P Chart Formula

P Chart Formula - Web a p chart is used to examine the variation in the proportion (or percentage) of defective items in a group of items. The percent of items in the sample meeting the criteria of interest. The ratio of observed variation to expected variation is calculated as follows: Here is the formula used to calculate a p chart. Web the p chart is used when the sample size varies. Either the item is defective or it is not defective. The p control chart is used to determine if the fraction of defective items in a. Open a new excel worksheet and enter your data into a table. P chart is used when you have defectives data with a variable sample size. To construct a p chart, we first need to calculate the proportion of nonconforming items for each sample (p) using the formula: To construct a p chart, we first need to calculate the proportion of nonconforming items for each sample (p) using the formula: Where is the mean proportion of defectives, calculated as follows: Either the item is defective or it is not defective. Web p’ chart formula data legend + chart 5. Control charts dealing with the proportion or fraction of. Web for a sample subgroup, the number of defective parts is counted and plotted as either a percentage of the total subgroup sample size, or a fraction of the total subgroup sample size. [1] center line, [2] upper control limit, & [3] lower control limit. Here is the formula used to calculate a p chart. Web trying to understand laney. Σ is the standard deviation of the sample proportion. Where nj is the sample size (number of units) of group j. The chart is based on the binomial distribution; Web control limits for p chart. Open a new excel worksheet and enter your data into a table. Steps in constructing a p chart. Web p’ chart formula data legend + chart 5. Each plotted point represents the proportion of defectives for one subgroup, pi: Web the p chart formula. Web the p chart is used when the sample size varies. Either the item is defective or it is not defective. The most common application is as a tool to monitor process stability and control. It is found by dividing the total number of defective units found in all subgroups of the study period by the total number of units inspected in the study period. The subgroup size must be large. Z is the number of standard deviations. The size, n (i), has to be sufficiently large to have defects present in the subgroup most of the time. Web for a sample subgroup, the number of defective parts is counted and plotted as either a percentage of the total subgroup sample size, or a fraction of the total subgroup sample size.. Z is the number of standard deviations. How do you create a p chart. Ucl = ps + zσ. Web control limits for p chart. Steps in constructing a p chart. Web 0.67 (to 2.d.p) 67% n = sample size per sub group (per row) np/n) σ = sum of sample size. A less common, although some might argue more powerful, use of control charts is as an analysis tool. Web a p control chart is used to look at variation in yes/no type attributes data. Web control limits for p. Web the p chart formula. Web p’ chart formula data legend + chart 5. Z is the number of standard deviations. 95% confidence limits for ratio. Each plotted point represents the proportion of defectives for one subgroup, pi: There is a difference between a defect and defective, as there is between a nonconformity and. The size, n (i), has to be sufficiently large to have defects present in the subgroup most of the time. Z is the number of standard deviations. Examples include the number of defective products, meals in a restaurant, incorrect prescriptions, bills, invoices, paychecks, etc.. An item is defective if it fails to conform to some preset specification. Web a p control chart is used to look at variation in yes/no type attributes data. Web for a sample subgroup, the number of defective parts is counted and plotted as either a percentage of the total subgroup sample size, or a fraction of the total subgroup sample size. [p chart formula] p chart example & calculation for constant sample size: Web trying to understand laney p chart formulas? Control charts dealing with the proportion or fraction of defective product are called p charts (for proportion). A less common, although some might argue more powerful, use of control charts is as an analysis tool. Each item on the chart has only two possibilities: The chart is based on the binomial distribution; The p control chart is used with “yes/no” attributes data. Σ is the standard deviation of the sample proportion. Each plotted point represents the proportion of defectives for one subgroup, pi: There is a difference between a defect and defective, as there is between a nonconformity and. Sample size (n) is 80. The percent of items in the sample meeting the criteria of interest. Examples include the number of defective products, meals in a restaurant, incorrect prescriptions, bills, invoices, paychecks, etc.

Control Limits for pchart by hand YouTube

Constructing pCharts Lecture YouTube

P Chart Calculations P Chart Formula Quality America

P Chart Calculations P Chart Formula Quality America

P chart example PresentationEZE

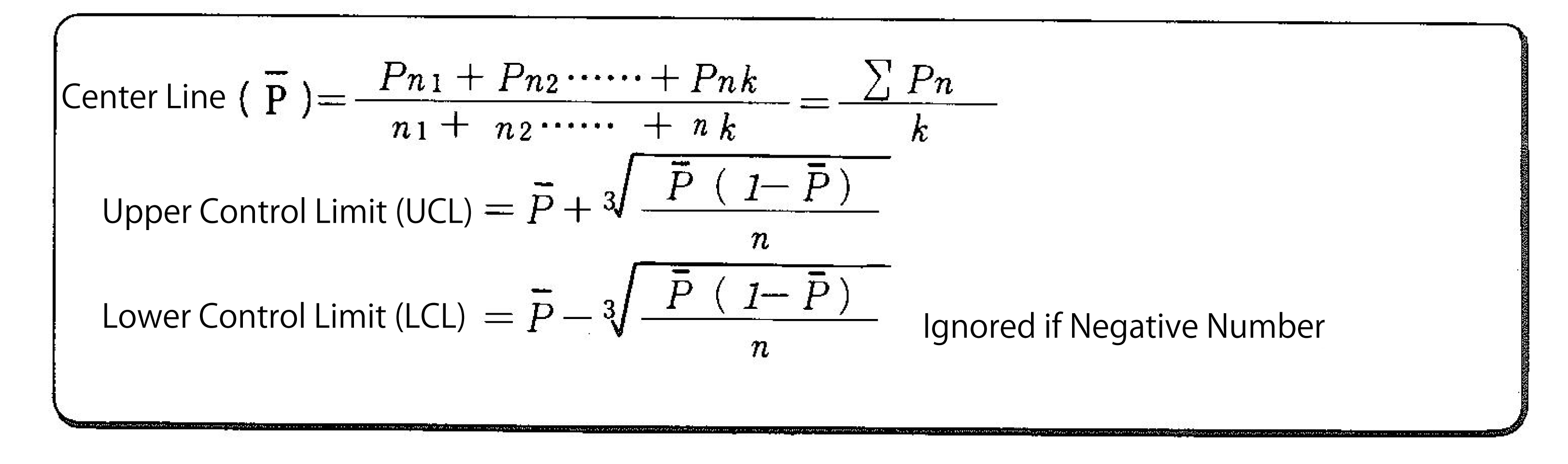

P' Chart Formula Quality Improvement East London NHS Foundation

P Chart Formula PDF

P Chart Calculations P Chart Formula Quality America

P Chart Quality Control MRP glossary of Production scheduler Asprova

Control Chart for Attributes 1 Control Charts Continuous

It Is Found By Dividing The Total Number Of Defective Units Found In All Subgroups Of The Study Period By The Total Number Of Units Inspected In The Study Period.

Determine The Size Of The Subgroups Needed.

Ucl = Ps + Zσ.

Use This Chart To Determine The Upper Control Limit (Ucl) And Lower Control Limit (Lcl) For A P Chart.

Related Post: