Oatey Cpvc Cure Time Chart

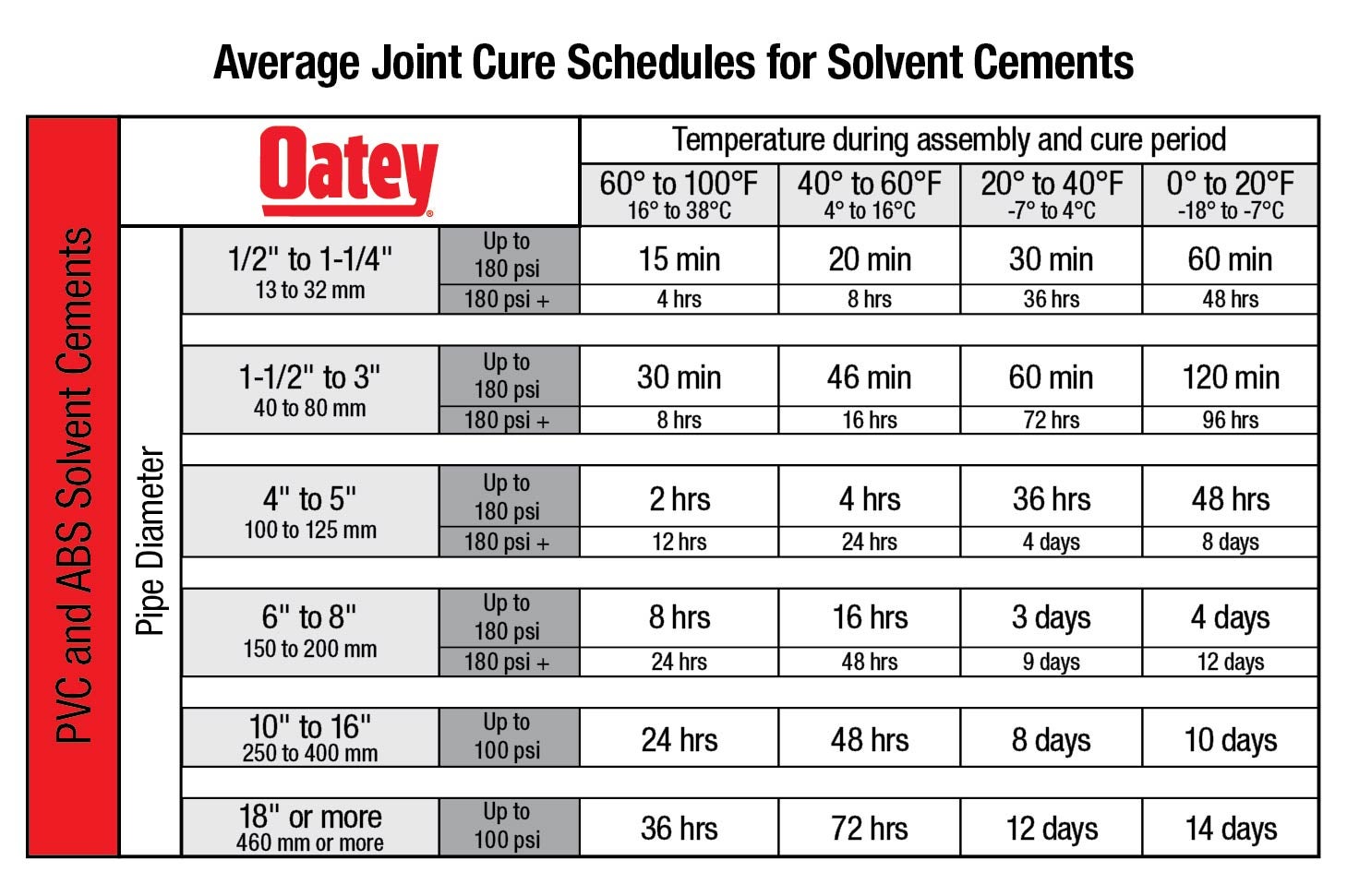

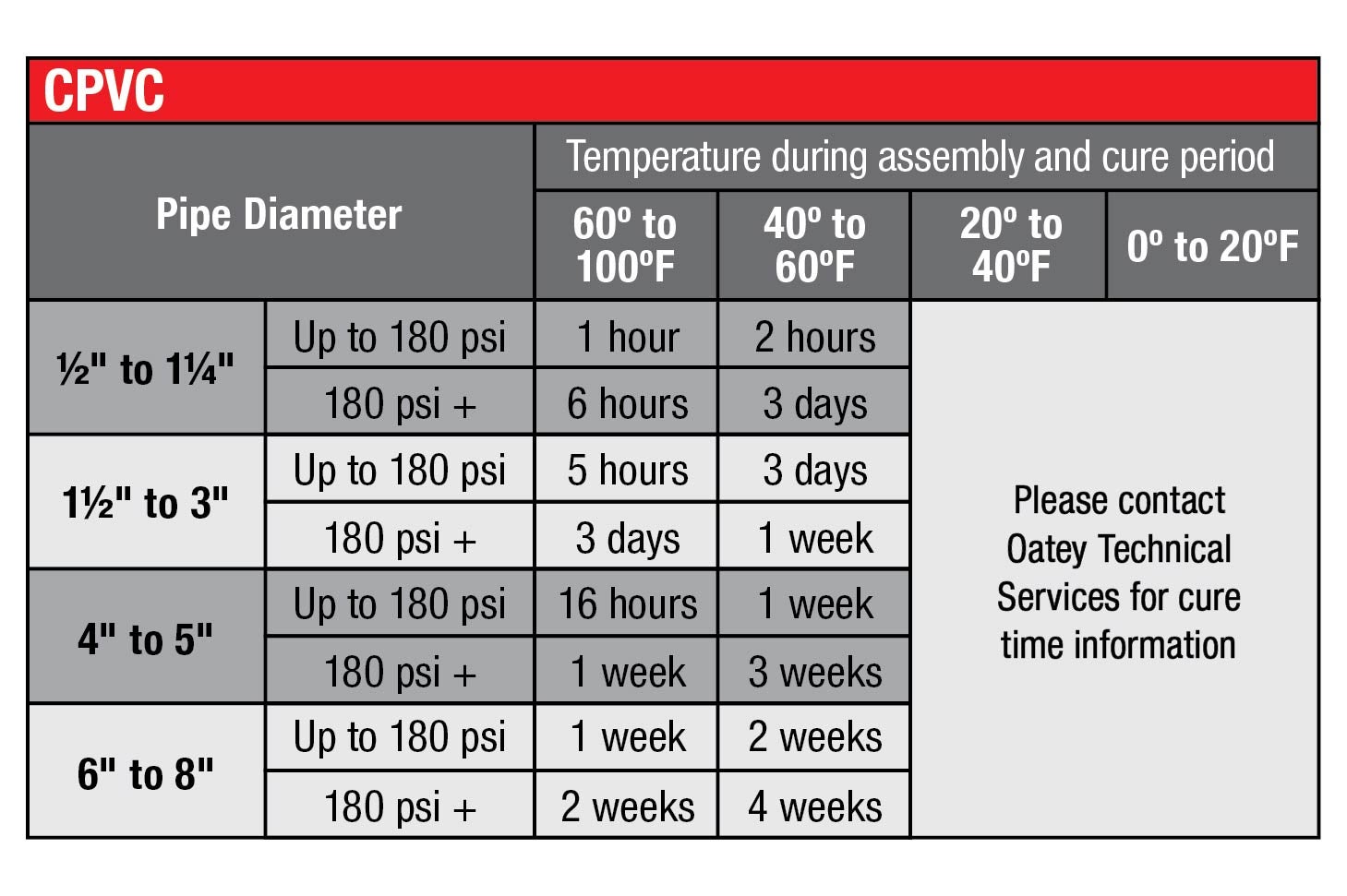

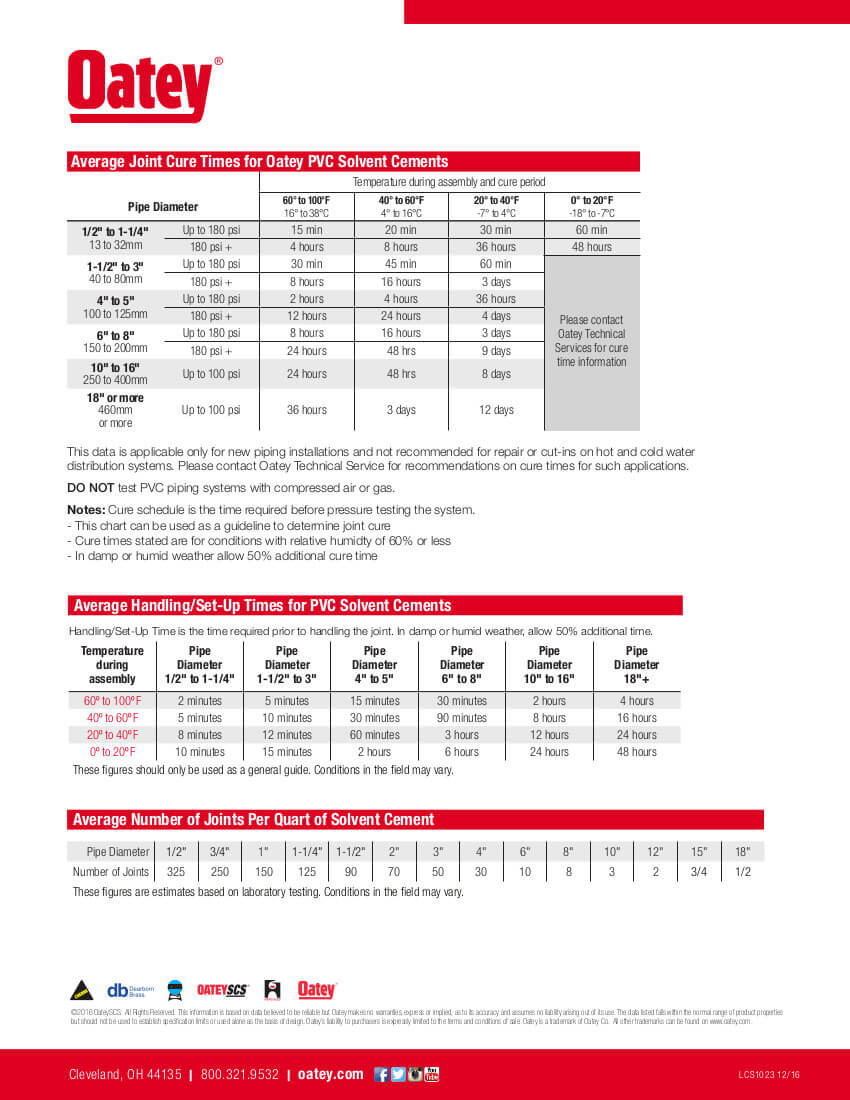

Oatey Cpvc Cure Time Chart - Cure times vary depending on a wide variety of factors. Web do not test pvc and cpvc piping systems with compressed air or gas. Pvc and abs cure quicker than cpvc because the solvents in the cement and primers penetrate further into cpvc pipes and fittings. Web typical joint cure schedule for christy’stm solvent cements. Test pressure (max) nominal pipe size (metric) ambient temperature: Web understanding the solvent welding process is crucial for installers using cpvc piping, particularly with products like blazemaster® fire protection systems. Web allow 15 minutes for good handling strength and 2 hours cure time at temperatures above 60°f before pressure testing up to 180 psi. To achieve optimal results when using oatey cement, follow these tips: Relative humidity 60% or less*. Solvent cement is comprised of solvents and resins. Web allow 15 minutes for good handling strength and 2 hours cure time at temperatures above 60°f before pressure testing up to 180 psi. For use on all schedules and classes of cpvc pipe and fittings up to 6 in. Web how are cure times determined? What happens during solvent cement welding? Web how are cure times determined? Pvc and abs cure quicker than cpvc because the solvents in the cement and primers penetrate further into cpvc pipes and fittings. Web do not test pvc and cpvc piping systems with compressed air or gas. Web cure time at temperatures above 60°f before pressure testing up to 180 psi. Recommended application temperature 40°f to 110°f / 4°c to 43°c.. Contact oatey technical services for set up times for pipe. Web here are definitions of plastic pipe gluing hold time (how long to hold the joint when gluing), set time (how long before you can move the piping around) and cure time (how long before the piping can be exposed to pressure. Cure time pipe sizes 21⁄2 to 8. Longer. Recommended application temperature 40°f to 110°f / 4°c to 43°c. Average joint cure times for pvc/cpvc solvent cements set up/ curing times the set up/cure time is dependent on several factors. To achieve optimal results when using oatey cement, follow these tips: Cure time pipe sizes 1⁄2 to 11⁄4. Solvent cement is the substance used to join chlorinated polyvinyl chloride. Please review the documents below and read our blog for more helpful information. Cure times vary depending on a wide variety of factors. Web cure times depend on four key factors: Web with a variety of formulas that range in cure times and pipe material and application compatibility, you can rely on oatey, hercules and harvey solvent cements to have. The ratio of solvent to resin varies, and determines the cement’s viscosity. For humidity over 60%, increase the curing time by 50%; Web how are cure times determined? Test pressure (max) nominal pipe size (metric) ambient temperature: Recommended application temperature 40°f to 110°f / 4°c to 43°c. Please review the documents below and read our blog for more helpful information. Average joint cure times for pvc/cpvc solvent cements set up/ curing times the set up/cure time is dependent on several factors. Pvc and abs cure quicker than cpvc because the solvents in the cement and primers penetrate further into cpvc pipes and fittings. To achieve optimal results. Web understanding the solvent welding process is crucial for installers using cpvc piping, particularly with products like blazemaster® fire protection systems. Recommended for residential and commercial hot and cold water systems up to 200°f / 93°c. Web generally, the cure time ranges from 15 minutes to 24 hours. Temperature range during assembly and cure periods. Pvc and abs cure quicker. Cure time pipe sizes 21⁄2 to 8. Contact oatey technical services for set up times for pipe. For specialty cements and chemical applications please see specific product label instructions. What happens during solvent cement welding? Web allow 15 minutes for good handling strength and 2 hours cure time at temperatures above 60°f before pressure testing up to 180 psi. Web do not test pvc and cpvc piping systems with compressed air or gas. Web how are cure times determined? Web understanding the solvent welding process is crucial for installers using cpvc piping, particularly with products like blazemaster® fire protection systems. Web to help avoid this issue, this resource explains what’s happening as a joint cures, how long you should. Allow 15 minutes for good handling strength and 2 hours cure time at temperatures above 60°f before pressure testing up to 180 psi. Web with a variety of formulas that range in cure times and pipe material and application compatibility, you can rely on oatey, hercules and harvey solvent cements to have exactly what you need for the job, whether you’re bonding one pipe fitting or one hundred. To achieve optimal results when using oatey cement, follow these tips: Web oatey technical services for cure time information 180 psi + 6 hours 3 days 1½ to 3 up to 180 psi 5 hours 3 days 180 psi + 3 days 1 week 4 to 5 up to 180 psi 16 hours 1 week 180 psi + 1 week 3 weeks 6 to 8 up to 180 psi 1 week 2 weeks 180 psi + 2 weeks 4 weeks set up & curing times the set up/cure time is dependent on several factors. Cure time pipe sizes 15+. Longer cure times may be required at temperatures below 60°f or with pipe above 3. Temperature range during assembly and cure periods. Web allow 15 minutes for good handling strength and 2 hours cure time at temperatures above 60°f before pressure testing up to 180 psi. Longer cure times may be required at temperatures below 60°f or with pipe above 3. Web key features & benefits. Key factors affecting cpvc cure times include pipe size, ambient temperature, and humidity, each of which influences how long does cpvc cement take to set effectively. Web generally, the cure time ranges from 15 minutes to 24 hours. Pvc and abs cure quicker than cpvc because the solvents in the cement and primers penetrate further into cpvc pipes and fittings. Contact oatey technical services for set up times for pipe. Solvent cement is the substance used to join chlorinated polyvinyl chloride (cpvc) pipe and fittings. Recommended for residential and commercial hot and cold water systems up to 200°f / 93°c.

Oatey Cpvc Cure Time Chart

The Complete Guide to Solvent Cement & CPVC Fire Protection Systems

Oatey Cpvc Cure Time Chart

Five Tips for LargeDiameter Solvent Welding Oatey

FilePVC Joint Curing Times.png Further Reading Trouble Free Pool

Solvent Cement Set and Cure Time Table WeldOn®

Oatey Orange Lava Cure Chart

Oatey Cpvc Cure Time Chart

Oatey Cure Time Chart

5 Common Solvent Welding Mistakes Oatey

Please Review The Documents Below And Read Our Blog For More Helpful Information.

For Specialty Cements And Chemical Applications Please See Specific Product Label Instructions.

Web Cure Time At Temperatures Above 60°F Before Pressure Testing Up To 180 Psi.

What Happens During Solvent Cement Welding?

Related Post: