Oxyacetylene Torch Settings Chart

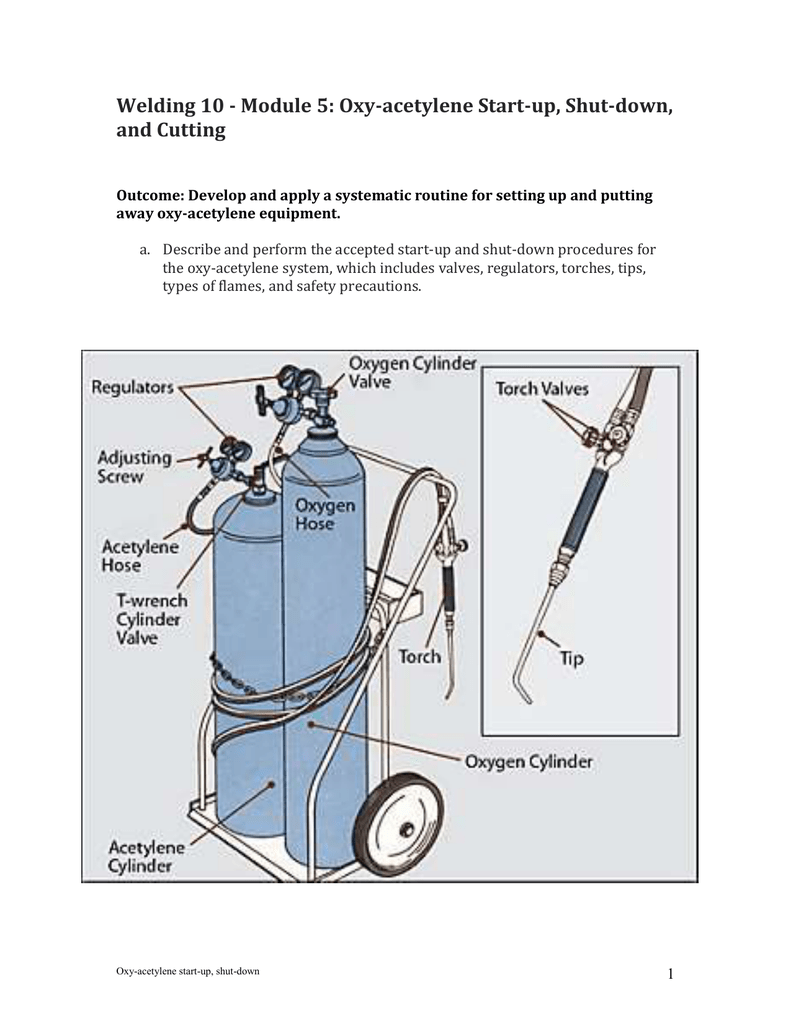

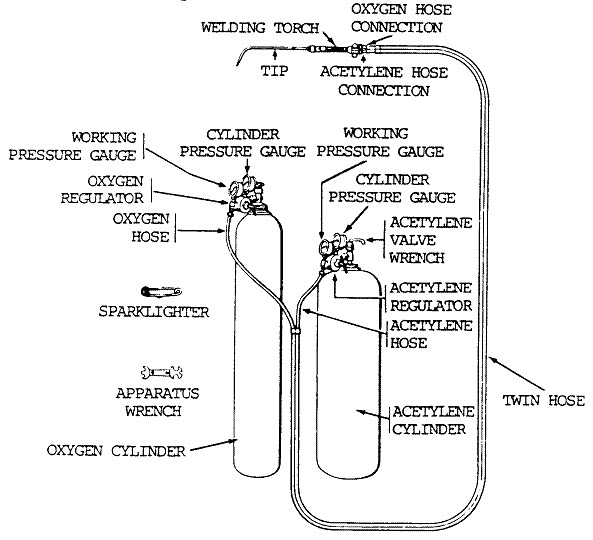

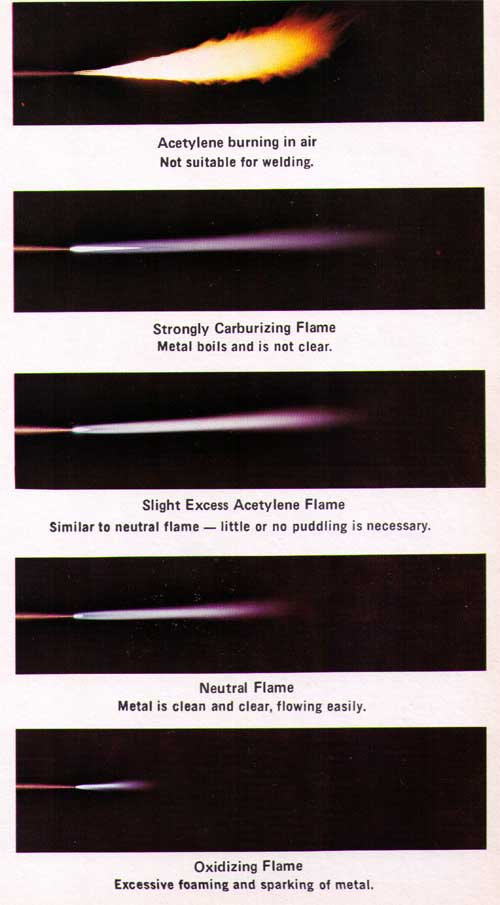

Oxyacetylene Torch Settings Chart - It can be used as a teaching and training tool for. Web this recommended practice describes the equipment, applications, and safe practices for oxyacetylene gas welding operations. As a heating tool, the torch. Depress oxygen lever and make necessary adjustments. First, we must clean the nozzle because if the head of the nozzle is dirty will cause a flame bad. Web acetylene is the commonly used fuel gas, and when correct proportions of oxygen and acetylene are mixed in a gas welding torch, you will get a hot flame of around 3200º c. In addition to these easy to follow instructions, you. Web it uses extreme heat to function, and setting it up properly is one of the most important steps in using it safely. Make use of correct welding & cutting technique. In this article, we will explore the best. Web oxy acetylene welding set up and pressure settings chart : This guide provides all the information you need, from choosing the right equipment to tips for safe and efficient. This powerful tool is commonly. In this article, we will explore the best. Web the oxy acetylene torch diagram is a visual representation of the components and processes involved in. Depress oxygen lever and make necessary adjustments. In this article, we will explore the best. Web mastering the oxy acetylene cutting torch settings is essential for achieving clean and efficient cuts. It can be used as a teaching and training tool for. Web open oxygen valve and adjust to neutral flame. Web the oxy acetylene torch diagram is a visual representation of the components and processes involved in using an oxy acetylene torch. Depress oxygen lever and make necessary adjustments. Web this flame will reach a temperature of 4400°f to 6000°f (2400°c to 3300°c), depending on the fuel gas used as well as the ratio of oxygen to fuel gas. Shutting. First, we must clean the nozzle because if the head of the nozzle is dirty will cause a flame bad. Web adjust to the correct flame setting. Web this flame will reach a temperature of 4400°f to 6000°f (2400°c to 3300°c), depending on the fuel gas used as well as the ratio of oxygen to fuel gas. Web understanding the. This will be done starting with. Web this powerful tool can generate intense heat to weld or cut metal, but it requires proper settings and techniques to use effectively. Shutting down the torch (with a positive/equal pressure mixer):. First, we must clean the nozzle because if the head of the nozzle is dirty will cause a flame bad. Web this. By understanding the basics, selecting the right tip, setting proper gas. Web open oxygen valve and adjust to neutral flame. Web adjust to the correct flame setting. Web understanding the proper oxy acetylene cutting settings is crucial for achieving precise and efficient cutting results. Web ** to optimize results, it is advised to use st1600c, st1900c, or st2600fc series torches. Web open oxygen valve and adjust to neutral flame. Web oxy acetylene welding set up and pressure settings chart : Depress oxygen lever and make necessary adjustments. 3.6k views 1 year ago. Web this powerful tool can generate intense heat to weld or cut metal, but it requires proper settings and techniques to use effectively. Web this recommended practice describes the equipment, applications, and safe practices for oxyacetylene gas welding operations. It can be used as a teaching and training tool for. Web acetylene is the commonly used fuel gas, and when correct proportions of oxygen and acetylene are mixed in a gas welding torch, you will get a hot flame of around 3200º c.. Web acetylene is the commonly used fuel gas, and when correct proportions of oxygen and acetylene are mixed in a gas welding torch, you will get a hot flame of around 3200º c. It utilizes a mixture of oxygen. Web this powerful tool can generate intense heat to weld or cut metal, but it requires proper settings and techniques to. Depress oxygen lever and make necessary adjustments. 3.6k views 1 year ago. Web carrying out your job. As a heating tool, the torch. Make use of correct welding & cutting technique. In addition to these easy to follow instructions, you. Web here's everything you need to know about using an oxy acetylene cutting torch, everything from setting it up to shutting off. Web understanding the proper oxy acetylene cutting settings is crucial for achieving precise and efficient cutting results. Web open oxygen valve and adjust to neutral flame. Web the oxy acetylene torch diagram is a visual representation of the components and processes involved in using an oxy acetylene torch. Web this powerful tool can generate intense heat to weld or cut metal, but it requires proper settings and techniques to use effectively. By carefully adjusting the gas pressures, flame characteristics,. It is also used in a variety of other applications, such as brazing, soldering, and heating metals. Web acetylene is the commonly used fuel gas, and when correct proportions of oxygen and acetylene are mixed in a gas welding torch, you will get a hot flame of around 3200º c. Web this recommended practice describes the equipment, applications, and safe practices for oxyacetylene gas welding operations. This powerful tool is commonly. Web carrying out your job. By understanding the basics, selecting the right tip, setting proper gas. In this article, we will explore the best. Web this flame will reach a temperature of 4400°f to 6000°f (2400°c to 3300°c), depending on the fuel gas used as well as the ratio of oxygen to fuel gas. Make use of correct welding & cutting technique.

Oxyacetylene Torch Settings Chart

Oxyacetylene Torch Settings Chart

OxyAcetylene Welding Tips Model WJ Compatible with "J" Series Victor

oxygen and acetylene pressure settings

Cutting Torch Guide

Oxyacetylene Torch Settings Chart

Oxyacetylene Torch Settings Chart

Oxyacetylene Torch Settings Chart

Oxy Acetylene Settings Chart

Oxy Acetylene Torch Tip Chart

It Can Be Used As A Teaching And Training Tool For.

3.6K Views 1 Year Ago.

As A Heating Tool, The Torch.

Web ** To Optimize Results, It Is Advised To Use St1600C, St1900C, Or St2600Fc Series Torches And 3/8 Inch Diameter Hoses When Using Cutting Nozzles Of Size 6 Or Larger.

Related Post: