Monokote Mk6 Thickness Chart

Monokote Mk6 Thickness Chart - Bs/ul fire tested and factory inspected. For thicknesses of approximately 1⁄2 in. Web target density of 43 ± 1 pcf (688 ± 16 kg/m) is most desirable. Web monokote® patching compound product data sheet. Overmixing monokote® will reduce pumping rate. X 18 in., is subjected to a swinging pendulum. (16 mm) or greater, apply subsequent passes after the first coat has set. 3 application of monokote ® fireproofing can be made in the following sequence: Web this test is designed to measure the resistance of a fireproofing material to penetration or removal due to impact forces. For thicknesses of 5⁄8 in. (16 mm) or greater, apply subsequent passes after the first coat has set. Gcp canada, inc., 294 clements road, west, ajax, ontario, canada l1s 3c6. Application of monokote® fireproofing can be made in the following sequence: Monokote® fireproofing products supplemental field application information 1.mix monokote as directed. (13 mm) or less, apply in one pass. The pendulum length is set so that the low point. Web check the charts on page 1 to determine yield and adjust the injection rate to yield 45.7 board feet per bag. 2.place an empty gcp 980 ml container on the scale and press on/tare to tare the container. Web for thicknesses of 5⁄8 in. Application of monokote® fireproofing can. Application of monokote fireproofing can be made in the following sequence: Web overmixing monokote® will reduce pumping rate. 3.fill the container with monokote, tapping Web target density of 43 ± 1 pcf (688 ± 16 kg/m) is most desirable. For thicknesses of 5⁄8 in. Low resistance to these forces means excessive damage to the material and loss of fire protection. Gcp applied technologies inc., 2325 lakeview parkway, suite 400, alpharetta, ga 30009, usa. (13 mm) or less, apply in one pass. Web overmixing monokote will reduce pumping rate. Monokote cementitious fireproofing offers many significant advantages to the architect, owner, applicator and building occupant. For thicknesses of approximately 1⁄2 in. X 18 in., is subjected to a swinging pendulum. Cellular decking for up to three hours hours of fire and protection, and with on. (16 mm) or greater, apply subsequent passes after the first coat has set. Bs/ul fire tested and factory inspected. (16 mm) or greater, apply subsequent passes after the first coat has set. (13 mm) or less, apply in one pass. 1.for thicknesses of approximately 1⁄2 in. Web for thicknesses of 5⁄8 in. A sample, measuring 12 in. (16 mm) or greater, apply subsequent passes after the first coat has set. Gcpat.com | north america customer service: Web for thicknesses of 5⁄8 in. Web this test is designed to measure the resistance of a fireproofing material to penetration or removal due to impact forces. Overmixing monokote® will reduce pumping rate. X 18 in., is subjected to a swinging pendulum. Web this test is designed to measure the resistance of a fireproofing material to penetration or removal due to impact forces. A sample, measuring 12 in. Web target density of 43 ± 1 pcf (688 ± 16 kg/m) is most desirable. Web check the charts on page 1 to determine yield. Web the architect will select an independent testing laboratory (for which the owner will pay) to sample and verify the thickness and density of the fireproofing in accordance with the the applicable building code. Cellular decking for up to three hours hours of fire and protection, and with on. (13 mm) or less, apply in one pass. Web this test. 1.for thicknesses of approximately 1⁄2 in. (13 mm) or less, apply in one pass. Gcp canada, inc., 294 clements road, west, ajax, ontario, canada l1s 3c6. Web target density of 43 ± 1 pcf (688 ± 16 kg/m) is most desirable. 3 application of monokote ® fireproofing can be made in the following sequence: Monokote cementitious fireproofing offers many significant advantages to the architect, owner, applicator and building occupant. For thicknesses of 5⁄8 in. Bs/ul fire tested and factory inspected. (13 mm) or less, apply in one pass. Web overmixing monokote® will reduce pumping rate. (16 mm) or greater, apply subsequent passes after the first coat has set. Application of monokote fireproofing can be made in the following sequence: Monokote® fireproofing products supplemental field application information 1.mix monokote as directed. (16 mm) or greater, apply subsequent passes after the first coat has set. Web monokote® patching compound product data sheet. Gcp canada, inc., 294 clements road, west, ajax, ontario, canada l1s 3c6. X 18 in., is subjected to a swinging pendulum. 2.place an empty gcp 980 ml container on the scale and press on/tare to tare the container. (16 mm) or greater, apply subsequent passes after the first coat has set. Web target density of 43 ± 1 pcf (688 ± 16 kg/m) is most desirable. 5.75 17.0 66.0 * 19.4.

(PDF) Monokote Fireproofing Type MK6s Spray Contec · 0804 Monokote

MONOKOTE MK6 , MK6/HY and MK6s Product data and

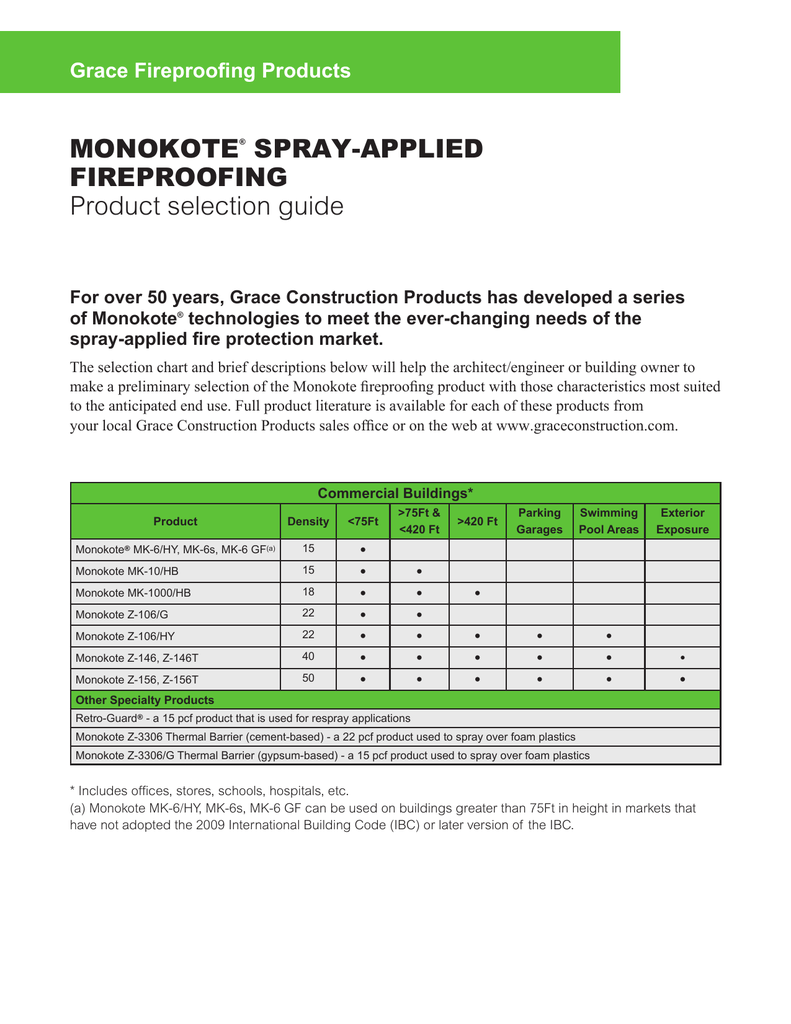

Product Selection Guide GCP Applied Technologies

UL Designs & Thickness — Floor Assemblies Resource GCP Applied

Monokote MK 6s 17 Concrete Materials

(PDF) MONOKOTE MK6 /HY SimplifiedYield Chart · This is valid for 55

Monokote® MK6s Negwer Materials

Monokote Fireproofing Type MK6s Spray Contec · 0804 Monokote

Monokote MK6

Monokote Mk6_hy Msds Chemical Substances Chemistry

(13 Mm) Or Less, Apply In One Pass.

Cellular Decking For Up To Three Hours Hours Of Fire And Protection, And With On.

Web Check The Charts On Page 1 To Determine Yield And Adjust The Injection Rate To Yield 45.7 Board Feet Per Bag.

For Thicknesses Of Approximately 1⁄2 In.

Related Post: