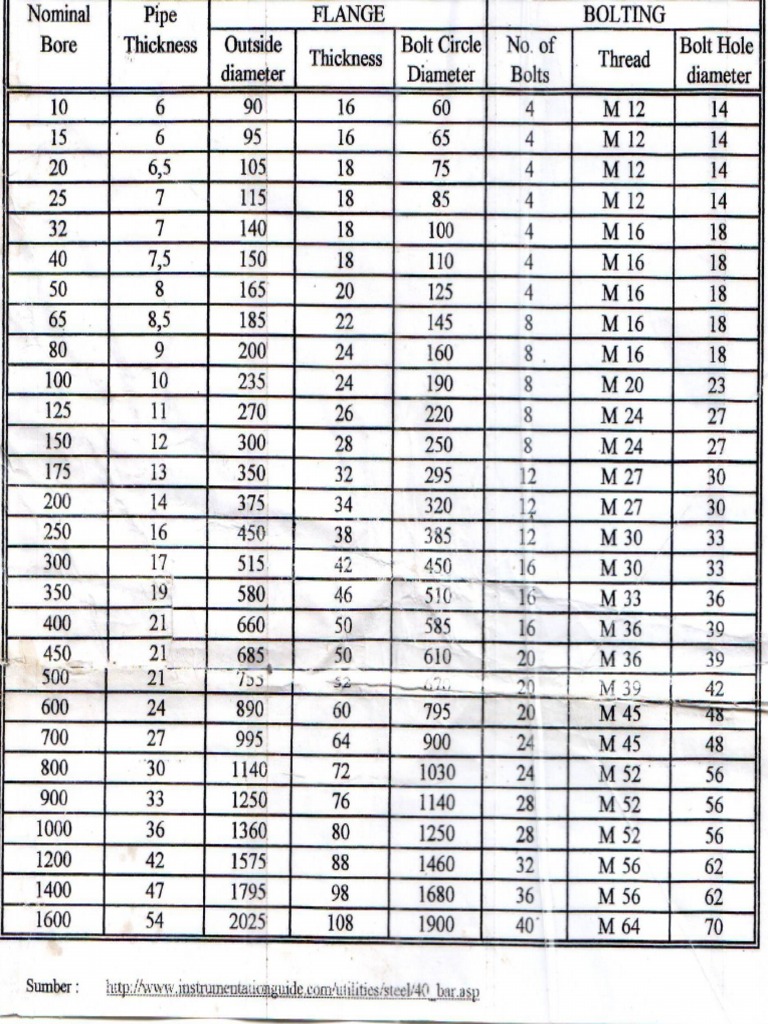

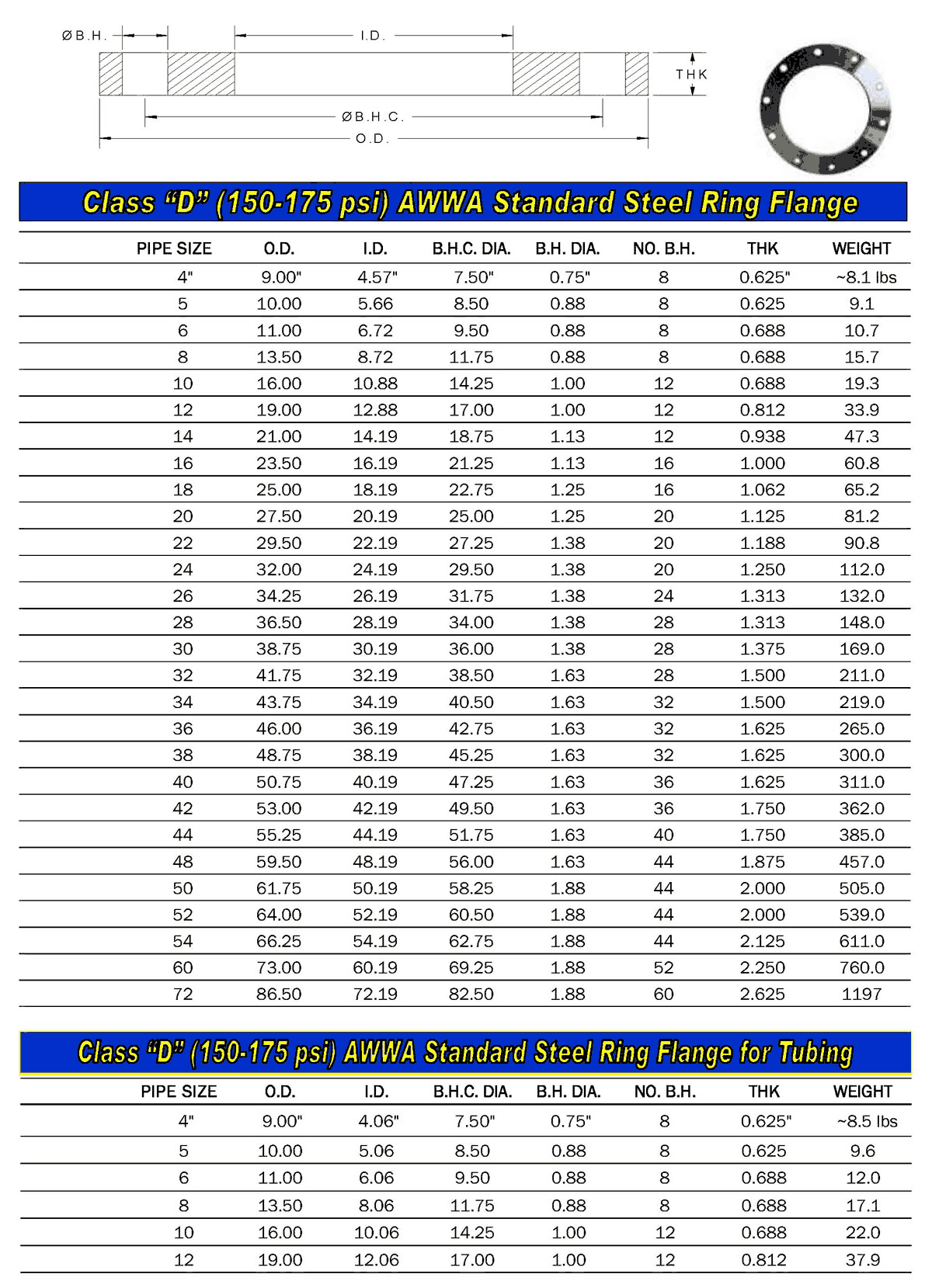

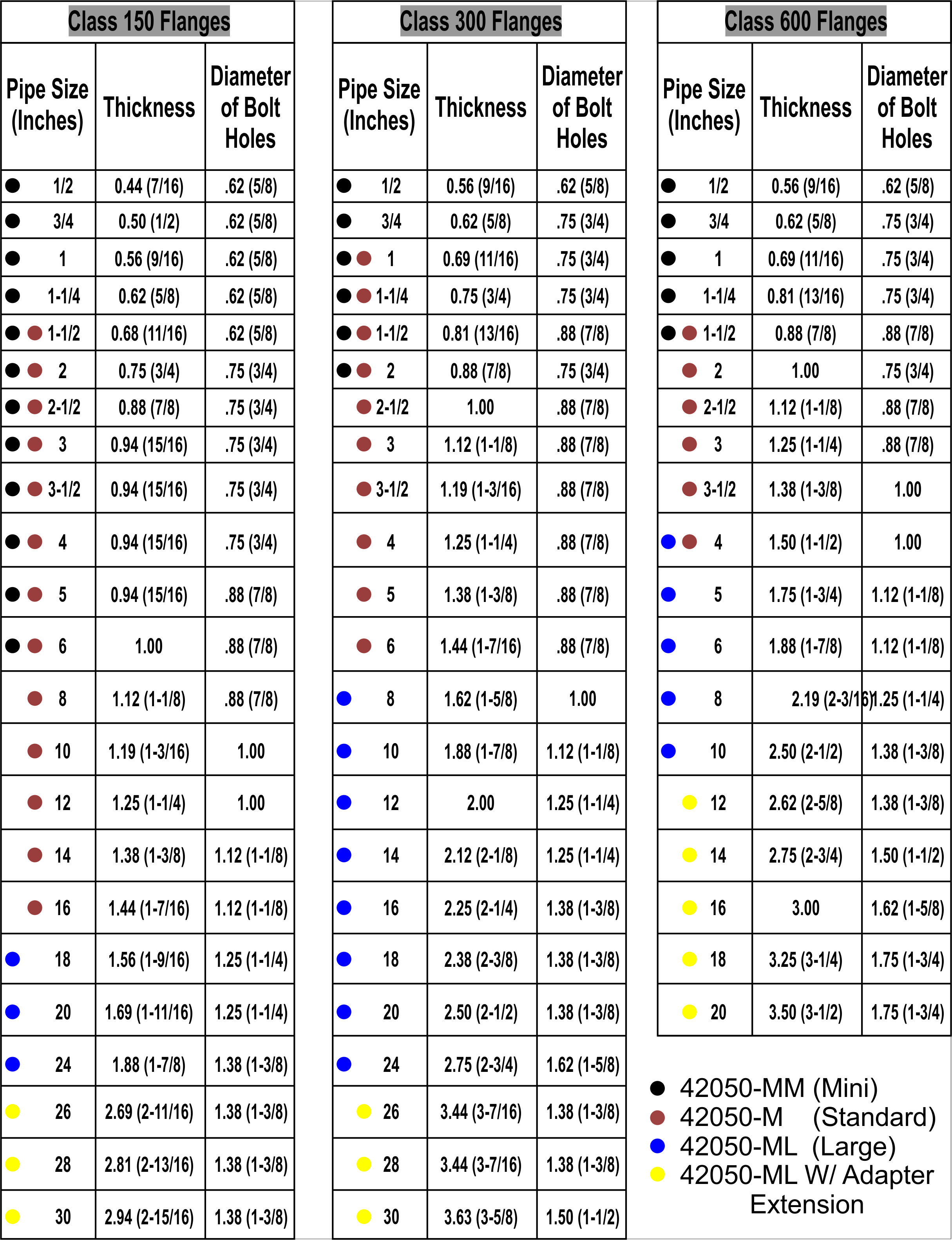

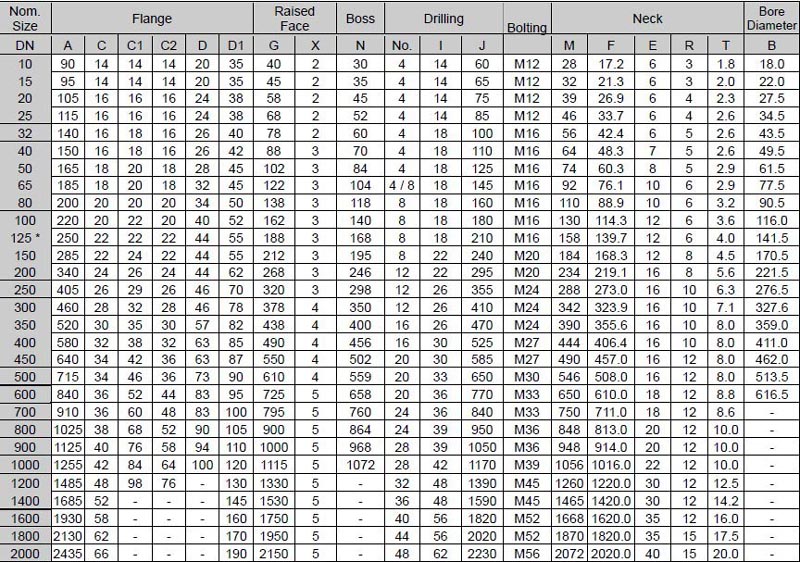

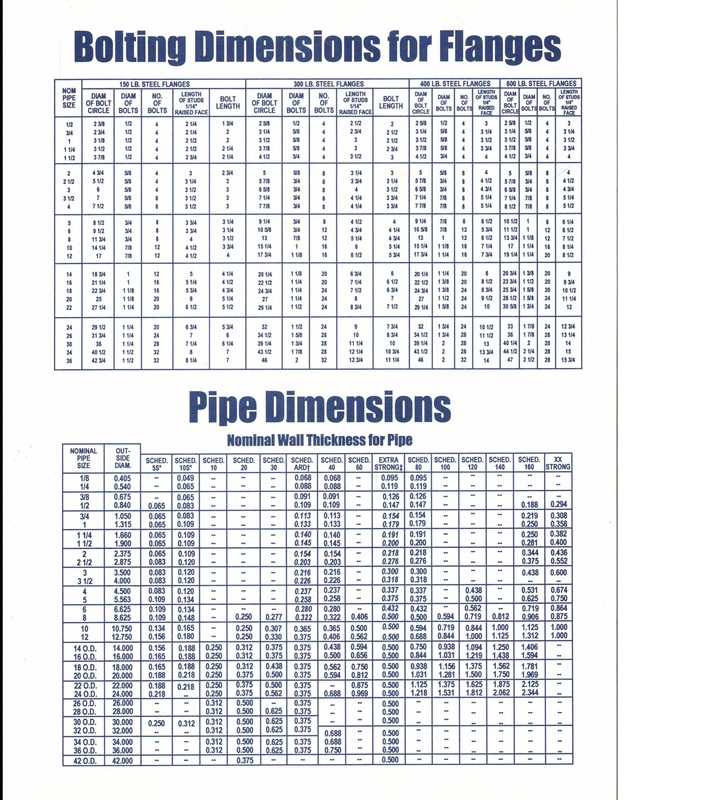

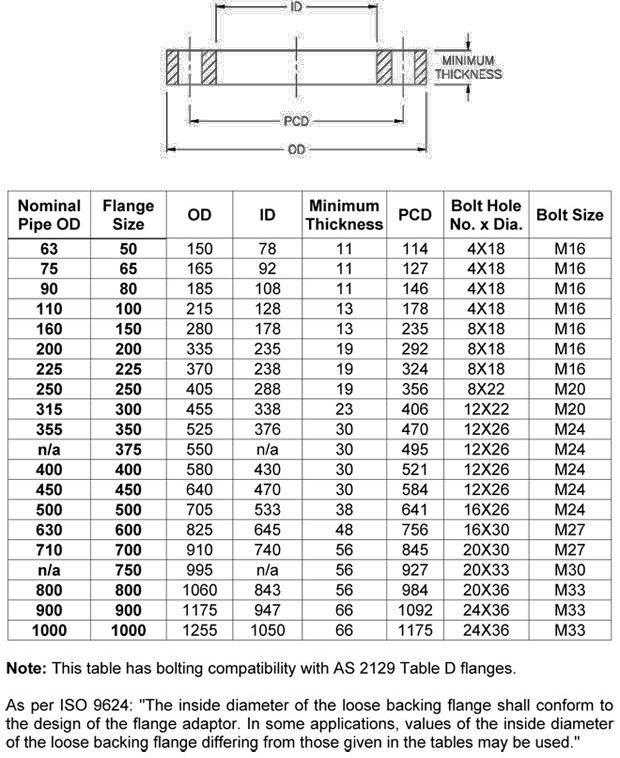

Pipe Flange Charts Sizes - 90 60 4 x 14. Web flange dimensions are covered in the following tables of asme b16.5 2020: 75 50 4 x 11. Web pipe flange datasheets are used by engineers and designers to select the appropriate flange for a specific application based on the required pressure rating, size, and material compatibility. D2 = diameter of raised face. Bolt hole diameter 1/8 in. B = thickness of flange. How can you evaluate the size of a flange? D 2 k d 3 h 2 ≈ r d 9 ds / 2 (w/n) / 3 (s/0) / 4 (scrwd) / 8 (blind) t / d t / e bs 4504 6 120 14 16 26 35 70 2 m12. D 1 flange raised face bolting drilling neck spigotboss d b b 1 h h 1 d 4 f no. N = number of bolts. You can also download our flange tables as a pdf for print or offline access. Nominal bore flange diameter (mm) thickness (mm) bolts (mm) number of holes p.c.d. Or the tf dimension thickness. D2 = diameter of raised face. D2 = diameter of raised face. > go to flange table. Pipe schedule number is the standard method to define the thickness of the pipes used in process plants. 90 60 4 x 14. D 1 flange raised face bolting drilling neck spigotboss d b b 1 h h 1 d 4 f no. Click to print our pipe chart spreadsheet. N = number of bolts. Talk with us directly using livechat. Styles we offer include weld neck, slip on, blind, threaded, socket weld, lap joint, orifice flanges, ring, and custom flanges in sizes from 1/2″ to 203″. The most common flanging used in australia in oil, gas and mining is now ansi flanging. Web the following ansi flange charts & flange tables provide flange dimensions including, flange overall diameters, number of bolts and bolt size for the most common sizes of ansi flanges for ratings from ansi 150 through to ansi 1500. Or the tf dimension thickness. This comprehensive guide will unravel the mystery behind pipe flanges, exploring their types, uses, and advantages. This comprehensive guide will unravel the mystery behind pipe flanges, exploring their types, uses, and advantages in piping. It's crucial to choose the right flange thickness. Styles we offer include weld neck, slip on, blind, threaded, socket weld, lap joint, orifice flanges, ring, and custom flanges in sizes from 1/2″ to 203″. Or the tf dimension thickness. > go to. The most common flanging used in australia in oil, gas and mining is now ansi flanging to ansi b16.5. 90 60 4 x 14. H = height of raised face (rf) All asme b16.47 flanges dimensions are in inches. D 1 flange raised face bolting drilling neck spigotboss d b b 1 h h 1 d 4 f no. N = number of bolts. It's crucial to choose the right flange thickness. How can you evaluate the size of a flange? D 2 k d 3 h 2 ≈ r d 9 ds / 2 (w/n) / 3 (s/0) / 4 (scrwd) / 8 (blind) t / d t / e bs 4504 6 120 14 16 26 35. Sans 1123 and bs 10/1962 tables d and e as amended 1965 32mm nominal bore pipe od 42.4 (d1) table pipe o.d. 90 60 4 x 14. H = height of raised face (rf) Types of pipe flanges 1. You must be wondering why it is. Dn = diameter nominal (size) a = flange. This comprehensive guide will unravel the mystery behind pipe flanges, exploring their types, uses, and advantages in piping. Web pipe flange datasheets are used by engineers and designers to select the appropriate flange for a specific application based on the required pressure rating, size, and material compatibility. (1) this dimension is for. Standardization of wrought steel pipe schedule and. B = thickness of flange. Asme b16.47 series a flange dimensions. Web we provide ansi, api, and awwa pipe flanges in carbon steel, stainless steel, alloys, and chrome steel. Types of pipe flanges 1. Raised face not included in dimensions t, l and l2. 90 60 4 x 14. Web below are flange tables for critical flange dimensions to help identify what standard you have. Web we provide ansi, api, and awwa pipe flanges in carbon steel, stainless steel, alloys, and chrome steel. Dn = diameter nominal (size) a = flange. Web the following is chart data for ansi b16.5 flange dimensional data table for sizes 3 to 10 inches. Web to buy the right one for a particular application, you must know the difference between these pipe flanges. N = number of bolts. The most common flanging used in australia in oil, gas and mining is now ansi flanging to ansi b16.5. You must be wondering why it is. (mm) 15 80 12 m10 x 45 4 55 20 90 14 m10 x 45 4 65 25 100 14 m10 x 45 4 75 32 120 14 m12 x 55 4 90 40 130 14 m12 x 55 4 100 50* 140 14 m12 x 55 4 110 65* 160 14 m12 x 55 4 130. D 2 k d 3 h 2 ≈ r d 9 ds / 2 (w/n) / 3 (s/0) / 4 (scrwd) / 8 (blind) t / d t / e bs 4504 6 120 14 16 26 35 70 2 m12. Dn = diameter nominal (size) a = flange. This comprehensive guide will unravel the mystery behind pipe flanges, exploring their types, uses, and advantages in piping. B = thickness of flange. However in general industrial, commercial and waste/water industries as2129 table flanging is.

Pipe Flange Chart

Flange Size Guide Printable

Technical Info Flange BoltUp Charts

Flange Size Printable

Printable Flange Size Chart Printable Word Searches

Flange Size Guide Printable

flange OD PCD hole dia PDF Free download/pipe flange dimension chart

Flange Size Guide Printable

Flange Size Guide Printable

Australian Pipe Flange Standards (AS/NZS 4331.1) Manufacturers

75 50 4 X 11.

Types Of Pipe Flanges 1.

For A Precise Match, Test Your Flange According To The Instructions Below And Compare The Results To The Dimensions.

90 60 4 X 14.

Related Post: