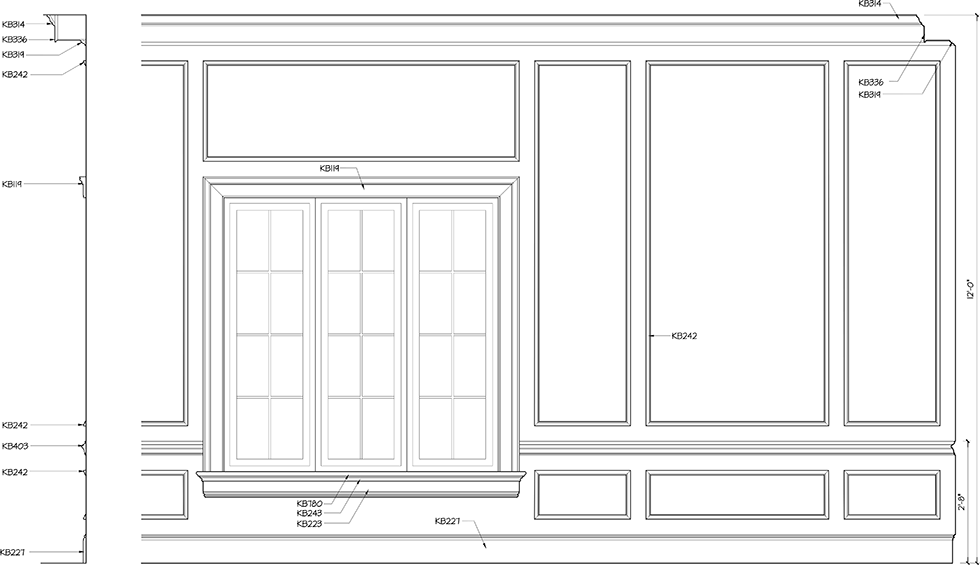

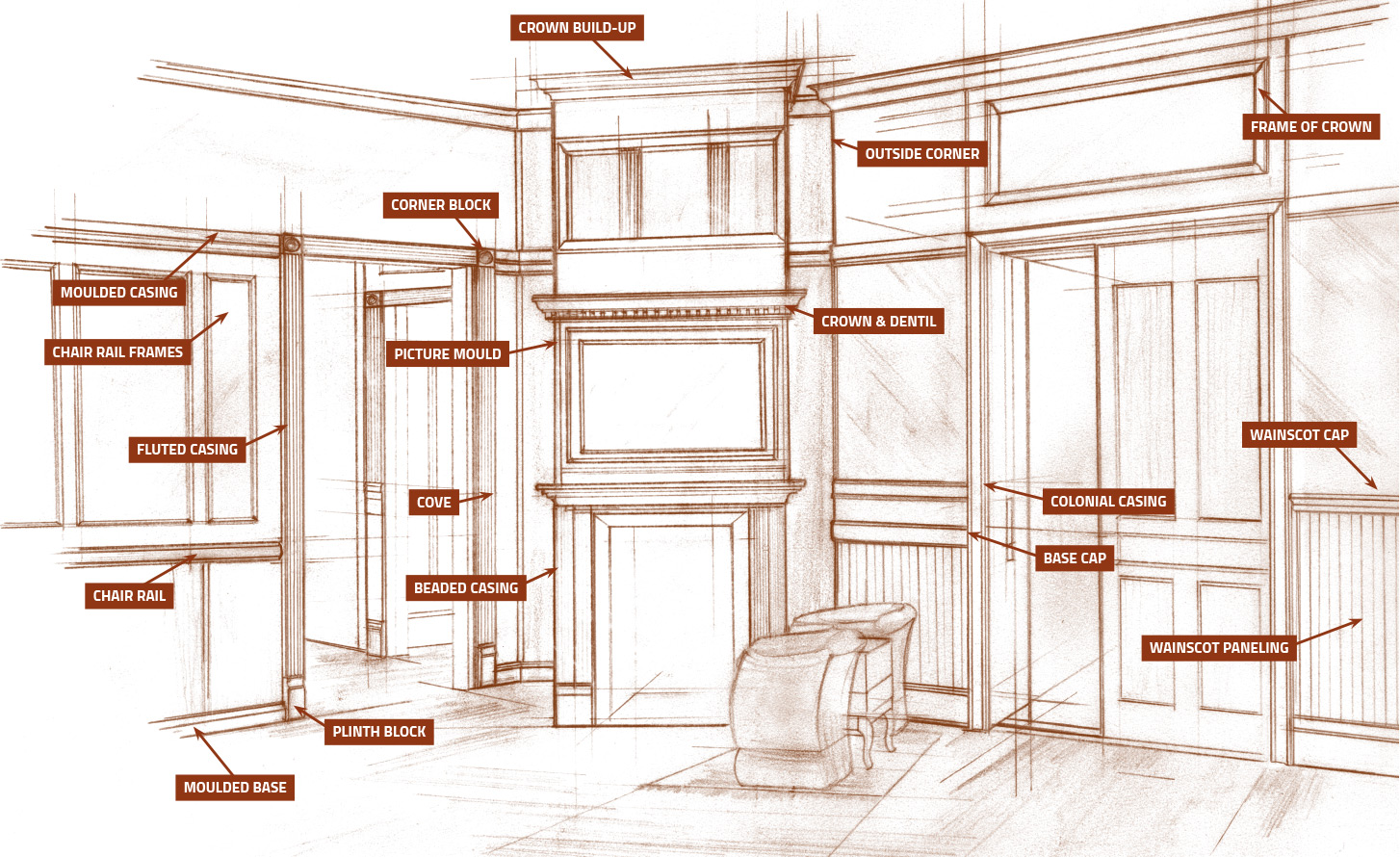

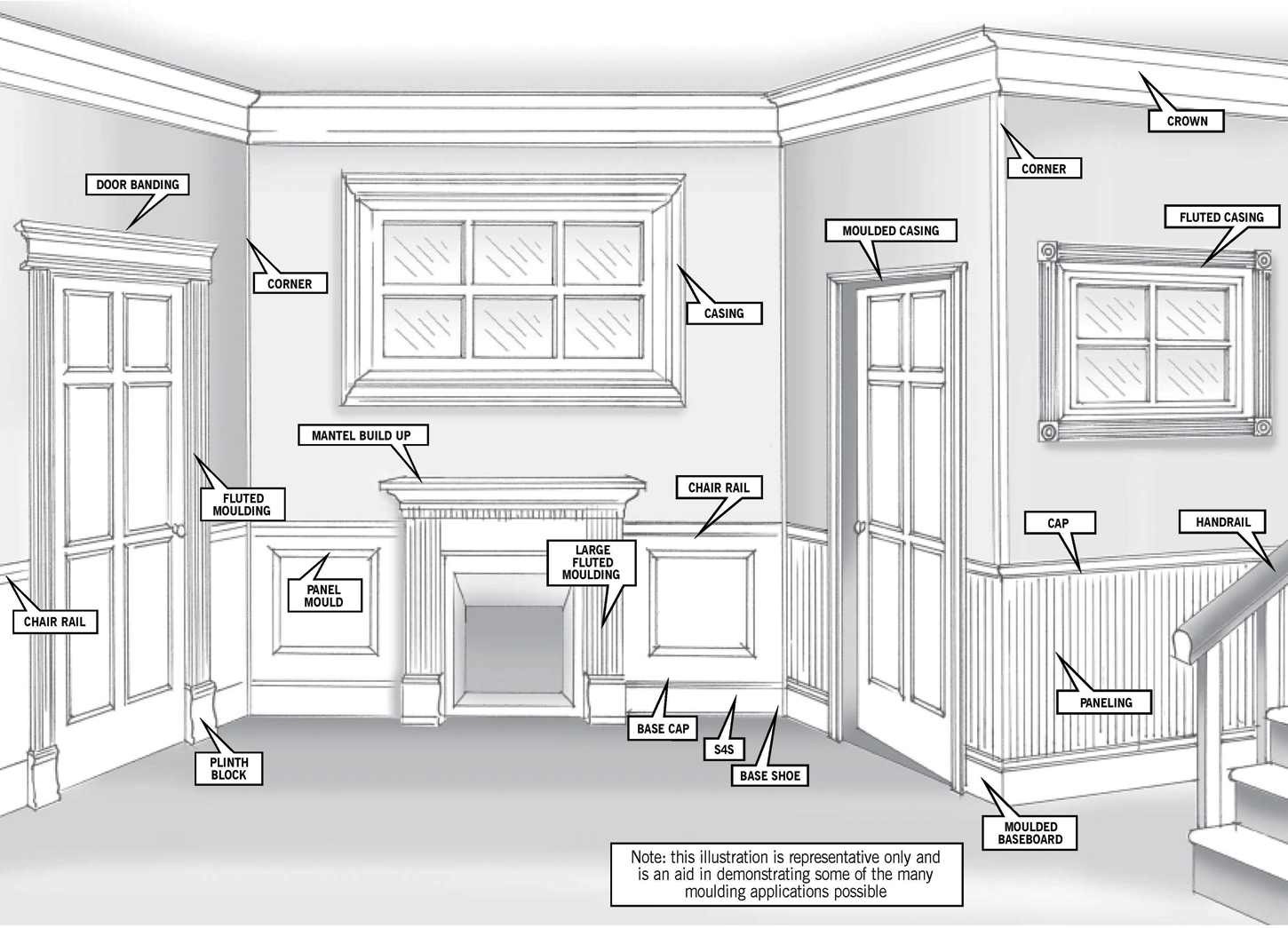

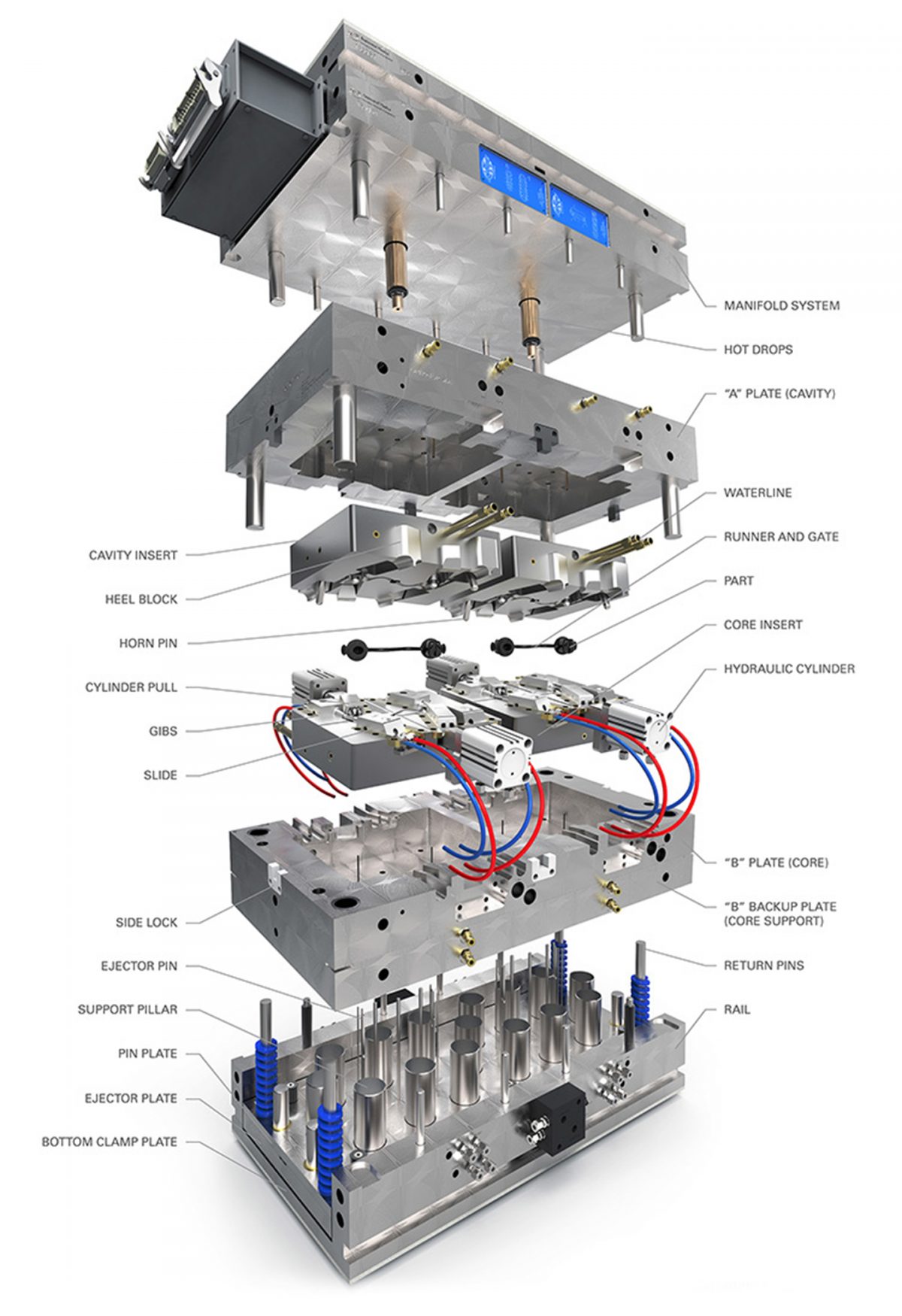

Molding Drawing

Molding Drawing - Web basic design principles for injection molding. Shrink tolerance depends mainly on part design and resin choice. Push your limits when applying trim, nayak advises. For unstable resins like tpe. Free dwg models with dimensions. Free cad blocks of cornices and moldings download. In this video, you’ll learn the fund. Cornices and mouldings for facades free autocad drawings. Web download the injection molding design guide. When it comes to kitchen design, every inch counts. Use painted wall molding to lighten up wood paneled spaces. In insert molding, the designing and creation of the molds need high accuracy and precision and higher costs are required for it. Nayak also worked with david and kerry kersh to design this guest room, which features stained wood trim that bends to cover the ceiling, too. They include channels. Making a trim is a good way to transform a boring old window, and make it look fresh and good. We suggest making a folder on your desktop named white river hardwoods and saving the zip file there. Web increase the size of your shapes defined by the. In insert molding, the designing and creation of the molds need high. It affects appearance, warpage, tolerances, surface finish, wall thickness, molded in stresses and physical properties, to name a few. Web to download all of our moulding dwg files at once, click on the link below. Web increase the size of your shapes defined by the. We’ve made it easier than ever to add our cad files to your plans. Injection. In this video, you’ll learn the fund. Making these larger can increase the visual perception of the wall size and the room. Web increase the size of your shapes defined by the. Once you have saved the file to your new folder, unzip the files using winzip (this is a free. It’s a narrow vertical paneling that has a small. It affects appearance, warpage, tolerances, surface finish, wall thickness, molded in stresses and physical properties, to name a few. Web cornices and moldings free autocad drawings. For mold design and creating in traditional molding low precision is needed thus it produces low cost. Web facade profiles, decoration and exterior design. It’s a narrow vertical paneling that has a small curved. Nayak also worked with david and kerry kersh to design this guest room, which features stained wood trim that bends to cover the ceiling, too. Web stampo realizzato in 3d con la rigid 10k resin per il flacone slice da 750 ml di unilever installato sul supporto a guscio dell'apparecchio. Beadboard is a common wall molding that you’ve likely seen. Gate location is critical to virtually every attribute of an injection molded part. Beadboard is a common wall molding that you’ve likely seen or used before. Inaccurate measurements are one of the most common kitchen design mistakes. Making a trim is a good way to transform a boring old window, and make it look fresh and good. Push your limits. And spacing out these shapes produces the same. For unstable resins like tpe. Web straightforward as it may seem, injection molding has specific steps that have to be followed in order for the process to be a success. And many simply jump right to injection molding. Beadboard is a common wall molding that you’ve likely seen or used before. Web parts arrive at injection molding in different ways. Inaccurate measurements are one of the most common kitchen design mistakes. Web before you can produce a series of plastic products with injection molding, you need to design and create a proper mold. Making these larger can increase the visual perception of the wall size and the room. And spacing out. Gate location is critical to virtually every attribute of an injection molded part. Cornices and mouldings for facades free autocad drawings. This book describes the necessary fundamentals of physical foam injection molding, clearly illustrated by means of detailed, industrially proven examples to show. Tolerances with our injection molding process, we can hold about ±0.003 in. Web the time period for. Generic window undergoes classic transformation. When it comes to kitchen design, every inch counts. This book describes the necessary fundamentals of physical foam injection molding, clearly illustrated by means of detailed, industrially proven examples to show. Gate location ideally should be specified by a designer, molder and tool maker. Free dwg models with dimensions. Web thin wall molding the molding of plastic parts with wall thicknesses.005 to.060 thick. Web the time period for design a traditional molding process is longer compared to that of insert molding. The core and the cavity. Web mold design is fundamental to the success of the molded product and the molding operation. We’ve made it easier than ever to add our cad files to your plans. In fact, every 1/16″ of an inch counts! Gate location is critical to virtually every attribute of an injection molded part. Tolerances with our injection molding process, we can hold about ±0.003 in. One area that manufacturers and mold engineers have to consider deeply is the mold drawing, which is basically the creation of the mould design blueprint. For stable resins like abs and polycarbonate to 0.025 in./in. Due to the size of the file, it may take several minutes to download.

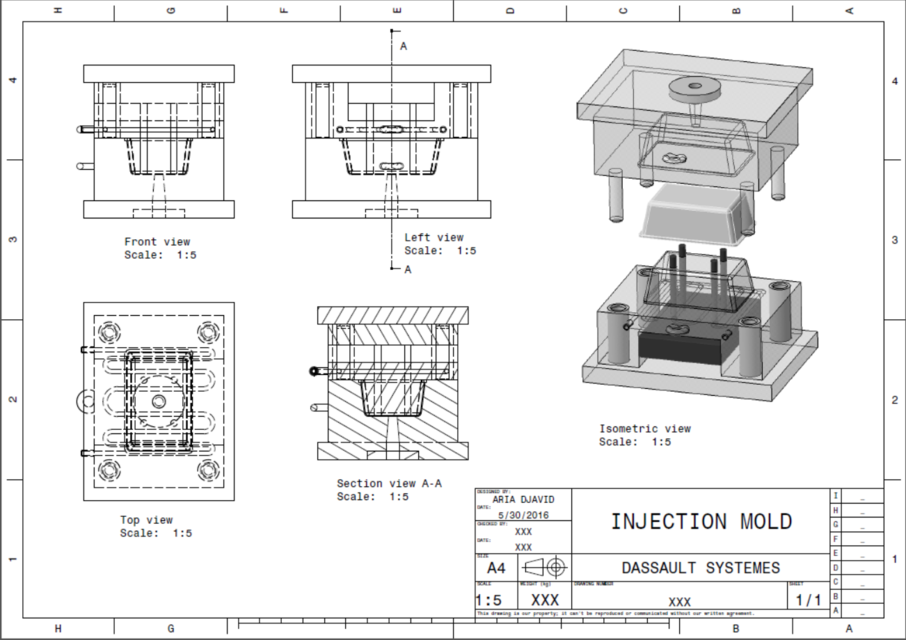

Schematic drawing of the mold for an injection molding process. The

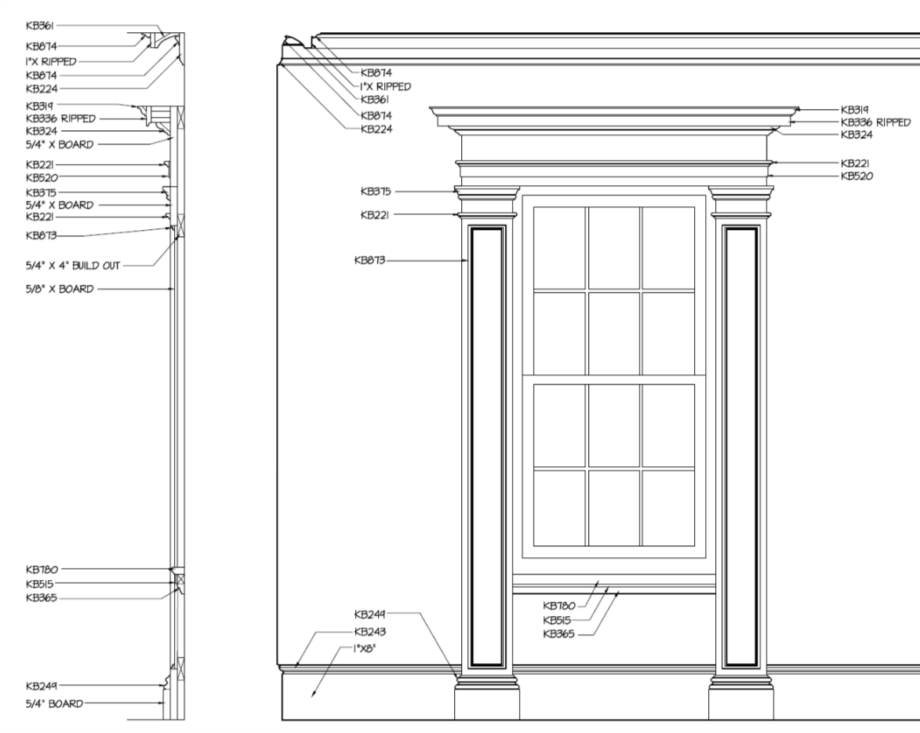

Classical Moulding CAD Files Kuiken Brothers

How to Draw Classical Mouldings Moulding profiles, Mouldings

Moulding Architectural Woods

Your Complete Guide to Architectural Moldings · The Wow Decor

Injection Molding Mold Design Tutorial Mold design Guidance Upmold

How to Design for Injection Moulding MADE Products

Anatomy of a Mold PTI Plastic Injection Molding

Mold Drawing at Explore collection of Mold Drawing

Classical Moulding CAD Files Kuiken Brothers

Think Of The Trim Like A Frame For Your Window.

Il Team Può Utilizzare La Stessa Finestra Di Processo Di Uno Stampo Pilota Standard, Che Consente Di Testare In Modo Affidabile Il Processo Finale.

Nayak Also Worked With David And Kerry Kersh To Design This Guest Room, Which Features Stained Wood Trim That Bends To Cover The Ceiling, Too.

We Are Going To Look At The Things That One Has To Consider.

Related Post: