Multivari Chart

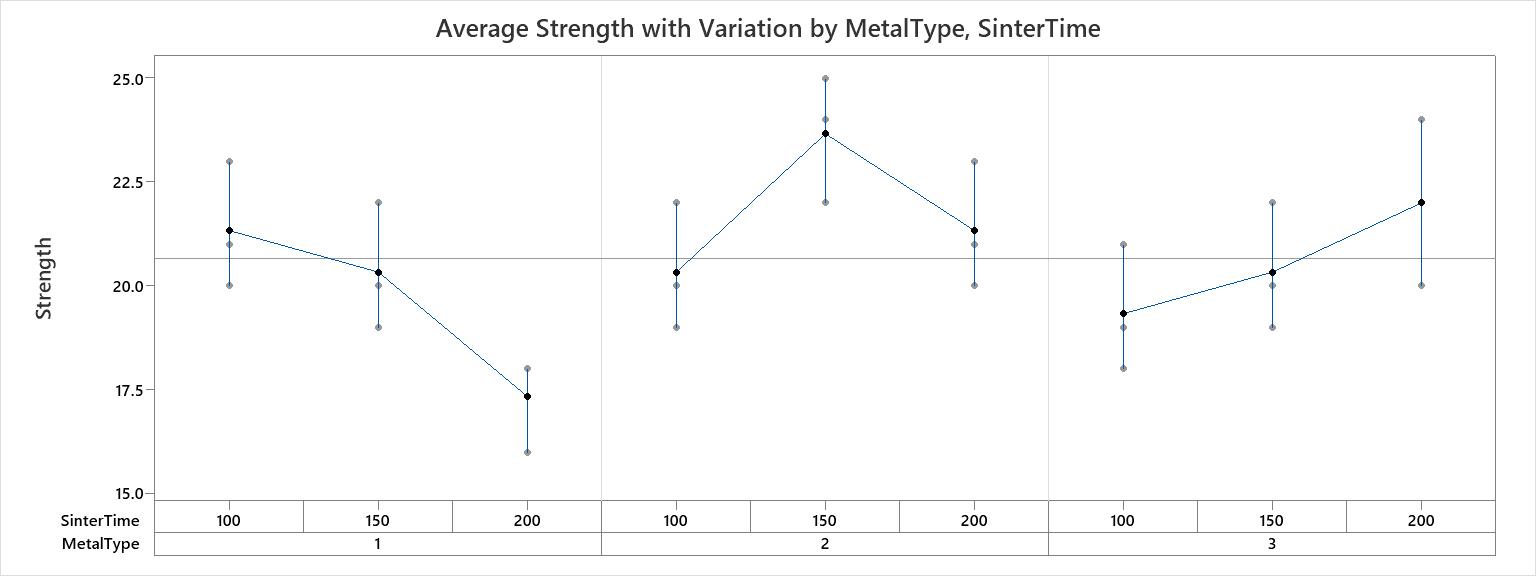

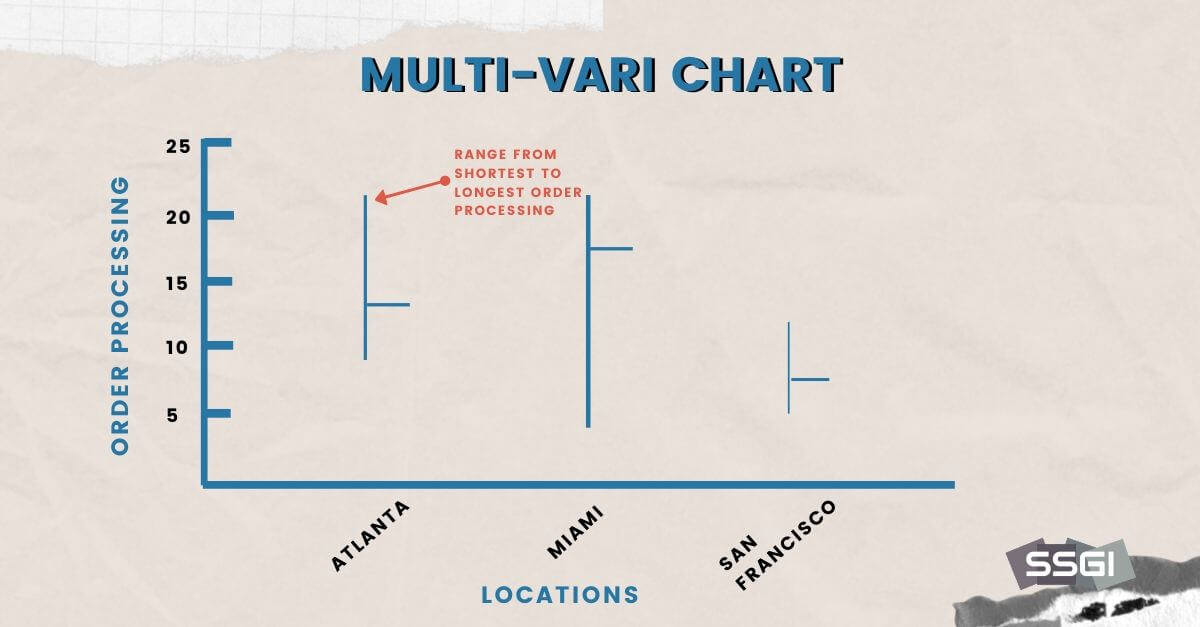

Multivari Chart - If you are interested in a free. Simple, yet powerful way to significantly reduce the number of potential factors which could be impacting your primary metric. The quality characteristic of interest is plotted across three horizontal panels representing: The content and format of the charts has evolved over time. Quick and efficient method to significantly reduce the time and resources required to determine the primary components of variation. Stem and leaf charts , histograms, and frequency distributions are all snapshots of process variation. They are used to drill down into the vital few inputs that are creating most of the variation and then the team can focus on the highest impact improvements. You can use them most effectively for problem solving. Multivari data can have one or more columns of words or numbers. It is applicable in service and manufacturing sectors. Variability on a single piece. In this context, process engineers might benefit from using multivariate charts which let you monitor up to 7 or 8 parameters together in a single chart. You can use them most effectively for problem solving. Web multivari charts evaluate process variability within & between categories. It is applicable in service and manufacturing sectors. Quick and efficient method to significantly reduce the time and resources required to determine the primary components of variation. Web multivarichart(y,group) displays the multivari chart for the vector y grouped by entries in group that can be a cell array or a matrix. Multivari data can have one or more columns of words or numbers. Simple, yet powerful way to. The content and format of the charts has evolved over time. You can use them most effectively for problem solving. Web hello friends, in this video, we are going to learn one of the important tools in the analyze phase of lean six sigma to investigate the variatio. Stem and leaf charts , histograms, and frequency distributions are all snapshots. The greatest compressive strength for metal type 1 is obtained by sintering for 100 minutes, for metal type 2 by sintering for 150 minutes, and for metal type 3 by sintering for 200 minutes. It is especially useful for inside and outside diameters, runout, and taper. The quality characteristic of interest is plotted across three horizontal panels representing: The last. The content and format of the charts has evolved over time. The quality characteristic of interest is plotted across three horizontal panels representing: Web hello friends, in this video, we are going to learn one of the important tools in the analyze phase of lean six sigma to investigate the variatio. In this context, process engineers might benefit from using. Web this matlab function displays the multivari chart for the vector y grouped by entries in group that can be a cell array or a matrix. Quick and efficient method to significantly reduce the time and resources required to determine the primary components of variation. Simple, yet powerful way to significantly reduce the number of potential factors which could be. Quick and efficient method to significantly reduce the time and resources required to determine the primary components of variation. Variability on a single piece. It is especially useful for inside and outside diameters, runout, and taper. Web this matlab function displays the multivari chart for the vector y grouped by entries in group that can be a cell array or. In this context, process engineers might benefit from using multivariate charts which let you monitor up to 7 or 8 parameters together in a single chart. The content and format of the charts has evolved over time. The quality characteristic of interest is plotted across three horizontal panels representing: It helps us narrow down our process inputs that are major. It is especially useful for inside and outside diameters, runout, and taper. In this context, process engineers might benefit from using multivariate charts which let you monitor up to 7 or 8 parameters together in a single chart. The quality characteristic of interest is plotted across three horizontal panels representing: It helps us narrow down our process inputs that are. You can use them most effectively for problem solving. Quick and efficient method to significantly reduce the time and resources required to determine the primary components of variation. The last column contains the values to be grouped and charted. The quality characteristic of interest is plotted across three horizontal panels representing: Web hello friends, in this video, we are going. Web hello friends, in this video, we are going to learn one of the important tools in the analyze phase of lean six sigma to investigate the variatio. It helps us narrow down our process inputs that are major co.more. Web multivari charts evaluate process variability within & between categories. The last column contains the values to be grouped and charted. It is applicable in service and manufacturing sectors. Variability on a single piece. The greatest compressive strength for metal type 1 is obtained by sintering for 100 minutes, for metal type 2 by sintering for 150 minutes, and for metal type 3 by sintering for 200 minutes. It is especially useful for inside and outside diameters, runout, and taper. If you are interested in a free. Web this matlab function displays the multivari chart for the vector y grouped by entries in group that can be a cell array or a matrix. In this context, process engineers might benefit from using multivariate charts which let you monitor up to 7 or 8 parameters together in a single chart. Multivari data can have one or more columns of words or numbers. The content and format of the charts has evolved over time. Monitoring upstream tool parameters might lead to a huge increase in the number of control charts, though. Stem and leaf charts , histograms, and frequency distributions are all snapshots of process variation. You can use them most effectively for problem solving.

Introduction to MultiVari Charts (Lean Six Sigma) YouTube

Lean Six Sigma The Definitive Guide (2024) SSGI

MultiVari Chart Definition

How to Use MultiVari Charts for Better Decision Making

MultiVari chart for Height by Batch, Speaker Type and Shift

MultiVari chart for the total yield. Download Scientific Diagram

MultiVari Chart Detailed illustration with Practical Example in

MultiVari Chart Example

Example of MultiVari Chart Minitab

Multivari chart for diameter by position, part and hour. Download

Web Multivarichart(Y,Group) Displays The Multivari Chart For The Vector Y Grouped By Entries In Group That Can Be A Cell Array Or A Matrix.

You Can Use Them Most Effectively For Problem Solving.

They Are Used To Drill Down Into The Vital Few Inputs That Are Creating Most Of The Variation And Then The Team Can Focus On The Highest Impact Improvements.

Quick And Efficient Method To Significantly Reduce The Time And Resources Required To Determine The Primary Components Of Variation.

Related Post: